Finishing of the surface often ends with varnishing. This provides it with protection from mechanical stress, atmospheric disasters and resistance to water. Different substrates are treated with formulations based on various liquid resins. The choice of the desired one is dictated by the type of base being processed, taking into account whether it is painted, the CM on a water or non-aqueous basis, and the place of varnishing. Since many surfaces are coated with water-based paint, the question comes to mind: is it possible to varnish water-based paint?

Acrylic paint: does it need a varnish layer?

The acrylic-based coloring composition has a water-dispersion base. The main binder (polyacrylates, polymers of various compositions) is distributed in water, but does not mix with it and does not enter into a chemical reaction. In addition to acrylates, the composition includes a surface-active additive (plasticizer) and an antiseptic.

The plasticizer is responsible for the formation of a protective surface film. Thanks to this additive, the coating is resistant to wear, mechanical damage and moisture. Acrylic dye is environmentally friendly, dries quickly, and many people find that it creates an impenetrable layer once dry. This is only partly true.

Acrylic is characterized by thermoplasticity. This means that if the coating gets too hot (for example, under the sun's rays), it will reduce its strength, and it is quite easy to damage the softened layer. It has been repeatedly observed that if two acrylic coated surfaces come into contact, there is a possibility of them sticking together.

The varnish layer increases the attractiveness of the furniture Source archidea.com.ua

As the painted acrylic surface dries, water evaporates. The process proceeds quickly, and at the end of it micropores remain. If you apply a layer of varnish on top, it will harden, close the pores and increase the durability of the paint layer.

Varnish is applied to acrylic paint in many cases; for example, artists varnish paintings painted with acrylic. Finishing craftsmen try to varnish wooden surfaces; the same rule is used in furniture production.

Varnishing: arguments for and against

Despite the fact that acrylic paint itself forms a durable and flexible coating, the answer to the question of whether acrylic paint can be varnished is often answered in the affirmative. Varnishing provides the following additional advantages:

- The painted surface receives additional protection from abrasion and moisture.

- The varnish layer prevents contamination, preserving the original characteristics of acrylic.

- Thanks to the varnish, the gloss of the surface is evened out, the color becomes brighter and more saturated.

- The varnish layer protects the base from fading under the influence of solar ultraviolet radiation.

The varnish composition is convenient to apply with a brush Source proekt-sam.ru

- The varnished surface is easier to care for.

The following arguments are put forward against varnishing:

- Acrylic is a polymer and was not originally intended for varnishing. If the varnish is applied carelessly, it can cause the base to peel off over time.

- The varnish layer complicates restoration work, no matter whether it is a painting, a wall or furniture.

See also: Catalog of companies that specialize in paints and varnishes and related work

Advantages of varnishing

Using wall varnish provides many undeniable advantages. You can varnish both external, concrete or brick walls, and internal surfaces, thanks to this the following goals are achieved:

- moisture and water cannot penetrate deep into the building material from which the walls are constructed;

- the surface is reliably protected from exposure to sunlight and ultraviolet rays, so the material does not fade or lose its shade;

- the structure of the building material is strengthened, therefore its service life is extended and it deteriorates much more slowly;

- the base acquires protection from the influence of chemical detergents and other aggressive substances, as well as from physical and mechanical stress and damage;

- the walls become visually attractive.

To reliably protect walls and ceilings, it is necessary to choose the right varnish, taking into account various nuances.

What to choose from: varieties of varnishes

The external selection criterion is the type of surface, which can be matte, semi-matte or glossy. You can be guided by the complexity of the composition, and according to this criterion, varnishes are divided into one-component (with acrylic as a base) and two-component, with an epoxy, alkyd or polyurethane additive. The composition classification is as follows:

- Acrylic varnishes. Homogeneous, ready-to-use, water-based liquid, transparent or milky in color. Used to protect wooden surfaces and for decorative finishing.

Water-based varnish for furniture and walls Source domingo.su

- Oily. The composition includes natural and artificial resins dissolved in turpentine (turpentine). Oil varnish is ideal for wood that absorbs oil mixtures well. The main disadvantage is the long (sometimes up to several days) drying time.

- Alkyd. They are obtained by mixing synthetic resins in organic solvents. Suitable for treating surfaces indoors and outdoors. They are convenient because they can be applied with any tool: brush, roller, spray gun.

- Nitrovarnishes (nitrocellulose). This is a solution of chemical components in a mixture of volatile organic solvents. This leads to the main properties: fast drying, good adhesion, toxicity (respirator required). Before starting work, a paint compatibility test is carried out.

- Polyurethane. Wood options have a reputation for reliable, durable finishes, regardless of wood species. They protect well from all types of influences, mechanical and weather. The disadvantages of the polyurethane composition are the high cost, multiplied by the complex application technology.

Glossy alkyd varnish for furniture Source absolut-dostavka.ru

- Epoxy. Epoxy resin in an organic solvent creates a durable waterproof layer, therefore it is used for varnishing wood in damp rooms (for example, in a bathhouse). The epoxy varnish layer can withstand alkaline environments, but lacks aesthetics.

Decorative properties

Of course, matte or glossy varnishes based on polyurethane or acrylic are in greater consumer demand. But if you know all the nuances and technologies, you can add various solutions to the varnishes, which will make the partition more decorative and stylish.

If you use tinting technology, you can enhance the antique effect of an ordinary wall, or the naturalness of wood.

There are several types of varnishes that are used to decorate partitions or other surfaces:

- Craquelure solution, the main purpose is to apply it to plaster walls, as an imitation of cracks. Which will give the wall the appearance of aging. You need to apply at least 2 times to enhance the effect. It harmonizes perfectly with a certain type of interior.

- Mother-of-pearl mixture is mainly used as a finishing finish. Which will give the wall an unusual, shimmering and iridescent color. Can be applied to wood, wallpaper. Is safe for humans.

- Glitter varnish is also the final wall finish. Large range of gloss colors, sold separately. Add the required amount to the varnish, stir and apply. Get original wall decor.

- Matt lacquer. Not everyone loves everything shiny and prefers to keep their walls looking matte by adopting a classic wall decorating style.

Varnishing walls is a fashionable trend for interior decoration. There are many different varnish solutions available for sale in specialized stores. Where every buyer can make his choice. Decide on the finishing of walls or other surfaces.

The question often arises, how to properly coat a wooden, brick or concrete wall. You just need to adhere to the technology written in the instructions. And if you are afraid of ruining something, trust the professionals. Which will make the decoration of a wall or surface stylish and unique.

What is suitable for acrylic

If the question arises about what varnish can be used to coat water-based acrylic paint, it is important to understand that two types of varnish are used for acrylic-based paints:

- Based on mineral alcohol. A volatile composition that requires respiratory protection and high-quality ventilation when working with it.

- Water-based (polymer). The composition is used exclusively for acrylic paints. It is safe, easy to apply and can be removed with ammonia. Acrylic varnish is fully compatible with the same paints.

Varnishes also have other characteristics, so when choosing, you will have to decide the following questions:

- The composition will be used for outdoor or indoor work.

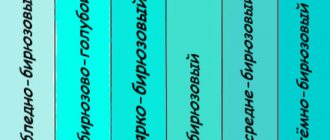

- What level of gloss is preferable? You can get a glossy, matte, satin surface.

Varnish compositions scatter light with different intensities Source semi-art.ru

- The varnish is permanently applied or you are considering removal.

- Liquid or spray form is best for you.

Which varnish composition is better to choose?

Acrylic varnish, which is fully compatible with the coloring composition, is more expensive than synthetic analogues. It is used if the appearance of the item has special significance, for example, a painting or a piece of furniture made for sale. If staying within your budget is important to you, you should stick with regular wood varnish. Before purchasing, you should study the label to find out the following points:

- Will the coating protect against moisture?

- Will the varnish layer be UV resistant and how quickly will it dry completely?

- The composition is permanent or removable.

- Is the varnish elastic or hard? Stretch film is suitable for flexible substrate (wood or canvas) that changes dimensions; it will not form cracks due to changes in temperature and humidity. Hard varnish is used if acrylic is applied to a hard wooden surface.

After drying, the varnish coating becomes transparent Source vitospb.ru

General information

The first thing that interests home craftsmen when they are faced with a similar task is whether it is possible to paint with paint over varnish? Of course, it is best to remove the old coating, but if this is not possible, or you need to save time, then you can paint over the old coating.

True, in order to say with confidence whether it is possible to apply paint to varnish, it is necessary to clarify what kind of paint and varnish material we are talking about. The fact is that not all compositions are suitable for these purposes. For example, you cannot use nitro paint, as the old coating will begin to peel off over time.

In addition, before applying the coloring composition, the surface still needs to be prepared in a certain way.

Silicone paint

Techniques for high-quality varnishing

The varnish is applied in two or three steps (with intermediate drying) in any convenient way: with a brush, sponge, spray gun. To ensure a high-quality result, you need to remember the following nuances:

- The surface coated with acrylic paint must dry completely. Depending on the thickness, the process can take from three days to two weeks (full strength gain takes 30 days).

- When choosing a varnish mixture, the quality of the surface is taken into account. Irregularities are more noticeable under the gloss, while the matte layer hides them.

- Pre-priming the surface will reduce varnish consumption. A water-based primer will do.

- Acrylic varnish is diluted only with water (preferably distilled), and water by volume should not exceed 10% of the composition itself.

The primer will help save varnish consumption Source gidpokraske.ru

Tips from a pro

If you don’t have confidence in your abilities and are afraid of ruining everything, then of course it’s better to trust a professional master. A person who knows everything about the properties of paints and varnishes and knows how to use them correctly.

If you have confidence, but little experience, let us allow ourselves some advice:

- If the surface is not painted, it should be primed before varnishing.

- Lightly sand the layers of varnish, except the last one, with fine-fiber sandpaper. This will give the surface additional shine and a mirror effect.

- You should choose a matte varnish. Firstly, acrylic paints have their own gloss. Secondly, the matte composition will be able to mask defects and errors, if any.

- You cannot dilute acrylic varnish with drying oil or solvent; if there is such a need, it is better to use clean water for this.

- Apply varnish only when the air humidity is at least 50%. If there is less humidity, the varnish will dry too quickly and crack.

- The surface to be varnished must always be degreased, for example with soapy water.

- To ensure uniform coverage, the varnish should be applied in several thin layers, if there are several of them.

Briefly about the main thing

Acrylic paint varnish is used in cases where they want to further protect the paint layer or give it a more presentable appearance. The best choice for this procedure would be a water-based varnish composition.

When purchasing, you need to pay attention to its qualities: ultraviolet resistance, elasticity, and removability. The varnish layer is applied to the acrylic after it has completely dried; If dilution is needed, use only water.

Ratings 0

Preparatory work

In order for the final work to be pleasing to the eye, before applying varnish it is necessary to carry out a number of actions related to preparing the surface for varnishing.

- Cleaning. Clean the surface from dirt and dust.

- Checking the surface for defects. If they are detected, the surface should be sanded and degreased.

- Varnish preparation. Before applying the varnish, it should be heated in a water bath for 5 minutes to a temperature of 50°C. When heating, the mixture must be constantly stirred.

Varnish application process

- If the product is not freshly painted, the paint has faded, then the surface should be painted again.

- Carry out all the preparatory work indicated above.

- Apply varnish only after the paint has completely dried and in good lighting.

- Varnishing should be done with a flute brush with a width of 50 to 150 mm.

- Polish with a dry brush. In a vertical position, apply with a dry brush until it sticks.

- Apply one layer, if necessary two layers of varnish.

It is important that no dust gets on the surface when varnishing. Heavy objects can only be placed after the varnish has completely dried.