Bitumen primer or bitumen primer is a building material, a homogeneous black liquid intended for waterproofing various surfaces. The mixture is based on high-quality bitumen, diluted to a fluid state with non-toxic solvents.

Homemade primer is familiar to Soviet summer residents. It was a troublesome and dangerous job - melting bitumen over a fire in an old bucket and then diluting it with motor gasoline. This explosive boiling composition was used to coat the seams of soft roofs and the buried bases of wooden and metal poles.

Modern professional primers do not require such manipulations. They are sold either in ready-to-use form or as a concentrate, and white spirit, kerosene, and gasoline solvent are used to dilute the mixture.

How long does it take for bitumen primer to dry?

When doing roofing work, you need to know how long the bitumen primer takes to dry. Drying time may vary depending on circumstances. But sometimes you have to figure out why it takes so long to dry, and what to do in such a situation.

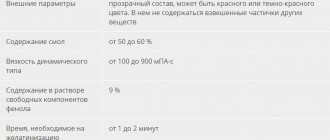

Specifications

This material has the following technical characteristics:

- specific gravity of the primer – 0.8 kg/l;

- content of non-volatile components – 30-40%;

- softening temperature – not less than +80ºС;

- conditional viscosity – from 10 to 30 seconds;

- Time for complete drying of the applied layer is 12 hours.

The material is sold in 10 and 20 liter sealed and easy-to-carry metal buckets – Eurocans.

They control the indicators possessed by the bitumen primer, GOST R 52487, as well as GOSTs 19007-73, 8420 and 9070.

Building materials cannot be sold without a passport. The seller must provide it upon the buyer's first request, regardless of the quantity of primer purchased. The lack of a document from the seller most often means that he is selling warehouse balances that have expired.

Why is it needed?

Before you figure out how long it takes a bitumen primer to dry, you need to step back a little. That is, find out the purpose of using the substance. A number of houses have flat rather than pitched roofs. But such a scheme, despite its convenience, complicates sealing. And additional primer preparations do not dissolve in water.

That is, when precipitation occurs, they will not allow liquid to pass through. In addition to petroleum bitumen, solvents based on kerosene or white spirit are added to the primers. Work with the composition is possible in a wide temperature range.

Of course, drying time is also very important. It indicates how soon it will be possible to begin subsequent work.

How to get rid of primer marks

The high adhesion of bitumen primer also has a downside: the composition does not dissolve in water, sticks to any surface and quickly stains clothes. Please note that stains cannot be removed using conventional means. A more serious approach is needed:

- Traces of primer can be removed from the surface of the instrument with white spirit. This solvent evaporates slowly: the bitumen has time to dissolve, and you can easily wipe off the softened mass with a soft cloth. Acetone-containing solvents are useless.

- Rubber can be cleaned with diesel fuel - it is not aggressive to rubber and does not cause swelling of the material.

- You can try to wipe the fabrics with light solvents (benzene, gasoline galoshes). Just keep in mind that these substances are quite toxic and can “burn through” synthetics.

- Any of the above methods is suitable for building surfaces.

When choosing a primer, pay attention to how much a bitumen primer costs. The price of quality products is about 900-1000 rubles per ten-liter bucket. If the type of packaging is in doubt, contact the seller and ask for accompanying documents. Certificates must have a blue seal.

How long does it take for the product to dry?

All manufacturers indicate how long it takes for the primer to work. Thus, in most cases, the average drying time for Proof bitumen primers is a maximum of 12 hours. But it also depends on the specific composition and on what the external conditions are. Things are different for TechnoNIKOL products:

model No. 01 will be ready in a maximum of 12 hours;

bitumen emulsion primer No. 04 will reach the desired state 60 minutes after application;

Finally, the quick-drying bitumen-polymer reagent No. 03 will make you wait a maximum of 15 minutes.

What to do if the primer doesn't work well?

Usually, after applying bitumen mixtures to the roof, you can simply wait a short time and begin further work. But specific conditions often have a strong impact on chemical processes. How long mastics and primers take to dry depends on:

thickness of the layer used;

average air temperature;

air saturation with water vapor;

type of treated surfaces.

But sometimes it is very difficult and even impossible to wait. It is important to know what to do to make the primer dry faster . It is recommended to start with application using notched trowels. The furrows increase the total surface area. Therefore, evaporation occurs more actively without deteriorating the quality of the surface.

When the drug is used, you need to ensure the safety of the applied layer. You will also have to protect it from additional moisture.

These simple requirements guarantee uniform drying without fluctuations in thickness. In enclosed spaces, heaters and heat guns are very useful. But then we must remember about fire safety and protection from bitumen vapors.

Of course, in order for the primer to dry faster, you will have to immediately choose the appropriate preparation. But even in this case, specific instances may behave differently. Whenever possible, preference should be given to the freshest mixtures. And it is very important to store the drug correctly. Otherwise, it easily loses its properties.

Material Information

Bitumen primer is a black liquid that should not contain foreign inclusions. The composition contains no impurities harmful to human health, since petroleum bitumen dissolves in an organic composition.

- If the store sells ready-made soil, it should be mixed with a construction mixer before use.

- When purchasing a concentrate, you will have to prepare it for use; for this you will have to buy a special solvent, the class of which will be indicated on the packaging. It is worth noting that a concentrated primer is much more profitable than a ready-made one - it is more economical. It should be diluted strictly adhering to the proportions specified by the manufacturer.

- The primer has a specific odor, so it must be used in a well-ventilated area or outdoors.

- The primer increases adhesion and can be used for all types of surfaces: metal, wood, reinforced concrete, concrete, asbestos-cement, and various types of porous materials. Before waterproofing an underground structure or roof, the surface of communications or the foundations of buildings, you need to apply bitumen primer.

- The primer has an anti-corrosion effect, so using a primer on metal surfaces protects pipes from rotting and increases their service life.

- The primer can be used at any time of the year, even in hot weather, since its softening process begins at 80 degrees.

If the surface of the material is very porous and dusty, then for further processing with insulating materials, experts advise using a bitumen primer for a better result.

Peculiarities

Bitumen primer TechnoNIKOL 01 is actually a primer on top of which a certain roofing self-adhesive or waterproofing roll building material is mounted.

Externally, it is a viscous, viscous liquid of a deep black color. It is made from petroleum bitumen and diluted with specially selected high-quality organic solvents.

Thanks to this composition, this primer does not have a harmful effect on the environment and the human body, allowing this primer to be used for waterproofing without any restrictions

Primer types

There are several types of this product, the cheapest is simple primer. Bitumen-polymer material is much more expensive; it contains special substances that promote rapid drying, while at the same time isolating the surface much better from the effects of nature. Primer, bitumen emulsion – used for interior work, diluted with water.

Application and positive aspects of bitumen-based soil

Bitumen primer is similar in properties to plaster, and is intended to protect porous materials, only, unlike gypsum mixtures, it can be used for metal surfaces and in roofing work.

Impregnation of the base with bituminous soil is intended as a starting coating before using various waterproofing materials.

Due to its dense composition, the primer clogs all the pores of the material, making it resistant to moisture. Waterproofing of various structures using a bitumen primer becomes better.

Let's consider in which areas it is most preferable to use bitumen primer.

Scope of application

Primer is a primer designed to fill the pores of the material, level out small roughnesses and irregularities, and remove dust from the material. It is used for primary treatment and improving the adhesion of the waterproofing material to the base.

The material can also be used as independent surface insulation, in cases where the base is not constantly exposed to moisture.

Many builders use emulsion primers to coat surfaces in the bathroom and kitchen, where air humidity is high.

Now there are many types of this material on the market, which are used:

- for roof treatment;

- floor coverings;

- basements;

- foundations;

- sewer pipes and water supply systems.

The performance characteristics of each type of bitumen primer differ from each other, and you only need to use the material that is suitable for a particular type of surface.

Characteristics of bitumen impregnation:

- dries within three hours;

- the temperature range at which the primer can be applied is quite wide -40 +80 degrees;

- easy to apply, elastic material;

- breathable;

- easy to use and affordable.

Types of primers and their areas of application

Bitumen primer is used for waterproofing foundations, concrete and cement-sand screeds; it is used to treat pipelines, metal and wooden structures to protect against corrosion and rotting.

The composition has excellent adhesion and penetrating ability. When applied to a concrete surface, bituminous primer penetrates the pores and glues together small loose particles. It sticks equally well to cement surfaces, metal, wood (and hopelessly stains work clothes). Simply put, wherever you need to apply a thin, uniform layer of waterproofing and anti-corrosion material, you need a bitumen primer.

The advantages of factory formulations are:

- Simplicity and safety of use;

- Good adhesion, fluidity and uniformity of application. Properly coated surfaces very rarely require re-treatment;

- Fast, complete drying;

- Temperature stability after drying. The bitumen used for the production of primers has a softening point of about 80 degrees;

- Anti-corrosion and waterproofing properties;

- Wide range of temperatures permissible for work.

Manufacturers offer various primers adapted for specific purposes:

- Roofing – used for pre-treatment of concrete surfaces of flat roofs. Creates additional waterproofing and significantly increases the adhesion of fused rolled materials to the base. It is also used as an adhesive for processing seams and joints of roofing material.

- Road – used as a binder for crushed stone before laying the road surface itself.

- For metal structures and pipelines – it has anti-corrosion properties and increased adhesion.

- Universal - suitable for application to any type of surface if operating conditions do not require the use of a highly specialized composition.

Application of coating waterproofing

Coating waterproofing is a thin-layer moisture-proof frost-resistant protective coating. In most cases, to protect the foundation from moisture, bitumen-based mastic is used - the most affordable and cost-effective composition for creating a moisture-proof coating. Bitumen mixtures are used on metal, wood, concrete, reinforced concrete, brick and other mineral surfaces .

- processing of walls, foundations, basements, swimming pools, reservoirs, hydraulic and other structures;

- protection from moisture of vertical and horizontal surfaces;

- for external and internal works.

Return to content

Foundation treatment

By using bitumen impregnation when carrying out waterproofing work on the base of a structure, you can be confident in the quality and durability of the coating. It is important to correctly calculate the consumption of bitumen primer, so that there is enough material to treat the foundation on both sides, in this case the base will be resistant to moisture.

Before applying the surface-mounted insulators, the impregnation must dry well; for greater reliability, you can apply a bitumen primer in two layers. In this case, even a porous foam block will become waterproof.

It is advisable to use deep penetration impregnation on a bitumen basis in damp rooms:

- kitchens;

- bathrooms;

- laundries;

- showers.

Calculation of the required volume

The required amount of bitumen primer can be determined based on the surface area that needs to be treated and the average consumption of the solution per 1 square meter.

The average consumption of the finished primer is indicated by the manufacturer on the packaging; for a primer made independently it is 0.5 liters per 1 square meter.

The application of bitumen primer, according to technology, occurs in 2-3 layers, so it is important to increase the amount of calculated material by 2 or 3 times.

Advantages and disadvantages

The main advantages are as follows:

- ready for use – does not require the cost of purchasing solvents and is ready for application after mixing;

- high ability to penetrate and fill the pores of the treated surface: when applying a primer to a concrete surface, it fills all the pores and cavities, thereby increasing the adhesion strength to the waterproofing material laid on it;

- possibility of use at low temperatures - this primer can be applied at air temperatures down to -10ºС;

- quick drying - a layer of primer applied to a concrete base hardens in 2-3 hours at high temperatures. Complete drying of all layers occurs in less than 12 hours.

Experienced builders try to apply the entire volume not in 1 layer, but in at least 2 or even 3. This application significantly speeds up the drying of the primer coating, making it more reliable and durable.

Advantages:

- convenience and ease of application using not only special compressors, but also simple brushes and brushes;

- low consumption, even when applying the material using brushes and brushes, the consumption per 1 m2 does not exceed 0.5 liters.

The few disadvantages of this primer composition are:

- high price;

- flammability - the presence of solvents in the composition makes this primer composition flammable, so its use and storage near open flame sources is prohibited;

- use only for external waterproofing work - flammability and characteristic odor make this primer unsuitable for waterproofing work inside buildings.

How to calculate the required quantity?

Knowing some nuances will help you more accurately calculate the amount of bitumen primer. Thus, a primer in a hot volume always diverges in a larger volume than a cold one. Although the hot primer is considered more sensible and practical.

It also matters what tool you are going to use - a brush or a roller, and what surface you will apply the composition to. Rollers require less material, and the vertical walls of the parapet require two or three layers, and each of them must dry well in turn.

And for a horizontal surface, the number of layers varies each time, depending on the task. For example, to glue roofing felt, one layer of primer will be enough, but to install a mastic roof, two or three layers will be enough. The surface area itself is easy to calculate.

Antifungal primers

Fungus is the scourge of rooms with high humidity. This is not only an aesthetic problem, because pathogenic organisms can cause many serious human diseases - bronchitis, conjunctivitis, allergies. By affecting the structure of building materials, it worsens their performance properties.

If you don't get rid of the fungus, it will spread and over time become a threat to the building and the people who are in it. An effective remedy is an antifungal primer. This is a composition with an antiseptic that is used to treat surfaces at the first sign of fungus.

In order for the solution to saturate the materials well, you need to completely remove the finish, thoroughly coat the areas where there is fungus, and use facing materials and adhesives with antifungal additives for the new coating. If the instructions for the composition contain a recommendation to repeat the treatment, it must be carried out within the prescribed time frame. To care for surfaces, it is recommended to use disinfectant household chemicals.

As for reliable brands of antifungal primers, you can choose “Fongifluid” from ALPA or one of the products, “Homeenpoisto”). When purchasing a product, you should carefully read the manufacturer's recommendations, since the composition of primers may vary depending on the type of surfaces for which they are intended.

Antifungal primer Ceresit

Materials and tools

When processing the foundation yourself with a primer, you will need:

- Bitumen primer;

- Solvent (if a concentrated solution is used) - gasoline, white spirit, etc.;

- Wide brush or roller of your choice;

- Tray or other container for solution;

- Protective elements – mask, gloves, goggles;

- Brush and coarse cloth.

Also, if there are various defects on the foundation, a spatula, putty, hammer and other tools can be useful to help solve the problem.

Standards of use

The consumption rate of bitumen primer per 1 m2 was mentioned above, but to achieve a positive result it is also important to know the technology of the work. The mixture is applied to cement-sand, concrete and other rough surfaces. If we are talking about a porous, dusty and uneven surface, then the treatment must be carried out using a brush or nylon brush. This application technology provides excellent impregnation of the base and high adhesion rates.

Surface priming allows you to increase the service life of materials. If there is a need to glue roll materials using a primer, the surface of reinforced concrete and concrete slabs, as well as the seams between the elements, must be primed. Each subsequent layer of rolled material is glued 4 hours after installation of the previous one. Rolled materials must be laid with an overlap, the width of which is 100 millimeters. In this case, cross-gluing should be avoided. Once the web is in place, it should be rolled with a special-purpose cylindrical roller.

Rules for applying primer

Hot and cold bitumen primer emulsion is available. Today, only the cold type of soil is on sale, which is a little more expensive than the hot type, but it is safer and not as fire hazardous. The hot composition must be heated to a temperature of 80 degrees, and the cold type does not need to be additionally heated; it can be used at an ambient temperature of +5 degrees. Cold soils fit perfectly on a prepared base, and have a fairly economical consumption per 1 square meter

It is important to observe the following precautions during application:

do not apply bitumen primers and rubber mixtures if there is an open fire nearby; It is important to carry out all work only in personal protective equipment, such as goggles and canvas gloves; Do not allow the composition to come into contact with skin or eyes. If the emulsion gets on the skin, it must be washed off immediately with an appropriate solvent, and if the mixture gets into the eyes, they must be rinsed with plenty of running water, and then consult an ophthalmologist; if application is carried out indoors, it is important to organize sufficient ventilation. When performing outdoor work, apply primer only in dry and warm weather; in the first day after application, it is important to protect primed areas from moisture and water

To apply the emulsion, you can use the following tools:

When performing external work, primer should be applied only in dry and warm weather; in the first day after application, it is important to protect the primed areas from moisture and water. To apply the emulsion, you can use the following tools:

- brush. The brush is used if small areas are covered, as well as hard-to-reach places;

- It is better not to use a fur or foam roller, since bitumen sticks strongly to it, leading to gluing, as a result of which the quality of the work performed decreases and primer consumption increases;

- spray gun. A spray bottle can only be used if the technical characteristics of the mixture allow it to be sprayed. Thanks to spraying, material consumption is reduced, and the emulsion is evenly distributed throughout the entire area;

- The pouring method is used quite rarely for mixtures with very high viscosity. Bitumen is poured onto the surface and distributed using a rubber mop. This method is considered the most expensive and uneconomical.

Using bitumen primers is quite easy; you do not need to have any knowledge or skills. Thanks to the use of this material, the base is significantly strengthened, the surface acquires waterproofing properties, and adhesive characteristics are also improved, that is, the adhesion of the base and the material applied to the primer is significantly increased.

Execution of work

The technology for waterproofing a foundation with a primer is quite simple and consists of several steps:

- Prepare the primer - mix the prepared solution thoroughly, dilute the concentrated primer, according to the instructions, with a suitable solvent;

- Pour the liquid into a convenient container and, using a wide brush or roller, apply an even layer to the cleaned surface;

- Wait the required time for the surface to dry completely and cover the base with the next layer of primer.

It is recommended to carry out foundation treatment work at a temperature not lower than -15 degrees Celsius.

When treating the base with a bitumen primer, you should be attentive to your own safety: during work, you must wear a mask and goggles to protect your mucous membranes from toxic fumes, as well as thick clothing that minimizes the possibility of bitumen getting on your bare skin.

general description

Gas floor-standing single-circuit boilers types and technical characteristics

This composition is a homogeneous black liquid, which is a solution of petroleum bitumen. To soften them, conditions are required, characterized by a temperature of 80 degrees or more, and organic substances act as a solution. There are no foreign inclusions in the mixture, and there should be no inhomogeneities. The mixture does not contain toxic solvents such as toluene. Roofing and waterproofing work will be made easier if you use a bitumen primer. With its help, you can reduce the time of manipulation, improving the quality of waterproofing.

Safety precautions

When working with bitumen primer or primer, the following safety precautions must be observed:

- the material contains flammable organic solvents, so it is necessary to have fire extinguishing equipment at the construction site;

- When working with primer/primer, smoking and using open fire are prohibited;

- The primer (primer) is not allowed to get into the eyes and mouth, as well as onto open areas of the skin. In case of contact with eyes, rinse them with plenty of water and consult a doctor;

- When carrying out work on applying primer, it is recommended to use safety glasses and gloves.

Different bitumen compositions

Various types of bitumen primers are manufactured; different components are used for their production:

- simple primer is made from bitumen and unleaded gasoline in a ratio of 1 to 3. You can even create such a mixture at home with your own hands;

- polymer primer is made from bitumen, gasoline and polypropylene (it can be in powder or atactic form). Such compositions have a higher price than simple ones; when purchasing them, you need to check the certificate confirming the high quality of the product;

- mineral-bitumen primer includes certain additives, namely asphalt and dolomatized limestone. Be sure to check the certificate of compliance with technical specifications;

- bitumen rubber primer contains special additives made from rubber waste. Typically, unusable rubber tires are added to this bitumen composition and crushed;

- water-based bitumen mixture. This composition is made from water and bitumen, it is used for indoor insulation, usually used to cover concrete floors. This bitumen mixture is slightly toxic to humans, so it must be applied in a well-ventilated area. This product has low consumption per m2.

All bituminous soils can be divided into 2 types:

- ready-to-use emulsions. These primers are simply mixed and applied to the surface;

- concentrated products that need to be diluted to a suitable viscosity. Gasoline, kerosene, or any other organic solvent specified in the instructions is used as a diluent. The consumption of bitumen primer per 1 m2 is very small, and it is also much easier to transport and easier to store.

According to their intended purpose, there are the following types of soils:

- road. They bind crushed stone fractions together, after which an asphalt coating is applied. Also, these compounds are used before laying concrete screed, during exterior work. One of the popular ones is the bitumen-polymer primer Izhora np 01, used for priming ordinary concrete, as well as asphalt concrete and reinforced concrete;

- roofing Used to create a waterproofing layer and level the base before covering the roof. Such rubber coating must be purchased with a quality certificate. One of the proven and reliable products is the bitumen primer from TechnoNIKOL;

- pipeline Used to protect metal pipes from corrosion and rust;

- universal. They are suitable for application to any surface, such as wood, concrete and sand slabs.

Making your own bitumen primer

If you wish, you can prepare a bitumen primer yourself; for this you will need the following materials:

- 1 kg bitumen,

- 2.5 liters of unleaded gasoline,

- Container for heating bitumen,

- Metal fine mesh sieve,

- Container for mixing liquids,

The manufacturing process is not complicated:

- Melt the bitumen to a liquid state;

- Leave the mass for some time until it cools - the optimal temperature for work is 80 degrees;

- Gradually mix the cooled bitumen with gasoline - add the mixture in small portions and mix thoroughly;

- Using a sieve, strain the resulting mass.

How and how much to store

The primer bitumen composition should be stored under the following conditions:

- temperature – from -20 to +30ºС;

- lack of direct sunlight;

- good ventilation;

- absence of open fire sources or heating devices nearby.

If these conditions are met, the shelf life is 12 months.

It should be remembered that the shelf life is indicated taking into account that the material has not been used and the container with it has not yet been opened. If the container is opened, the shelf life will be significantly reduced, even if all the storage conditions described above are met.

Primers TechnoNIKOL

TechnoNIKOL Corporation is one of the Russian market leaders in the production of bitumen mixtures for various applications.

TechnoNIKOL 01

Bitumen primer TechnoNIKOL 01 is considered one of the most popular universal waterproofing materials. This is a classic version of a ready-to-use bitumen mixture based on organic solvents. Widely used in roofing work, and as an independent waterproofing for concrete and cement surfaces.

Primer TechnoNIKOL 02 is a concentrated analogue of TechnoNIKOL 01. The concentrate is more convenient for transportation and when used in large volumes. Before use, the mixture is diluted with white spirit or kerosene in a ratio of 1:1.5 – 1:2 by volume and mixed thoroughly. It is acceptable to use gasoline solvent.

TechnoNIKOL 03

Bitumen-polymer primer Technonikol 03 has increased adhesive and hydrophobic properties due to the additives included in its composition. The composition is used for processing metal and non-uniform surfaces, pipelines and bridge structures. It is sold as a ready-to-use bitumen primer.

TechnoNIKOL 04

TechnoNIKOL 04 is an emulsion bitumen primer, i.e. ready-to-use aqueous bitumen emulsion. It is used for interior work (for example, for treating the floor in the bathroom). Since the composition does not use organic solvents, the mixture does not have a strong odor and does not emit harmful fumes. Drying time for the primer at room temperature is no more than an hour.

The water base allows you to apply TechnoNIKOL 04 primer to wet surfaces.

AquaMast

Primer AquaMast is an environmentally friendly primer based on organic solvents for pre-treatment of surfaces. A special feature of the AquaMast composition is that it can be used both in combination with roll materials and when installing coating waterproofing.

The use of bituminous soil can significantly reduce the consumption of waterproofing mastic.

| Indicators | 01 | 03 | 04 | AquaMast |

| Primer consumption, l/m2 | 0,25-0,35 | 0,25-0,35 | 0,25-0,35 | 0,35 |

| Drying time at 20 0C, h | 12 | 10 minutes | 1 | 12 |

| Application temperature, 0C | from -20 to +40 | from -20 to +40 | from +5 to +30 | from -10 to +40 |

Table 1. Technical characteristics of TechnoNIKOL primers

Healthy competition for the TechnoNIKOL corporation comes from the Vitumast company, which offers its line of bitumen primers with similar technical characteristics.

When choosing a universal primer, the golden rule “price – quality” applies. It is better to ask your sales consultants in more detail about the properties of special-purpose mixtures.

Construction of houses

0 votes

+

Vote for!

—

Vote against!

To improve the adhesion of concrete slabs, rough or porous surfaces to waterproofing or roofing materials, the Technonikol primer is used. In the production of this material, only high-quality organic solvents and bitumen are used. We will consider the features and scope of use of the TechnoNIKOL primer below.

Table of contents:

- TechnoNIKOL company - general information and product range

- Bitumen primer: purpose and characteristics

- Primer “Technonikol” - features and scope of use

- Bitumen primer “Technonikol” - review and characteristics

- Advantages of using TechnoNIKOL primer

- Features of applying the TechnoNIKOL primer

TechnoNIKOL company - general information and product range

The Technonikol Corporation produces a large number of materials for roofing, waterproofing, heat-insulating and sound-proofing work. It hosts seminars and training courses for builders, customers and engineers.

Technonikol products have certificates of quality and compliance with all regulatory documents. The warranty on roofing materials is more than ten years. The company's specialists in the field of development of building materials take training courses abroad and, having gained foreign experience, implement it in production.

Enterprises have computer control systems that facilitate the production process. Each plant has a scientific laboratory.

Today, the TechnoNIKOL corporation consists of 38 production sites located in the CIS countries.

The Technonikol company produces:

- roll roofing materials;

- membranes for drainage;

- polymer membranes;

- materials for thermal insulation;

- shingles made of bitumen or composites;

- sealants;

- roofing felt

The product range is constantly expanding to meet the needs of all customers. The newest development is the TechnoNIKOL building system, which provides thermal, sound and waterproofing of all parts of the building.

Bitumen primer: purpose and characteristics

Bitumen primer is a black homogeneous liquid consisting of a solution of bitumen and an organic solvent. There are no foreign inclusions, toxic solvents or homogeneities in this composition.

The main function of this material is to facilitate roofing and waterproofing work. It reduces the time required for waterproofing.

There are two types of bitumen primer:

- concentrate;

- standard.

The first option requires dilution with an organic solvent before use, while in the second the organic solvent is already present. The advantage of the first type is the ease of its transportation and storage. And standard bitumen does not require additional time for its dilution, therefore it reduces the time of work.

The scope of use of a bitumen primer is limited to priming concrete, reinforced concrete, metal, asbestos-cement, wood, and porous surfaces when carrying out waterproofing or roofing work. It is used both as an independent waterproofing material and in combination with other types of waterproofing materials.

It is recommended to use a bitumen primer to prepare for waterproofing:

- flat roof bases;

- fundamental structures;

- underground structures;

- bridges;

- metal pipelines.

The primer has a number of anti-corrosion properties, so it is often applied to protect metal from rust formation.

The primer is applied using brushes to ensure high adhesion to the surface being treated. The use of a bitumen primer significantly extends the service life of the coating to which it is applied.

The advantageous characteristics of bitumen primer are:

- high level of adhesion to the surface being coated;

- accelerated drying process;

- no sticking;

- ensuring good waterproofing;

- resistance to high temperatures;

- anti-corrosion;

- it can be used as an adhesive on which roll-type waterproofing materials will be installed;

- ease of use;

- possibility of application at low temperatures;

- presence of water-displacing properties.

The main task of a bitumen primer is to ensure high adhesion of the waterproofing material to its installation site. If the room temperature is about 15 degrees Celsius, the primer dries within 16 hours.

If there is a need to use the material in winter, then this is possible, but only if it is laid on a surface previously cleared of snow and ice. Before starting work, you should heat the material and the rolled waterproofing in a warm room.

If the bitumen primer is used indoors, it should be well ventilated. It is possible to use the material only if its temperature is more than ten degrees. It is recommended to wear glasses and overalls to prevent the primer from getting on the mucous membranes.

Primer “Technonikol” - features and scope of use

TechnoNIKOL bitumen primer has the form of a water emulsion based on petroleum bitumen, which is used to treat concrete bases and cement-sand screeds. Before installing self-adhesive and guided waterproofing materials for the roof, a solution of TechnoNIKOL bitumen primer is applied.

To produce the material, only high-quality organic solvents and bitumen are used. Therefore, the primer has high heat resistance and good penetrating properties. The Technonikol bitumen primer penetrates very deeply into the surface and ensures its adhesion to subsequent materials. This property has a positive effect on the service life of materials.

TechnoNIKOL bitumen primer dries very quickly and does not stick to the surface. The Technonikol company produces the primer in concentrated form, which facilitates its delivery to its destination and storage.

To improve the quality characteristics of the primer, you should follow certain rules for working with it:

- Before using the material, it is necessary to ensure that it is thoroughly mixed;

- the surface on which the work will be performed must be cleaned of dirt, dust and dried;

- the surface moisture level should not exceed fifteen percent;

- After applying the primer, you need to wait until it dries completely, at least 1.5 hours.

Bitumen primer “Technonikol” - review and characteristics

We invite you to familiarize yourself with the main primer options from TechnoNIKOL:

1. Primer “TechnoNIKOL No. 1” - is sold ready-made and does not require additional organic solvents. Available in 20 liters or 50 liters. It is the most popular primer, which is suitable for treating surfaces before installing waterproofing on them. Consumption of TechnoNIKOL primer is from 250 to 350 ml per 1 m². This primer is universal and does an excellent job of preparing various types of surfaces for installing waterproofing. Its main advantage is the provision of high-quality and reliable fastening to cement-sand screed, concrete and other surfaces with roughness.

Characteristic:

- For the production of primers, exclusively organic solvents are used, which are harmless to health;

- to obtain the desired solution, some types of bitumen are used, which soften at a temperature of 80 degrees;

- the absence of inhomogeneities and foreign inclusions ensures product quality;

- non-volatile substances occupy less than half of the composition;

- has a high penetrating effect;

- dries in 10-12 hours;

- the material is heat-resistant.

There are two forms of release of the TechnoNIKOL No. 1 primer:

- in the form of a ready-made solution;

- in the form of a concentrate.

The concentrated primer should be diluted with kerosene, gasoline or white spirit. Then you need to stir it and use it for its intended purpose.

2. Primer “Technonikol No. 4” - has improved physical and chemical characteristics.

Can be used both outdoors and indoors. It only takes 60 minutes to dry. A material based on an aqueous emulsion of petroleum bitumen, which is modified with the help of technological additives and mineral fillers.

Advantages:

- fast drying process;

- excellent penetrating properties;

- heat resistance;

- There is no stickiness during operation.

Scope of use:

- priming of rough surfaces before laying waterproofing or roofing material;

- in order to ensure strong adhesion between the base and waterproofing.

Before using the bitumen primer “TechnoNIKOL No. 4”, it should be mixed, and the surface that it will cover must be thoroughly cleaned of dust and other contaminants, and then dried. Do not use automatic devices when applying primer; use manual devices such as a brush, roller or brush. The primer can be used at temperatures from 5 to 400 degrees Celsius.

The consumption of the material is affected by the type of surface on which it is applied and the method of application; the average consumption of TechnoNIKOL bitumen primer is from 250 to 350 ml per 1 m². One primer package contains 20 kg of material.

3. Bitumen primer “TechnoNIKOL No. 3” - used in the process of treating the surfaces of spans and bridges. And also before laying waterproofing or roofing materials on sandy and concrete structures.

This primer contains petroleum bitumen, polymers, adhesive additives and organic solvents. The material dries quickly and perfectly protects metal surfaces from rust. After installing the waterproofing, strong adhesion between the surface and the waterproofing material is ensured.

To apply the primer, use a roller, brush, brush or airless spray. For four square meters of surface you will need one liter of primer.

Primet "TechnoNIKOL" price for 20 liters is about $18.

Advantages of using TechnoNIKOL primer

The fact that the TechnoNIKOL primer has a certificate of compliance with all standards once again proves the high quality and reliability of the use of this product.

Bitumen primer “TechnoNIKOL No. 1” has the following advantages:

- classic and universal;

- the most affordable price;

- low consumption;

- two forms of release: regular and concentrate;

- high penetrating abilities;

- Possibility of use at low temperatures.

Bitumen primer “TechnoNIKOL No. 3” has a number of advantages:

- wide scope of use;

- the polymers that make up the primer significantly improve its properties;

- provides reliable protection against corrosion;

- reliable to use as it provides maximum grip;

- dries within five minutes;

- easy to use;

- Can be used in winter.

Emulsion primer “TechnoNIKOL” is different:

- the presence of a water base;

- possibility of application indoors;

- absence of solvents;

- fire safety;

- speed of application;

- at an affordable price.

Features of applying the TechnoNIKOL primer

1. Before starting work, you should clean the surface on which the primer will be applied.

2. Determine the type of primer; if it is a ready-made mixture, then you just need to mix it. If using a concentrate, dilute it with kerosene, gasoline or other organic solvent.

3. Using a nylon brush or roller, apply primer to the surface.

4. If the material is intended to be used on a surface with a large area, it is possible to pour the primer and level it with a rubber squeegee.

5. If the primer is applied to a vertical surface, use a spray bottle to apply it.

6. Before applying the material, you should read the instructions and find out its drying time. After the primer has dried, proceed with roofing or waterproofing work.

Bituminous mastic for surface insulation

When using a primer as a primer, it is advisable to waterproof the surface with mastic, which can be applied cold or hot.

The material is sold in construction stores, and its cost depends on the components and additives included in its composition. The cheapest is mastic, which must be heated before application - a hot-use material.

This method of arranging waterproofing was very popular until recently, until mastic, based on bitumen and solvent, ready for use, appeared. These compositions do not require heating before use and are applied with a brush or roller.

As soon as the solution hits the surface that needs to be insulated, the solvent begins to evaporate rapidly, and the bitumen hardens, forming a durable waterproofing film. If the purchased material is too viscous, or you purchased a concentrate, then you can dilute the composition with white spirit or a solvent recommended by the mastic manufacturer.

Make your own mastic

Even with a small construction budget, you should not neglect waterproofing - the durability of the structure depends on it. There is no money for ready-made mastic, it’s okay, you can make it at home with your own hands. How to do it:

- Prepare the ingredients: plasticizer, bitumen, filler. The material is purchased in the required quantity depending on how much waterproofing material you need. Let's look at an example of preparing 10 kilograms of mastic, for this you will need:

- 8.5 kg – bitumen;

- 0.5 kg – plasticizer.

1 kg – filler;

The filler for mastic can be rubber chips, sawdust or mineral wool. To make the material plastic, you need to add used engine oil or kerosene to it.

- The mastic is prepared in a large thick-walled container. Before putting it on the fire, you need to put bitumen, well crushed, and filler, the fraction of which should be fine.

The container should not be filled to the brim, since when melted, the bitumen greatly increases in volume.

- The mastic cooking temperature should be no more than 190 degrees, as the bitumen may begin to peel off, which will lead to damage to the material. The foam from the surface of the bitumen must be constantly removed and a plasticizer must be introduced in portions.

- The mastic is ready after all the components are introduced into the bitumen.

The composition, prepared independently, is not stored for a long time - only a day. As soon as the mastic has cooled to 120 degrees, it can be applied to the surface.

How to make your own primer

A material such as a bitumen-based primer can be prepared with your own hands. To prepare the composition you need to take three parts gasoline and one part bitumen.

Removing bitumen

Treating them with white spirit, turpentine or any other organic solvent helps to wash off the remnants of bitumen or bitumen-polymer primer from tools.

A simple tip - on the container with the primer you can see the composition and list of liquids with which it is recommended to dilute it, if required by the application technology. These compounds are recommended for removal.

If you need to clean accidentally formed smudges or splashes of bitumen from the surface, then the sooner you tackle this issue, the better - fresh stains can be cleaned without the use of chemicals. For example, you can remove bitumen primer from concrete or cement screed with a scraper or other sharp, flat tool.

Removing old bitumen stains is possible using special gel compositions, which can be applied to most types of bitumen primers without damaging the surface.

What is the difference between bitumen primer and bitumen mastic?

Is it possible to replace one composition with another? A very similar set of components and appearance sometimes mislead the inexperienced consumer. Both liquids are dark, viscous, and are produced on the basis of bitumen, which acts as a binder with the addition of polymers and minerals. Both products are used at the waterproofing stage, however, they have a different set of basic characteristics and, accordingly, different purposes.

A primer is a multi-component primer that improves adhesion with a subsequent layer of waterproofing, penetrating deeply into the base and improving its water-repellent properties. Priming is also often used for anti-corrosion surface treatment. The primer can be used in the cold season, with high humidity; it dries faster than mastic, on average 2-4 times.

The main task of the primer is to ensure the absolute waterproofness of the preparatory layer, filling all the unevenness and cracks of the base.

Mastic is a composition with a wider range of applications, the main of which are: direct waterproofing of surfaces made of concrete, reinforced concrete, metal or wood, gluing tiles or roofing felt on the roof, insulation of swimming pools and wells. Mastic should only be used on a completely dry base in warm weather.

Ideally, both products are used sequentially, first priming the building surface, then waterproofing with mastic, thus providing reliable protection against moisture and corrosion.

Technology for performing bitumen waterproofing of foundations

Work on installing waterproofing with bitumen compounds is carried out in several stages:

1) preparation of the base;

2) applying a primer for the foundation;

3) applying bitumen mastic.

Preparing the base.

At the initial stage of work, the surface of the foundation is cleaned of various types of contaminants (debris, dirt, dust) and the technical condition of the concrete base is assessed.

If there are a large number of holes, chips and bubbles, the surface should be smoothed using fine-grained cement mortar.

It is also necessary to make a smooth transition at the junction of the horizontal and vertical parts of the supporting structure.

The main criterion for the readiness of the foundation for applying waterproofing is the level of humidity.

The surface of the base must be as dry as possible, otherwise, the formation of blisters or complete peeling of the waterproofing layer is possible.

You can check the readiness of the foundation for applying waterproofing using one simple method: place a 1x1 m piece of polyethylene film on the surface and if condensation does not form under the film over the next 24 hours, then you can proceed to the next stage of work.

Primer application

. The foundation surfaces are treated with a primer to increase adhesion. The primer is applied using a roller or brush. To treat the base of the foundation, it is enough to apply the primer in one layer; the abutments should be treated twice.

Application of bitumen mastic.

The mastic is applied after the primer layer has dried. Bitumen waterproofing of the foundation involves the use of bitumen solutions or emulsions, asphalt or bitumen-polymer mastics.

The foundation is treated with bitumen mastic in several layers, the number of which depends on the depth of the supporting structure. If the foundation is laid underground to a depth of 2 m, the mastic is applied in 2 layers, at a depth of over 2 meters and up to 5 - in 3-4.

Applying a new layer begins after the previous one has dried. The drying speed depends on the type of waterproofing material, temperature and air humidity.

The waterproofing material is applied from the bottom up, starting from the base of the foundation and ending at a height of 150-200 mm from the ground surface.

Depending on the consistency of the mastic, the waterproofing material is applied using a roller, brush, spatula or spray. It is important to maintain the same layer thickness at all points of the surface being treated and to avoid gaps.

When installing bitumen waterproofing in particularly vulnerable areas of the foundation, such as abutments, cold seams and interfaces, a reinforcing layer is provided.

Reinforcement of waterproofing is carried out using fiberglass materials, which are laid in designated areas when applying the first layer of mastic.

Primer / primer “Acryl Primer”

- Decorative plaster

- Venetian plaster

- Textured plaster

- Decorative paint

Acryl Primer is a special composition for final preparation for the application of decorative plasters, putties or paints. Serves to increase adhesion (sticking of the material to the surface), as well as reduce the water absorption capacity of the base. Acryl Primer is made on an acrylic base and is used before applying thin-layer decorative materials. This can be bark beetle plaster, fur coat, structural paint, textured putty and other materials. Apply to pre-plastered concrete or brick bases, gas silicate blocks, plasterboard and particle boards. Also used in facade insulation systems. It is tinted according to various catalogs, for example; NCS, Monicolor, Ral and others. You can buy Acryl Primer, white or tinted to match the finish coat, in our office, or by leaving an online application on the Plaster website.

Why use Acryl Primer

[Video] Attempts to save budget when finishing the facade are a fairly common and quite appropriate occurrence at the final stage of construction. Unfortunately, it is very common to see people abandon Acryl Primer because of its high cost and use a regular deep penetration primer. However, this is the most wrong decision. Acryl Primer is a subbase that neutralizes the effect of water absorption of the base. This is necessary so that the natural composition of the plaster does not lose the liquid required for normal crystallization. The second reason not to give up Acryl Primer is that if your workers suddenly made a mistake, for example, they left a bald spot, then when it dries you won’t notice it, thanks to the tinting to match the color of the plaster. If you use a regular primer, the bald spot will be noticeable and will differ in color from the general facade.

The technology for applying Acryl Primer is somewhat different from the standard one - apply the primer to a previously prepared surface in an even layer, like paint, without streaks, stripes or bald spots. Allow the primer to dry for 12 to 24 hours, then decorative plasters can be applied. Soil consumption – 200 grams/m2.

You can buy decorative primer Acryl Primer, white or tinted in the color you need, in the quantity you require, on the Plaster Internet portal by filling out the application form. Acryl Primer

always available in our sales office. We do not recommend using Acryl Primer under plasters, putties and paints from other manufacturers, because This is a deviation from regulated technology.

Tips for use

These recommendations were compiled by the manufacturer and professional builders.

- Before work, it is necessary to clean the surface on which the primer will be applied from dirt and dust.

- The concentrate should be diluted in proportions of 1: 1.5 or 1: 2. Recommended solvents are indicated on each product: from gasoline and kerosene to toluene and white spirit.

- Primers should not be applied with a foam roller, as the solvents contained in the product will destroy this material.

- Before starting work, the primer should be mixed, using a low-speed drill using a special attachment.

- The maximum application thickness is from 0.5 to 1.5 mm depending on the selected product.

- When working with primer on vertical surfaces, it is recommended to use a spray bottle; on large horizontal areas, the method of spilling and leveling using a rubber mop is allowed.

- The product can be used after the expiration date, but it is worth considering that its quality and physical and mechanical characteristics will sharply decrease.

- It is advisable to work in equipment or just gloves and goggles to avoid unpleasant consequences.

By following all safety and application rules, the work will be completed quickly, efficiently and efficiently.

In the next video, watch the presentation of TechnoNIKOL waterproofing primers.

How to work with primer - instructions for use

Work on applying bitumen primer begins with surface preparation. They should be cleared of dirt, snow, debris, and significant delamination of building materials should be removed. The composition will impregnate and stick together some amount of debris and dust, but this increases the consumption of material.

The humidity of the treated surface is of great importance for reliable adhesion of bituminous soil - it should not exceed 4%.

A primer based on bitumen has excellent waterproofing characteristics.

Bitumen does not allow water to pass through, and after applying the composition, excess moisture will have nowhere to evaporate. Therefore, in order to prevent the bitumen coating from peeling off, surfaces that are too wet need to be dried or the weather suitable for the work must be selected - a warm sunny day. The only exceptions are water-based mixtures, where during operation humidity levels of the treated surface are allowed up to 8%.

Application of bitumen mixture

Before use, the primer is thoroughly mixed. If necessary, the composition can be diluted with suitable solvents to the desired consistency.

The application technology is similar to the painting process. The composition can be applied with a paint roller, brush or spray gun. For horizontal planes, the pouring method is sometimes used: the mixture is simply poured from a bucket and distributed over the surface with a rubber mop.

Attention! Manufacturers indicate more detailed instructions on the technology for applying bitumen mixtures on the packaging for each specific type of soil.

Drying time varies slightly depending on ambient temperature. You can check this by lightly touching the treated surface - the completely dried composition does not stick to your fingers at all.