Most of Russia's territory is located in latitudes with a cold climate. The heating season there can last six months or more. The population of most regions of our country has to spend a lot of time in heated rooms, so very high demands are placed on heating systems in terms of their efficiency and the presentable appearance of the batteries. Increasingly, more modern appliances are being preferred to the cast-iron monsters of Soviet times. There is a growing demand for bimetallic radiators - heating elements that combine the excellent heat transfer of aluminum and fairly good corrosion resistance of steel.

Battery features, advantages and disadvantages

Bimetallic radiators are a symbiosis of aluminum and steel. Inside the structure there is a steel core, and outside the body is made entirely of aluminum. The use of these two materials made it possible to compensate for the individual disadvantages of analogues made from only one material. For example, due to the steel core, the radiator's resistance to water hammer has improved and sensitivity to low-quality coolant has decreased. The aluminum body is a good heat conductor. It provides quick heating of the room and also reduces the final weight of the radiator.

Thus, the advantages of bimetallic heating radiators:

- the ability of the structure to withstand high pressure and hydraulic shocks;

- resistance to water composition, which is important in central heating systems;

- optimal heat transfer;

- small volume of coolant, thereby increasing the efficiency of the heating system;

- light weight, simplifying independent installation of a bimetallic radiator;

- the ability to add sections if there is not enough power to heat the room.

Minus:

- the price of bimetallic heating radiators is higher than aluminum ones.

Obviously, the advantages outweigh the disadvantages, so it is worth considering installing this type of radiator. But you still need to understand some more points, such as calculations and technical parameters.

Why we prefer bimetallic devices

Combining the useful characteristics and properties of different materials in one product often gives very good results. A clear example of this is bimetallic devices, which have both the reliability of steel and the high thermal conductivity of aluminum. The combination of these two metals made it possible to design batteries with high heat transfer, an impressive modern design and the ability to withstand hydraulic shocks. Initially, radiators of this type were created for use in centralized heating systems, characterized by high operating pressures and low-quality coolant. Now the scope of application of bimetallic radiators has been significantly expanded; they have begun to be successfully used in the arrangement of individual autonomous heating.

We have been using steel and aluminum radiators made in our country or abroad for a long time. Steel batteries are characterized by strength and immunity to the effects of alkalis, acids and other impurities added to the coolant composition. But the efficiency of steel radiators is not too high, since this metal, although it heats up very quickly, also cools down just as quickly. Aluminum undoubtedly has high heat dissipation, but cannot effectively resist corrosion. Bimetallic batteries use the best properties of these metals, so the heating system in which they are used is characterized by increased efficiency. This is especially important given the high price of energy.

On what principle do bimetallic batteries work? The coolant, which can be not only water, but also more aggressive liquid substances, transfers heat to the internal radiator core made of steel. It is important that contact of easily oxidized aluminum with an aggressive coolant is completely excluded. The heated steel then transfers thermal energy to the aluminum body, which directs it to heat the room.

Main characteristics

The parameters of bimetallic batteries are indicated in the product passport. It is important to familiarize yourself with them before purchasing so that the radiator is sure to fit the existing heating system and operating conditions.

Let's look at the main characteristics and find out what they indicate:

- Heat dissipation. The parameter is also called thermal power. For bimetallic batteries it is 180-200 W per section. For comparison, cast iron radiators produce 80-160 W, which is noticeably less.

- Maximum pressure. This refers to the maximum value that the structure can withstand without loss of tightness. It is safe to use bimetallic radiators in heating systems where the pressure reaches 30 atm. In this case, the maximum pressure is considered to be up to 200 atmospheres.

- Maximum coolant temperature. Bimetallic radiators can easily withstand 110 degrees, which is enough for most heating systems.

- Center distance. Typically, manufacturers produce standard designs of 500 and 350 mm. Thus, bimetallic devices are suitable for most heating systems in Russia.

- Weight of one section. Let's draw a parallel with cast iron devices. One section of them weighs about 7 kg, while for bimetallic heating radiators it weighs 1-2 kg. The difference is dramatic.

- Life time. Bimetal devices cannot be called the best in this regard, but a period of 25 years of uninterrupted operation is usually enough.

Correctly selected characteristics greatly influence the efficiency of radiators. Of course, if the optimal number of sections is selected and proper installation is performed.

Aluminum or bimetal - learning to distinguish between radiators

Manufacturers offer various models of hybrid batteries. They come in different designs, differ in power, and in the technology of connecting to the system. Radiators are available with top and bottom connections. After installing these heating elements, it is almost impossible to visually determine the difference between bimetallic devices and aluminum batteries, especially for a non-professional. This must be done before connecting them. The main sign that you have a bimetallic radiator is the presence of an internal steel core encased in an aluminum body. This structure ensures excellent performance properties of the device. The weight can also give away a bimetallic battery: a radiator weighted with a steel core cannot be as light as an aluminum one.

Sectional bimetallic radiator Royal Thermo BiLiner 500 black 6 sections

Recommendations for selection

It is clear that you need to select the appropriate characteristics of bimetallic radiators. But this is not the only point. Calculations are one of the main tasks when purchasing a radiator. It is recommended to calculate the number of sections using the following formula:

Room area *100/power of 1 section

. For example, we have a 15 m2 room and a bimetallic heating radiator with a heat output of 185 W. We count: 15*100/185=8.1. We round up and get 9 sections.

But that's not all. There are many correction factors that affect the final calculations. This is the average temperature outside in winter, wind rose, floor, ceiling height, etc. Sometimes errors in calculations reach up to 50%, so correction factors need to be taken into account.

A couple more tips for choosing bimetallic heating batteries:

- Choose products from a manufacturer that has proven itself well. And not necessarily imported. Domestic brands are no worse, and the cost of radiators is more affordable.

- For an autonomous heating system there is no point in using bimetal. There are no large pressure surges here, the coolant composition is of a higher quality. Bimetallic devices are better suited for the harsh conditions of central systems, although no one forbids installing them in individual highways.

- Don't go for a very low price. A low price indicates the poor quality of the materials from which the radiator is made. It is unlikely that such a device will satisfy you with its performance and service life.

If possible, it is better to enlist the help of a specialist in choosing batteries. He will help with calculations and determination of characteristics.

How to calculate the number of sections in a battery

Even a heating system installed in accordance with all the rules will not be able to provide heat to the object on which it is installed if an error was made during preliminary calculations. This primarily relates to calculating the number of sections.

The main characteristic of a radiator is its power, this indicator must be indicated by the manufacturer. Having information about the power of one radiator section, it is easy to calculate how many sections are needed to heat a particular room. To do this, you need to measure the area of the room in which the battery will be installed and perform simple arithmetic. To determine the required number of sections, you need to multiply the area of the object by 100, and divide the resulting value by the capacity of one section declared by the manufacturer. For example, to heat a room with an area of 10 m2, you need a radiator of six sections with a power of 180 W each - the number 5.5555 obtained in the calculation must be rounded according to the rules - up.

You might be interested

The best aluminum heating radiators for a private home

Installation of aluminum heating radiators

Radiators in the floor heating in the house

Power of one section of aluminum radiator

The tap on the radiator is leaking

Heating area of an aluminum radiator (heating radiator power per 1 m2)

Replacing heating radiators: how to avoid mistakes

How much water is in one section of an aluminum radiator

Bimetallic batteries for a private home

Design and operating principle

The principle of operation of a radiator is that the heated energy carrier moves through a pipe system and enters the batteries, transfers heat, then moves along the return branch to the heating source. A radiator heats the air in a room using radiation and convection. Different types of devices have different ratios of thermal radiation and convection.

Steel and cast iron radiators heat the room by radiation, and plate and panel heaters transfer energy by convection due to the large total area of ribs and strips. The warm flow tends upward; in return, cold air is drawn in, which heats up.

Types of bimetallic batteries

In addition to bimetallic ones, the production of semi-bimetallic radiators has now been established. It is important to understand what their differences are.

Fully bimetallic

In such models, aluminum is used only for the manufacture of the outer casing of the device. The production procedure is as follows: steel cores are placed in special molds and filled under pressure with aluminum, a material with good thermal conductivity. In turn, it does not withstand aggressive environments and high coolant temperatures. But, in solid, completely bimetallic versions, aluminum simply does not come into contact with the liquid - it is used purely as a heat exchanger. This design is optimal for central and autonomous heating systems.

Some models are not equipped with a copper core, but made of stainless steel: such batteries are suitable for autonomous systems with special antifreeze as a coolant.

Semi-bimetallic

Different metals are used to make internal channels for such batteries. For example, stainless steel is used to produce vertical pipes, and aluminum is used for horizontal pipes. There are also reverse options.

This variety is not installed in central heating systems, which is explained by the quality of the coolant, which may contain a high concentration of alkali. When in contact with aluminum, corrosion processes easily form. In addition, each metal has its own rate of thermal expansion. And if the system experiences extremely high temperatures, internal components can shift, causing a leak.

Often such radiators are confused with completely bimetallic ones, since visually they are no different. If the buyer does not understand the intricacies, he, as a rule, buys the cheaper version. But, looking at the description, you can see that this is not a particularly reliable investment.

Methods of operation

The operating principle of heating radiators is extremely simple. Hot water moves through pipes to radiators to heat the room. In turn, the principle of heating using radiators is divided into two types.

In the first case, the process of heating the room occurs by heating the incoming cold air and converting it into warm air. This method is called converter.

- The next method of heating a room occurs by heating the air using a heated surface. The method of heating a room in this way is called radiator.

- The heating system can combine panel and convector heating radiators.

- In terms of room heating efficiency, convector heating is considered more efficient. It also has a minus; if you look at a cross-section of a convector radiator, you can understand that when heated, dust particles are released into the room along with the air. In turn, this factor adversely affects people’s well-being.

- A convector heating system is used in buildings in which another type of heating cannot be installed due to its size.

Regardless of the temperature to which the battery is heated, it will only release 60% by transferring heat to the room. The remaining percentage of heat is spent on heating the air using a converter method. This is how you can describe the system of operation of a radiator; to some extent, it is similar in principle to working with a heated floor.

Installation of equipment

The installation of bimetallic heating radiators must be carried out in accordance with the instructions given by the manufacturer. And, of course, the installation must be carried out by a specialist who has a license to carry out this type of work.

Before installing batteries, wash the communications.

A valve will need to be installed on each battery; it can be either manual or automatic and designed to release air from the radiator. To prevent the valve from becoming dirty, special filters are installed on the supply risers to protect against dirt.

Aluminum or bimetallic radiators?

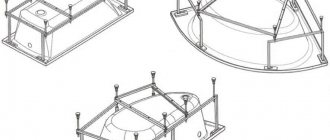

Radiator installation procedure:

- Mark the mounting locations for the brackets;

- Attach the brackets using dowels or cement mortar;

- Connect the battery to the supply lines, this is done using a tap or thermostat;

- Install an air bleed valve at the top of the radiator.

The bimetallic heating radiator must be installed so that the horizontal sections of the heads lie directly on the brackets. It is undesirable to cover radiators with various screens and cabinets, as the operating conditions of the equipment may worsen.

What should you consider when choosing a radiator?

To achieve the proper thermal effect, it is necessary to calculate the total power of the battery. Bimetallic equipment is not a cheap purchase, so you should take care of its durability. The conscientious execution of the radiator is guaranteed by trusted manufacturers.

Capability assessment - thermal calculation

Having decided on the appropriate technical characteristics and dimensions of bimetallic radiators, it is necessary to calculate the required number of sections.

Basic formula: N=Ptot./Ppass., where Ptot. – required battery power for the entire room, Ppass. – thermal power of the section according to accompanying documents

The section’s heat transfer rate is taken from the radiator’s passport, and the total power must be calculated.

Calculation by area

The normalized value of thermal power per 1 sq.m of living space for the average climate zone, subject to standard ceilings (250-270 cm):

- the presence of one window and a wall with access to the street - 100 W;

- there is a window in the room, two walls adjacent to the street - 120 W;

- several windows and “external” walls – 130 W.

Example. The section power is 170 W, the total area of the heated room is 15 sq.m. Additional conditions: window – 1, external wall – 1, ceiling height – 270 cm.

N=(15*100)/170 = 8.82.

Rounding is done upward. This means that to heat the room it is necessary to use 9 sections of 170 W each.

Calculation by volume

SNiP separately regulates the amount of thermal power per 1 cubic meter of space in the amount of 41 W. Knowing the volume of the heated room, it is easy to calculate the heat transfer of the entire battery.

Example. Heating the room with the previous parameters. For the purity of the experiment, we leave the power of the section unchanged - 170 W.

N=(15*2.7*41)/170= 9.76.

It is necessary to install a radiator into 10 sections. The second calculation is considered more accurate. When calculating, attention should be paid to sources of heat loss indoors.

The calculated value must be increased by 10% if the apartment is located on the first/last floor, the room has large windows or the wall thickness does not exceed 250 mm

How to avoid fakes: radiator inspection

In addition to analyzing passport data, it would be useful to conduct a visual assessment of the product. Some manufacturers, in pursuit of customers, tend to “embellish” their products by introducing incorrect data into the documentation.

First of all, pay attention to the thickness of the core and aluminum “jacket”, overall dimensions, weight and quality of components.

Steel core. The minimum thickness of the steel tube is 3 mm. With smaller standard sizes, the declared strength of the product - resistance to water hammer and the development of corrosion processes - is significantly reduced.

The walls of thin metal provide access for the coolant to the aluminum “shell”, which, due to chemical activity, begins to quickly collapse

The result of a low-quality steel core is the formation of through holes and the creation of emergency situations in the heating network.

Radiator fins. Aluminum panels must be checked for strength - they should not bend from the efforts of the fingers of one hand. The minimum thickness of the panels is 1 mm.

It is better to choose models with profiled channels between the ribs. The formed confuser increases the speed of air flow, increasing the intensity of convective heat transfer.

To reduce the risk of injury, the outer edges of aluminum panels are rounded. There should be no streaks, uneven coloring or “gaps” on the surface.

Dimensions and weight. By individual order it is possible to produce radiators with a section width of less than 80 mm. However, store-bought models with inappropriate parameters are most likely fake.

To reduce costs, some manufacturers significantly reduce the width of the internal ribs, “masking” them behind standard-sized front panels. This measure worsens the heat transfer of a bimetallic radiator.

Battery components. It is almost impossible to check the quality of gaskets and nipples on site. Rely on the manufacturer's name and warranty period. Reliable companies guarantee up to 15-20 years of trouble-free operation.

Types of bimetallic radiators

Bimetallic batteries are available in three types. This:

- two-channel with aluminum manifold;

- single-channel with aluminum manifold;

- single-channel with steel manifold.

The design of a two-channel radiator device includes two tubes connected to the manifold. This allows you to double the heat transfer, but at the same time the weight of the product will also increase. The disadvantage of a bimetallic heating radiator is the risk of corrosion at the points of contact between steel and aluminum.

Two-channel bimetallic radiator

Batteries whose frame is made of steel are less susceptible to corrosion due to the lack of contact of hot water with aluminum. Products with channels that are reinforced with steel have a more durable fixation of steel inserts. This ensures safety in case of various types of emergency problems (blockage of the collector, etc.). Their cost is significantly higher than that of the first type of radiators.

Copper, which is part of the structure, provides good heat transfer and protection against corrosion. All this determines such a long service life.

The main characteristics of copper-aluminum radiator products are heat transfer, which shows the heat given off by the batteries, operating pressure (within 35 atmospheres), distance between collectors (axial), temperature (maximum 90 degrees).

Copper-aluminum radiator

Along with all the listed positive qualities that bimetallic heating systems have, it is worth noting their appearance, which undoubtedly beats cast iron ones.

Their low cost, long service life and excellent quality are the most correct decision when choosing heating equipment.

Comparative analysis: bimetal and competitors

Before choosing a bimetallic or other radiator, it is advisable to compare its capabilities with its closest competitors. For composite convectors these are aluminum, cast iron, steel batteries.

The assessment should be carried out according to the main criteria:

- heat transfer;

- endurance to pressure changes;

- wear resistance;

- ease of installation;

- appearance;

- durability;

- price.

Heat release. In terms of heating efficiency, aluminum units are the leaders, bimetal takes an honorable second place. Steel and cast iron radiators are noticeably inferior.

Aluminum is characterized by minimal thermal inertia - after starting the system, the air in the room warms up within 10 minutes

Resistance to water hammer. The most durable are bimetallic units, capable of withstanding up to 40 atmospheres (sectional models). The maximum operating pressure on an aluminum heating system is 6 bar, a steel one is 10-12 bar, and a cast iron one is 6-9 bar.

It is the bimetal that can withstand numerous water hammer shocks from a centralized heating system. This property is a key argument in favor of composite radiators for apartment buildings.

Chemical inertness. According to this criterion, positions were distributed as follows:

- Cast iron. The material is indifferent to adverse environments. Cast iron radiators can be used for decades, transporting an “alkaline”, “acidic” environment.

- Steel and bimetal. The steel core itself withstands the effects of aggressive components. The weak point of a steel pipeline is its interaction with oxygen, contact with which leads to the formation of rust.

- Aluminum. The metal reacts with various impurities in water.

Aluminum walls are especially susceptible to acidic environments - the pH of the coolant must be within 8. Otherwise, corrosion will actively develop.

Easy to install. In terms of installation, aluminum and bimetallic products are easier. Cast iron radiators are more difficult to install due to their impressive weight.

In terms of durability, the leaders are composite and cast iron batteries. Aluminum and steel products, subject to operational requirements, must be replaced after 10-15 years. Among the designated batteries, bimetallic ones are the most expensive

We can conclude. The purchase of a bimetallic radiator is definitely justified for assembling a heating network in a multi-storey building, where there are risks of pressure surges and contamination of the coolant. In a private house, with stable operation of the boiler and filtration of incoming water, affordable aluminum batteries can be used in the heating device.

Manufacturers and prices

Looking through the information on official websites, you can notice one pattern. The description of some models clearly states: all the tubes through which the coolant flows are made of steel. There are even drawings and photographs demonstrating this. In others, there is not a word about what metals the collectors are made of. And these are models from the same manufacturer.

Modestly priced Radena produces quality equipment

So here it is. Those modifications where there is no mention of materials are partial bimetal. It's just that the manufacturers are silent about it. For what reasons, one can only guess.

Now about the prices. Let's give them in dollars (the exchange rate is not stable, so...) and approximately. We all know that people have different appetites, but we have derived the approximate cost. They are taken from online stores; offline they may differ noticeably. More information about how the companies were selected (if indicated): these are the most popular ones in stores or on forums. And about standard sizes: prices are given for models with an interaxial distance of 500 mm.

| Bimetallic radiators | Aluminum radiators | Notes | ||

| Full bimetal | Partial bimeta ll | |||

| "Clean" China | 7-10$ | 6-7$ | It is possible to determine what material the collectors are made of only visually | |

| Rifar (Russia) | 12$-14$ | 12$ | "Rifar" produces sectional only partial bimetal. Only the “Monolith” is complete, but it is not type-set, but welded. And one section is not sold | |

| Radena (Italy+China) | 12-14$ | 10-11$ | Only fully bimetallic batteries are produced | |

| Sira (Italy+China) | 16-18$ | 14-15$ | 10-11$ | Full bimetal only one model Ali Metal |

| Ferroli | 18-19$ | 16$ | 10-11$ | |

| Global | 19$ | 10-11$ | Only fully bimetallic batteries are produced | |

As you can see, prices for aluminum radiators (at least from these manufacturers) are not much different. There is a difference, of course, but it amounts to tens of rubles per section. But the spread in bimetallic ones is more than respectable.

If you go by the reviews, there are very few negative reviews about Global bimetallic radiators; the modestly priced Radena has none at all. Moreover, these companies produce only with an all-metal manifold. But one has production located in Italy (Global), and the other in China (Radena).

All the rest have approximately the same picture: negative reviews occur. But it is difficult to determine whether the problem is due to an installation error or a manufacturing defect. And one more nuance: the prices of Russian Rifar from the manufacturer are lower. The table contains intermediary prices.

Not only the presence of steel is important, but also the quality of welding: vertical and horizontal collectors are welded

Connecting the radiator yourself

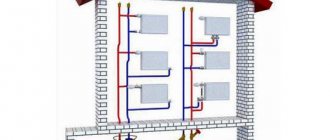

Single-pipe and two-pipe radiator connection diagrams

In the multi-apartment sector, the batteries are mounted on one side of the room. The radiator is connected using several methods depending on the pipe layout.

Diagonal or cross connection is used. The underwater pipe is connected to one side of the battery at the top, and the outlet pipe is connected to the other side at the bottom. This scheme is relevant for installations with a large number of sections of considerable length.

The bottom connection involves connecting the inlet and outlet from the radiator from below to two pipes on both sides of the heat exchanger. The scheme is characterized by low efficiency, but this option cannot be avoided if the heat supply system is located in the floor.

Possible problems during operation

Bimetal devices have a large number of advantages. Which of their features can be considered disadvantages?

- Despite the possibility of using bimetallic batteries in a system with any coolant, the low quality of the latter negatively affects the service life of the device.

- Different coefficients of expansion of the metals present in the battery design can, over time, lead to instability of heat transfer and a decrease in the strength of the device.

- The use of low-quality coolant in the system can lead to clogging of channels, corrosion, and deterioration of heat transfer.

Heating radiator design

When planning a heating system, it is quite difficult to calculate the amount of heat required. You have a choice between a sectional battery system and a convector one.

When choosing a sectional radiator, it is possible to add additional sections or subtract them if necessary. When choosing a sectional radiator, it is possible to eliminate elements that have come out of order. The convector radiator system does not provide this opportunity.

- An important aspect when installing heating radiators is the interaxle distance.

- This is the distance between the inlet and outlet sections of the radiator displayed vertically.

- When replacing the radiator, this indicator must be taken into account.

- You need to purchase a radiator with an identical indicator.

- Otherwise it is necessary to change the heating system.

To prevent premature and unwanted clogging of the heating system, it is necessary to take into account the diameter of the pipe. The small diameter contributes to the formation of blockages.

The heating system functions by running hot water through it. And the water may contain various microelements, sand, rust, and other debris, which causes congestion.

This, in turn, can disrupt the functioning of the heating system or completely render it unusable.

Choosing a suitable sectional design of heating radiators presupposes good functioning of the heating system.