When using polyurethane foam, the first priority is to accurately understand the level of its consumption and output from one cylinder. If this ratio is determined incorrectly, you may experience overspending when purchasing material, or you may run out of material in the middle of work, resulting in reduced quality of installation. The consumption of polyurethane foam has many nuances and may primarily depend on the foam itself and external factors. Let's take a closer look at what to pay attention to when making calculations and how to avoid possible problems in your work.

What is the difference between one-component foam and two-component foam?

One or two components

The only difference is that in a can of single-component foam

these two elements are already in a mixed state, i.e. the reaction is already underway. After the ingredients leave the container under the influence of moisture and air, rapid polymerization of the substance begins.

Interesting materials:

Which thujas are the most beautiful? Which thujas are the most unpretentious? What are the roots of birch? What fertilizers should I use on acidic soils? What fertilizers are best for pelargoniums? What fertilizers are needed to sow a lawn? What fertilizers are needed for beets? What fertilizers should you use when planting strawberries in the fall? What fertilizers are recommended for planting potatoes? What fertilizers contain potassium and magnesium?

Consumption standards

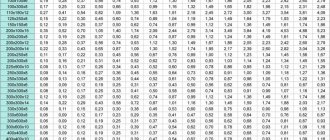

Correct calculation of how much polyurethane foam will occupy seriously affects the final estimate for a large volume of work. Indicators may vary significantly for different types of compositions. You can make the necessary calculations if you know the following basic indicators:

- total output volume - indicated in liters;

- fillability in the seam - indicated in linear meters indicating the depth and width of the seam.

For example, Sika Boom®-580 Fix & Fill has an output of 42 liters and can fill 33 linear meters of a 20x50 mm joint. Based on these data, further calculations of the required amount of material can be made. There are foams with increased expansion rates. One of them is Sika Boom®-590 High Yield. With almost the same capacity of the tube, the output is 53 liters, which is equal to 36 linear meters of a seam measuring 20x50 mm. If you understand and have data on the exact value of the characteristics of the working composition, you can make calculations in accordance with specific indicators of the width and depth of the joint. Experts recommend purchasing with a small margin, which is due to various unevenness of the base, technological losses, changes in foam properties as a result of external influences, different shelf life and a number of other factors.

How to properly use foamed polymer from a balloon

Before you start filling cracks with foam or making airtight connections, you need to thoroughly study the rules for using this material.

- Before installing the cylinder into the gun, put on gloves and a respirator (in particular, this applies to people who develop allergic reactions to spraying aerosol products).

- Before using the can directly, shake it for 30-60 seconds. The foam should mix well while still inside the container. If this procedure is omitted, then when you press the trigger of the gun, resin will come out of the nozzle.

- Wet the gap or any other area that will be filled with foam with water. Just do it lightly, not generously, for better fixation of the aerosol material.

- The next step is to turn the can over so that its bottom is facing up and slowly press the gun lever. Apply pressure evenly—the polymer should be well distributed over the desired area.

- If the gap is vertical, then fill it with material only from bottom to top and only to 1/3 of the depth. Since the material tends to expand, during the solidification process it will completely fill the entire gap.

Basically, the foam will be ready for cutting within thirty minutes after application, provided that the rules of use are followed. Also, immediately after removing the excess, the sealed areas can be plastered. Even if the composition is not completely dry inside, it will harden over time.

What to look for when purchasing

Of course, you won’t be able to evaluate the quality of the material right in the store, but there are several signs that will help you choose a truly high-quality product.

Such a quick visual inspection will tell you a lot about the product you are holding in your hands and will protect you from counterfeits.

Range of quality products

The Sika company offers its customers a range of polyurethane foam for winter, summer, universal professional or household use. We have been present on the market for more than 110 years, manufacturing products taking into account European quality standards. The foam is stable during expansion and has high performance properties. We invite you to familiarize yourself with the product catalog and consult with our specialists when choosing materials. We offer products to legal entities - construction companies and other organizations. We work with individuals through dealers on competitive terms.

Who produces it?

Our market is currently overcrowded with all kinds of polyurethane foam, but this does not mean that all the products offered are of high quality. A lot of polyurethane foam that does not meet certain requirements reaches the shelves of stores and especially markets: for example, when gases harmful to the ozone layer are used as a propellant. Or there are cases when manufacturers simply do not add polyurethane foam into the cylinders.

Unfortunately, many Russian traders (fortunately, not all) put the price first, and not the quality of the polyurethane foam they sell. And our consumers “help” them with this. After all, the average buyer has practically no idea what the foam should be like (how much of it should be in the cylinder, what quality.).

Added: 09/10/2017 21:37:23

Briefly about the manufacturers

The key to high quality material is the choice of a reliable and trusted manufacturer. It is no secret that the cost of a product can say a lot about its properties, because it is not possible to make a high-quality product from cheap ingredients. But the inflated cost is not always associated with the use of high-quality raw materials. Often, overly promoted brands spend a lot of money on advertising a product, which automatically increases its price, and you simply get brighter and more memorable packaging, and not higher technical characteristics than a less expensive product. Therefore, let’s consider proven brands with not inflated prices:

- "Macroflex" - has a high rate of adhesion and uniformity of structure. The foam yield stated on the packaging is true. However, recently a lot of fakes have appeared, which has led to numerous complaints about the deterioration of the quality of the product. The cost, depending on the type of foam, is 150-470 rubles.

- “Moment Montazh” - has a dense and uniform structure, is easy to paint, and is quite common in the network of hardware stores. It has a high rate of secondary expansion, and after a couple of years it may lose elasticity. The price is 145-245 rubles.

- Soudal is a very high-quality product with a fine-grained structure. Differs in the absence of shrinkage. Available in several versions - winter, summer and fire-resistant. Has a slight odor. But it is not sold everywhere. Cost – 195-395 rubles.

- “Penosil” has a good foam yield from the container, is distinguished by its bright white color and low coefficient of secondary expansion. Not intended for outdoor use. At temperatures above +35° it stops foaming. Price – 200-485 rub.

- “Titan” has a dense structure, no shrinkage and a low rate of secondary expansion. Used for thermal insulation of heating and water supply systems. The foam yield can be defined as average, not full. The price varies from 200 to 265 rubles.

Factors that affect drying time

The ability of the sealant to increase in size is the main advantage of polyurethane foam. You can read the yield of the composition in liters on the cylinder, but the expansion coefficient and hardening time will be influenced by the following factors:

- Ambient humidity level. Polymerization of the installation composition will occur when exposed to atmospheric moisture. If it is dry and hot outside or in the room, then the air humidity will be minimal. In this case, the foam will not expand to its full volume. A sealed layer with a thickness of 50 mm under such conditions will harden after 3 hours, and complete hardening occurs after 7-12 hours. How long does it take for polyurethane foam to dry outdoors? With normal humidity in or outside the apartment, this will take 20-30 minutes, after 4 hours hardening will occur, and after 12 hours the composition will fully polymerize.

- Temperature conditions. Manufacturers produce frost-resistant sealants that can easily maintain temperatures as low as -50 degrees. But it is recommended to blow foam when the thermometer reading is within +5...+25 degrees. If this requirement is not met, the sealant will lose its qualities. The higher the temperature inside the room, the sooner the liquid foam will dry out. It is best to apply the product at average temperatures (+10...+15 degrees), so that a lot of atmospheric moisture is involved in polymerization.

- The quality of the can - polyurethane installation will be packaged in sealed cans. They will contain expelling gas under enormous pressure. The highest quality tubes are equipped with reliable blocking valves that are able to return to their original position without allowing air into the can and without releasing gas. You can compare a pair of cylinders with the same volume - the one that weighs more is better in quality. The contents will begin to slowly roll around the tube, but will not dangle inside.

- Layer thickness - if sealing foam with a thickness of 50 mm is applied to the surface under ideal temperature and humidity conditions, it will dry within 3 hours, and then the excess product can be cut off. Complete polymerization will occur after 12 or more hours. In order for the thick layer of polyurethane foam to dry out completely, experts recommend waiting a day, and then removing the excess mass and protecting it from moisture and ultraviolet rays. High quality polyurethane has a dense structure with perfectly spaced pores.

The drying speed will be fully influenced by the characteristics of the surface. If it has noticeable flaws, unevenness, or changes in altitude, much more money will be spent, and the result will be a layer that differs in thickness. This can “push back” the time for 100% drying of the composition.

Performance

The properties of polyurethane foam after application are described as follows:

- When applied, MP adheres to the surface without flowing off vertical areas.

- Some time after application (about a day), it increases in volume, fills voids, and hardens upon contact with air.

- Air and surface humidity are important for hardening (polymerization). To speed up the hardening process, installers moisten the surface and spray the MP itself.

- After hardening, it turns into a hard, light and at the same time elastic mass. Color – cream (almost white), light yellow.

- After drying, MP does not shrink significantly and does not crumble in the cold.

Destruction of the structure under the influence of ultraviolet Source zhk-akvapolis.rf

- The material does not conduct electricity and is a good sound and heat insulator.

- When the outer side of the foam hardens (usually it takes several hours), the fragments protruding beyond the plane are cut off, and the surface is painted, puttied with acrylic sealant, covered with special adhesive tape or plastered. Foam is sensitive to ultraviolet radiation and without protection begins to turn yellow, lose elasticity and collapse.

How to reduce the yield of polyurethane foam?

If you do not intend to reduce the consumption of building materials, use the advice of professionals:

- The building material must not be touched until it is completely dry. Only after complete polymerization can it be trimmed and other manipulations carried out;

- Before starting work, be sure to check the information on using the cylinder in the instructions. The shelf life, volume, integrity of the cylinder, and conditions of use are taken into account;

- The optimal operating temperatures of the cylinder are from +10 to +30 degrees. Don't forget about storage rules. The cylinders are kept upside down without freezing or heating;

- it is recommended to work on a damp surface, but without water;

- The time for complete hardening of the foam is 24 hours, but the period may vary due to the characteristics of the manufacturer. After polymerization, the foam is covered with paint or plaster.

Polyurethane foam: technical features and application

The technical features of foams mainly determine the quality of the material and its scope of use. Let's consider several basic criteria:

- Foam expansion volume. This is actually the filling feature of foams. The foam hardening time and consumption depend on the indicator. For professional brands, the expansion rate reaches 300%. This is significantly more than that of household foams.

- Foam viscosity Determines the contact of foam with the surface. The better the indicator, the less the material will slide. The foam setting rate also depends.

- Foam bottle volume. Consider the scale of the work before purchasing a cylinder. On the market you can find foam from 300 ml to 100 liters, which is enough to carry out large-scale construction projects.

Polyurethane foam is a universal substance that is used in the fields of construction and repair. It is suitable for solving roofing problems, insulation, filling cracks, sealing doors and windows, pipes, and sound insulation. With its help you can not only fill cracks, but also level surfaces.