When getting acquainted with materials about floor construction, many visitors to construction sites for the first time encounter the recommendation to reinforce the screed. The editors of the StroyGuru website decided to clarify this issue and introduce home craftsmen to types of reinforcement, materials for its implementation, features of the process, as well as cases when reinforcement is required.

First, let us briefly recall what a screed is and what functions it performs. This will allow you to understand the meaning of reinforcement.

What is a screed

A screed, in simple words, is a layer between the ceiling (subfloor) and the external final finish (floor). At the same time, its structure must be monolithic so that the floor covering does not sag or deform. You can obtain a monolith using the DSP. However, concrete is brittle under high bending loads. To ensure that the screed does not crack or crumble over time, reinforcement is used.

What is reinforcement

Reinforcement refers to a method of increasing the strength characteristics of a product by introducing high-strength materials into the structure. Two types of reinforcement are used for screeds:

- using mesh reinforcement, which is filled with mortar;

- dispersive - fiber made of metal, propylene, glass or basalt fibers is mixed in the CPR.

The latter type of reinforcement successfully replaces the traditional one, and in some cases surpasses it. Difficulties arise only when introducing fiber into the composition of a dry mixture - it is time-consuming and labor-intensive. You can't do it with your hands. Small mechanization is needed. For those who are interested in the method, we recommend watching the work “Floor screed with fiberglass.”

Functions of screed reinforcement

Reinforcing the screed with mesh allows you to:

- increase the strength of concrete;

- increase the service life of the leveling layer, and with it the floor covering;

- Preserve the surface of the screed from cracking as the concrete gains strength;

- prevent deflections and subsidence of the floor base, as well as the appearance of bulges;

- protect concrete from the expansion of cracks that appear during the operation of the floor;

- reduce shrinkage.

Types of reinforcing products

To reinforce a concrete floor or cement-sand screed, several types of mesh are used:

- metal (it in turn is divided into reinforcement, wire and welded);

- polymer;

- fiberglass product.

In addition to them, fiber can be used to reinforce screeds. This material consists of microscopic fibers of glass, polypropylene, metal and basalt. But since our article is about grids, we will not consider it in detail.

Popular manufacturers

Mesh for screed reinforcement is produced at many enterprises. The most popular among them:

Armplast produces fiberglass reinforcement for heated floors. The light weight of the mesh and the size of the cells allow it to be used for plastering work. Product advantages:

- does not corrode in the alkaline environment of the CPR;

- long service life;

- high strength - twice as strong as steel reinforcement of the same diameter;

- has almost the same coefficient of expansion as concrete;

- does not conduct electric current.

Tenax specializes in the production of polypropylene fittings. The product is characterized by increased strength and flexibility. It does not deform when the screed shrinks, has high resistance to aggressive chemicals, and is easy to cut. According to experts, plastic mesh is the best option for a 7-8 cm thick screed when installing electric or water floor heating systems.

"Gridex". The company supplies construction organizations and retail chains with basalt reinforcing materials. Product Features:

- impregnated with acrylate - improves adhesion to the central fiber board;

- standard cell size 25 x 25 mm;

- ideal for various “warm floor” systems;

- not afraid of the alkaline environment of concrete;

- does not conduct heat, unlike metal.

"LenStroyDetal". The company welds metal mesh for the screed (mesh size 100x100 mm) from galvanized rods with a diameter of 4 mm. Galvanizing steel significantly increases the service life of the metal inside the alkaline environment of concrete, and with it the screed.

Reinforcing elements: what strengthens the screed?

The following materials can be used to reinforce the screed:

- metal mesh (including road mesh, originally intended to strengthen the road surface);

- polymer mesh - made of plastic;

- fiberglass mesh;

- fiber – microfibers made of polypropylene, glass, basalt, metal (steel).

The most durable and reliable reinforcement is performed using metal mesh, which distributes the loads in screed structures and protects them from damage during bending. Metal mesh is capable of maintaining the shape of thick screeds subjected to significant loads - in workshops, warehouses, shopping centers, offices. In individual construction, reinforcement with metal mesh is a guarantee of trouble-free operation of the screed for many decades.

Polymer and fiberglass meshes are weaker in tensile strength than metal ones, so they are used for screeds subject to light loads. As a rule, these are floors in apartments and private houses.

To strengthen screeds, fiber is also used - bulk fibers from various materials that are mixed into the composition of the solution. The use of fiber reduces the risk of shrinkage microcracks, makes the screed monolithic and increases its impact strength. But fiber is not able to replace “power” reinforcement with mesh. In other words, a fiber screed will be able to dry perfectly without cracks or shrinkage, but will not be able to resist large tensile and bending stresses.

Let's look at each type of reinforcing elements in more detail.

Option #1 - metal mesh

Special metal mesh for reinforcement is made from VR-1 steel wire connected by spot welding. The diameter of the wire used is 2.5-6 mm.

The wire in the reinforcing mesh forms square or rectangular cells of different sizes - from 50 mm to 200 mm. The smaller the cells, the more metal used in the mesh, and accordingly, the higher the strength of the reinforcement. The most popular meshes are made from wire with a diameter of 3 mm, with square cells with sides of 100 mm, 150 mm, 200 mm.

Nets are supplied in rolls or cards (sheets). Rolls are easier to transport, but only a mesh of thin wire no more than 2-3 mm thick can be “twisted” in this way. The standard width of such rolls is 1-1.5 m, the length reaches 25 m. The main part of the reinforcing mesh is produced in cards with dimensions of 0.5x2 m, 1x2 m, 2x3 m, 2x4 m, etc.

The main advantages of metal mesh for reinforcement:

- high tensile strength, which is transferred to the screed during reinforcement;

- resistance to temperature changes, heating, freezing;

- binding ability, which allows the screed to maintain its shape even under high loads;

- unlimited service life.

The main purpose of the metal mesh is to distribute the load throughout the screed, increase its strength and thereby reduce the risk of subsidence, cracks, potholes and any other deformations. The mesh wire rods absorb tensile stresses and protect the floor structure from damage during bending and tension. Accordingly, the load-bearing capacity of the screed increases.

When reinforcing, the mesh is placed inside the screed - in the lower third of its thickness. In this case, the mesh must be raised above the subfloor in order to “work” in the body of the screed, and not outside it. You can raise the mesh above the base by installing it on special plastic stands of the required height (pieces of drywall or other similar material are also used).

To lay a screed reinforced with metal mesh, do the following:

- Clean the floor surface from debris, loose pieces of concrete, and dust.

- All detected cracks and cracks are filled with mortar or putty.

- Prime the surface.

- If necessary, hydro-, heat- or sound-insulating material is laid on the primed base.

- Determine the height of the screed. To do this, using a hydraulic level or laser level, marks are made along the walls of the room (at the same height). When connecting all the resulting points, an absolutely flat line relative to the horizon is obtained. From this line, measure the distance to the existing floor level - at several points. Where the distance is minimal is the highest point of the floor, from it you can “count” the desired thickness of the screed (here the thickness of the screed will be the thinnest). From the highest point upward, measure the thickness of the screed (minimum thickness 2.5 mm), mark this level on the wall. A new horizontal line is drawn along the found point - the surface of the future screed will pass along it.

- Install the mesh, laying its sheets overlapping by at least one cell.

- Guide beacons (metal profiles, slats, boards) are installed on the mesh, securing them to cement-sand mortar or using screws. Beacons are set strictly level, so that their upper part is flush with the surface of the future screed (along a line previously marked on the wall). The distance between the beacons is about 1 m, but not more than the length of the rule used to pull the tie.

- The solution is poured into the spaces between the beacons and leveled, pulling it out using the rule.

- After a few hours, when a supporting surface appears on the screed (marks will no longer form), remove the beacons and seal their recesses with fresh mortar.

- To avoid rapid drying of the solution and the formation of cracks, the surface of the screed is moistened with water for 5-7 days. On hot days, it is additionally recommended to cover the screed with plastic film or other moisture-retaining material.

Thus, the reinforcement procedure does not significantly complicate the screed creation technology. At the same time, it significantly increases its performance characteristics.

Option #2 - plastic mesh

When reinforcing unloaded screeds up to 80 mm thick, the metal mesh can be replaced with a polymer analogue - a mesh made of polypropylene (plastic).

Plastic mesh, unlike metal mesh, is lighter and more elastic. This allows it to stretch without deforming and retaining all its qualities. This property can be very useful when shrinking a building. The resulting shrinkage deformations will simply stretch the mesh and the screed will retain its integrity. In the same situation (with significant shrinkage), the metal mesh may “lead” and it will break the screed.

Most often, general construction plastic mesh – OSS – is used for reinforcement. It is supplied in rolls with dimensions: width – 1-4 m, length – 10-50 m. The weight of such a mesh is very small, thanks to which it can be easily transported and then mounted in a screed of any configuration. The simple cutting of polypropylene cells into pieces also helps reduce labor costs during reinforcement.

Plastic mesh is not subject to corrosion and is not affected by aggressive environments. The appearance of rust in the cement mortar and, as a consequence, the appearance of red spots on the surface of the screed are excluded.

Advantages of polymer mesh as a material for screed reinforcement:

- increased elasticity;

- exceptional tensile strength;

- chemical inertness (does not rust, does not interact with chemical media);

- the ability not to shield communications (plastic does not interfere with radios, televisions, telephones, walkie-talkies);

- high geometric stability;

- light weight;

- easy installation, which allows you to save on labor costs;

- low cost.

Reinforcement of the screed using plastic mesh is carried out according to the same scheme as with metal mesh.

Option #3 - fiberglass mesh

Another option for screed reinforcement involves the use of fiberglass mesh. These are meshes with square cells (usually 4-6 mm), made of aluminoborosilicate glass by openwork weaving.

Several brands of fiberglass mesh are produced, some of them are impregnated with alkali-resistant polymer dispersions to improve performance characteristics. You need to pay attention to this when purchasing. The SSP-95 and SSDor-330 (road mesh) grades are coated with impregnation, but their closest “relatives” SSM-85 and SSDor-300 are not. Alkali-resistant impregnations play an important role. The fact is that the cement screed mortar in which the mesh will be located has an alkaline reaction. Exposed fiberglass in an aggressive alkaline environment can be “eaten” (usually within 5 years). To prevent this from happening, the meshes are coated with a polymer composition that is neutral to alkali.

Fiberglass is very light and does not create unnecessary loads on the floor. Due to its light weight and the ability to roll into rolls, the material is easy to transport even by non-truck transport or carried manually.

In a screed, fiberglass performs the same functions as plastic mesh. That is, it prevents the occurrence of shrinkage cracks and local destruction, and increases the strength of the screed.

Advantages of fiberglass mesh:

- light weight;

- high tensile strength;

- resistance to temperature changes;

- resistance to aquatic environments;

- chemical neutrality (in case of using alkali-resistant impregnations);

- easy installation.

Installation of fiberglass mesh is carried out in the same way as when using other types of mesh.

How to use it correctly

The screed reinforcement technology step by step is as follows.

Step 1. Determine which mesh to use for floor screed: its type, thickness of wire or fiber, cell dimensions. We remind you that with heavy loads on the floor or screed on the ground, the thickness of the reinforcement should be greater and the cell size smaller.

Step 2. Choose quality fittings. The wire should not have areas damaged by corrosion, no oil stains, welding should firmly grip the rods together. The mesh made of propylene and composites should not contain cuts or damage to the protective layer.

Step 3. The base for pouring the screed is prepared: the surface of the ceiling is repaired, hydro- and thermal insulation work is carried out, and a damper tape is attached to the wall. Details of the process can be found in the article “Preparing the floor for pouring screed.”

Step 4. A reinforcing mesh is placed over the prepared surface. It must be laid in strictly parallel strips, overlapping, but not more than 15 cm. The mesh should not reach the entire perimeter of the wall. The gap is 3-4 cm.

Step 5. The laid mesh rises 1-2 cm - it should be placed in the lower third of the concrete. To hold the reinforcement in a suspended state, improvised materials can be used: pieces of brick, pipe cuttings or factory-made stands. The options are shown in the photo below.

Step 6. Using a level, the horizon of the laid mesh is checked. If necessary, adjustments are made.

Step 7. The solution is prepared and the screed is poured.

There is a nuance when reinforcing with polypropylene mesh. Here they carry out preparatory work, pour a small layer of mortar over the entire surface of the floor, after which they spread the mesh and press it into the screed. After gaining strength, the first layer is poured with a second, finishing layer.

Kinds

Floor screed mesh is sold in stores:

- steel with galvanization;

- plastic polypropylene;

- fiberglass (fiberglass);

- basalt.

In the first and second cases, meshes for floor reinforcement are made of steel or polypropylene. And the last two options are composite materials based on glass or basalt, which are supplemented with a binder plastic.

Reinforcing screed makes the floor stronger and more durable

Steel

Steel mesh should only be galvanized, otherwise its service life in the screed will be short. The main advantage of the metal version is fire resistance. All other analogues consist entirely or partially of plastics and are susceptible to high temperatures. If there is a fire on the floor, only the steel in the concrete will retain its properties.

Despite all its strength and reliability, steel reinforcing mesh is susceptible to corrosion. Even after galvanizing, it begins to rust over time. If the screed is done on the floor in a bathroom, bathhouse, shower or near a swimming pool, then it is better to choose a different material.

Advantages of steel mesh for reinforcement

Polypropylene mesh for screed

The polypropylene screed mesh is resistant to moisture and alkalis, which are characteristic of concrete mortar. It is slightly inferior in strength to steel, but weighs 6–7 times less. If the floor has to be reinforced in an old house with wooden floors, then this point is extremely important. Plus it has much better tensile strength.

Polypropylene mesh options

Another advantage of this plastic mesh is elasticity. With strong pressure from above on the screed, it stretches without breaking, and then returns to its original state. Steel and fiberglass with similar loads on the floor often simply break at the junction of the rods with each other.

Advantages of using plastic mesh

Fiberglass

Fiberglass (fiberglass) is contraindicated in high temperatures and alkalis. But it is not afraid of water and is cheap. And to withstand alkaline effects, meshes made from this material are coated with polymers during manufacturing. Without such protection, fiberglass is “eaten up” in a concrete screed within literally five years. And with it, the leveling layer of the floor lasts for 40–50 years without any problems.

Fiberglass mesh

Fiberglass is lightweight and easy to install. In terms of strength, fiberglass reinforcement is not inferior to other options. But, like all non-metallic analogues, fiberglass is superior to steel in thermal conductivity by almost two orders of magnitude. If the floor is poured onto the ground, then preference should be given to fiberglass reinforcing mesh.

Basalt

The basalt version is similar in characteristics to fiberglass. Only here in production a different supporting material is used - basalt fiber. This mesh has a bronze tint, is resistant to corrosion and can easily withstand the effects of alkalis.

Application of basalt mesh

In addition to the lack of susceptibility to rust, basalt, fiberglass and polypropylene reinforcement of floor screeds do not conduct electricity and do not shield communication signals. In this regard, it greatly outperforms its steel counterpart.

Advantages of using basalt mesh

In some cases you can’t do without a mesh

Reinforcing screeds is a somewhat labor-intensive and financially expensive process. It is better to fill the screed without a mesh. But there are situations when it is impossible to obtain a concrete layer leveling the base with a long service life - it will crumble a few years after the installation of the floor.

Among them:

- flooring on the ground (garage, private house). In this case, layers of crushed stone, gravel or expanded clay, which are not stable, are poured under the screed. Any slight movement of the soil under the influence of frost, water and other natural factors will inevitably lead to the destruction of the floor pie;

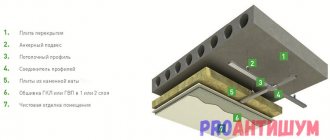

- absence of direct contact of the screed solution with the concrete base, i.e. a so-called floating screed is made - a waterproofing film (bitumen), a layer of insulation or noise-proofing material is laid between it and the ceiling;

- pouring a rough screed;

- the thickness of the poured layer of mortar is more than 5 cm. It takes a long time to dry, as a result of which a network of small cracks appears on the surface. The reinforcing mesh for the screed prevents their further growth;

- “warm floor” device - under sudden temperature changes, concrete is constantly in motion: it either expands or returns to its original linear dimensions. And these are more and more cracks;

- Excessive load on the floor is planned: oak furniture, stove, fireplace.

Attention: when pouring a 3-4 cm thick screed onto a reinforced concrete floor, no tensile loads leading to deformation occur in the leveling layer. Therefore, reinforcement is not performed in such cases.

Purpose of the reinforcing mesh inside the screed

Appendix B of the building standard SP29.13330 , which is the main document for both professional and individual developers, provides terms for floor structures:

Paragraph No. 8 of the same regulatory document outlines the requirements for screeds:

There are several technologies for manufacturing the structure layer in question, therefore:

Mesh inside the wet screed.

Important! According to the SP 29.13330 standard, screeds as part of the floor structure are not reinforced with either wire mesh or fiber. However, developers, including professional ones, often do not comply with the given terminology; they call the rigid underlying layer, which in some cases is reinforced, using screeds.

The main requirements for a rigid underlying layer are:

Scheme of insulated floor screed on floor slabs.

Important! In practice, semi-dry screeds are usually reinforced with fiber or BP wire mesh for reinforced concrete products with a mesh of 20 x 20 cm or masonry mesh made of 4 mm wire with a mesh of 5 x 5 cm. Wet screeds over elastic materials (rigid mineral slab, EPS) are reinforced only with meshes the last two types.

At the same time, designers either rely on the design manuals of Soviet times, or explain the expediency of overspending on the construction budget by the absence of shrinkage of the structural material and the opening of cracks.

Reinforcing the screed is a simple way to make the floor last forever

The main purpose of reinforcement is to increase the strength of the structure, as well as improve the load-bearing capacity. Thanks to this, deep cracks will not appear on the floor surface, and bending loads will also be reduced. An increase in the strength characteristics of the screed is achieved by introducing reinforcing materials into the structure that have high strength indicators.

To screed the floor covering, two types of reinforcement are used:

The procedure for reinforcing the screed is not always mandatory, but on most construction sites, building codes require the laying of a reinforcing layer. With this procedure, the floor will be more monolithic, and the likelihood of cracking will be significantly reduced.

There are small cracks on any concrete surface. If you do not see them, then wet the surface a little - the cracks will become clearly visible. Such defects are not critical. The most important thing is that the entire concrete structure is single and monolithic, and not assembled from separate fragments. It is the reinforcement that ensures the integrity and solidity of the entire structure.

The mesh for pouring the floor with concrete is laid over the entire area, and after filling with mortar it turns the entire top layer into a durable slab. Under the influence of external forces, small cracks will still appear, but the mesh will not allow individual fragments to move freely. If you install quality reinforcement materials, your floor will last forever.

Reinforcement of floor screed - when necessary

Reinforcing the concrete mixture with reinforcement is done to create a strong structure that is resistant to tension, compression or bending. For this technology, different working methods, materials and tools are used, based on operating conditions and the characteristics of the building. The finishing coating is laid after pouring the rough base.

This method performs the following function:

In residential premises, a similar measure is not used, since the slabs are covered with a 30-40 mm layer of mortar, which levels them. In this case, reinforced concrete floors account for a significant portion of all overloads.

Reinforced cement-sand screed is required for:

Important! The moving base must be reinforced, as it is prone to bending and stretching, compromising the integrity of the coating.

Reinforcement is more often used when installing rough and multi-layer structures, when pouring self-leveling floors and to reduce mortar consumption. In construction work, meshes made of metal, fiberglass, polymers, and fiberglass are used. When choosing an option, the requirements of design documentation and operating conditions are taken into account. Calculations are made according to GOST and SNiP.

Advantages, what is the difference from a conventional screed

A subfloor made without reinforcement and a reinforced one differ not in appearance, but in the presence of an additional layer in the form of a mesh made of different materials.

Screed reinforcement affects:

Additional Information! All requirements for the composition of solutions and stages of work are specified in regulatory documents (SNiP, VSN, MDS).

5 main advantages of floor reinforcement

The reinforcement procedure has many useful functions and advantages, but among all this diversity, builders highlight 5 main advantages:

The reinforcement procedure is simply necessary when the leveling layer is made on an unreliable base. Such bases include: mineral wool, wood, polystyrene foam and various stone backfills. The screed also needs to be strengthened in places with increased load. For example, in places where fireplaces, stoves, various machines and massive equipment are installed.

Experts' opinion

Experts recommend installing a mesh if the leveling layer will have several layers, or in the case of any unstable base.

The reinforcing material is placed at the very bottom in order to avoid the occurrence of tension as a result of exposure to deflecting external loads. As a result, deep cracks on the floor surface will be completely absent.

Very often, heated floors are installed in apartments and houses. In this case, the surface layer will be subject to regular temperature changes, which leads to cracking and loss of strength. For high-quality installation of heated floors in an apartment/cottage, it is also necessary to make a screed with additional reinforcing elements.

Strengthening the floor screed with mesh is required when the thickness of the leveling layer is too large or too small. If the thickness is large (from 10 centimeters and above), then it is necessary to lay reinforcement with sufficiently large cell sizes. A wire diameter of about 4-5 millimeters would be suitable. When the thickness of the leveling layer is less than 50 millimeters, a mesh with smaller cells is used.

Purpose of the grid

Is reinforcing mesh needed when pouring heated floors? Laying is not mandatory, but experts advise using it. After all, with its help, you can get a number of positive effects, such as:

- Increased strength and durability - it will protect the structure from deformation when the system heats up, and therefore from the formation of cracks.

- Uniform distribution of load across the base from furniture and finishing coating.

- Reducing cement consumption when preparing the mixture.

- Reducing the thickness of the screed, but this does not affect the strength properties of the device.

- Possibility of fixing heating elements to it.

- Increased system performance. Does not allow the heating cable or pipes through which the coolant circulates to lie close to the base. After all, cement mortar must penetrate into the space between them, this increases the heat transfer of the floor.

In addition, the use of a reinforced structure allows you to obtain the most even surface.

What types of materials are used to strengthen floors?

There are the following types of reinforcing elements that are used in the construction industry:

During the construction of industrial and residential buildings, in most cases, steel mesh is installed as a reinforcing material for the floor. It allows you to correctly form the load over the entire surface and avoid deformations under sufficiently large loads and bending forces. If you use steel mesh for reinforcement, you are guaranteed decades of reliable operation.

Features of floor mesh production

Floor mesh is produced at specialized enterprises from prepared VR-1 wire. This is a cold-drawn wire made of high-quality low-carbon steel. Depending on the geometric dimensions of the cells and the intended purpose, the wire diameter can vary from 2.5 to 6 millimeters. The wire is cut into individual rods and welded into a special mesh using spot welding.

The rods have special notches along their entire length, which are applied every 3 millimeters. They are necessary to provide stronger adhesion to the concrete mixture.

The cells have equal sides (square shape) with clearly fixed dimensions:

Products with thinner wire and small cell sizes are supplied from the manufacturer's factory in rolls. Products made from large thick wire are quite problematic to roll into rolls, so they are supplied in cards. Twisted rolls are much more convenient to transport.

What can replace the mesh?

When constructing a warm water or electric floor, the mesh is often replaced with special bosses, which can be separate or mounted on polystyrene insulation, and heating elements are attached to them.

If time permits, you can make a reinforcing product with your own hands from reinforcing bars or a metal profile. To do this, the rods are placed on top of each other to form a lattice and connected by spot welding or wire.

To strengthen the screed of heated floors of a small area, it is allowed to use panser mesh from beds.

To obtain a flat surface when constructing a heated floor structure, it is recommended to reinforce the concrete screed. Indeed, during the heating process, the surface may crack, and the presence of a mesh in the “pie” prevents this. In addition, this product makes the floor smoother and significantly increases its service life.

What kind of mesh for floor screed is needed to ensure that the floor lasts forever. 3 choices + styling technology

When laying floors during renovation or during the construction of a new building, leveling of the floors is always carried out at the final stage. As a result, the top layer becomes more neat and even. To give the surface strength, you need a floor screed mesh of various geometric sizes; it is used for high-quality reinforcement.

Reinforcing mesh for floor screed has many applications. But its main industry is construction.

Installing a reliable screed mesh can significantly increase the service life and make the floor almost eternal.

You should choose and purchase the screed mesh correctly. It must be of proper quality. If the material is chosen incorrectly, the floor will quickly begin to deteriorate, and you will have to repeat the floor leveling procedure. This is a waste of time and money.

In this article we will look at the main features of choosing a mesh, as well as the correct laying technology.

Reinforcement technology

Since there are no instructions in the SP standards as to whether the screed needs to be reinforced for a particular floor structure, wire mesh and polymer and steel fiber are usually used. When the layer thickness is 3–4 cm and in the absence of dividing horizontal cutoffs in the form of sound and heat insulation, reinforcement is not used.

Diameter and cell size

If, in order to prevent the opening of shrinkage cracks or the possible occurrence of tension zones in the structure, screed reinforcement is still included in the design, you should focus on the following values:

Wire mesh for screed.

In a floor screed on the ground, a reinforcing mesh with a square cell of 10 - 20 cm from reinforcement 5 - 18 mm is used, since the screed in this case is a slab. It is necessary to take into account that swelling of clay soils is possible even in the absence of negative temperatures when this rock is excessively saturated with moisture. Therefore, soil water should be drained using wall or ring drainage (if the groundwater level is high).

Location inside the screed

Since the screeds are not subject to heaving forces in principle, the mesh for reinforcement becomes necessary only in the lower part of the structure, according to the location of the tensile zone. In the presence of elastic layers of insulation and sound insulation, the possibility of sagging of these materials remains.

In this case, the screed becomes a slab with a much smaller supporting surface. The reinforcement from purely structural becomes functional, absorbs all operational loads from the weight of furniture and residents, and prevents the concrete layer from collapsing from tensile forces on the base of the structure.

The location of the reinforcement inside the screed.

Important! It is important to understand that the normal fine-porous structure of concrete in a factory or poured on site is achieved by vibration compaction. Screeds have a small thickness in comparison with the elements of foundations, lintels and slabs. Therefore, the use of a deep vibrator is impossible, and the beacons along which the mixture is leveled are shifted from the vibrating slats. Therefore, it is extremely important to provide care for concrete as it gains strength (moistening, covering).

Fiber and fiberglass reinforcement

Experts do not recommend using fiberglass rods to reinforce screeds. Unlike steel reinforcement, the tensile coefficient in this material is much higher. That is, when tensile loads occur, the fiberglass first stretches, and only then begins to resist the resulting forces. This can lead to cracks opening, despite the fact that the reinforcing layer is present in the structure.

Such problems do not arise with polymer and steel fibers, since the fibers of these materials are evenly distributed throughout the entire volume of the structure.

Thus, screeds of small thickness rigidly connected to the base without a separating layer do not need to be reinforced. Mesh or fiber are used when there is insulation or soundproofing material inside the screed, with a thickness of more than 5 cm.

Advice! If you need floor repair specialists, there is a very convenient service for selecting specialists from PROFI.RU. Just fill out the order details, the experts will respond and you can choose who to collaborate with. Each specialist in the system has a rating, reviews and examples of work, which will help with the choice. Looks like a mini tender. Placing an application is FREE and does not oblige you to anything. Works in almost all cities of Russia. Without your desire, no one will see your phone number and will not be able to call you until you yourself reveal your number to a specific specialist.

If you are a master, follow this link, register in the system and be able to accept orders.

Source

How to calculate the thickness of the screed?

In each individual case, the thickness of the finished screed is calculated individually. First of all, it depends on the quality of the base itself and its type. The thickness is also affected by the need to install underfloor heating. Builders have developed several basic rules for determining the thickness of the screed:

- The screed is at least 3 cm if the base is relatively flat and strong.

- If there is a heated floor system in the floor, the thickness is about 5 cm (for an electrical system). For a water heated floor, the thickness of the screed will be 7-10 cm.

- When planning to make an expanded clay or sand cushion, count on at least 5 cm of screed.

Sequence of flooring

In order for indoor floors to serve for a long time and reliably, you need to carefully perform each stage of work:

- Prepare the surface of any base properly - clean it from dirt and debris.

- If the base is an old concrete surface, you need to open up the cracks, clean them and fill them with liquid mortar.

- If provided for in the project, waterproofing and thermal insulation are installed.

- Using a water level, the floor level is marked on the walls of the room.

- Plastic clamps for the reinforcement are laid out, or pads are made from the solution for the mesh to ensure its position in the thickness of the concrete.

- A mesh is laid on the clamps with sheets overlapping by 1-2 cells.

- Next, beacons are installed - boards, slats or guides for factory-made plaster. The distance between the beacons should be 10-20 cm less than the length of the rule.

- Concrete or mortar is poured between the beacons.

- When the screed has set, the beacons, if they were bars or boards, are removed, and the holes are sealed with concrete or mortar.

To prevent the reinforced fresh screed from drying out unevenly in places, it needs to be watered for several days and covered with plastic wrap.