Thanks to the ability of wood to “breathe,” a special microclimate is created in wooden houses. However, the flip side of the coin is the gaps in the seams and cracks that appear during operation. Let's find out how to restore the walls' tightness and minimize heat loss - let's figure it out with the FORUMHOUSE craftsmen. Consider:

- Why do wooden walls need to be sealed?

- What is caulk?

- What is a warm seam?

In what cases is it necessary to protect the log house with sealant?

During the shrinkage of a wooden house, cracks and gaps appear between the crowns, through which heat escapes. The acute question arises of how to seal the cracks in order to prevent the penetration of cold into the house.

The oldest method of insulation is caulking. It uses jute, felt, tow, and moss. But these materials are short-lived. Insects infest them, birds pull them out and after 2-3 years they need to be added.

Birds can easily pull ordinary tow out of the seams

The warm seam for wooden houses is strong and reliable. It will preserve the thermal insulation of a house for more than 50 years without replacement, and will eliminate cracks and defects in logs.

Professional cord installation gun

General information

The essence of insulation technology

Joints between logs in a wooden house require sealing, as do joints in brick and concrete buildings. Still, the insulation process is very different from the others, and also involves the use of other materials. Typically, building compounds do not last long, and when the wood shrinks, it can begin to crumble, crumble, and everything will have to be replaced quite often. But sealant using the “warm seam” technology works many times better and is the most reliable.

So, the method of sealing seams is multi-stage and will imply the following:

To begin with, the gaps between the timber and the logs are sealed with any material for thermal insulation.- The joint will end at the top with a special cord, which will prevent the insulation from coming into contact with the sealing compound.

- At the end of the work, you should apply a layer of warm joint - a special sealant that is suitable for wood, and it is made on the basis of silicone, acrylic or even polyurethane.

The finished seam can be decorated with any available means. The joint turns out to be durable, does not allow moisture to enter the house and also prevents blowing. Sealant is extremely rarely used in isolation, without caulking with additional means, because the gaps between the logs are quite large, and everything can fall out when the materials are displaced.

Features of sealants for sealing joints in wood

Professional products for sealing wood are considered to be universal and quite effective products. They are perfect for creating warm seams in a log house, for filling cracks and holes in masonry made of bricks, concrete, natural stone, and are also suitable for working on foam concrete and aerated concrete, plastic, as well as surfaces that are plastered. Warm joint sealant protects wooden buildings 100% from winds, temperature changes and precipitation. All products also contain antifungal additives that prevent mold from growing. The characteristics and properties of sealants are as follows:

- Safe for the environment and humans.

- Suitable for interior and exterior work.

- They have excellent elasticity (the elongation rate of certain sealants sometimes reaches up to 700%).

- High degree of adhesion to wood and other building materials.

- They are resistant to atmospheric factors and ultraviolet radiation.

- They do not suffer from yellowing or darkening after a while.

Good compositions have exactly these properties, and they are also thixotproof. This means that they can be used without problems on vertical type bases and inclined surfaces - they will not flow in a calm state.

Selection of sealant for a warm seam

The choice of one or another means for sealing seams must be carried out with special care. If you buy low-quality wood sealants, then there is a big risk of wasting effort and money on use. When purchasing, you should make sure that the product is truly suitable for the warm seam technology of a wooden house, and also has excellent adhesion to wood. The service life in outdoor conditions should be from 15 to 20 years or more, and shrinkage after drying should be absent or completely minimal. The excellent elasticity of the compositions is also important, as well as ease of application - they should be produced in a tube that is ideal for a metal mounting gun.

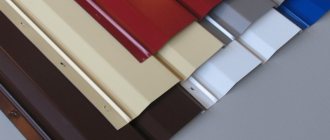

Seam sealants are produced in an incredibly large assortment. The most inexpensive and at the same time safest in cost are acrylic compositions, and they are ideal for interior work because they are environmentally friendly, do not release toxins, and they do not contain solvents. Acrylic adheres well to porous wood, and after polymerization it can even be painted to resemble wood. It is also useful for outdoor work, but is considered less resistant to moisture and ultraviolet radiation than other compounds.

Silicone sealants are perfect for creating a warm seam. They can last 20 to 25 years, are flexible, durable, and also reliable. Acid-based products are inexpensive, and those that are neutral (do not contain acids) boast a higher degree of adhesion to building materials. Silicone doesn't have many disadvantages. This means that a dried seam cannot be painted, although there are ready-made painted mixtures on sale. You should not add pigment to the composition yourself - this can only be done using a special vacuum mixer. There is another type of “warm” sealant, or rather, polyurethane compounds.

They have the following characteristics:

Optimal adhesion and strength when applied to wood.- Tolerance to mechanical and chemical influences, moisture.

- No shrinkage after drying.

- Suitable for painting as the joint cures.

- Resistance to ultraviolet radiation.

- Excellent elasticity, resistance to deformation.

Many polyurethane-based sealants contain solvents, and therefore should ideally be used outdoors. When choosing a product, you should give preference to formulations from famous brands.

We offer you signs of really good products:

- Neomid (Wood Professional Plus) is an acrylic-based sealant that is tear-resistant, elastic and low-flow.

- BARTONS “Warm House” is a silicone-based composition that does not shrink, and also contains a high concentration of fungicidal additives.

- Perma Chink is an acrylic-based sealant that sets quickly, is also quite durable and has minimal consumption.

- Energy-Seal is an acrylic-type product, perfect for processing seams up to 2.5 cm in size, and tolerates deformation well.

Now let's talk about how to use sealants correctly.

Pros and cons of sealing a log house

environmentally friendly The sealant does not contain harmful substances and has no pungent odor;

universal. It is used for insulating seams inside and outside the house, eliminating minor damage;

hypoallergenic. Does not have a harmful effect on the health of people, even those prone to allergies;

Wear-resistant: resists weather conditions. The warm seam is not afraid of rain, heat, wind or frost;

thanks to special additives, it does not harbor pests;

when sealing a log house, the seam is invisible, because the product is matched to the color of the walls;

dense filling with cord and sealant eliminates heat loss in a wooden house;

sealing is an economical method of insulation. Thanks to it, the costs of heating, repairs, and periodic sealing of cracks and gaps between logs are reduced;

optimizes air exchange, creating a healthy microclimate in the house.

the need to carry out work in dry weather;

warm seam technology is carried out only a year after the construction of the building;

the surface of the seam must be thoroughly cleaned and dried; only in this case is high-quality insulation of the log house possible;

Self-sealing errors

Non-professional craftsmen, when sealing the crown joints of a log house on their own, inevitably encounter problems. To do the job correctly yourself, you need to know certain subtleties and nuances.

Among the typical mistakes that untrained professionals most often make are:

- Wrong choice of sealant.

- Carrying out work in inappropriate weather conditions.

- Violation of work technology.

- Poor surface preparation, as a result of which the sealant does not adhere well and lags behind the wood.

- Careless application of the composition, which is why the warm seam looks rough and sloppy.

To ensure that the warm seam is made efficiently and accurately, and serves you for many years, contact professionals.

has many years of experience in insulating houses made of timber and logs using the “warm seam” technology. In our work, the main priorities are quality indicators. We employ experienced and highly qualified craftsmen. Our company has established a two-level system for checking the integrity and quality of work performed, which is carried out by the construction supervision department and the quality control department.

When you trust us to seal your home, you can be sure of excellent results. You can contact us using the coordinates on the “Contacts” page.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

How to choose a quality sealant and what they are like

To choose the right sealant for warm joint wood, it is important to become familiar with its types and the properties of each of them. For warm seam technology, silicone, polyurethane and acrylic sealants are used. They come in one- and two-component types.

One-component and two-component silicone

Silicone sealants have a rubber base. They:

- plastic, can stretch;

- durable and wear-resistant: resistant to environmental factors and aggressive detergents;

- increased adhesion to various surfaces: concrete, wood, plastic and others puts them in the category of universal ones, used for external and internal work;

- retain protective properties within a wide temperature range from -50 to +300 degrees.

Silicone sealants come in one-component and two-component types.

Single-component ones are used in construction and repair, two-component ones are used in industry.

Two-component formulations are formed by mixing the components. A curing catalyst is added to the bulk. The work of mixing is complex; it is important to correctly dose the mixed material in order to obtain a high-quality composition.

Drawing conclusions

The “warm seam” sealing technology certainly solves the set tasks - people get a warm home and neat, aesthetic seams. Our online store offers the following products for these purposes:

- German Remmers acrylic sealant without grain;

- Remmers acrylic sealant with grain;

- Russian Neomid Wood Professional joint sealant for wood;

- Neomid Wood Professional Plus “Warm House” professional joint sealant for wood;

- Russian VGT acrylic sealant for log houses.

Instructions for sealing seams

The warm seam technology is effective only if it is strictly followed. It includes several steps that should be performed in a certain sequence. When insulating seams, it is necessary to use tools that will help in the correct application of the sealant.

In hot summer weather, it is better to seal cracks in the shade, because under the influence of direct sunlight the product dries quickly, disrupting the technology.

May be interesting: Window decoration in a wooden house: slopes and window sills

Required Tools

To complete the work you will need the following tools and consumables:

- masking tape. It is necessary in order not to stain the crowns. Used by beginners. Specialists who professionally seal a log house apply the seam precisely and do not use masking tape;

- primer for wood impregnation;

- cord made of extruded polyethylene. They use it to seal large gaps;

- putty knife. Use it to insert the cord into the gap, remove excess sealant and level the seam;

- construction gun for applying sealant;

- an aqueous solution is needed to moisten the spatula blade when smoothing seams in a wooden house;

- Using a brush with artificial bristles to smooth and level the sealant and apply primer will increase the adhesion of the product to the surface of the log.

Preparatory operations

To properly insulate the seam, you need to carefully prepare the surfaces of the walls, cleaning them from dirt and dust. In an old wooden house, the paint and varnish coating is cleaned and the caulking is removed. The walls are treated with a primer solution obtained by mixing water and sealant 10:1. Brushes are used to apply the primer. The primer dries for a day.

Technology of applying material to interventional seams

Before sealing the cracks with sealant, they are filled with polyethylene cord, inserted using a chisel or spatula. The cord will help protect the seam from blowing and freezing and save sealant. If you decide to make a warm seam yourself, then step 2 cm away from the joints of the logs and stick on masking tape. Apply the sealant with a construction gun at a distance of 1 cm from the joint into which the tube is filled or the product is collected from a bucket in parts.

When the sealant is applied, take a spatula, dip its edge into an aqueous solution and level the edges of the seams, while simultaneously removing excess product. You can not wet the spatula, but spray the surface of the seams with water. After leveling with a spatula, the seam is smoothed with a brush dipped in water. Stains after water are wiped with a cloth. Remove the masking tape. It is necessary to treat the walls with an antiseptic and apply varnish or paint after 2 weeks.

Sealing cracks and cracks

If the cracks or crevices are less than 10 mm, then there is no need to lay the cord inside; it is enough to apply sealant with a construction gun. If the cracks are more than 10 mm, then first lay the cord along its length, then seal it with sealant.

Corners, cuts, joints

The most difficult things to seal are corners and cuts. Preparation is carried out in the same way as when sealing log joints. Cords of the required length are prepared, which are inserted into the joints using a spatula. The sealant is applied and then leveled with a spatula and brush. The excess is removed.

Take note: Interior decoration of a wooden house - we deal with materials in a modern style

Self-sealing errors

Warm seam technology requires precise execution. Sealing errors can lead to negative consequences. To avoid them, watch the video about common mistakes.

The following can lead to problems:

- incorrectly selected sealant;

- careless work done. The seams look ugly, rough, spoiling the appearance of the house;

- violation of technology;

- non-compliance with the temperature regime for applying the sealant;

- poor quality surface cleaning;

- the absence of a primer leads to poor adhesion (adhesion) of materials.

Characteristics of sealants

There are several types of sealants that can be used to insulate roof joints and cracks:

- acrylic;

- silicone;

- polyurethane;

- bituminous.

The most popular of the presented types is acrylic composition. Among its advantages are:

- elasticity;

- good adhesion;

- moisture resistance;

- biosustainability;

- color fastness;

- simplicity and ease of application.

Silicone-based sealant withstands high temperatures and humidity well, which is why it is often used to seal cracks in baths and saunas.

The polyurethane composition also has decent characteristics, but due to the fact that it contains toxic components, it can only be used for external insulation.

Bitumen mastics have a very high degree of moisture resistance, so they are usually used to seal the dampest places: basements, basements and roofs.

More detailed characteristics of acrylic and other types of sealants can be found in the article “Sealant for a wooden house - a review of materials and manufacturers.”

Types of packaging

The sealant is produced:

- In cartridges. This packaging is intended for use in special construction guns.

- In tubes. The mass is squeezed out of the tube directly onto the seam, and then it is given the desired shape with a chisel. Leveling is carried out within 10 minutes after application, otherwise the sealant will polymerize and it will be quite difficult to correct the frozen shape.

- In plastic buckets. In this case, the sealant is applied using a spatula.

Recommendations for using sealant

Log and timber houses can be insulated no earlier than 1-2 years after construction.

The exception is houses made of laminated veneer lumber, which can be sealed almost immediately after construction. To achieve maximum effect, it is advisable to carry out sealing outside and inside the house. However, only external thermal insulation of seams is also allowed.

The sealant can only be applied in dry weather at a temperature of at least 5 degrees Celsius.

If work is carried out in the summer in hot sunny weather, the shady side is sealed first. When the sun is active, the sealant dries quickly, which is undesirable, since the technology is disrupted.

When applying sealant to a previously painted surface, it is necessary to first conduct an adhesion test with the dye on a small area.

Insulation of a log house using the “Warm seam” technology is:

- Aesthetically.

When choosing a color, there are two approaches - choose a product that matches the tone of the log (paint it later) or make contrasting seams. - Just.

No special tools are needed for work. - Practical.

They do the work once, unlike caulking, which is repeated regularly. Over time, the seams do not separate due to the plasticity of the sealant. - Economical.

Application does not take much time and does not require expensive tools. Used to seal openings between the casing and the wall. - Durable.

Does not lose its properties at temperatures from -40 to +80 degrees, service life up to 50 years, but subject to professionally performed work. - Eco-friendly.

The composition does not contain alkylphenol ethoxylates and formaldehyde, there is no ammonium hydroxide, so the product can be used for internal insulation. - Safely.

Does not cause allergies, application is not associated with discomfort for others, because there is no noise, dust or strong odor during operation. - Effective.

High degree of adhesion due to the formation of a membrane film, high plasticity, complete filling of voids. - Reliable.

Resistant to rotting and insects, the sealant is not pecked by birds or damaged by rodents, it is not affected by ultraviolet radiation.

Tools and raw materials

To start treating cracks with sealant, you need to purchase a retainer in a form suitable for the installation gun. For work you will also need:

- polyethylene foam in the form of a cord;

- narrowed spatula;

- brush for painting;

- a piece of fabric;

- water;

- spray;

- masking adhesive tape;

- primer for wood.

You can process the seams by hand, but using a mounting gun will speed up and simplify the process.

The device helps to comply with the consumption rate, treat the cracks with sealant, applying the fixative evenly in strips. It is almost impossible to achieve this manually.

Characteristics of “warm joints” for wooden coverings

Wood fixings for professional use are multifunctional and effective.

They can be used for processing warm joints of log houses, brick walls, cracks in concrete and stone structures, as well as for use with materials such as plastic, foam and aerated concrete, and plaster.

The seam lock completely protects wooden structures from adverse weather conditions. All sealants contain substances that prevent the appearance of fungi and mold.

How to check the quality?

Caulking is done only with materials specially designed for this purpose.

Often developers illegally use polyurethane foam for this purpose, which is categorically unacceptable, since it not only worsens the environmental safety of the log house, but also its durability.

Control is carried out using a not very large pointed tool that can pass through the caulk. A chisel or metal ruler is suitable for this.

Before checking the instrument, a visual inspection is carried out :

- the spaces between the crowns are carefully sealed;

- the insulation must lie closely;

- you can try to pry and remove the caulk; if the entire strip comes out, then the job was not done satisfactorily;

- the seal must be made of the same material inside and outside with the same density;

- Corner joints are checked with particular care, since this area is most susceptible to cracking.

Also, preliminary control is carried out by the owner of the house at the time of performing preparatory work on the insulation.

If the performer uses moss for this purpose, then it must first be moistened in a special solution consisting of: 0.200 kg of ordinary laundry soap and 0.500 kg of vegetable oil mixed with 10 liters of water. The tow is pre-soaked in antiseptics.

In the case when the roller twisted from insulation threads turns out to be bulky and loose, it is strengthened by adding an additional strand of material. The auxiliary strand will be able to catch on the ends of the insulation falling from the wall and fit quite tightly between the logs.

Important! The contractor must inspect the insulation before installation.

If it contains a lot of foreign elements or if it crumbles in your hands, then it cannot be used, since it is made from second-class material. It is also not recommended to use cheap insulation, which, as a rule, has a short shelf life.

After completion of the work, better quality control can be carried out by inspecting the log house using a thermal imager during the cold season. This device allows you to visualize all losses of thermal energy at home.

If the caulking process is performed poorly, it will show “cold bridges” along the inter-crown joints and in the corners of the house.