Characteristics of epoxy grout

The material consists of the main components: epoxy resin and hardener. Based on this, the grout is called two-component. The mass also contains quartz sand and pigment. These are auxiliary components.

Resin and hardener - these substances are contained separately, because they immediately react, resulting in a material that has a limited period of use, because it dries quickly.

Two-component tile grout has a number of technical characteristics:

- increased strength;

- resistance to aggressive chemicals;

- the material is non-hygroscopic (does not absorb moisture);

- the surface of the coating is smooth;

- high wear resistance;

- there is no shrinkage when applied to the surface to be treated;

- cracks do not appear as the material dries;

- high adhesion;

- wide range of operating temperatures: -20…+100°С;

- a large number of flowers.

The listed properties appear only after combining the epoxy resin with the hardener. Separately, these substances are not used for grouting tiles. When epoxy resin and hardener are combined, a cross-linked polymer is formed. This results in excellent waterproofing and strength characteristics.

How to choose grout color

Two-component tile grout is available in a wide range of colors.

Most often, the compositions are sold already painted. If you couldn’t find the right shade, you can color the white grout by adding a combination of pigments to it. This can only be done during the process of mixing the composition. The color of putty that has already been applied cannot be changed.

Sometimes colored sand or shiny particles are added to the mixture.

Some buyers prefer shades that are as close as possible to the tone of the tiles, others prefer contrasting colors for zoning or adding variety to the decor.

Valera

The voice of the construction guru

Ask a Question

White grout is often chosen for light-colored tiles. However, this will not be the best solution for flooring, since as the coating is used, the seams may acquire a grayish tint.

To decorate a small room, you can choose a grout tone that corresponds to the lightest color in the tile pattern; for a spacious room , on the contrary, the darkest color. Sometimes the shade is chosen based on existing pieces of furniture.

Choosing the appropriate composition

First of all, you need to pay attention to the type of main components that the epoxy-based grout contains. The composition of such materials may include cement, various additives that increase elasticity and improve other properties. The cost of grouting will depend on this. Another factor is brand. Common options:

- Mapei Kerapoxy Design;

- Litokol Litochrom Starlike;

- Diamond.

The cost varies between 900-1100 rubles. per 1 kg of substance. The grout does not have to be updated regularly, since it does not lose its properties throughout its entire service life.

By comparison, the cement version quickly deteriorates. This substance loses strength, over time it begins to absorb moisture more strongly, and cracks form on the surface.

You also need to calculate the volume of grout required to finish the wall or floor. In this case, information from the manufacturer is taken into account. In most cases, the label indicates how much substance is consumed per 1 m². Based on this, you need to calculate the total amount of grout per area to be treated. If you immediately purchase the required amount of material, you can reduce the surface finishing time.

How to remove cloudy plaque?

Novice craftsmen are faced with the problem of how to clean off epoxy grout after completing installation work? For this purpose, special compounds have been developed that remove any type of darkening after the grout has dried.

For example, Litokol Gel is a concentrated substance that is pre-diluted in a container with water. For matte surfaces it does not need to be diluted in liquid. It is enough to apply a small amount of the composition on a foam sponge.

Foam is formed in the process. It must be quickly removed with a damp cloth. If you skip this moment, bubble marks will form on the surface of the tile. In the future, they are difficult to remove from the decorative plane.

Final cleaning involves using a soft cloth. Experts recommend choosing a cloth with a microfiber base. To give a glossy shine, use a special polish. However, it should be noted that after some time an oily film forms on the surface, which must be removed with detergents.

Note!

Mosaic for the bathroom: TOP-150 photos of new designs, as well as modern ideas for combining mosaic tiles

Do-it-yourself water heated floor under tiles step by step: installation instructions with photos and descriptions, installation and connection

Quartz vinyl floor tiles - what is it? Application features, advantages, disadvantages, choice, manufacturers, photos

Scope of application of the composition

Grout based on epoxy resin is suitable for protecting the seams of tile coverings made of different materials: ceramics, clinker, porcelain stoneware, glass products, natural and artificial stone. Considering that this composition hardens quickly, and working with mosaics requires more time, it is better to choose a different type of mixture to cover this type.

If you use a material based on epoxy resin, it will be more difficult to clean the mosaic. It is necessary to remove contaminants from each product. In this case, the grout hardens quickly. You may not have time to remove stains from a large area of the surface.

Epoxy grout for tile joints can be used in different rooms: in the kitchen, bathroom, attic, swimming pool and even on the balcony. This material can withstand significant loads, so it is used for finishing floors, walls, and steps.

The recommended width of seam joints, which can be filled with epoxy resin-based joints, varies from 1 to 15 mm.

The material should be used not only in private housing, but also for the purpose of finishing industrial, commercial, and administrative buildings. More often, such compositions are used at larger facilities with high traffic. This is due to the fact that the epoxy mixture has increased strength. This means that it is not advisable to use it for private houses due to the inconsistency of the parameters with the operating conditions.

The material is suitable for installation of heated floors. It can withstand high temperatures. In addition, there is a lack of destructive processes during the expansion of the material.

Application

It’s worth noting right away that you can start grouting joints with epoxy grout only after the adhesive solution has completely dried. The manufacturer indicates the time information on the packaging. This could be 24 hours or 3 days.

Preparation

First of all, you need to clean all the seams and the tile itself from excess glue and other construction debris. The surface of the cladding should also be wiped from dust. It is recommended to additionally protect light edges with masking (paper) tape.

Preparation of the working mass

Before you start working with epoxy tile grout, it is important to familiarize yourself with the proportions of the base and hardener. If in the case of cement compositions deviations from the recipe are acceptable, then this is excluded here. As a rule, the ingredients included in the kit have the optimal volume for complete mixing. If you need to use the compositions partially, then you should use scales.

Application

Since epoxy grout hardens quickly, it is better to grout tile joints with two people. One person applies the working mass with a rubber spatula and rubs it into the gaps, the second then removes excess from the facing surface. To do this, use a sponge soaked in water.

Erosion of the applied composition Source kraski-net.ru

Pros and cons of using epoxy grout

Positive traits:

- strength, under the influence of increased mechanical loads the layer does not deform;

- versatility: the mixture can be used to decorate coatings made of different materials outside and inside the object;

- working with epoxy grout is done without much effort, it does not require experience to prepare the mixture, you do not have to calculate the number of components, since they are already specified by the manufacturer;

- long-term operation;

- resistance to ultraviolet radiation;

- the material retains color throughout its entire service life;

- ensuring waterproofing of seam joints;

- large selection of shades;

- high adhesion;

- the coating is much easier to clean from contaminants during operation, this is due to the smooth surface of the epoxy layer and the absence of cracks;

- resistance to alkalis and acids, which allows the mixture to be applied in rooms where there is a high risk of contact with such substances (bathroom, kitchen).

Grout can be used for different purposes. It improves the appearance of the coating and gives it completeness; allows you to hide minor defects on the surface; protects against moisture; It is used in the same way as glue, which allows you to further strengthen the coating. However, there are also disadvantages to this type of material:

- the mixture instantly hardens, therefore it requires increased care and quick reaction, since it is necessary to immediately remove excess substance from the tile;

- special tools are prepared for the work and special chemicals are used;

- difficulty in cleaning, due to increased adhesion and strength of the material;

- high cost of the mixture.

What kind of grout will you use?

Epoxy Cement

Advantages of epoxy grout

Note that polymer grout is much more expensive than conventional cement grout. The second drawback is the difficulty of cleaning the hardened composition from the front side of the tile or mosaic. Otherwise, grout has the same advantages:

- Seams filled with grout do not absorb dirt and dust. Cured “epoxy” resembles plastic in its properties. Even if dirt sticks to the surface of the seams, it will not be difficult to wash it off. You can use any household chemicals, even strong ones, or clean the seams with a wire brush. The main thing is not to damage the tile itself. This quality is of great importance when cleaning mosaics - the number of seams in this type of coating is an order of magnitude greater than in conventional tiles.

- Epoxy grout for tiles and mosaics does not change color when water or chemicals come into contact with its surface. This material, in principle, does not react in any way upon contact with them and does not absorb any compounds. For this reason, epoxy self-leveling floors, which are similar in formula to grout, are used in the construction of various laboratories and chemical industry enterprises.

- After hardening, epoxy grout does not change its technical characteristics throughout its service life. If you happen to dismantle tiles whose seams were sealed with epoxy grout, you will see that it is as strong as the ceramic itself, and sometimes even surpasses it.

If this is your first time working with this kind of grout, we recommend that you start working with seams in a small area. For example, experiment in the bathroom. The high viscosity of the material makes it difficult to apply grout into voids, but it is worth it.

Colors

Epoxy material is available in a large number of shades, ranging from light to dark. A common option is to use glitter. If desired, you can purchase a metallized mixture. There are colorless polymer grouts. The choice is made taking into account the shade of the treated coating, the color scheme of the interior and its style.

Using this mixture you can make the surface of the floor/wall more neutral. In this case, use grout 1-2 shades darker/lighter.

To get the appearance of a solid coating, select a material of the same color as the tile.

Another common option is to use grout that contrasts with the base coat. In this case, caution must be exercised, since creating accents in a room where they already exist is not recommended. As a result, the interior design deteriorates.

Area of use

Due to its long service life and resistance to aggressive environments, the epoxy mixture can be used in rooms with high humidity and temperature changes. The paste can be used as an adhesive when covering surfaces with small fragments - mosaic, glass, metal. The composition is used for industrial and domestic purposes:

- Swimming pools, car washes, bathrooms, saunas.

- Industrial workshops, laboratories, canteens.

- Installation of kitchen countertops and splashbacks.

- External facing and finishing works.

- Sealing tile joints in the hallway and shower.

The use of grout for glass mosaics allows you to create beautiful decorative fragments in rooms. The tiled areas last for many years, giving the room an exclusive look. Manufacturers do not set restrictions on the use of mixtures - grouting pastes are used for cladding facades, terraces, bathhouses, and open street areas. The only condition is that it is not recommended to cover the seams when finishing stoves and fireplaces.

Required tools and materials

Prepare:

- electric drill, used to mix the material (used together with the nozzle);

- rubber spatula for applying the mixture;

- 2 containers for preparing material;

- a grater with a cellulose attachment is prepared when you plan to simultaneously grout a large area of tiles;

- sponge;

- rags;

- water.

In addition, a solvent is prepared. This is a necessary measure, because the grout dries quickly, and when processing a large area, stains will remain in some places. If you plan to make seams between the tiles with a recess, prepare a former. Instead of this tool, you can use a large cross-section wire.

Instructions for working with the composition

Before using the material, you must read the instructions very carefully. It is recommended to practice on an inconspicuous area, first diluting a small portion of the product.

You can also first work with ordinary cement grout - this will also allow you to gain certain skills. Prepare the epoxy mixture in small portions, working as quickly as possible, otherwise the composition will set in the container and deteriorate.

Materials and tools

To work with epoxy, you should definitely buy the following devices, consumables and tools:

- rubber spatula with a durable handle;

- cellulose sponge (can be replaced with foam rubber, but the latter soon fails);

- skipper (bucket with rollers for squeezing);

- a grater with a cellulose attachment for removing drips;

- latex gloves;

- Cleaning agent for tiles and glass.

To mix the grout, it is better to have a drill with a special mixer attachment. Mixing the mixture thoroughly by hand is much more difficult. To wipe the tiles, it is worth buying a cellulose sponge - it can easily handle up to 30 square meters. m of seams without losing appearance and properties.

Preparation of the solution

The two-component material requires preparation before application. Components A and B should be mixed strictly in the proportions indicated on the label. The ratio may vary between brands.

It is worth measuring no more than 300 g of the mixture, calculating the proportions and mixing. Weighing should be done on a kitchen scale - they are very accurate. If necessary, the color is added to the ready-made mass. We must remember that its vitality is no more than 30 - 60 minutes, so it is better to start working right away.

Rubbing seams

Before applying the tiles, the tiles must be dry, clean, and any remaining adhesive has been removed from the cracks. The crosses and leveling system are also removed. To reduce labor intensity, you can cover the edges of the tiles with paper tape. For mashing you will need a rubber spatula.

Operating procedure:

- apply the mixture with a spatula, carefully distribute it along the seams of the tile area;

- form joints, completely filling the seams;

- take a sponge, dip it in clean water, carefully wash out the seams (do not go all the way to the end of the seams, so as not to wet the unsanded area);

- after forming the seam, rinse the sponge again and wipe it clean (the grout will remain semi-liquid);

- After half an hour, when the joint has dried, you can spray it with water from a spray bottle and iron it again.

During work, large excess grout is removed immediately using a clean sponge or grater with a fiber attachment. After just 5 – 10 minutes it will be much more difficult to remove them.

Cleaning tiles

It is almost impossible to complete the job without deposits appearing on the tiles. You will have to clean it with special detergents (for example, Litonet for stains).

In order not to damage the formed seams, cleaning is done only after a day, not earlier. You will need a microfiber cloth or soft sponge. You need to wash off the plaque several times, periodically changing the water. Next, wipe the tiles dry. The contaminants will be completely washed off only during operation.

Possible mistakes

The most common mistake made by beginners is preparing grout without accurately measuring the proportions. You cannot prepare the material by eye; you must strictly follow the instructions. Otherwise, the mass will be spoiled.

Another possible mistake is leaving the grout on the tiles in the hope of removing it after the job is complete. The composition will have to be cleaned mechanically, because the material does not dissolve in water, and there is a high risk of damage to the tiles.

You should not work with epoxy mixture using conventional tools that were previously used for cement grout. You should purchase a special spatula and other tools, otherwise the application technique will become much more complicated.

Tips for use

When opening containers of substances, the epoxy resin may appear to be too thick and this will affect its application. However, during the process of combining this material with the hardener, the consistency gradually changes. The resin becomes less viscous. It is recommended to follow the instructions for connecting the grout components. This will allow you to obtain a material with excellent properties. It is necessary to work with gloves. As a result, contact of the grout with the skin can be avoided.

How to divorce?

Take a plastic container. The components must be combined in accordance with the proportions and manufacturer's recommendations. Thus, mixtures are produced in different quantities, which allows you to prepare the required volume of grout. As a result, the material will not dry out. The likelihood of this increases when a large amount of grout is prepared at once. It will not be possible to use it all, which will lead to increased costs for finishing work.

The grout hardens completely after 60 minutes. The mixture begins to set immediately after mixing the main components. For this reason, it is better to first prepare no more than 300 g of the substance. This amount can be used for a short period of time. The mixture is prepared using an electric drill with a special attachment.

It is important to operate it at no more than 300 rpm.

Moreover, the construction mixer should have as few blades as possible. The quality of the mixture will depend on this. If a nozzle with a large number of blades is used, and the drill speed is high, then the material will be oversaturated with oxygen. This will lead to a change in the color of the grout and will also cause heterogeneity in its structure.

How to apply?

Before use, transfer the solution to a clean container. This measure allows you to avoid damaging the structure of the material. During the mixing process near the walls of the container, the mass may be less actively saturated with the hardener. This leads to a decrease in strength and loss of the basic qualities of the mixture.

At the next stage, the process of grouting the seam joints begins, since the material immediately hardens. In this case, a harder rubber spatula is used. With its help, a sufficient amount of mixture is placed in the space between the tiles.

Movements should be directed perpendicular to the seam. Using a corner section of a spatula or a special shaper, create the desired surface shape. Remove excess grout immediately.

How to clean?

Litonet Litokol solvent is widely used. This is a special product for removing epoxy mixtures from the surface. Its main characteristic is alkaline pH. The substance can be applied to different types of tile coverings. This is a concentrated solvent and can be diluted to reduce consumption. This measure also allows you to reduce the degree of aggressive impact on the tiles. The product is universal.

There is also a gel-like version of this solvent, which allows you to reduce its consumption. The container is equipped with a spray bottle. This product is convenient to use for treating vertical surfaces, since it is characterized by increased viscosity.

The substance can be applied at temperatures within +5…+35°C. The duration of exposure to the surface is up to 15 minutes. A 1 liter container is enough to clean 10-15 m². Regardless of where you plan to do the work: in a garage, workshop or living space, it is important to ensure effective ventilation.

The substance is diluted in accordance with the manufacturer's instructions. The concentration of the solution depends on the degree of complexity of the tile contamination. The more time has passed since the grout was filled, the more difficult it will be to remove stains from the surface. After applying the solution, you need to wait 10-15 minutes, then remove the remaining substance and wipe the tiles.

When it is not possible to use a solvent, you need to prepare water. If you use a special sponge (with increased rigidity), you can remove fresh dirt immediately after grouting the seam joints. It is possible to simplify the cleaning process. To do this, cover the edges of the tiles with masking tape.

Application of Starlike EVO epoxy grouts and surface cleaning

The technology for using epoxy grouts is almost standard; working with the composition does not require specialized professional tools or special skills. Grouting is carried out in several stages.

Surface preparation - grout seams must be clean; if necessary, excess glue that appears must be carefully removed, and the surface must be dusted and wiped.

Preparation of the mixture - Starlike EVO two-component epoxy grouts are sold as a “kit”, including the main component (a mixture of epoxy resins, microspheres and organic additives) and an innovative organic catalyst (hardener). The fugue is prepared from two components by thoroughly mixing them (with a mixer attachment) immediately before use. Depending on the type of facing material, area of application and volume of product, either the entire mixture is mixed, or in parts, as it is produced.

Grouting joints - when using mosaic grout, the paste is applied to the entire surface using a large rubber (plastic) spatula and distributed evenly over the seams. When the facing material is of a larger format, the paste is placed directly into the seams, and the excess is immediately removed from the surface. Due to the fine-grained structure of the paste, additional smoothing of seams is not required.

Cleaning the surface after grouting - the advantage of epoxy compounds over cement is that residues (on mosaics) or excess (on tiles) can be removed almost immediately, with ordinary warm water, as soon as the seams set. Remains of grout from the surface of the mosaic can be easily removed with a special spatula with a felt attachment after wetting it with water from a spray bottle. Then the mosaic must be wiped clean with a well-wrung out cellulose sponge. When laying paste in the joints, excess from the edges of the tile can also be easily removed with a damp sponge in two steps.

However, if for some reason the surface of the tile after grouting was not cleared of residues and excess, specialized means are used to remove them.

Litonet EVO is a liquid, concentrated cleaning composition designed to clean ceramic tiles, porcelain tiles (and polished), glass and ceramic mosaics, as well as natural stone (and polished), from residues, streaks and stains of epoxy grout. When diluted (from 1:10 to 3:10), the product can be used to remove various contaminants from joints and tiles; it effectively cleans even stubborn household contaminants from polished and lappated marble and porcelain stoneware. The composition with low viscosity in any concentration is designed for use on horizontal surfaces and floors, both for interior and exterior use.

Litonet Gel EVO is a liquid detergent with a similar scope to the previous one, produced in the form of a spray for ease of use. A more viscous consistency allows you to effectively remove epoxy grout residues and complex stains from vertical surfaces. Thanks to their non-aggressive and safe composition, both products can be used to clean not only tiles and mosaics of all types, but also linoleum or PVC floor coverings from organic and inorganic contaminants that accumulate over time.

Possible errors

Before applying other types of mixtures, it is necessary to moisten the surface with water. This is done to increase the adhesion of the grout. However, when working with epoxy material, it is not recommended to wet the surface. Other errors:

- the proportions are violated during the preparation of the mixture;

- the wrong type of solvent is used; when choosing it, you need to pay attention to the manufacturer’s recommendations for the use of the material;

- To work with epoxy grout, the same tools are prepared as for cement compositions; as a result, it is more difficult to achieve the required quality of the coating.

Advantages and disadvantages

The structure of the frozen mixture resembles plastic - it is smooth and looks very attractive. A huge advantage of the material is the ability to wash the floor in any convenient way:

- with funds;

- using brushes, including metal ones.

Tiles are more likely to be damaged than epoxy grout - they are so durable.

Other advantages of the material:

- a huge variety of colors and shades;

- can be used for any premises;

- maintaining an ideal appearance in any weather conditions during active use;

- no need to update;

- the ability to replace tile adhesive, which is important for mosaics or panels;

- drying without cracks;

- lack of response to temperature changes;

- harmless to humans after drying.

The material also has disadvantages. It will be difficult for a beginner to glue onto epoxy and rub the seams. The product hardens quickly, and without experience it is not easy to adapt to it. The price of repairs is not encouraging - the cost of epoxy grout paste is much higher than the price of cement paste. To grout joints, you will have to buy special devices, without which it is impossible to work with epoxy. Another disadvantage lies in the strength of the material. If you need to replace the tiles, you will have to try hard - removing them will be somewhat more difficult than with other types of grout.

Saving Tips

The main recommendation for reducing costs is the need to mix small amounts of the mixture. If you prepare a lot of solution, most of it will dry out immediately. You will have to mix the ingredients again. At the same time, the cost of purchasing another container of epoxy grout increases. Considering that the material is expensive, such actions are considered inappropriate.

It is necessary to move the solution from the container in which the kneading was made to another clean one. Thanks to this, it becomes possible to fill the seam with high-quality material. Then you won’t have to deal with coating repairs in the near future.

At what price and where can you buy epoxy grout for tiles - an overview of current offers

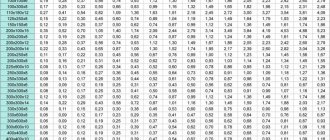

The price of epoxy grout for tiles in different trade organizations may differ, which is due to the sales volumes of similar companies, the level of specialization, as well as the presence of dealer contracts with manufacturers. The following table shows the cost of brands of epoxy grout used in laying tiles and other finishing materials, as of the beginning of the second quarter of 2022, when sold through large retail chains of building materials.

| Brand (Weight – 5 kg) | Average cost (as of April 2022), rub. | ||

| "Starlike C.350 Crystal" | 3700 | 3400 | — |

| Starlike Defender | 5305 | — | — |

| "Litochrome Starlike" | 5750 | 5400 | — |

| "Epoxystuk X90" | 3900 | 3500 | — |

| "Ceresit CE 79 UltraPox" | — | — | 4100 |

The luminescent properties of epoxy grout create the individuality and uniqueness of the room in which the finishing is done using them.

Manufacturers

Several of the most famous foreign and domestic manufacturers:

- Litokol (Italy). The material is stored for two years at a temperature of +5°C. The temperature must not be allowed to drop, otherwise the components will become hard and lose all their properties. This manufacturer offers grout in 103 colors, including various additional effects. Suitable for both indoor and outdoor use. The price ranges from the smallest (1 kg) - 1300 rubles, the medium (2.5 kg) - 3500 rubles. up to the largest package (5 kg) – 4000 rubles. Positive qualities of the brand's products:

- No smell.

- Suitable for use in rooms with poor air ventilation.

- Easy to apply.

- High resistance to temperature changes and high humidity.

- Mapei Kerapoxy. The main difference between the products of this manufacturer is that the grout has minimal grain size. However, the range of products is limited: only 26 colors are presented. The manufacturer produces a grout of three components, which is even more resistant to acids and other aggressive chemicals. Price 3 kg – 3500 rub., 10 kg – 5600 rub.

- "Diamant" (Russia). The grout is available in an assortment of 46 colors. But it can only be used to treat the bathroom. Sold in packages of 2.5 kg - from 2000 to 5000 rubles.

- "Basic." The epoxy grout from this company is characterized by high resistance to temperature changes (from – 50 to + 75°C), elasticity, hydrophobic properties and is not prone to the development of fungus. The solution is usable within an hour. The grout is available in 29 colors, packing 2.5 kg - 2000 rubles. In general, it has all the properties that are characteristic of epoxy.

- "Fugue". The product has all the properties characteristic of epoxy grout. Suitable for processing both indoors and outdoors. The solution is usable within two hours. The material is available in 32 colors. The cost varies significantly, for example, in online stores you can purchase 2.5 kg of dry mixture for literally 2,000 rubles, while in retail stores the product will be much more expensive.

Whatever company the buyer chooses, when starting to work, it is necessary to read the instructions on the packaging and act on them.

Technical description

The main pros and cons of epoxy grout for tiles are determined by the base component of the material - epoxy resin. This is a universal product that, in combination with a hardener, forms a polymer compound with high strength and hardness. You can compare the parameters with a monolith made of heavy concrete. The permissible load range is from 40 to 90 MPa.

Another property characteristic of epoxy resin is excellent adhesion to most types of substrate. Thanks to this, not only glues cope with the task, but any products with one or another content of a resinous component. Grout is no exception.

For materials used to fill tile joints, moisture resistance is considered one of the important qualities. This is especially true for rooms with variable humidity and floor coverings (they are often exposed to water and detergents). After hardening, epoxy-based grout is practically vapor-tight and inert to household chemicals.

Moisture resistance of rubbed seams Source amazonaws.com

Also, the advantages of the grout composition include the following:

- serves for more than 50 years if operating rules are observed;

- used in conditions of temperature changes from -20 to +100 degrees Celsius;

- does not shrink;

- exhibits resistance to cracks;

- not afraid of alkaline and acidic compounds, household chemicals;

- considered hypoallergenic and environmentally friendly.

One of the main disadvantages is the difficulty of installation, so it is important to know how to work with it correctly. Epoxy tile grout cures quickly and bonds to the substrate. Excess can only be removed with a special remover. On the user's part, there is a disadvantage regarding cost, but this is ultimately compensated by the quality and durability of the composition, which is unchanged in shape and color.

Grout composition

Filler for tile joints is sold in the form of a base base and a hardener.

Example of epoxy grout configuration Source insales.ru

The first, in addition to epoxy resin, includes a fine quartz filler, a pigmenting agent and a plasticizer. The latter is necessary to simplify the process of rubbing the tiles with a plastic mass. The second component has an organic base and promotes the rapid formation of strong chemical bonds between the ingredients in the working mixture.

See also: Catalog of companies that specialize in finishing materials and related work

Color

Dyes, colored quartz, and glitters are added to the epoxy-based tile grout. The result is a material with almost any shade of saturation, including inclusions of silver, gold, and bronze. On sale you can find both transparent and tinted compositions, as well as a white base and individual coloring additives.

Glitter for epoxy composition Source bazazakonov.ru

Reviews

Consumers prefer epoxy grout due to its high stability, long service life and wide range of applications. In addition, many argue that this mixture is ideal for porous tiles, since it does not leave behind colored stains, which often form after a cement mixture. Epoxy is a godsend for designers who value a clear color selection and decorative effect.

Consumers note that the grout does not depend on temperature and easily tolerates changes from -20 to 100°C. The composition does not shrink, and after drying, cracks do not form on it, like with cement grout. They also emphasize the hypoallergenic nature of the material and its complete safety for the health of others.

Flaws

Despite many advantages, epoxy grout has disadvantages that should be considered before starting repairs:

. The grout sets within 45-60 minutes after application, during which time you need to have time to apply it, level the seams and remove residues from the tiles. Cement grout takes much longer to dry; minor imperfections can be easily corrected after application.

Maximum curing speed- High price . Mixing components are more expensive than cement mixture. If you need to restore a small area, you will have to buy a new set. In addition to the epoxy mixture and hardener, you will need chemical cleaners, special sponges, precision dosing devices and much more.

- Difficult to apply . In order for the seams to look perfect, it is necessary to carefully distribute the composition and quickly remove excess. Incorrectly applied grout looks rough and leaves unsightly streaks or a cloudy coating on the tiles.

Examples of using epoxy grout, photos

Seam filling technology

Before using the grouting material, you need to thoroughly clean the surface of the tiles, if necessary, vacuum well and degrease the seams. Since epoxy grout has two main components, they are sold in different containers. The material is very viscous and hardens quickly, so it makes no sense to combine the entire volume of grout. Unprocessed paste will dry out and lose its quality. Technology for processing tile/mosaic seams:

- Cleaning gaps from dust, dirt, and glue residues.

- Removing plastic crosses and alignment elements.

- The paste is applied to a dry base with your hands or a spatula.

- The mixture is evenly distributed over the entire depth of the gap.

- Decorative joints are made with a molding spatula.

- Remove excess colored or transparent grout from tiles.

Some craftsmen pre-glue the surface around the seams with masking tape to reduce staining of the facing material. If you leave the mixture for more than five minutes, you will have to remove the sealant with a cleaner. Complete polymerization occurs after five days - epoxy grout takes longer to dry in the gaps than cement grout.

Important: After combining the grout components, leave the resulting mixture for several minutes and mix it again with a drill with an attachment at low speed.

On video: master class on applying grout

How to seal seams

Filling the gaps between tiles and mosaic fragments is done gradually - first, seal the seams in one small area, then move on to the next. The transparency of epoxy grout can be skillfully used when making mosaic and glass compositions.

The seam is filled in the classic way, using a spatula. After this, take a foam sponge, soak it in warm water and run it over the paste-filled seams. It is important not to wet adjacent gaps that do not already have grout, since it can only be applied to a dry surface. Next, the master takes a new clean sponge, wets the foam with water again and forms a seam. To make the epoxy grout gap look perfect, after half an hour or an hour the seam can be sprayed with a spray bottle and gently rubbed in with your finger. All work can be divided into three main stages.

Connecting components

The total mass of the hardener and epoxy resin is divided into three or four parts. It is important to strictly observe the proportions so that each batch contains the same amount of catalyst and resin. If you use less hardener, the mixture will not harden completely, which may affect the strength of the tile joints. The composition must be mixed using a drill with an attachment, turning on the device at low speeds - no more than 300 rpm. This will keep the paste from filling with air bubbles.

Seam filling

The technology for treating tile joints with epoxy material is no different from finishing with cement grouts. When working with epoxy grout, you need to use a harder rubber spatula. Some craftsmen find it more convenient to fill the seams with their fingers, carefully rubbing the gaps between mosaic or tile fragments. The substance practically does not stick to your hands. First, fill the seams in the horizontal direction, then in the vertical direction.

Surface cleaning

To prevent excess mixture from remaining on the facing material, you need to purchase a professional epoxy grout solvent in advance. The mass must be removed immediately, without allowing the paste to harden. Fresh grout can be easily removed with a colorless detergent or washed with warm water, but this must be done simultaneously with filling the joints, until the mixture has “set” to the surface of the tile. It is not recommended to clean traces of grout with improvised means - there are special solvents for this.

Conclusion

Mapei. If we consider the epoxy grouts Kerapoxy and Kerapoxy Design, the first has more shades and is not as grainy. Although the second one is much simpler and easier to work with.

Litochrome Starlike. If you look at this grout, you can note its excessive softness. In the finished state, it may seem much lower than usual elasticity. It is difficult to smooth out with your finger, even after spraying. In this case, you need to wait a long time for it to partially harden. It is difficult to wash it off even with a cellulose sponge.