24.02.2021

Sewerage

Editorial staff of the “New Place” website

Share

From this article you will learn

:

- Regulatory framework for storm drainage

- SP requirements for storm sewer slope

- Calculation of storm sewer slope

- Storm sewer installation

- Consequences of incorrect calculation and installation of storm sewer systems

- Professional calculation of slope and other storm drain parameters

The slope of a storm drain is one of the key parameters, the incorrect calculation of which paralyzes the operation of the entire system and can lead to a local disaster if a large amount of precipitation falls. We are not just talking about excess water, but about the risk of flooding the site, damaging the foundation of a house or the foundations of other buildings, which will most likely result in their deformation and destruction.

Despite the fact that there is no strict requirement to comply with the standards, it would still be more correct to follow the recommendations given in the regulations. In our article we will tell you what the slope of the storm drain should be, how to calculate it, and also analyze the correct installation of this sewer system and what problems may arise if you make a mistake.

On the role of slope in the operation of the drainage system

Every homeowner knows that long and trouble-free operation of a home depends on many factors, one of which is a well-designed and installed drainage system. Properly installed gutters can solve several important problems:

- Timely removal of precipitation and melt water from the roof .

- Drainage of water from the building , due to which the soil does not become waterlogged, the foundation is not subject to premature destruction, and dampness does not settle in the house.

- Protection of the facade from water . No matter how high-quality the wall decoration is, under the influence of water it becomes unusable much faster.

- Water collection . Rational use of water is important for owners of flower beds and vegetable gardens.

Water drainage is the main task Source navacanal.es

The operation of any gravity system is based on the gravitational principle - water always flows in the downward direction, therefore the slope of the gutter is one of the main reasons for the good (or poor) functioning of the drain. It is this value that sets the speed of water flow and determines whether the gutters and funnels can cope with the given current.

Rainwater drainage via other networks

Private real estate projects traditionally include other communication networks along with storm drainage. Domestic sewerage and drainage systems are also part of household communications. The principle of their operation differs little from the functioning of storm drains, in which owners of private houses often see the possibility of using these networks.

Meanwhile, the combination of storm sewerage with a domestic or drainage drainage scheme is prohibited by SNiP. The ban on combining different types of sewage systems is due to obvious factors. Thus, provided that rainwater is discharged into the domestic sewer system and taking into account the high intensity of precipitation, the normal level of sewerage is increased several times.

Flooding of working wells leads to blockage of household and fecal wastewater. Mud deposits and natural debris flow into the domestic sewage system. As a result, after the next rainstorm, the organizers of the structure will have to clean the system.

Combining a stormwater system with a drainage main threatens to result in even more disastrous results. Overflow of drainage due to violation of design loads leads to flooding of the building foundation. Frequent flooding disrupts the structure of the soil, which causes displacement of foundation blocks, and in the future can lead to the destruction of the building.

About the drain and its components

Organizing a functional drainage system is not a trivial task. There are no general recipes; for each roof, the project and its parameters are determined individually; The factors influencing the operation include the following quantities:

- Roof area.

- Design parameters . In addition to the slope of the gutters (the slope of the drain is taken into account by 1 meter), their optimal cross-section and length, the cross-section of the drain pipes and the number of funnels are calculated.

- Minor factors . These include the gutter material and installation features (how the hanging brackets will be attached).

One of the varieties of systems Source 2gis.ru

The drain consists of many elements; In order for the collection and drainage of water to proceed according to plan, they all must comply with the design parameters and be installed in a clear sequence. The standard system consists of the following set of components:

- Basics . Horizontal and vertical movement of water is ensured by drains and pipes, the most voluminous components. The funnel connects these elements, collecting and directing water.

- Additional . In most cases, the arrangement will require a tee (a part for branching the system), an elbow (the final part of the drain pipe), a bypass (a part for turning the pipe), as well as the outer and inner corners of the gutter, necessary for complex-shaped facades.

- Auxiliary . Brackets are used to fix the gutter and adjust its tilt. Connecting parts also include clamps, couplings and rubber seals. An important part of the system are gutter plugs, which prevent leaks and add rigidity to the structure. You can’t do without a leaf catcher or spider net, which also protects from leaves and branches.

Installation of brackets Source clip.fail

See also: Catalog of companies that specialize in roof repair and design.

Storm sewer installation

Technically, the process of laying pipes for stormwater drainage is almost no different from arranging an external pipeline.

- What pipes are needed for the underground part of the storm drain.

According to the requirements of SNiP, pipes made of the following materials can be used for the construction of external drainage networks:

- ceramics;

- steel;

- plastic.

Ceramics are often used when installing external pipelines and storm drains. The main disadvantage of the material is its weight and fragility (a pipe with a diameter of 100 mm weighs 24 kg or more).

Steel pipes weigh less (a meter of pipe weighs about 10 kg), but they rust, which makes them not the best material for installing rainwater drainage systems.

Modern builders are increasingly giving preference to plastic and HDPE pipes for the sewer system. Their advantage is lightness, strength, and corrosion resistance. No welding is required to connect the elements. Can be used:

- PVC pipes; there are special orange pipes for external sewer networks;

- multilayer polymer pipes are the best option. Thanks to the smooth inner surface, there is virtually no hydraulic resistance.

- Installation of the roofing part

How to prepare an autonomous sewer system for winter

Stages of work:

- To install rainwater inlets, holes are made in the ceiling walls. The junction areas are treated with sealant.

- Then the outlet pipes or trays are strengthened.

- The next step is installing risers.

- Lastly, the water discharge unit is assembled into a collector or outlet into trays.

Special clamps are used to secure the devices. The places of their fixation are preliminarily marked in compliance with the recommended slope values.

- Arrangement of the underground part

First you need to dig trenches for laying pipes. Their depth depends not so much on the degree of soil freezing, but on the availability of practical experience in operating storm drains in a particular region.

Stages of work.

- Dig trenches. It is important that their depth is uneven. It gradually increases to provide the desired slope.

- A 20-centimeter cushion of sand is poured over the entire bottom of the trench.

- Next, they dig a pit specifically for installing the collector.

- Pipes are laid in prepared ditches. They are connected to each other using conventional fittings.

- If the sewerage system consists of one continuous branch no more than 10 m long, then it is planned to erect an inspection well in its middle. In addition, a manhole must be installed at each network branch.

- Sand traps are installed at the junction of water inlet gutters and sewer pipes.

The next step is to backfill the trenches and install the gratings on the trays.

- Why are security zones needed?

What a security zone is and what its purpose is is not clear to everyone. But SNiP provide for the mandatory organization of security zones of a certain size near pipes. If this is a branch of a storm sewer, then it is necessary to provide a distance of 3–5 m from the external walls of the pipeline in each direction. In the security zone it is prohibited:

- Build structures not only permanent, but also temporary.

- Set up landfills.

- Organize parking.

- Plant trees and shrubs at a distance of less than 3 meters from the pipe.

- Block access to manholes.

We conclude: storm drainage equipment is a mandatory measure when landscaping a site. The construction of such systems requires compliance with the rules provided for by regulatory documents.

About the need to calculate the slope

In the eyes of an uninitiated person, the accuracy of the calculations is not so important, and the slope of the gutter is an unimportant thing and, in general, useless. Obviously, water can drain from the roof on its own and find its way down in the gutter. At the same time, if you do not follow the rules of calculation and installation, you may soon encounter the following problems:

- If you do not set the drainage angle , then horizontally installed gutters will cope with the load until the first serious downpour. Water will begin to accumulate at low tide, and before it can get into the pipe, it will overflow over the side. The result will be wet walls and damp soil around the foundation. If overflow occurs frequently, the purpose of the drainage system is lost.

- With a zero slope, the solution may be to use oversized gutters and large-capacity pipes - only if you do not care about the appearance of the facade, the proportions of which will be spoiled. The negative side effect is that wide drains fill up with debris more quickly, making them less efficient and requiring cleaning much more often.

Gutter parameters Source koon.ru

- Installing drains at too steep an angle , contrary to expectations, will not improve the operation of the system. Undoubtedly, water even through small gutters will flow in the right direction. The problem will begin when the funnels and drainpipes no longer cope with the drainage of water, and overflowing begins. Funnels and pipes of huge diameter can save the situation, but they are unlikely to decorate the facade.

Consequences of incorrect calculation and installation of storm sewer systems

Violation of the standards for the depth and slope of storm drains established by SNiP entails a number of problems:

- flooding of the area due to poor drainage of rainwater/melted snow (gradual waterlogging);

- the formation of plugs of debris, silt, sand or simply water in some areas of the sewerage system;

- pushing out pipes when the soil swells;

- the need to clean or repair pipes draining water from the site;

- rupture of drains due to freezing of pipes or trays at low temperatures;

- high risk of dismantling the entire system and the need to install a new one.

You should study SP 2.04.03-85 or its updated version SP 32.13330.2012 in advance, preferably before drawing up the storm sewer design scheme.

Types of system and gutter

Storm drains are classified in various ways; They are usually distinguished by throughput, which is determined by the dimensions of the pipes and gutters (their diameter). According to this criterion, drainage systems are divided into two types:

- Small . Installed on small and medium-sized houses. The size and configuration of the roof of such dwellings allows the installation of pipes with a diameter of 90 mm and gutters with a diameter of 125 mm, which is quite sufficient for the needs of the building.

- Big . If the house (and, therefore, the roof) has a large area, choose a design with increased dimensions: a pipe of 100 mm, a gutter of 150 mm. Experts recommend such a system for small houses if the roof has a complex shape or the house is located in an area with high levels of annual precipitation.

Copper gutter and snow guards Source factum.ru

Occupancy level

Sometimes standards require additional calculations, namely, determining the fill level coefficient. Calculation is required if the following materials are used:

- Plastic;

- Asbestos cement;

- Cast iron.

The fill level lets you know how fast the water should move to avoid possible clogging of the system. The fullness is calculated using the following formula:

Y=H/D

- H – water level;

- D – pipe diameter.

SNiP regulates two main pipe fill numbers - maximum and minimum. According to the documentation, Y=0.3 when it comes to the minimum indicator , and Y=1 when the structure is filled to the maximum . The last number indicates that there is no slope.

As for practical calculations, the pipe fill value usually lies in the range from 0.3 to 0.6. Often they take a value of 0.5 or 0.6, considering this number to be optimal.

The material of the pipe can affect how quickly it fills. For example, when using cast iron or asbestos-cement material for a structure, the filling of this structure will occur quite quickly, since the walls of the pipe will be rough.

An example of calculating the fill level of a pipe

The use of all the above formulas indicates the use of a hydraulic method for calculating the slope of pipes.

To make it clearer how to determine this coefficient, it is worth considering a clear example. Let’s assume that the initial data contains pipes with a diameter of 110 mm and a water rise height of H=60 mm. The coefficient calculation will look like this:

60/110=0.55. This number will be the desired Y .

Next, you should check the ratio of the calculated coefficient to the optimal water flow rate. The result should be within:

К≤V√Y

- K – coefficient of filling level. The optimal indicator, as already mentioned, is considered to be 0.5 for plastic pipes and 0.6 for other materials;

- V – flow velocity;

- √Y is the root of the previously determined indicator.

Based on the calculation results, it was determined that the found coefficient passed the test.

Designing the slope of a gutter

The parameters of the drainage structure are calculated at the roof design stage, based on its area. There are special formulas that allow you to determine the cross-section (diameter) of a drain based on the area of the roof sector from which water will be collected into a given drain. There are also special tables with ready-made ratios, which in most cases is much more convenient. They contain precise calculations that allow you to select the appropriate standard of pipes and gutters, as well as the number of drainage funnels per roof sector.

Different building layouts and roof configurations make different stormwater systems possible. At the same time, there are optimal installation schemes and practice-tested methods for installing gutters. Installation of the drainage system is carried out based on the following principles:

- For effective water drainage, the shape and design of the drain are selected in advance . During installation, you will need not only straight, but also corner drain elements connecting parts of the system on adjacent walls; You can't do without end caps.

Slope calculation Source blues-dev.ru

Important features of laying sewer pipes

- When installing a pipeline system in deep basements or in places with low relief, versions with an extremely low sewer installation depth are provided, in which the installation of a pumping station is provided. The depth of the pressure line must be calculated according to the requirements of regulatory documents.

- Practice has shown that in problem soils (water-saturated, compacted to strong and silty) communications should be laid to a depth of four meters, in dry soils the depth is determined from four to seven meters.

- Communications built with a depth of less than 0.7 meters must necessarily have a sewerage protection zone on the surface of the earth. The security zone is equipped with a system to protect against possible mechanical damage to the pipeline.

- When carrying out projects for laying sewer communications, it is mandatory to take into account the difference in terrain relief lines.

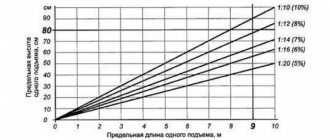

Optimal tilt angle

The movement of water can occur already at an angle of inclination of 1° - this is 1 mm of vertical displacement of one of the edges of the gutter relative to the opposite side, taking into account the length of the gutter of 1 m. But for a drainage system, this parameter is critical, especially when there is a rainstorm. No one forbids using this indicator in the process of designing or installing a drain, but in this case the horizontal part of the drain cannot cope with a large flow of liquid.

There are recommended standards:

- the minimum slope of the gutters of the drainage system is 3 mm;

- maximum – 5 mm.

The slope is also increased if the drain is a prefabricated structure: the system has a complex structure consisting of separate sections joined together. Typically, such gutters are installed on multi-level roof structures.

Preparing the base on the ground

The two main problems that you will have to deal with in a structure located on the ground are as follows:

- reverse capillary movement of moisture from the ground to the screed;

- intense loss of heat, which simply goes into the ground.

When pouring the floor in a bathhouse with a slope, if construction is carried out on the ground, several features must be taken into account:

- you will have to make a massive pillow that will stop the rise of moisture;

- the cushion should act as a damper if the soil in the construction area freezes;

- The rough screed is made with increased thermal protection.

The problem of creating a reliable foundation for a floor covering in a building on the ground is solved as follows:

- the depth of the bottom point of the pillow should be 500-600 mm from the ground level;

- A layer of construction waste, stone fragments, large fractions of gravel, and concrete fragments is poured as a damper. Recommended zone thickness – up to 400 mm;

- A two-layer pillow acts as a neutralizer for the reverse movement of condensate. It consists of zones of backfilling fine gravel with a thickness of 100 mm, and 50 mm of sand. Each layer after filling is leveled, wetted, and compacted with a vibrating machine;

- After the layers of sand and gravel have dried, you can lay the rough support screed.

The main signs by which you can determine the need for drainage work

Clear signs of the need for drainage Source otoplenie-help.ru

You cannot do without drainage on the site if:

- Water-loving plants predominate in the garden and vegetable garden, sow thistle has appeared, the ground is soft and wet all year round, trees grow poorly, some die, moss has appeared on the soil and trees in the garden. All these are signs of excessive soil moisture - drainage is required.

- High humidity in the basement or basement, condensation on the basement walls, the appearance of microcracks in the basement of the building, distortions in door and window openings, a feeling of dampness and mold in the room. The building needs to be saved - without drainage work, the foundation and the house will be destroyed.

- Even after light precipitation, puddles remain for a long time, blind areas crack and move away from the base, sidewalks and road surfaces sag - at a minimum, drainage of surface water is necessary.

Significant advantages of arranging a drainage systemSource vse-o-kanalizacii.ru

Basic work on creating a floor

Work on creating a floor in a bathhouse must be carried out carefully, with attention to all details. It should be remembered that in the steam room and washing room there is always a lot of water, and there are sudden changes in temperature. Therefore, a clear knowledge of how to fill the floors in a bathhouse under a drain, with or without a slope, under ceramics or plank flooring will help to do the job so that the coating lasts a long time and does not cause trouble.

Therefore, a clear knowledge of how to fill the floors in a bathhouse under a drain, with or without a slope, under ceramics or plank flooring will help to do the job so that the coating lasts a long time and does not cause trouble.

- At the first stage, the surface of the rough supporting screed of the bathhouse is carefully waterproofed using a coating method. You can use both bitumen mastic and one-component polymers or special ready-made building mixtures.

- A special construction tape is glued around the perimeter of the room, which is separately coated with a waterproofing agent.

- The second stage is laying roll materials under the floor screed in the bathhouse. Ruberoid and glassine are effective, inexpensive, but have a limited service life. You can use a thick polymer film. Excellent results are shown by bituminous materials based on fiberglass and fiberglass. The strips are overlapped by 10-15 cm. In the case of bituminous materials, the joint area is melted with a construction hairdryer. The polymer film is glued along the seam with wide tape. The waterproofing should extend onto the walls, about 10 cm.

- The third stage is laying insulation. The classic option for bath floors is felt. Basalt, mineral, and glass wool show good results.

- The fourth stage is the creation of a second layer of waterproofing under the floor screed. Rolled materials are laid on the insulation. To save money, it is allowed to use polymer film. If you have some money left over, you can lay a one-sided membrane that will remove moisture from the insulation. The rules for creating a coating are similar to those given above for the first layer of waterproofing.

- The penultimate stage is gluing the perimeter of the bathhouse rooms with damper tape to compensate for thermal expansion of the final screed.

Criterias of choice

The drainage system is selected based on two indicators:

- The material from which structural elements are made.

- Element sizes. This is mainly the width of the trays and the diameter of the pipes.

Plastic or metal?

Today, manufacturers offer drainage systems made either from steel sheet (galvanized and painted), or from copper, or from plastic.

Note that steel drainage systems have been used in the construction of drainage systems for a long time. And today this is one of the popular types. About it we can say that it is:

- increased strength of elements,

- their long-term operation,

- the ability to decorate in different colors by painting,

- low price,

- ease of installation.

Copper gutters belong to the premium class category. In all technical and operational characteristics, they are superior to both steel and plastic ones. They have an excellent appearance, but a very high price. This is why copper gutter systems are not as popular as the other two.

When it comes to plastic products, the first thing consumers pay attention to is the low price. But the main advantage of this material is its 100% corrosion resistance. In terms of their performance characteristics, these gutters are not much inferior to steel and copper ones.

For example, they have a smooth inner surface, which ensures quiet water flow. They are lightweight, making installation easy. But they also have one rather serious disadvantage. This is a rupture of plastic pipes in winter if an ice jam has created in them. Today, many manufacturers of plastic drainage systems offer models that can withstand any load. Therefore, you need to choose exactly these

In terms of their performance characteristics, these gutters are not much inferior to steel and copper ones. For example, they have a smooth inner surface, which ensures quiet water flow. They are lightweight, making installation easy. But they also have one rather serious disadvantage. This is a rupture of plastic pipes in winter if an ice jam has created in them. Today, many manufacturers of plastic drainage systems offer models that can withstand any load. Therefore, you need to choose exactly these.

How to calculate the size of gutters

The dimensions of the drainage system elements are calculated relative to the area of the roof slopes. Here is a table with some relationships regarding plastic and metal systems.

| Roof slope area, m² | Width of gutters (plastic-metal), m | Pipe diameter (plastic-metal), m | Number of drainage risers for one slope, pcs. |

| Up to 70 | 0,9/1 | 0,75/0,75 | 1 at the edge of the wall |

| 70-140 | 1,3/1,5 | 1/1 | 1 at the edge of the wall |

| Up to 110 | 0,9 | 0,75 | 1 in the center of the cornice |

| 110-200 | 1,3 | 1 | 1 in the center of the cornice |

| Up to 140 | 0,9/1,25 | 0,75/0,9 | 2 risers |

| 140-220 | 1,3/1,5 | 1/1 | 2 risers |

Even from this ratio it is clearly seen that plastic structures are smaller in size, but the volume of water they pass through is exactly the same as large metal systems. It turns out that even in this case, plastic gutters are preferable. But we must pay tribute to the manufacturers of metal drainage systems, who today offer products made of galvanized steel, coated on both sides with a polymer layer. This, first of all, increases their service life, and secondly, brings the technical characteristics closer to plastic analogues. But in terms of strength, metal ones are still better.

And another table comparing the advantages of plastic and metal gutters.

| Plastic gutters | Metal |

| Cheaper than metal | High strength characteristics, because it is made of galvanized sheet with a thickness of 0.6 mm |

| Less waste during installation | Variety of decorative designs |

| The degree of deformation is lower | Does not respond to temperature deformations |

| Resistant to scratches during installation | Blends perfectly with metal roofing materials |

| The same is true during operation. | Copes well with temperature changes |

| Small defects are not scary | Does not deform when exposed to sunlight |

| When deformed after the snow melts, it can be restored in shape and size | Has high load-bearing capacity |

| Installation is easier than metal | Not as fragile as plastic |

| Weight less | This is a non-flammable material |

| Neutral to biological and chemical stress | Service life 15-30 years |

| Sound insulation properties are better | |

| Does not corrode | |

| Service life 10 years |

These are the comparative characteristics that can be offered to make the right choice of drainage system. The main thing, as practice shows, is long-term operation and appearance, which should fit into the design of the house. Efficiency can only be discussed from the perspective of accurate sizing calculations.

Device

Internal drainage is a system that ensures the collection and removal of melt and rain from the roof surface through drainpipes into the storm drain. This design is equipped when the house has a flat or pitched roof. The internal type drainage system consists of the following elements:

- Water intake funnels. This term refers to devices that carry out the primary collection of liquid accumulating on the roof surface. The material and price of this element differs significantly: there are inexpensive models made of plastic or stainless steel and exclusive ones made of copper. If the roof has a flat surface with a slight slope, in accordance with the requirements of SNiP, a flat funnel for internal drainage is installed on it, and a bell-shaped funnel is installed on pitched roofs. The quantity and diameter of this element is determined by the calculation, which takes into account the area of the slope and the volume of precipitation. Specialized stores sell heated funnels with protective filters and flow stabilizers, however, the price for such models is much higher.

Note! To ensure high-quality operation of the internal drainage system, the flat roof is sloped, which is the name given to the process of creating the minimum slope necessary for water to flow into the funnels. Installation is carried out in such a way that they are located below roof level

Material

A wide range of materials for drainage trays makes it possible to choose a decent option for each specific case.

- Among the advantages of innovative plastic drainage trays, primarily their light weight, high resistance to aggressive environments, strength, and resistance to corrosion and rotting are noted. They are widely used in areas where excessive loads are not expected.

- Traditional concrete trays are characterized, along with their low price, by good frost resistance, low moisture absorption, and strength. But they have a high weight, making installation work difficult.

- Polymer concrete varieties with a service life of more than 50 years, unlike concrete, have low weight, smooth surfaces, ensuring high speed of water movement. They are designed for a maximum load (class C-250) of 1.5 - 25 tons.

- Reinforced concrete trays with increased resistance to destruction are characterized by long-term operation.

- Metal analogues are used quite rarely due to their higher cost compared to other similar products.

Regardless of what material the drainage tray is made of, galvanized steel, cast iron or copper with an anti-corrosion coating are most often used for gratings. Plastic is less common.

Methods for laying drains

There are two types of drainage systems - surface and deep. In the first option, drains are laid in small (30-40 cm) ditches. The second installation method is more expensive, since you have to dig deep trenches.

It all depends on the condition of the soil and the level of the foundation of the main building on the site. You need to find out to what depth the ground freezes in a given region. Every local construction organization probably has this information.

The pipeline must not be laid above the freezing level of the soil. Otherwise, the drainage system will freeze and fail in the winter. It is necessary to insulate the drains or bury them deeper into non-freezing soil.

Surface type of drainage system.

Excess moisture harms not only plants, but also buildings, including solid ones. During periods of spring floods, groundwater rises, washing away and destroying the foundations of even permanent buildings. To avoid such troubles, the drainage system should be laid half a meter deeper than the foundation.

Storm gutters.

Concreting the yard: site preparation, reinforcement, installation of beacons, preparation of mortar

How to concrete a yard with your own hands? Do I need to prepare the site? What should be the bedding?

What and in what proportions should you prepare your own concrete? We will try to answer these and some other questions.

Concrete platform in the courtyard of the cottage.

Goals

First, let's define our goals (