Do you want to cover your home with metal panels, but you don't have enough information? We will tell you which materials from which manufacturers are on the market, which metal and protective coating is best to choose, and we will not forget to show interesting solutions that you can adopt.

Figure 1. Metal facade panels

Corrugated Metal Siding

Corrugated metal siding, originally used for its durability and strength, has grown into a staple product for both residential and commercial projects. Since metal panels (facade cassettes) can be created in a wide range of colors, the subtle waves of corrugated wall panel can create different shades of color throughout the day. Combined with a relatively simple installation process, this aesthetic appeal has made corrugated panels very popular in modern, traditional and rustic designs.

A simple reason for the popularity of this type of metal panels is their durability. The natural shape of a corrugated metal panel gives it a design advantage over a flat panel made of the same base material. In addition, continuous corrugation helps hide small imperfections over time from weather conditions or impacts. For these reasons, corrugated metal systems have been used everywhere for many years.

Metal panels for facades have many undeniable advantages, such as:

- reliable protection of insulation and walls from negative atmospheric influences;

- maintaining the dew point inside the insulation so that the load-bearing wall remains dry, without freezing in winter and not overheating in summer;

- prevention of moisture accumulation in the insulation due to the presence of a ventilation gap;

- light weight, when reconstructing buildings there is no need for major repairs of walls;

- installation is quite simple and can be performed at any time of the year, because... “wet” processes are excluded;

- noise protection, creating an acoustic buffer effect;

- cyclic thermal deformations are structurally excluded;

- low cost of the entire facade system as a whole;

- fire safety;

- very long service life (more than 30 years);

Vertical metal siding

Metal wall panels (facade cassettes) provide the ability to vertically align each panel to create attractive exterior lines. Using traditional panels or more modern ones, living spaces are provided with a variety of designs. A popular option in commercial, residential and agricultural applications, vertically controlled metal siding provides clean lines and can help draw attention to key features of a build.

The most common use for metal siding is to run it vertically. The choice between credential and horizontal siding comes down to visual appeal. Vertical siding creates the traditional look of tall, clean lines while making spaces appear larger than they actually are. Although vertical siding can be a little more difficult to install, the end result will be worth it.

Design

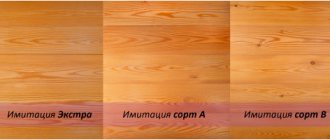

In addition to differences in the material from which façade panels are made, they can differ in surface topography.

- Smooth. Regular steel panels that differ only in color. They can repeat the wood pattern, make up one large picture from fragments, or be coated with gloss, creating a mirror effect.

- Corrugated. Curved with a soft wave or hard angular protrusions.

- Perforated. They come in a variety of patterns: from geometric to individual, custom-made patterns. In the dark, such panels transmit the light emanating from the building and create a bizarre picture, embodying all sorts of designer ideas.

- With additional decorative ribs. Depending on the distance between such ribs, you can visually expand the facade or make it higher.

When finishing industrial and public premises, cassette panels are usually used.

There are several types of such panels.

- Cassettes are three-dimensional panels consisting of aluminum sheet or steel coated with polymer coating. Such a cassette has a bend at the edges and is manufactured not only in factories, but also directly at construction sites due to the simplicity of the design. Most often they have a square shape and a smooth surface.

- Linear – elongated panels for exterior and interior decoration. Due to this design, the facade is mounted with a minimum number of gaps at the joints or without gaps at all. Linear designs are similar to long cassettes, but can have a perforated or 3D surface.

Despite the variety of materials, most facades are faced with sandwich panels made from several layers of different materials. The simplest products have three layers: two facing layers (metal, wood board or other materials) and one layer of filler (most often this is insulation).

Horizontal metal siding

Horizontally aligned panels are currently very popular in modern commercial projects and are also a traditional siding option in residential projects. Horizontally executed wall panels (facade cassettes) are often used due to their ability to be used over long lengths, creating a seamless line along the length of the building.

The choice between horizontal and vertical siding often comes down to visual appeal. Vertical siding offers a unique look, while traditionally horizontal siding is considered easier to install. With horizontal metal siding, you can achieve both a traditional and modern look for your home. With so many panel options, you can now create a unique or modern look by choosing the panel rather than deciding the direction in which it runs.

Methods for applying perforation to aluminum sheet

Aluminum panels with through slots in the form of ornaments are used for the production of facade panels - screens, for decorating facades over translucent glazing or for decorating opaque surfaces, as well as for creating media facades. Moreover, any shapes are possible, the only limitation is that the area of the cuts should be no more than 55% of the total surface area, otherwise the aluminum panels cannot withstand wind loads, bend and break.

Cutting is performed in a single sheet using different methods depending on the batch size:

- Small batches are cut out using a cutter on a special cutting plotter, according to the same principle as volumetric letters;

- For single aluminum sheets, laser cutting can be used for small batches, giving excellent precision and repeatability of the design. The disadvantage of this method is its high cost;

- For the production of large batches over 1000 sq. m. You can use a perforating press.

Rustic Siding Options

Whether you're building a mountain cabin or want a country-style design, use a combination of metal siding with wood and exposed metal panel fasteners.

For many years, metal siding has been used in finishing private and country houses. The most popular panel styles have traditionally been corrugated siding, or barn panel siding. Colors play an important factor in achieving the rustic appearance of siding. As a more traditional alternative to painted metals, many people choose rust-proof steel siding to create an aged appearance on the side of their home.

Review of manufacturers

The production of metal panels can be either manual (directly on site) or professional (in large factories). Products from foreign suppliers are represented by various companies, among which there are several brands that have received the best reviews: Finnish metal panels of the Ruukki brand (on the construction market for more than 50 years), American siding from Alcoa, made mainly of aluminum, as well as the British-Dutch brand Corus Group.

Among domestic manufacturers we can name façade panels of the Grand Line brand. The products of the Lipetsk roll forming equipment plant and the INSI holding are widely represented on the market. The products also received positive ratings from customers. The main difference between Russian manufacturers is that, with the same quality, domestic products have a lower price than foreign ones. This difference is due to the lack of transportation costs.

Rusty metal siding

A popular option, flat and corrugated panels are very attractive for residential and commercial buildings. Choosing the right panel can make rust metal siding the focal point of the entire project.

While rusty metal siding can be an interesting and attractive accent to your building design, before applying such panels it is important to determine if the site is suitable for a building with a rusty surface. Designed to naturally rust and protect the inner layers of steel, the steel is not recommended in areas with high humidity or within 100 meters of the sea. You can use this material in these areas, but the rusting process will be significantly accelerated.

Tips for choosing panels

In order for the facade finishing to be of high quality and attractive, it is necessary to follow certain recommendations for selection:

- Study the characteristics carefully. The quality of heat and sound absorption, as well as resistance to aggressive external influences, depends on the right choice.

- Take into account the weight of the panels, since if you install it yourself, heavy elements will be difficult to install without the involvement of equipment.

- Choose a harmonious color. It is important that the finish fits into the surrounding environment and also suits the architectural style.

It is important to ask the manufacturer for the accompanying documentation, since this is a guarantee of quality, as well as assistance in installation, since the manufacturer provides its recommendations for installation.

Calculation of materials for facade cladding

To calculate the number and dimensions of metal cassettes, it is necessary to create a facade cladding project. This service is offered by all manufacturers and stores selling finishing materials. If it is not possible to contact a specialist, you can make an independent calculation based on the proposed instructions.

To calculate the cladding, you can use the simplest formulas

Step 1. Using a tape measure, measure the length and height of walls, window and door openings. Measure the distances between the corners of the wall and the openings located on it, between the openings. Record the obtained values.

Step 2. Calculate the area of walls, window and door openings by multiplying their length by width. Record the obtained values.

Step 3. From the area of each wall, subtract the area of the openings that are located on it. As a result, you should get 4 numbers that need to be added to get the total area of the space to be covered.

Step 4. At this stage, you need to find the optimal length and width of the metal cassettes. The calculation is carried out on the basis that solid panels should be installed on the walls, without trimming. It is important to consider the width of the corner profile shelves. If necessary, metal studs can be used to close gaps.

Material consumption standards for the construction of a ventilated facade made of metal cassettes

In order to simplify the calculation of the amount of materials, it is recommended to find out in advance the sizes of metal cassettes and additional elements that can be purchased in a given locality.

Drawing up a subsystem diagram

Based on the calculations obtained at the previous stage, a diagram of the supporting frame is drawn up. It should indicate the mounting points for the brackets to the wall. Take into account that each metal cassette has corresponding holes for fixing to the subsystem. When drawing up a diagram, they are guided by the distance between these holes.

It is important to consider the type of metal cassette. If a panel with an open fastening is used, the shelves of adjacent products will overlap each other. The distance between the horizontal sheathing profiles is determined based on the height (length) of the metal cassette.

Frame for metal cassettes

Example

The distance between the holes on the metal cassette shelves is 53 cm. The length of the wall from corner to corner is 9 m 60 cm. 18 panels should be installed along the horizontal line. We multiply 53 cm by 18, we get 954 cm. Subtract 954 cm (total length of the panels) from 960 cm (wall length), we get 6 cm.

This gap will be closed with corner profiles, the width of the shelves is 5 cm. Since we need to close only 6 cm, and the total width of the shelves of the corner profile installed on both corners of the house is 10 cm, the corner profile will go into the places where the metal cassettes are attached. In this way, the required structural integrity will be achieved.

The length of each metal cassette is 535 cm. The distance between the holes in the shelves is 530 cm. The height of the wall from the base to the roof is 310 cm. 6 metal cassettes must be installed vertically, the total length of which will be 318 cm. The extra 8 cm will need to be cut off and the cut covered with a finishing strip.

Shape of perforated holes

Perforation creates holes of various shapes.

Often we are talking about round, rectangular, rhombic, square, elliptical or oval holes. Moreover, it is round holes that make up about 80% of the total quantity of all perforated products. This is explained quite simply. After all, this format is a universal solution for arranging facades of any type and geometry. And from an economical point of view, creating round holes requires the least labor and financial costs. The matrix for placing the holes themselves in the façade cassettes is also different. Moreover, there are no strict standards in this aspect. And when ordering, you don’t have to be limited to standard options. The implementation of an individual sketch will be just as simple and hassle-free.

Structure of a ventilated façade

To install metal cassettes yourself, you need to know about the design features of ventilated facades. All manufacturers of materials for exterior finishing of buildings also offer subsystems for their installation. In some cases, the cladding technology is called “NVF” (hinged ventilated façade). To better understand the information, you need to understand that an NVF and a “ventilated façade” are one and the same.

Detailed installation diagram of facade cassettes

This system of exterior finishing of buildings is the most practical, as it allows for high-quality thermal insulation and ventilation. Main elements of illegal armed groups:

- bearing wall;

- thermal insulation layer;

- brackets that are necessary for fastening the facing material;

- facing material (in this case, metal cassettes).

Installation diagram

The finishing material performs two functions: it ensures the aesthetic appeal of the architectural appearance of the building and protects the heat insulator from the adverse effects of the external environment.

The principle of operation of a ventilated facade

The difference in temperature inside and outside the premises ensures the creation of a heat flow directed from the inside to the outside (air tends to move from a warm point in the environment to a cold one). On its way, the air flow overcomes an obstacle in the form of a wall and an illegal armed formation.

Heat exchange diagram of a wall with a ventilated facade

As it passes through these materials, it heats them to varying degrees. The closer the material is to the outer surface of the facade, the lower its temperature. Since air is the best heat accumulator, the ventilation gap of the NVF ensures a higher temperature of the outer layer of the facade than that of the environment. Average: the cladding temperature is 1-3°C higher.

As a result, cold air, coming into contact with the air force, heats up and rushes upward. In this way, a continuous air flow is created along the wall of the house, the average speed of which is 0.5 m/s.

Through the gaps in the cladding and the lower vents, fresh air enters the NVF, which guarantees the evaporation of moisture. Passing along the wall from bottom to top, the air flow leaves the façade, carrying the vapors with it.

Ventilated facades, diagram

It is important to know: brackets play a special role in heat transfer. If they are made of a material with high thermal conductivity, heat loss reaches 10-15%. To compensate, a thicker layer of thermal insulation material must be laid. Therefore, when choosing brackets, you need to pay attention to what they are made of. Aluminum (including anodized aluminum) has the highest thermal conductivity coefficient. The optimal choice is steel and alloys.

Table of materials required for installation of a ventilated facade made of metal cassettes

| Name of material | Unit Dimensions (cm) |

| U-shaped profile | Width 6.5 length 300 |

| L-shaped profile | Length 300 |

| Z-profile | Length 300 |

| Vertical crossbar strip | Length 200 |

| Horizontal seam strip | Length 200 |

| External corner | Length 200 |

| Internal corner | Length 200 |

| Brackets | 35x22x8 |

| Klyammer | |

| EDPM tape | |

| Self-tapping screws | |

| Disc dowels | |

| Anchors | |

| Thermal insulation material | |

| Metal cassettes |

Profiles for installation

Subsystem configuration

Installation of closed metal cassettes

Installation of panels is carried out in the direction from bottom to top. Work begins from the left corner of the building.

Step 1. Before installing the cassettes, remove the protective film from the sides of each panel.

Step 2 . Place the lower part of the panel behind the starting bar so that a characteristic click is heard.

Installation of the first row

Step 3. The upper shelf of the metal cassette is attached to the vertical profiles using self-tapping screws.

Installation of the second row

Step 4 . The lower protrusion of the next panel is hooked onto the upper shelf of the already installed one, and the cassette is lifted up.

Step 5. Attach the panel to the metal profile.

Checking installed metal cassettes with a level

Step 6. Slopes are installed along the perimeter of window and door openings.

Video - Installation of window frames

Step 7. Continue installing metal cassettes in the direction from bottom to top and from left to right. To close the gaps, jointing strips are used, which are a U-shaped narrow panel, the recess of which is inserted into the gap between the lines of metal cassettes. The side flanges of the crossbar are attached to the profile using self-tapping screws, the heads of which are painted in the color of the facing material.

Step 8. If necessary, the top panels are trimmed.

Step 9. Attach the finishing strip to the top of the wall.

Step 10. After finishing the cladding of two adjacent walls, install corner profiles.

Prices for popular electric drill models

Electric drills

Installation of open-type metal cassettes is carried out in a similar way, but in any convenient direction. The installation of these panels is much simpler, since the connection of the shelves does not require snapping into each other.