Here you will learn:

- Why is vapor insulation necessary?

- Izospan insulation range

- Features of Izospan AM

- Advantages and disadvantages

- Where is the material used?

- Instructions for installing isospan

- Useful tips

Izospan is a film or non-woven membrane used in thermal insulation structures to protect insulation from moisture, wooden and metal elements from rotting and corrosion.

Vapor barrier membranes are necessary when arranging multilayer building structures, mainly external ones. These are external insulation systems, pitched roofs, frame housing construction, and the installation of wooden interfloor ceilings.

The main task of the Izospan vapor barrier is to prevent the appearance of a “dew point” in the structure. Warm air tends to leave the room, and cold air tends to get inside. Without a well-equipped barrier, flows of different temperatures will meet in the density of the wall and condense into droplets of moisture. The result is that wet insulation freezes, thermal efficiency decreases, and mold appears inside.

Vapor barrier solves this problem - the membrane allows moist air to escape without being trapped in the thermal insulation layer. The dew point moves - condensation does not fall.

Characteristics and differences

Izospan is a non-woven building material. It is produced in the form of films and membranes, which are designed to protect and insulate surfaces. Izospan goes on sale in rolls.

Materials are divided into three groups:

- Windproof. This includes all insulators marked with the letter A. They are needed to retain internal heat and prevent winds from blowing through the insulation. The material does not allow moisture to pass through, but is capable of removing evaporation.

- Fully waterproofing. They are marked with the letters B, C, D. And they do not allow water or evaporation to pass through.

- Energy saving. They are marked with the letter F. They have the same characteristics as the previous group, but have a metallized reflective layer.

From the above it can be understood that only the first group has the ability to pass steam. It is precisely this that should be used to insulate residential premises, since all living organisms emit fumes into the atmosphere. And if the liquid in the form of steam is not able to leave the room, then the humidity in it will soon rise critically.

Types of vapor barrier Source stroychik.ru

The remaining groups are solid insulators. But the latter has a thin metal coating that can reflect heat, preventing it from leaving the room. This feature requires an air gap between the mirror layer and the other material. It must be at least 3.5 cm.

And before you think about how to properly lay Izospan, you need to fully study the brand on the product. The first letter on the marking is often followed by others. They indicate additional insulation properties. For example, the letters M or S indicate the presence of reinforcement. And the abbreviation of small letters “fix” indicates the presence of applied strips of glue along the edges. And when buying such a product, you don’t have to worry about tape.

Why is vapor insulation necessary?

As we said earlier, wood is a rather specific material for construction: it is excellent for air permeability, but likes to absorb water, and for this reason it swells. Ignoring this fact, you may encounter the following troubles:

- the floor will become crooked or “bulge”;

- finishing materials or coatings will be damaged;

- You can find mold in the corners, which will make the house smell disgusting;

- when water freezes during winter frosts, it expands, causing cracks and small crevices in the wood to become larger - this causes rapid wear of materials (if we are talking about open spaces);

- After a few years, the floor will no longer function correctly, and you will have to install it again - this is costly both financially and in terms of effort.

Moisture frozen in winter expands, and this can lead to damage to building materials.

All of these problems can be avoided if you make a high-quality vapor barrier for the floor.

Izospan A

The material is produced in the form of a diffusion membrane, which is capable of completely retaining any liquid. But evaporation passes through it easily. Therefore, if it is positioned correctly, it serves as reinforcement and protection of thermal insulation. It also does not allow the latter to accumulate moisture from evaporation coming from the room.

Vapor barrier marked A Source roofing façade34.rf

The exception is Izospan A (base). This material serves only as a wind barrier and, in addition to steam, it also allows moisture to pass through. It is used to insulate the ceiling located above the facade, in which there is good air circulation. Place the membrane on top of the mineral wool, on the subfloor side. And it allows the insulation to get rid of not only steam, but also water.

The temperature range for operating the material is quite wide. The insulator can be used from severe frosts of -60 °C to serious heat of +80 °C. Izospan A is able to retain its characteristics even when exposed to ultraviolet radiation. But the truth is only for 3-4 months. Then a sharp decline in performance begins.

The insulator is able to withstand a fairly large tensile load, and some materials even have fire-fighting properties. Based on these parameters, group with the letter A is best used for ventilated facades and frame-type enclosing structures. Also for a roof that has double sheathing and a slope of at least 35 degrees.

Waterproofing for metal tiles Source stoydiz.ru

See also: Catalog of companies that specialize in home insulation

Basic rules for working and instructions on which side to lay Izospan A to the insulation:

- The material on the wall begins to be mounted from below.

- The same sequence must be maintained when working on a pitched roof.

- On horizontal roofs, Izospan is laid starting from any of the walls.

- The next panel must be laid with an overlap on the previous one. Ten centimeters are enough on the walls, and ceilings and roofs should have at least fifteen centimeters.

- If there are no adhesive strips on the edges, then all connections are fixed using double-sided tape.

- For a clearer connection to the rafter system, it is better to use a special sealing tape.

- For material with clear markings (only one letter A), it makes no difference which side the insulator is applied to the insulation.

- Izospan, which has double markings (AS, AM and others), must be unfolded so that the logo is on the outside.

Installation of vapor barrier Source dolgostroi.pro

The last point is very important. If you make a mistake, fumes will begin to accumulate in the insulation. It will get wet, which will lead to the loss of its positive properties. The process will speed up significantly when moisture begins to partially penetrate from the outside as the other side allows steam to pass through. And there is enough vapor everywhere.

Reviews

Is Izospan AM really that good? Reviews will show whether it is worth buying and using this material? Here's what users who have already tried waterproofing write.

Peter, 50 years old, Omsk

“Winters in our area are very cold. Therefore, it is impossible to do without insulating the house. Since I live in a private sector, I had to insulate the roof too. Izospan AM was used as waterproofing of the heat insulator. The heat remains excellent and the insulation does not get wet. I did the installation myself, quickly and easily. What can I say, I recommend it for use. In addition, the price of the material is affordable, everyone can afford it.”

Dmitry, 54 years old, Moscow

“I have a balcony, it’s cold. I thought why not turn it into a living space. And this means that it needs to be insulated. I don’t particularly understand the construction business and all these technologies, but a neighbor said that the insulation must be covered with waterproofing. He even advised me to use Izospan AM. This is a universal membrane that is easy to work with. Even I was able to complete all the work myself. The material is good, no complaints. It has been in service for 4 years.”

Izospan B

Unlike the previous material with a mark in the form of the letter A, all other markings are vapor barriers. And since they do not allow evaporation to pass through, they completely protect the insulation from moisture. Therefore, Izospan is placed in front of the insulation, and not behind it, as in the previous case. This is if you look at it from the room. They are produced in the form of film, and it is usually two-layer.

Izospan marked B, consisting of polypropylene, is used to strengthen the ceiling insulation and protect it from moisture. The material has the same temperature range for use as Izospan A. The characteristics of water resistance and ultraviolet resistance are also the same.

In order to understand how to properly lay Izospan with such markings, you need to carefully examine the sides of the material. One of them is perfectly smooth. On the other there are the smallest fibers. So they do not allow moisture to accumulate on the walls.

Izospan B Source opotolkax.com

The lint on the surface helps water roll down quickly. Therefore, the smooth side of the material should be adjacent directly to the insulation, without any gaps. The latter is necessary before a rough surface. Otherwise, moisture will not be able to move down.

Areas of use

You can use similar moisture and wind protection of the thermal insulation layer when installing attic floors. Regardless of which building structure is used, the membrane must be installed with the white side facing the thermal insulation. We can talk about a wall, a pitched roof, a ceiling or a ventilated façade. The layer should be laid as tightly as possible on the thermal insulation; a ventilation gap is not required.

The use of “Izospan AM” is prescribed by technology for the installation of insulated pitched roofs. In this case, the film is laid on the rafters on top of the insulation. The canvas should be rolled out horizontally, starting from the bottom, ensuring overlap. A counter-lattice is attached on top, and a solid wooden flooring is placed on top. The next layer will be the roofing material. A ventilation gap of 5 cm should be left between Izospan and the coating.

Izospan C, D

Marking C indicates that the material is well suited for insulating insulation under the roof. It is often used instead of a waterproofing substrate under metal tiles. It is also laid when arranging concrete floors in places where humidity exceeds specified standards.

Marking D indicates that the insulator has good UV resistance. This circumstance and the fact that the material has greater strength allows it to be used as a temporary roof. Otherwise, it is used like the previous insulator.

There is no need to guess which side to lay the Izospan with these markings on. The materials also have a rough surface on one side. So she should look into the room. And the smooth side must be adjacent to the insulation.

Stages of vapor barrier installation Source krepezhinfo.ru

Useful tips

Using the material is quite simple, but the process should be approached responsibly. There are some tips for laying the membrane:

- Try to ensure natural drainage of moisture from the insulation. To do this, do not cover the bottom edge of the canvas.

- Since the material is sold in large sizes, it will have to be cut. This can be done at a construction site. Moreover, the material should be spread directly on the insulation.

- Please be careful when using this product despite its durability.

- The membrane should not be used as a permanent or even temporary roof covering. It will not last long in direct sunlight. And a real roof is more reliable.

Please note that you will be performing work at heights, so all actions must be performed as carefully as possible. You must take care of your own safety (wear comfortable shoes that will not slip). It is not advisable to carry out work in windy or rainy weather, as this may lead to a fall from a height. For added safety, tie yourself to the rafters. That's all the recommendations for laying this material. Good luck with the installation!

Izospan F

A distinctive feature of an insulator marked F is a metallized layer on one of the surfaces. It allows you to reflect the heat coming from the room back. This ability not only enhances the characteristics of the insulation, but also allows you to maintain a favorable atmosphere for as long as possible.

Izospan F is also used as a vapor barrier and is used in the same places as materials marked B or C. But it is more widespread to enhance the characteristics of heated floors. And the layout is as follows.

First, insulation is laid on the floor slabs. Then the vapor barrier is laid with the reflective layer facing up. After this, the heating system is installed. In this case, moisture does not penetrate downwards, and the insulation retains its characteristics. And the underfloor heating system does not heat the ceiling of the neighbors, but transfers all the heat into the room.

Layered cake

Once the installation is completed, it is necessary to fasten it with plastic or wooden slats, which are fixed to the surface or using a rafter structure. In the latter case, it is necessary to prepare the nails. The technology for installing the Izospan AM film involves installing slats, the distance between which will be 30 cm. After this, you can begin laying the materials that will form the insulating layer. If you combine Izospan with slats, this will create a small ventilation gap so that moisture evaporates quickly and easily.

Briefly about the main thing

To work correctly with Izospan, you must carefully study the instructions, as well as the product labeling. How fully the insulation will perform its functions will depend on which side the insulator is adjacent to the insulation. An error in location will cause the heat insulator to quickly fail.

Loss of the positive characteristics of the insulation will lead to the formation of an atmosphere in the room unsuitable for life. Expensive repairs will be required. After all, you will have to open the walls and completely change both insulators.

Ratings 0

Installation of waterproofing for non-insulated pitched roofs

To protect the wooden elements of the frame of an uninsulated roof from precipitation, wind and condensation, it is recommended to use Izospan film grade D or DM (featuring an anti-condensation surface), as well as RM or RS as a wind-waterproof barrier.

On roofs of complex configuration, or taking into account further insulation of the roof, it is recommended to use vapor-permeable reinforced material of the AQ proff brand.

Since it is not necessary to insulate the roof before laying waterproofing, the material is immediately rolled out over the rafters and cut to size. The strips are mounted horizontally, from bottom to top, using a construction stapler with staples or nails with wide heads. The overlap at all horizontal and vertical joints is from 15 cm. Joints and junctions should be glued using a special mounting tape. Self-adhesive tape is installed over the flashing along the rafters to seal the attachment points. Counter battens are placed on top under a solid or sparse sheathing for installation of roofing material on the roof.

Roofing pie of an uninsulated pitched roof

Which side to lay the wind-waterproof barrier

:

- for films D, DM, RM, RS, the smooth side should be facing upward, towards the roofing;

- Membranes used as waterproofing, including AQ proff, are laid with the white side down.

The used waterproofing film D, DM, RM or RS additionally requires the installation of a ventilation slot in the roof ridge.

Types of materials for vapor barrier

Despite the same purpose, means intended to contain steam differ both in the components from which they are made and in their properties. Of the most popular, four groups of vapor barrier materials can be distinguished:

- Polyethylene film

- Polypropylene film

- Foil mats

- Diffuse membrane

Polyethylene film

The most budget-friendly type of vapor barrier protection. The thin film, which does not react well to sudden temperature changes, breaks easily, making it inconvenient for installation.

Peculiarities:

- Low cost;

- Requires a ventilation gap;

- does not allow air to pass through, thereby creating a “greenhouse effect” indoors;

- Weak strength. During installation, rupture easily occurs, sharply reducing the vapor retention rate;

- high flammability;

- breaks down at low temperatures.

Polypropylene film

It is a more practical analogue of polyethylene. At the same time, they are not significantly more expensive. It does its job well and is less susceptible to damage from temperatures, exposure to UV rays, and mechanical stress.

Peculiarities:

- Strength;

- In reinforced versions, one side is equipped with viscose or cellulose fibers that retain vapor and moisture;

- Similar to polyethylene films, requires a ventilation gap;

- average flammability indicators.

Foil mats

Rooms exposed to high levels of humidity and temperature, such as baths, deserve special attention. Temperatures sometimes reach 120 degrees, which can lead to melting and release of harmful substances from the above-mentioned materials.

In such cases, it is customary to use special vapor barriers. A layer of foil applied on one side not only prevents the penetration of steam, but also helps preserve heat: infrared radiation from the metallized surface returns inside the steam room. This type of vapor barrier is called “reflective”.

Peculiarities:

- foil-based insulation helps to further retain heat inside the room;

- tolerate high temperatures;

- depending on the base material, they may release chemicals;

- have low strength;

- The combination of foil and fiberglass is quite durable and has good thermal insulation properties, but is expensive.

Diffuse membrane

The most modern, durable and reliable method of vapor barrier with excellent vapor permeability indicators (up to 7 g per square meter per day).

The material was first used for the space industry, from where it gradually moved into the construction of ground-based structures. It is a sandwich of non-woven polypropylene and tensile reinforcement. Due to this, in addition to vapor barrier properties, it also has hydrophobic properties.

Separately, there are 3 classes of membranes:

One-sided. It is laid with a smooth layer to the thermal insulation, and a rough layer to the floor. This ensures vapor retention along with more efficient heat storage.

Double sided. The membrane is made of mirror-like layering of synthetic fibers, providing identical properties on both sides. Increases steam/heat insulation and simplifies installation. You can style it any way you like.

Intelligent. High-tech (three-layer) type of diffusion membranes. In addition to protecting floors from cold and fumes, it helps dry out the building structure underneath due to its structure. The absolute champion in the vapor barrier technology market.

Peculiarities:

- strength;

- durability;

- vapor control performance;

- the breathable structure does not require a ventilation layer at the “floor pie”;

- ease of installation.

Vapor barrier for floors in a wooden house - a detailed description of the work process

Glassine. It is paper impregnated with a bitumen-based composition. This option is distinguished by its low price, but its reliability and durability raise questions. The use of this type of product is not recommended.

Polyethylene film. The standard version is often used for vapor barrier of the floor. But this type of product is not very suitable for wooden structures, since it does not allow evaporation and condensation can form inside the cavity, which is extremely undesirable.

Polypropylene film. This option is best suited as it combines reasonable cost and high performance properties.

One of the most popular brands is Izospan B - this type of product is ideal for flooring in a wooden house.

The cost of a roll of 70 square meters is approximately 1000 rubles.

Vapor barrier membrane made of non-woven material. This version of perforated film has a two or even three-layer structure.

It has excellent vapor permeability, which is very important when used in wooden structures. The only negative is the high price of vapor barrier material

The membrane will cost you 3-4 times more than the same Izospan

The only negative is the high price of the vapor barrier material. The membrane will cost you 3-4 times more than the same Izospan.

Which vapor barrier to choose is up to you. Personally, I recommend Izospan - it is perfect for the floor in a wooden house.

Below we describe in detail how to use Izospan and other materials for vapor barrier

In addition to vapor barrier, other materials are needed:

Special double-sided tape. Most often it is sold together with insulating material and is intended for reliable connection of sheets. The amount of tape is determined by the length of the joints that will be on the floor. In addition to connecting the rolls, you need to glue the tape around the perimeter of the walls to fix the film on the surface;

A special tape allows you to securely connect the edges of the vapor barrier film

Mineral wool. It is laid on the bottom layer of vapor barrier; the layer of material depends on the requirements for insulation and can be from 5 to 20 cm. You can use either a roll or sheet version;

Mineral wool is an ideal insulation for wooden floors

Wooden slats. Needed to construct a counter-lattice on top of a vapor barrier film. The thickness of the elements must be at least 30 mm to create a ventilation gap, and the width can be any, most often it is 40-50 mm;

Choose a dry wooden strip so that it does not crack after installation

Fasteners To attach the slats, you need wood screws 50-60 mm long. And to fix the membrane, you cannot do without special staples 6-8 mm long. It is better to choose the hardened version, as it is much stronger and drives perfectly even into hard, dry wood.

The staples make it very easy to attach the film.

Tool

To do the work yourself, you will need the following tool:

Screwdriver. It is used to make rough flooring when preparing the surface. The tool is also used when installing counter-lattice on top of the vapor barrier layer. The kit should contain nozzles of the required configuration for tightening screws;

A screwdriver is an indispensable tool for construction work.

Construction stapler. With its help, the installation of the vapor barrier layer will take place very quickly.

This way you can securely fix the material without damaging it, which is very important when installing the film;

A construction stapler greatly simplifies the process of attaching film to wooden structures.

Scissors or construction knife. Used for cutting film. There is not much difference, use what is more convenient for you;

Scissors allow you to quickly and efficiently cut any film

- Measuring tool. To work, you will need a tape measure, a pencil or felt-tip pen and a level to check the planes;

- Knife or hacksaw. Used for cutting insulation. You may also need a hacksaw to cut the wood block.

Membrane advantages

- rough base;

- wooden logs;

- thermal insulation layer;

- waterproofing;

- finishing floor;

- finishing coating.

You should not violate the technology for installing a wooden floor, because otherwise the structure will turn out to be unreliable. The entire pie should ideally rest on brick or concrete supports, with a small ventilated area between the soil and the wood floor. The vapor barrier should be installed immediately during the construction of the house; there is no need to postpone this stage “for later”.

Vapor barrier will reliably protect against moisture and condensation

Connecting tape (adhesive tape) Izospan FL

Laying Izospan B does not require any special skills or knowledge. Even a novice master can handle the material.

Step 1. The required amount of Izospan V material is purchased. It will be equal to the size of the floor area, to the value of which a certain amount of material required for the overlap is added. This is approximately 15-20% of the total area of Izospan V.

First you need to purchase suitable material

Step 2. A number of preparatory works are carried out in advance, as mentioned above. Next, insulation is laid between the joists.

Laying insulation between joists

Example of laying vapor barrier material

Step 4. To attach Izospan B, it is best to use a stapler. The material is targeted to the joists.

Fastening the material with a stapler

Step 5. The next piece of material is laid overlapping the previously laid and secured one. The overlap width is at least 15 cm.

The material is laid with an overlap

Step 6. Two Izospan B sheets in the overlap area are glued together using adhesive tape. This will allow you to achieve a certain tightness of the vapor barrier layer.

Adhesive tape is used to glue the canvases together

Step 7. It is recommended to additionally protect the lower part of the floor structure with a vapor and waterproofing layer of Izospan D material. It is also fastened using a construction stapler.

Izospan D

An example of using Izospan ML tape

The vapor barrier has been installed, now you can begin laying the final layer of the floor. As you can see, the installation of Izospan B is quite simple and does not require special skills, so you can carry it out yourself without calling specialists.

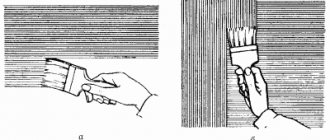

They need to be fastened differently. It is necessary to lay Izospan correctly: the film should be laid with a smooth surface against the thermal insulation, and the fibrous side of the roll remains outside. It will retain moisture generated from steam to prevent it from penetrating into the structure.

It is recommended to lay the vapor barrier with overlapping strips of 15-20 cm. The joints need to be firmly sealed. For this purpose, special adhesive tape with markings or Izospan tape are used. The area of contact between the sheets, counter slats, air gap and sheathing slats is sealed with a sealing strip. Its self-adhesive side is pressed simultaneously against Izospan and the adjacent surface.

Tape material is used in the area of joining niches, holes, windows, and in the construction of communications:

- water pipes;

- ventilation;

- sewerage

Izospan tape is also used in finishing joints with wooden and concrete structural elements. The installation scheme will largely depend on the element of the structure.

Vapor barrier is often used for external walls. If you need to cover the facade of a building, the strips are installed indoors, and the rough part of the roll will be adjacent to the thermal insulation.

Izospan is designed to protect insulating materials during the construction of industrial and residential buildings of any height.

It is able to protect polystyrene, mineral wool, and polyurethane foam from moisture.

Among the advantages are:

- reliability and strength;

- versatility and easy installation;

- environmental friendliness;

- resistance to elevated temperatures.

Installation of steam-waterproofing on insulated flat roofs

If a flat roof requires external insulation, use Izospan grade D or RM; it is also possible to use RS and C films. The material is rolled out onto a base of concrete slabs with an overlap of 15–20 cm. The choice of side of installation does not matter. To connect the strips to each other and to attach them to concrete structures, proprietary connecting tapes are used. Insulation and roofing are installed on top.

Pie flat roof

Types of vapor barrier materials

In construction, various materials are used for waterproofing and vapor barrier:

- polyethylene and polypropylene film;

- breathable (diffuse) membranes;

- bitumen mastics;

- liquid rubber.

The last two types are suitable for concrete surfaces and are not used on wooden structures. Each of the listed types of waterproofing and vapor barrier has its own characteristics.

The most common and budget option for vapor barrier is polyethylene sheet. It comes in different thicknesses. Consists of 1-2 layers.

Manufacturers produce perforated and non-perforated polyethylene film. The first is used for waterproofing. It contains micro-holes with a higher degree of vapor permeability (Sd=1...2 m). In non-perforated products this indicator is lower (Sd=40...80 m). Because of this, it is used as a vapor barrier.

Modern development of polyethylene films for hydro- and vapor barriers - products with reflective aluminum coating. The vapor barrier ability of this type is higher than traditional samples. It is used to protect plank floors in rooms with elevated air temperatures and humidity exceeding optimal parameters: in kitchens. In bathrooms, saunas, baths.

The main disadvantage of polyethylene sheets is low strength. Any impact will cause them to break.

They are mounted with extreme caution, trying to avoid sharp corners and strong tensions. They have a short shelf life

A more durable and wear-resistant artificial material is propylene. It is similar to the previous option, but surpasses it in quality and performance characteristics when used as a hydro- and vapor barrier product for a wooden floor.

Polypropylene reinforced fabrics, in addition to the main synthetic layer, have a viscose-cellulose insert. It is she who absorbs a large amount of liquid and holds it to prevent the formation of drops. When the air temperature rises, the humidity level drops, and this layer dries out. To make the process happen faster, an effective ventilation system is created.

The main advantage of polypropylene products is a high degree of resistance to any weather conditions. They are strong and durable, affordable and quite easy to install. When using polypropylene sheets for hydro- and vapor barrier, the anti-condensation layer is turned towards the rough flooring boards. A ventilation gap is created between the insulation mats and the film.

The most expensive material for hydro-vapor barrier is breathable (diffuse) membranes. These are high-quality modern products with a high coefficient of vapor permeability. They have a special microstructure. The basis of this material is a non-woven fabric woven from synthetic fibers.

Breathable membranes come in 1-2-3 layers. They contain a special anti-condensation layer in which moisture accumulates and then evaporates. Multilayer products include smart membranes. They combine the properties of hydro-, heat- and vapor barrier, and have the ability to independently regulate steam exchange depending on the level of humidity and temperature.

A serious advantage of breathable membranes is the possibility of using them without a ventilation device. This property allows you to save space on the floor by making the ceiling higher. When using these products, there is no need to install additional insulation.

Diffuse membranes are a durable, wear-resistant material that reliably protects boards from moisture. It is expensive, but has a long shelf life and is easier to install.

To choose the right material for vapor barrier of a wooden floor, you should correlate the structural features, the design of the rough and final coating, and financial capabilities.