Noisy neighbors and sounds from the street are not the only nuisance that annoys residents of apartments and private houses, and office employees. Sometimes the source of irritation is much closer - behind the room partition. How to solve the problem of insufficient sound insulation in this case?

Conventional interior partitions often do not protect against noise

Materials used for soundproofing partitions

When the issue of the location of the partition has already been decided, it is necessary to decide on the materials used for the wall structure. Interior partitions are erected from various materials:

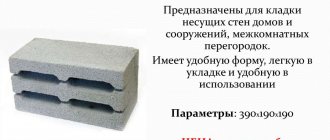

- Foam and aerated concrete blocks. Aerated concrete blocks have a fairly high surface quality and open interconnected pores (the material has good vapor permeability and the ability to take moisture from the air). Foam concrete does not have such a “sore spot”, since the air pores are not connected and isolated from each other. Foam blocks with a thickness of 75 to 100 mm are used for the construction of partitions, since thinner ones may not withstand the load on the wall in the form of a fixed TV or bookshelf.

- Tongue-and-groove slabs. To produce such boards, environmentally friendly material (gypsum) with mineral fillers and cement is used as a binding element. Such partitions do not require a full layer of plaster, but only sealing the seams and a light layer of putty.

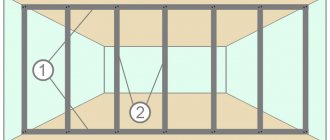

- Drywall. Partitions are created from a load-bearing profile and plasterboard sheets. The surface is perfectly flat; such wall structures are air and vapor permeable. Also, insulation is placed inside the wall (void) to increase the sound insulation of the partitions.

Why these materials?

The mineral membrane Liplent Zik meets the requirements for partitions in residential construction and provides a high level of sound insulation:

- it is only 3.5–3.7 mm thick and saves space;

- the adhesive base has good adhesive properties, so the material is easily glued and securely fixed;

- the composition does not contain any components harmful to health;

- due to viscoelasticity and high volumetric weight, the membrane has high personal sound insulation (28 dB), and in combination with plasterboard on a metal frame it allows one to obtain decent results.

It is no coincidence that Liplent Zik50 tape is used in soundproofing structures for interior partitions:

- it has record high damping characteristics in relation to metal elements;

- flexible and elastic – it is easy to work with on surfaces of any configuration;

- laid on uneven surfaces and firmly fixed;

- has a strong adhesive layer;

- Resistant to moisture, mold, high and low temperatures.

Liplent tapes and membranes retain their performance characteristics for many years

Thin interior partitions are the bane of modern apartments and offices. It is not at all necessary to put up with this design flaw in housing. The most correct solution is to build a partition from scratch according to one of the schemes proposed above in order to save space. If finances and the characteristics of the room do not allow you to take drastic steps, you can also make adjustments to sound insulation using Liplent materials. Anything is possible – if only you have the desire!

Various types of structuring of structures and materials of partitions

Partitions according to their design can be divided into single-layer and multi-layer structures:

- Single-layer partitions. For construction, dense material is used, connected with each other by “mortar”. These can be brick, plaster, expanded clay concrete and even reinforced concrete wall structures.

- Multilayer partitions. Constructed from two or more alternating layers. For example, a frame-sheathing plasterboard partition, a frame partition on one or two frames with environmentally friendly fiberglass, etc.

Article on the topic: Soundproofing plaster for walls

Methods for effective sound insulation

It is possible to achieve maximum results when carrying out soundproofing of plasterboard partitions only if requirements are met that are not directly related to the structure itself. In particular, the essential conditions for creating favorable conditions in the room are:

- installation of a window equipped with at least a double-glazed window;

- finishing walls with sound-absorbing materials (plaster mixtures, gypsum board, etc.)

This will reduce the noise level coming from the street or from a neighboring apartment.

As for the plasterboard partition itself, reliable sound insulation for it is created by alternating hard building materials with soft products. This is the only way that drywall will not allow noise to pass through, and soundproofing materials will become a barrier to neutralize various sounds. Good sound insulation will be obtained when the following conditions are met:

- installation of two separate frames was carried out, which serve as the basis for plasterboard sheets;

- all elements and fasteners are fixed using noise-absorbing gaskets;

- the absolute tightness of the partition is ensured (there should be no cracks, holes or other deformations).

To ensure that the design meets the last criterion, all existing seams are subject to puttying using a shock-absorbing mesh. When laying electrical wiring and other communications, the joints are treated with silicone sealant.

How effective is a partition in reducing noise?

Various sounds entering a home from the street (transport, work being carried out, etc.) exceed the noise emanating from neighboring apartments, but due to the psychophysiological characteristics of human hearing, it is these quiet sounds from neighbors that irritate (baby crying, music, loud voices etc.), therefore acoustic comfort should be taken into account. Maximum sound insulation can be achieved through the use and variations of components and components.

The overall soundproofing effect also depends on the choice of material for the middle layer.

Choosing the right soundproofing partition

When choosing one type or another, the question inevitably arises: which partition has the best sound insulation characteristics at the least thickness, weight and cost? The traditional answer goes like this:

Multilayer frame walls are preferable as internal enclosing structures. With significantly lower weight (which is very important for reducing loads on floors and foundations) and thickness, they have almost the same, and sometimes higher, airborne noise insulation index (Rw) than single-layer structures.

Table 1 Comparison of soundproof partitions

| Soundproofing design | Thickness | Rw |

| Half-brick wall (thickness with plaster 150 mm) | 150 mm | 47 dB |

| Single brick wall (thickness with plaster 280 mm) | 280 mm | 54 dB |

| Wall made of two bricks (thickness with plaster 530 mm) | 530 mm | 60 dB |

| Soundproof frame partition on a 50 mm frame | 108 mm | 56 dB |

| Soundproof frame partition on a 100 mm frame | 158 mm | 61 dB |

| Soundproof frame partition on a double frame 2x50mm | 168 mm | 65 dB |

| Soundproof frame partition on a double frame 2x100mm | 268 mm | 68 dB |

Note! To isolate interior “household” noise, it is more preferable to use a lightweight partition structure with a thickness of 108 mm, which has a level of noise insulation comparable in magnitude to the sound insulation of a significantly more massive and thick wall with a thickness of 280 mm.

In our table, to compare the sound insulation properties of partitions, we use the airborne noise insulation index Rw. Despite some shortcomings, it is a very convenient parameter for quickly comparing the sound insulation of various partition designs with each other and with the standard values of sound insulation of enclosing structures. On the territory of the Russian Federation, since 2012, an updated edition of SNiP 23-03-2003 “Noise Protection” has been in force, according to which the sound insulation of an inter-apartment wall in a residential building must be at least 52 dB (Rw), and between adjacent rooms of the same apartment - at least 43 dB.

As “sanitary standards” these figures may still be reasonable, but for truly comfortable living in conditions of increased noise levels in modern housing they are clearly insufficient. The background noise in apartments, even not counting powerful sources such as home theater or Hi-End systems, has grown significantly in our country over the past decades. Currently, almost every home and every room has a TV, telephone, radio, and in the kitchen and bathroom there is a washing machine or dishwasher, extractor hood, air conditioning, etc. The home computer also contributes to the overall noise level.

Available experience allows us to assert that for modern conditions, the airborne noise insulation index of an interior partition should be at least Rw = 50 dB, and for an inter-apartment wall - at least Rw = 60 dB. Only with such standard values of enclosing structures can we really talk about acoustic comfort. However, even walls with sound insulation Rw = 60 dB will not completely solve the problem of soundproofing a bedroom if the neighbor behind the wall decided to watch a new action movie in his home theater at night.

Interestingly, noise coming from the street through slightly open windows causes much less irritation than weaker sounds: music, screams, laughter coming from a neighboring apartment. The noise of vehicles, like the rumble of thunder, is impersonal, and behind the general hum there is no evil will of a particular person, while the neighbor behind the wall who prevents you from falling asleep with his TV is a well-known and clearly unpleasant person... Therefore, intra-house noises of much lower intensity are well identified by the ear and brain. This is due to the psychophysiological characteristics of human hearing and psyche, and in the struggle for the acoustic comfort of a home, this also has to be taken into account.

Cost of soundproofing partitions

Let's consider two options for soundproofing partitions:

- Basic version, with a thickness of 100 mm. Maximum sound insulation of wall structures at low cost (plasterboard partitions). They have sufficient rigidity and the ability to withstand heavy loads. Due to their simple design, they are popular when solving sound problems in apartments, offices, and recording studios. Cost - from 380 rubles per m2 of double-sided partition.

- Reinforced version with a thickness of 150-160 mm. It is distinguished by the use of a design with separate frames. The partition consists of two parts, independent of each other and installed in parallel, without touching each other. This option is often used for local separation of a bedroom from a children's room or for soundproofing a room with video and audio systems (cinema). The cost of a double frame starts from 500 rubles, depending on the material.

What not to do

In the absence of experience, mistakes can be made that can significantly damage the sound insulation of gypsum plasterboard walls. The first mistake is inappropriate materials, for example, polyurethane foam. It is not intended for soundproofing equipment and also does not meet fire safety standards. Polystyrene foam is also not very suitable for creating a noise-absorbing layer. This material is an excellent heat insulator and is intended primarily for insulating the walls of the facade of a building.

The process of soundproofing a wall with foam plastic

Exactly from the street side. Using expanded polystyrene inside an apartment or house can provoke a transfer of the dew point inside under the plasterboard sheathing, as a result the formation of mold is possible, since water vapor will condense in this place.

Soundproofing walls with polystyrene foam

Rolled materials, membranes or mineral wool are installed only overlapping; they should not form gaps at the joints between the individual panels.

If your financial situation does not allow you to completely soundproof your home yourself, you should not save or replace materials. It is better to arrange one room, for example a bedroom, for a more comfortable pastime. Using these recommendations, it’s quite easy to create a high-quality soundproofing pie. Which will help reduce noise in an apartment or house.

Acoustic drywall

A good solution for soundproofing is to install acoustic plasterboard. The plasterboard sheet has a perforated structure, and a non-woven fabric is stuck to the back side. The front side of the sheet is the perforated part. By reducing the frequency of reflected sounds, it effectively eliminates the sound effect such as “echo”.

Sheathing with plasterboard in two or more layers

Often, when constructing partitions, a double (or more) layer of drywall is used in the structure. This is done in order to make the partitions heavier and more stable, as a result of which the structure will be more durable. Also, accordingly, the noise insulation effect increases.

What are the advantages of the material and are there any disadvantages?

Gypsum fiber sheets, like other materials, have their advantages and disadvantages. The main disadvantage of GVL slabs is its cost. This material is currently somewhat more expensive than materials such as plasterboard, plywood, chipboard and MDF boards. Also among the disadvantages of the canvas is its significant weight

When making a frame, it is important to correctly calculate the strength indicator, since the mass of the slabs is considerable. As for the minuses, that’s probably all

Gypsum fiber has many advantages, which is why this material is often used in modern construction. Thanks to the hypoallergenic qualities of the finish, it can be used for residential premises and in particular children's rooms. The microporous structure of gypsum fiber sheets allows the walls to breathe, which helps protect the surface from fungal growth and mold.

Due to the hygroscopicity of the composition, the canvas can independently regulate the humidity of the apartment. If the apartment has high humidity, then the surface of the gypsum fiber board absorbs it. In case of increased levels of dryness, gypsum fiber releases moisture to create optimal climatic conditions. It is also worth mentioning the possibility of using GVL panels in rooms with temperature changes. Gypsum fiber sheet is an ideal material for finishing rooms without heating.

Materials with high sound absorption coefficient

Sound-absorbing materials can be divided into the following types:

- Porous sound absorbers (also called fibrous). Made from porous materials - kaolin, slag, pumice, vermiculite with a binder (for example, cement);

- Porous, with perforated screens;

- Resonant;

- Layered structures;

- Piece or volumetric.

Article on the topic: Soundproofing substrate for wallpaper and acoustic wallpaper

What to make an interior partition from: foam blocks

Foam concrete is a material that is quite light in weight, especially compared to brick. Of course, depending on the brand, the weight may vary. It varies from three hundred to one thousand two hundred kilograms per cubic meter. The structure of foam concrete blocks has a large number of closed pores. Nowadays, foam concrete blocks are actively used not only in the construction of interior partitions, but also in the construction of entire low-rise buildings. It is because of this that different brands have such different densities, because different construction situations require different weights. The less the foam block weighs, the better quality of sound insulation it creates from airborne noise. However, foam concrete blocks are inferior to other options, since the sound insulation of a foam concrete partition, with a standard thickness of one hundred millimeters, reaches a normal acceptable value only if a ten-millimeter layer of plaster is applied on both sides. So low density protects well from airborne noise, but very poorly neutralizes structural noise. In addition, the low density of the material does not allow anything more or less heavy to be attached to the partition. Of course, you can hang a picture or a clock, but you will have to forget about shelves and, especially, additional structures.

Which is better: heated floors or radiators?

Warm floorBatteries

Among the advantages of foam concrete blocks are their significantly larger size compared to brick. The standard size of a foam concrete block for walls is three hundred by six hundred millimeters with a thickness of two hundred millimeters, and for interior partitions - one hundred. In addition, creating a partition from foam concrete blocks is a much easier process, although here you will need to apply basic construction skills. The thickness of a regular foam concrete block is twenty centimeters. This means that such an interior partition will take up more space in the room. Like brick, it will have to be plastered before finishing.

Materials used to fill partitions

A partition, designed not only to divide a room into sectors, but also for sound insulation, consists of a frame and filler. The aggregate plays an additional role in sound insulation. Let's look at some types of partition filler:

- Schumanet-BM. Premium acoustic mini-slab. Basalt-based mineral wool, moisture-resistant and non-flammable.

- Schumanet-SK Neo. Acoustic mini-plate of a new generation. Fiberglass based mineral board. It is used in partitions, cladding and ceiling structures.

- AKULite (AkuLight). Acoustic mineral slab. When laid in one layer, the sound absorption class is B, when laid in two layers - class A.

The procedure for performing noise insulation work

Photo: mineral wool slabs

First of all, you must understand that you can even handle the construction of this partition yourself, i.e. even the owner of a country house, be it wooden or brick, can do all the work with his own hands.

You need to start by marking and attaching profiles around the perimeter, constructing a frame from them, onto which the drywall will subsequently be attached. To do this, you need to cut the required sections of the profile with metal scissors and simply drill them to the walls, ceiling and floor.

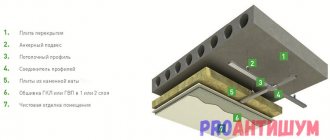

When the frame is ready, you need to attach sheets of drywall to one side, but so that they fit tightly (without the slightest gap) to each other. All joints are puttied and laid on the inside with a layer of mineral wool, then sheets are attached on the reverse side. Thus, you will get a dense partition, tightly packed with mineral wool from the inside.

Such soundproofing of interior partitions will serve you for many years and will truly protect you from noise coming from the next part of the room. However, there are cases when these measures are not enough, then this partition can be strengthened with special materials. You can also use wooden beams to build the frame, but this will only be a waste of money, and such a frame will take much more time.

Filling the frame and covering with sheets

In the case of using materials to improve acoustic properties, first a finished frame made of profiles is attached to one side - sheets of plasterboard. Next, the voids are filled with the selected material (trimming to size and fixing the slabs). After the partition is filled, the second side is “sewn up” with plasterboard. Pay attention when attaching the second side - make sure that there is no piece of mineral wool or other filler between the profile and the sheet of drywall - this can lead to bumps on the surface of the drywall.

How to calculate the thickness of a partition for walls

Sound insulation calculations are made based on the width of the profile and the sheets attached to both sides of the frame. For example, with a profile width of 10 cm and double the value of the gypsum board, the result will be 12.6 cm. When using thin gypsum boards, an arched profile with a width of 6.4 cm is often installed. Now the thickness of the plasterboard screen with insulation will be 7.4 cm.

Permissible loads on the partition

When forming a design for interior screens, they proceed from the profile parameters. The optimal size is 12.5 cm. For a future load on the frame of 40–50 kg per 1 m², take a sheet no more than 1.6 cm thick. If a load of 70 kg or more is planned per 1 m², it is recommended to install additional racks on the structure.

| GVL thickness, mm | Permissible loads on dowels, kg | |||

| Plastic | Metal | |||

| 0,6 | 0,8 | 0,6 | 0,8 | |

| 10 | 15 | 20 | 30 | 40 |

| 12,5 | 20 | 25 | 30 | 50 |

| 2x10 | 30 | 35 | 40 | 55 |

| 2x12.5 | 35 | 40 | 50 | 60 |

Mistakes when arranging sound insulation

There is a misconception that when filling voids in partitions, you can get by with any available material, and there will still be a sound insulation effect. Sometimes they even use expanded polystyrene or polystyrene foam for these purposes, but these materials will not help reduce sound insulation; on the contrary, they will increase it (they are not intended for this).

Also, when constructing partitions, some owners leave empty space inside the frame. This results in a sound effect called "echo".

Also, to save money, unskilled workers are hired. Even if you spent money on high-quality materials, the builder may not carry out the installation correctly (not completely adjacent to the floor, etc.), and therefore the partition will not fully perform its soundproofing function.

What distinguishes gypsum fiber from drywall

Based on the previously reviewed qualities of gypsum fiber, it is quite difficult to say anything about its difference from gypsum board. When comparing the characteristics of these materials, we can confidently say that they are somewhat similar. If the house is being renovated, then you can use any of the materials, the main thing is that it is suitable in quality and cost.

Due to the high level of stability of the GVL material, it can be used in the construction of gyms and industrial premises. As for less demanding buildings, plasterboard will be the optimal solution for them. When manufacturing complex building structures, it is better to choose gypsum fiber, which has increased strength to mechanical loads.

Both materials can be used to level walls and ceilings, but in most cases preference is given to plasterboard, since the loads in such structures are small and there is no need to use denser panels.

Step-by-step algorithm of actions

After drawing up a preliminary scheme and estimate, they proceed directly to procurement. You will need an electric drill or hammer drill with a set of drills, fasteners (self-tapping screws, screws), a hacksaw or a grinder saw. From the materials you need to prepare a metal profile for the frame, gypsum fiber sheets, and noise-insulating filler.

It is necessary to follow the procedure approved by standards and technologies. The master builds an insulated partition in one day. If you do the work yourself, you need to be patient. It’s better to spend 2-3 days, but do it conscientiously.

Space marking

According to a pre-drawn diagram, markings are applied to the floor, walls, and ceiling. A building level must be used. It is recommended to use a laser device that will immediately highlight straight lines. All that remains is to draw everything on a ruler or tape measure with a pencil.

If there is no equipment, you need to measure each point separately with a tape measure. Marks cannot be placed relative to each other; they must be measured from identical points within their planes.

For example, first measurements and markings are made on one wall, then on the other. But you cannot first mark one surface and then transfer the marks to another, this will lead to strong errors. Mark sheets of drywall that will not be used entirely. You need to cut off small pieces to create minimal joints between the elements.

Preparation of material

The assembly of partitions with sound insulation begins with the installation of a frame structure. You will need to accurately draw and calculate all sections of the frame, measure, and cut profile blanks. If you use wood instead of metal, you will need to sand the cuts to prevent destruction of the wood structure, and also impregnate them with protective antiseptics.

They make a frame around the perimeter of the frame to firmly fix it on walls and horizontal surfaces. A substrate is placed in the places where the structure adheres to the base. The interlayer will provide a better level of insulation.

Frame installation

According to the applied markings, a self-adhesive seal is attached to all edges of the room. Then the starting profile is mounted to the ceiling on metal dowels. It is necessary to immediately treat the hardware with sealant to reduce noise.

Example of a finished frame

Fix the profile along the lower horizontal, then proceed to installing the vertical elements. This is the most critical stage, at which it is necessary to lay wide cells to insert sound insulation, but narrow ones so that the filler does not fall out of place. The opening of the future passage is made with a beam, which is inserted into the profile.

Filling the frame

When the preparatory part is completed, they proceed to filling the partition frame with soundproofing material. There are no specific restrictions on the choice of raw materials for insulation; each case is individual and may require different types of products.

Filling frame voids

You can significantly simplify the task if you immediately sew up the frame with gypsum fiber sheets on one side, and put sound insulation into the remaining space - nothing will fall out. You need to take care in advance about the removal of the necessary wires and a protective casing for the wiring. Craftsmen advise starting to lay sound insulation from the bottom up, placing solid elements first, then sections. It is possible to increase the soundproofing properties of wool if you cover it with a layer of membrane on top.

How to sew up the structure

To close the building, regular gypsum plasterboard is used, which is used to cover the second side of the new wall. The stitching is carried out in two layers: first, a full covering of plasterboard is carried out in a convenient order, then a new layer is applied with partial offset to cover the joints of the previous one.

Finished wall

Overlapping the seams between the sheets is required to prevent noise from leaking through the joints - these are additional sound insulation measures. Upon completion of the installation work, the external joints are treated with sealant, after which it dries, you can begin decorative finishing.

The general process of constructing a soundproof partition can be seen in the following video:

How to fill partitions

Several solutions are offered for high-quality sound insulation. To make a room quieter, you can use insulating foam, sound-absorbing membrane, cotton wool filler, or acoustic drywall.

The acoustic material is easy to use and does not require handling skills. An acoustic gypsum board is first sewn on top of the prepared frame, then it is sheathed on top with a gypsum fiber sheet (GVL).

Soft porous wool is a popular method of sound insulation. The peculiarity of the structure allows the material to absorb most of the sound waves, but you must first assemble the frame. The raw material does not exist in just one form; you can choose different types of cotton wool.

Membrane for ceiling cladding

A membrane is chosen when you need to make a thin wall that will take up a minimum of space. The noise-absorbing surface holds back sounds well. After application, the foam gradually increases in size, less noticeably than mounting foam, but enough to form a porous filler. To work with the material you will need equipment, there are requirements for labor safety and application.

Sliding interior partitions

Interior sliding wooden partitions are more expensive and a more complex process, since their installation is impossible without some experience. Moreover, you will need to make movable blocks yourself and install them on the travel system. In this situation, in order not to complicate your work and not waste precious time, you can always bypass making wooden partitions of this type with your own hands and simply buy moving parts or just the movement mechanism.

Installation of the moving parts of a wooden partition can occur on the outer part of any side of the partition, or inside the partition, but this process is quite labor-intensive.

Interior partitions in a wooden house are a mandatory stage in arranging the interior of a new house, because having kicked out the common box, you will need to correctly divide the room into functional zones. Interior wooden partitions are installed strictly according to the house design or independently if this type of work is not provided for in the plan. This is possible only if you are making non-permanent wooden partitions in a room, for example, to move a doorway, to delimit a room, for decoration, and so on.

interior wooden partitions with your own hands only if you thoroughly understand the process and know how to work with wood and its finishing.

Popular materials

High-quality sound insulation of walls depends on suitable raw materials. The products have different installation methods, the degree of absorption of extraneous noise and price. Let's look at the strengths and weaknesses of materials that are worth knowing about.

Cork

Natural wood is an ideal soundproofing component for walls, safe for home occupants. Raw materials are produced in 3 types:

- Decorative veneer panels. A beautiful, warm finish will help protect the room from extraneous noise. Protective impregnation ensures durability. The downside is the high price.

- Products made from pressed crumbs. The material is based on wood residues and 4% acrylic resin. Slightly cheaper than the first option.

- Technical covering. The crushed cork is combined with a binding ingredient. Produced in the form of sheets collected in rolls. Raw materials are cut before use.

The material is very thin and light, which makes installation easy. Soundproofing sheets are screwed to the walls with self-tapping screws or glued with a special compound. The partition must be leveled before work, otherwise bumps and dents will be visible.

Beautiful soundproofing of the living room Source centrpol.com.ua

The optimal thickness of the panels is 3 cm. Thinner types weakly absorb sound. Models that are too thick will have to be mounted on a metal profile frame, which increases the construction budget for soundproofing the walls.

Video description

Instructions for gluing cork wall coverings.

Polyurethane boards

The second name of the material is acoustic foam. Foamed polyurethane dampens the slightest sound waves and provides ideal acoustics in the room. The thickness of the slabs is no more than 1.5 cm, so the raw material does not take away useful centimeters in small rooms.

Soundproofing polyurethane foam is simply glued or screwed to the wall. The products are lightweight and convenient in size, so installation can be carried out without an assistant. The raw materials do not stink, and the variety of designs and colors will harmoniously fit into the interior of the room.

Polyurethane slabs Source yanashla.com

High price is the main disadvantage of polyurethane boards. Acoustic foam was developed for recording studios, so the material is suitable for musicians, film and music lovers. Due to its porosity, the raw material absorbs moisture, which limits its use in damp rooms. The foam surface is very soft, without protection it will easily tear from mechanical stress.

Mineral wool

Fibrous soundproofing material is produced in the form of sheets or plates. The general name often refers to several types of raw materials:

- basalt;

- ecowool;

- glass.

If you need cheap soundproofing of walls, then it is better to use mineral wool. The material combined with an absorbent component and drywall provides good insulation and noise reduction. The thicker the stand, the less sound will penetrate the room. Due to the frame fastening, the structure can take up to 12 cm of area, which is not suitable for tiny rooms.

Soundproofing agent Source ecoacoustic-spb.ru

Gypsum plaster: will it be possible to make a better interior partition?

Plaster of Paris is made from alabaster and various additives. To create an interior partition, hollow tongue-and-groove gypsum boards are used. They have a number of advantages. For example, they are very light, but at the same time quite durable. Gypsum plaster creates excellent sound insulation and holds nails well. This means that you can hang shelves or other structures on the interior partition.

Gypsum plaster has a very low volumetric weight even compared to foam concrete. Plaster interior partitions have an interesting structure, which makes it possible to quickly assemble them using alabaster mortar. This assembly does not require any professional skills at all, so even an amateur can install such a partition. The surface of such a partition is even and smooth. This is due to the fact that gypsum can perfectly fill absolutely any shape. This is a definite plus, since there is no need to align the partition after its installation. You can immediately begin finishing, having first applied only the finishing layer of putty.

Ways to find silence

The problem of sound insulation is more pressing in apartment buildings. People do household chores and work at different times; during the day, people are more often disturbed by the sounds of animals, stomping, knocking, and the noise of an electric drill. Sometimes it seems that this is not happening with neighbors, but directly next to the person.

To significantly reduce the amount of incoming sounds and make living in an apartment more comfortable, sound insulation is required. There are enough materials and methods of fastening them to find one that is suitable in terms of characteristics and cost.

You can least hear anything through the main brick or block walls laid by the developer. But lightweight partitions between rooms made of plasterboard have become common practice. If you do not use insulation when constructing them, you will be able to talk to each other while in different rooms - the sound wave propagates so strongly without an absorbing layer.