The interior of a room largely depends on how well the flooring is made. In most cases, a person entering a room pays attention to the floor. If it has many defects, then no amount of wallpaper or chandeliers can give the room a finished look. To achieve a perfectly flat surface, before laying the finishing coating, it is necessary to competently perform the work of grinding the floor screed.

Why sand floors?

Most often, grinding is carried out on horizontal concrete bases, both on new and old ones. Experts do not recommend ignoring this manipulation, since it is polished concrete that is cleared of the less durable top layer and becomes more reliable and durable. If we are talking about a recently poured screed, then cement laitance accumulates on top of it, reducing the reliability of the array. After sanding, the surface will be smooth, even, and its adhesion to the finish will improve.

As for old concrete screeds or other structures, microcracks, chips, and other minor defects associated with long-term use inevitably appear on their top layer. In this case, grinding the concrete floor will help remove the damaged layer, get rid of dirt, chips, and cracks. In general, grinding has other positive effects:

- eliminating stains from dirt and spilled liquids - oils, fuel oil, gasoline, etc.;

- increasing the hardness of the floor and its moisture resistance;

- prevention of new cracks;

- simplification of further surface care;

- relief leveling;

- facilitating the further installation of any decorative covering.

Monolithic slab

A monolithic slab is the most reliable foundation.

It involves pouring and forming a monolithic concrete block with metal reinforcement inside. The specific design ensures the “buoyancy” of the entire structure. A garage built on a floating slab base is protected from changes in ground level and, accordingly, from destruction of the walls.

The slab base is shallow, but unlike tape, in this case the entire floor area is reinforced.

There are several types of monolithic foundation:

A continuous horizontal fill is arranged for rooms without a basement or plinth: the upper surface of the slab is the basis for laying the floor covering. A ribbed slab is poured along the perimeter of a monolithic strip (or as intersections), the height of such a ribbed fill is equal to the level of the plinth. Pouring a box means that the walls are continuation of the base, and have common reinforcement.

The height of the ribs is displayed at the floor level. Floor slabs are laid on top of the ribs. This method maximizes the area of load distribution.

Typically, the foundation slab is poured for garages in which it is not planned to install an inspection pit. But if the type of soil allows it, you can lower the filling level to the height of the basement or inspection hole and bring the ribs to the level of the soil surface, arranging an overlap over them.

Types of concrete grinding

Concrete processing for the purpose of grinding can be carried out in two ways - dry and wet.

Wet sanding

This technique is most often used when sanding mosaic floors. It is equally well suited for polishing marble and granite surfaces. Wet grinding allows you to remove up to 0.5 cm of the concrete surface in one pass. After pouring water, the surface is treated with wheels with an abrasive coating. At the same time, you have to remove excess liquid using a water suction. In addition, during work, dirty splashes fly everywhere, and it is very difficult to control the intermediate result. The labor intensity of wet grinding is high, and the time required to carry it out is considerable.

Dry sanding

This method is used when grinding ordinary concrete. It takes a minimum of time, and the result of the work can be assessed almost immediately after the dust settles. The master always has a chance to quickly correct grinding flaws. However, due to the dustiness of the method, it is necessary to use a special construction vacuum cleaner and be sure to use personal protective equipment. The disadvantage of dry concrete grinding is that in one pass you can remove a layer no more than 2 mm thick.

What method should I use when sanding?

Surface treatment by grinding in the apartment is carried out using the dry method. During the floor sanding process, a large amount of dust is generated. It can be easily removed using a powerful industrial vacuum cleaner. This method of performing work ensures good visibility, so minor sanding flaws can be corrected immediately.

After sanding the coating using a dry method, a flat and smooth surface is obtained, which has high levels of sound and heat insulation. The advantage of this method is that after it is completed, you can immediately begin pouring the polymer coating, painting, impregnation, etc.

After all the procedures completed, your floor will be completely ready for laying linoleum, parquet, laminate and other coverings on it.

Concrete Grinding Tools

A concrete grinding machine is a fairly popular product that can be found in any hardware store. For small volumes of work, you can use an ordinary grinder, which every master probably has in his arsenal. To obtain perfectly smooth, high-quality coatings, it is better to buy a professional device.

Industrial grinders

Large coatings should be sanded using industrial equipment. In such grinding machines, the abrasive element is attached to rotating disks, the operation of which leads to the removal of the top concrete layer. The discs rotate in the opposite direction, and the devices themselves have the ability to adjust the power and speed of action. Large discs have auxiliary wheels with diamond attachments.

The use of professional grinding machines allows you to obtain a surface with the desired properties:

- glossy;

- matte;

- mirror;

- semi-matte.

Among other things, such devices have the ability to dose water, which is important when using the wet grinding method. Also, most devices have a built-in dust collector for the dry grinding method. The disadvantages are the high cost and heavy weight of the devices.

Household grinders

At home, grinding and polishing concrete can be done with small devices with wheels or cups. Most often, concrete is polished with a grinder, which costs an order of magnitude cheaper than professional equipment. It is convenient to work with an angle grinder - it is light in weight and allows you to process even hard-to-reach areas.

Using a grinder, remove old coatings, level the screed, and clean surfaces near the walls and ceiling. To work, you will need a special abrasive disc for grinding concrete using a small grinder or a diamond-coated bowl.

It must be remembered that the household appliance is not designed to operate for a long time, because its power is usually low.

Initial stage of work

If there are metal elements (reinforcement or mesh) at the top of the concrete, then you need to think about removing them first - otherwise the grinding machine may become faulty. A grinder is good for removing reinforcement.

The beginning of work generally comes down to eliminating uneven surfaces and removing the old coating. To do this, you can use milling, shot blasting or a special grinding tool (for example, diamond boards with a grain size of about 25-30).

After that, you need to deal with minor flaws. As a rule, epoxy materials are used for this, with the help of which any gaps can be easily filled. When applying such material, it is important to ensure that it does not protrude onto the surface, otherwise the sander will cling.

Consumables for angle grinders

The result of the work greatly depends on the quality of the attachments used - circles, cups, Frankfurts. When choosing consumables, you need to take into account their specific purpose and application features.

Grinding discs

Wheels, or disks, have a flat surface on which an abrasive is applied. Depending on the purpose and type of material to be grinded, the grain size of the disc is selected. Wheels with coarse and medium diamond grits are used for grinding rough concrete bases.

Products with different size chips (faceplates) are suitable for removing the first thin layer from any floor. Discs with fine crumbs or a cellular structure (turtles) are suitable for finishing floors. They are usually equipped with a fine polymer abrasive and are very conveniently attached with Velcro.

Sanding cups

These are discs with a recessed center. A similar attachment to a grinder for grinding is used to remove a thick layer from the surface. The purpose of the cups can also be different:

- with a double segment - for removing the upper concrete layer, carrying out rough processing, eliminating serious defects;

- with square pads - for cutting off protruding elements of concrete and removing fairly large pieces, for roughing, for grinding before applying polymer compounds;

- with boomerang pads - for delicate and finishing polishing.

Frankfurt

They are special trapezoidal nozzles. Used to create a glossy smooth finish and mirror-like bases. They have an emery base attachment.

Mixtures for the production of polished surfaces

First of all, the concrete floor must meet the strength class B25, which is easy to achieve if you use Portland cement of a grade no lower than M350 with low water consumption. The situation with fillers is much more complicated. As a rule, crushed stone obtained by crushing rocks (for example, basalt or diorite) is used to prepare such mixtures. This type of filler is characterized by increased compressive and tensile strength (when compared with a cement monolith). Due to this discrepancy in characteristics, during operation of the base, the areas around the filler grains will wear out to a greater extent. As a result, the polished concrete floor will lose its smoothness and after a few years, bumps will form on it.

In order to avoid such defects, it is necessary to take into account the following nuances when selecting the composition for arranging the base:

- The more high-strength filler in the solution, the better. In this case, it is worth giving preference to crushed stone, which should occupy at least 85% of the total mass of the mortar.

- It is best if crushed stone of different sizes is used for the mixture, then the solution will be much denser. The best option is to mix two different fractions of quartz sand and several gravel components in equal parts. However, grains that are too large (more than 20 mm in size) should not be used.

It is best to prepare mixtures for subsequent grinding and polishing in a forced-action concrete mixer. When the solution is homogeneous, you can proceed to pouring it.

Procedure for grinding concrete

Grinding of the concrete base is carried out no earlier than 2 weeks after hardening. If you do the procedure faster, the crushed stone will begin to fly out of the concrete layer. Typically a 40 grit diamond blade is used. For a glossy finish, nozzles with numbers 1500-3000 are used.

Defect removal and preparation

First, a thorough preparation of the base is carried out, which includes the following actions:

- removal of foreign objects - wires, protruding fittings;

- repairing cracks in the old coating, cutting potholes to a depth of 2-3 cm and sealing them with mortar;

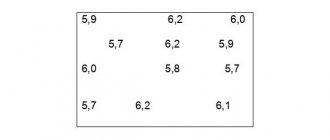

- checking the flooring for evenness using a three-dimensional ruler or level;

- cutting off large bumps and protrusions (more than 5 mm) with a diamond grinder disc, blowing sand from the area and priming it with special strengthening compounds;

- testing the concrete for strength along the entire perimeter (tapping and re-filling weak areas);

- determining the rigidity of the base - testing by grinding a small area with a grinder;

- general cleaning of dust and dirt, impregnation with primer.

On the old crumbling floor, the covering is dismantled, then backfill is made from crushed stone and blast furnace slag. Afterwards, beacons and profiles are installed and a screed with a thickness of 50 mm or more is poured, and only then, after complete hardening, they begin to grind it.

Grinding process

If you decide to use the wet sanding method, water the floor with water from a hose in advance. Afterwards it is polished in several passes with a gradual reduction in the size of the abrasive particles. Hard-to-reach places are treated with an angle grinder (grinder). Take a break from work every 15 minutes so as not to damage the device.

Finishing work

The sanded floor is cleaned of dust and dirt using wet cleaning or a vacuum cleaner. After drying, polyurethane varnish is applied to the concrete surface (for shine and a mirror look). Also, polished concrete can be coated with special paint for 2-3 layers. At the end of the work, the baseboards are put in place.

FAQ

Is it possible to grind concrete the day after the screed is formed?

No, grinding is possible 5-6 days after pouring, when the surface does not deform when exposed to it.

Is it necessary to wet clean the concrete surface after grinding?

If you don’t have a powerful construction vacuum cleaner, then you can. It is best to collect dust immediately so that it does not get into the air.

How long should the impregnation dry before sanding?

It all depends on the manufacturer and composition. Some dry in literally an hour, others take much longer. Read the instructions carefully, where all these nuances are indicated.

What to do if the surface is difficult to sand?

Pay attention to the abrasive. Each type of grinding has its own standards. Perhaps you should take a coarser nozzle.

Is polishing necessary?

If there is a need to give the coating a more attractive look and texture, then yes. Some connoisseurs of the loft style prefer to leave everything as it is.

Grouting fresh screed

There is a special technology for working with fresh screed, which is practiced within 4-20 hours from the moment of pouring. It allows you to create durable, wear-resistant coatings for commercial and industrial facilities and even floors for open areas. For work they use a grinding helicopter - a special type of trowel. It is manual or self-propelled, equipped with a diesel, electric or gasoline engine.

This technology helps compact the top layer of the poured screed. First, rough cleaning of the concrete is done using cement-based toppings. After 10-16 hours, finish grinding is carried out with rubbing in dust-removing impregnations. For a decorative effect, toppings with added pigments are applied over the screed.

Grinding with a grinder

As a rule, the grinding process begins with preliminary cleaning using a bowl with square pads - it perfectly cuts off large sagging and irregularities. Using a cup with a double segment, the top layer of the screed is removed, and the final polishing is done with a boomerang or turtle attachment. It is important to carefully read the instructions for a specific tool in advance so that no problems arise during the work.

Grinding equipment

This technique is divided into two groups:

- Professional. It is a machine equipped with large discs with abrasive material. The movement of the working elements occurs in different directions, so subsequently a perfectly polished surface is obtained. In addition, the devices are equipped with dust collectors and a control system for the speed of rotation of working parts and the intensity of processing. The main disadvantage is the cost. Even if you rent equipment, the budget can be very large.

- Small household grinders. The most popular is the grinder. To work with this tool you will need an abrasive disc. If polishing is required, it is recommended to buy a special machine. It is inexpensive and very easy to work with.

Safety precautions

To avoid injury and keep the instrument safe, you need to follow simple recommendations:

- Before starting work, inspect the device for damage, cracks in the housing, and reliability of wire insulation;

- put on protective clothing and shoes, gloves, goggles and a respirator in advance;

- ensure good lighting of the workplace;

- when replacing wheels and attachments, be sure to disconnect the device from the network;

- If vibration or a burning smell appears, stop grinding immediately.

If you strictly follow the technology, you can create a beautiful, monolithic and perfectly smooth floor with your own hands, which will not be inferior in strength to stone. Considering its wear resistance, long service life and ease of operation, it is probably worth mastering the simple technique and applying it in practice.

Preparation

In order for polished concrete to last a long time, its proper preparation plays an important role.

To do this, you need to take the following steps. First of all, dismantle the old coatings and check the evenness of the plane with a three-meter ruler. The presence of holes, potholes or bumps determines the degree of cup wear.

Then you need to examine the surface for the size of cracks, seams, etc. If available, seal them with any hand tool.

Before starting sanding work, you also need to tap the floor or walls for strength.

If it is missing, some areas will have to be refilled. At the same stage, complex work is performed, for example, diamond drilling of concrete

It is important to ensure the reliability of the power supply - any interruptions can have a detrimental effect on the outcome of the process

Important criteria in assessing the readiness of a floor for sanding are the absence of cracks, seams and other elements that could damage the delicate sanding tool.