Hello friends! This week I was looking for a sealant for drywall: in Gossnab, Prorabe, Domostroy, Repair of RU, Zenit - I couldn’t find it. Inkoststroy had a tape, but the width was 27, and I have a guide profile - 75. I found a way out of the situation, bought an insulating material - teploflex, in some offices it is called isoflex, I took it 3 mm thick. I compared the composition of the material with the tape, the same polyurethane foam, only the tape is lubricated with a self-adhesive compound for ease of fastening to the profile. While I was looking for the necessary information, I collected a bunch of materials about sealing tape for drywall. You will need it if you decide to create a metal frame for drywall. In this article I will tell you where it is used, what types of sealing tape there are - damper and separating, subtleties and nuances when working.

Sealing tape for drywall profiles is a special material used when creating a metal frame for drywall, as well as when sealing gypsum board joints. It has its own varieties and distinctive properties.

Sealing tape for drywall

Advantages

The main advantages of sealing tape for drywall are the following facts:

- good noise, steam and sound insulation;

- vibration damping;

- lack of water absorption;

- temperature stability;

- elimination of various surface roughnesses;

Sealing tape - resistance to all kinds of negative manifestations;

- the existence of construction allowances that help the structure not to deform when the geometry of the frame walls changes.

All of these properties are achieved due to the flexible, soft texture of the material. The positive side is the ease of operation when sealing joints. The price range ranges from 75 to 1500 rubles.

Advantages

The tape is made of an elastic material with an adhesive base, so it is convenient to use and installation does not take much time.

Advantages of this material:

- good sound insulation;

- does not absorb water, which means it does not damage the sheet of drywall;

- elasticity and low weight of polyethylene, ease of installation;

- resistance to fungus, alkalis and acids;

- resistance to temperature changes;

- environmental friendliness;

- durability.

The most popular on the Russian market are Knauf Dichtungsband noise-absorbing sealing tapes, EUROBAND PES and Sound Guard products.

Types of sealing tape

There are a large number of sealing agents on the construction market, which differ in their structure and purpose. Almost all types of tape have the only common property - on one side there is an adhesive layer designed to fix the material to the base. This layer of adhesive is protected by paper, which must be removed before use.

The tape and its application can be divided into:

- for rough finishing - damper;

Sealing tape for drywall damping - for sealing joints between plasterboard sheets - reinforcing;

Sealing tape for plasterboard reinforcing - for separation - sliding joints.

Sealing tape for drywall sliding joints

Before you start decorating your apartment or office, you need to figure out where and which types of drywall sealants are used.

Characteristics of sealing damper tape

This type is made from polyethylene foam material. On one side there is a sticky layer for gluing. It is easily applied to metal elements used to create a frame for drywall and is firmly fixed. This tape has advantages:

Damper sealing tape

- is a noise absorber;

- When using tape during installation, the metal profile does not come into contact with the concrete base, which prevents the occurrence of condensation and oxidation;

- absorption of vibration arising from neighbors above or from construction (other) work on the street.

If vibration of structures occurs, the use of the material prevents cracks from appearing on the drywall.

Watch the video: using sealing tape.

Sealant is not always used when working with drywall, but it is advisable to use it.

Using profiles for other purposes

Each type of plasterboard profile has its own purpose. Sometimes a ceiling profile is used instead of a rack profile, this leads to the fact that the partition structure turns out to be fragile. In addition, this is associated with difficulties in work, since sheets cannot be attached to the ceiling profile on both sides. It is not recommended to bend profiles, cut or change their geometry.

This error is due to the fact that the use of ceiling profiles is allowed when covering walls or when creating boxes for shelves, a fireplace or a TV.

Ceiling profile partition.

Read more about the types of profiles for fastening drywall in the article “Profile for drywall: a brief educational program”

Application

By following the correct technology for using a damper seal in repair work, it will create additional protection for the plasterboard structure from harmful influences.

The sealing material should be glued to the side of the mounted profiles to the rough surface. For convenience, you should have a cutting knife on hand. Since the tape has a layer of glue, it is quite easy to fix it on the profile.

The cost on the construction market ranges from 157 rubles. up to 400 rub. per roll.

Drywall damping tape

Characteristics of reinforcing tape

Reinforcing tape is a specially created material for strengthening drywall joints. It performs the important function of fastening gypsum board joints, which gives a durable structure. Subsequently, there are no cracks or deformations of the ceiling or plasterboard walls. There are several types of reinforced tape:

- serpyanka – self-adhesive

reinforcing tape with a composition similar to a synthetic bandage. Used to seal joints in plasterboard sheets; - perforated paper - used manufactured by KNAUF, distinguished by its strength and quality of functions. Thanks to the perforation, the tape does not gather like an accordion during installation, air bubbles do not collect under it, and has excellent air-permeability properties, which is important for a plasterboard product;

Sealing tape for plasterboard KNAUF - bandage - is a durable fiberglass material made from non-woven material. It is attached with a “raw” putty solution to the joints. Has the same properties as serpyanka.

Sealing tape for drywall bandage

The use of reinforcing tape is mandatory when finishing drywall, since it strengthens the created structure and prevents further impacts on the structure.

Application

The installation of reinforcing material is required depending on its type. Self-adhesive is applied and fixed easier than paper or non-woven tape.

Watch the video: laying reinforcing tape at a gypsum board joint.

Installation of KNAUF paper is carried out in stages:

- preparation of joints - it is required that the plasterboard joints have a chamfer. If it is not there, then you should use a construction knife to carefully make cuts on the edges of the drywall at 45 degrees, 5 mm deep;

- chamfered joints should be cleaned of dust and plaster stones;

- Using a brush, cover the seam well and thoroughly with the primer mixture. Let dry;

- after this, the Knauf Uniflot putty solution is diluted (considered by the masters to be one of the best mixtures), according to the table on the bag;

- Cover the seam with a thin layer of putty. A paper tape is applied evenly to the wet putty and pressed with a spatula so that the edges are firmly fixed in the putty. Excess solution comes out and remains on the spatula. They can be used to seal fasteners.

Installation of KNAUF paper - After drying, the tape should be covered with a second layer of putty. When dry, remove all excess pieces from the finished joint with sandpaper.

The cheapest of this series is serpyanka - the price is 50 rubles, the most expensive - “Knauf” non-woven fabric costs 190 rubles. Paper tape can be bought for 70 and 95 rubles.

Separator tape

The separation seal creates a sliding joint between the gypsum board and parts of the building so that cracks do not appear at the points of contact with another surface. Used in those houses where there is a lot of shrinkage. During shrinkage, the biggest problem is the appearance of cracks. The tape prevents this from happening.

Drywall release tape

Application

The strip should be glued between the edge of the drywall and the structural element of the building. However, it is worth saying that such strips are rarely used and are extremely difficult to find on sale.

A roll with a Knauf dividing strip costs approximately 900 rubles.

Tape for sealing joints in drywall plays an important role in the installation of structures. To get an excellent result, you must definitely use sealing tape. This will help increase the service life of the model and achieve good quality of the product.

Application of sealing tape for drywall

To use a plasterboard product for many years, you should carefully and carefully create the frame base, not lose sight of the small nuances that arise during the work, be precise and prudent. The use of tapes is an important point in the process of creating a suspended ceiling or false wall. When creating a plasterboard tabletop or fireplace, you do not need to neglect sickle tape or sealing tape. It protects the product from deformation.

Which is better: heated floors or radiators?

Warm floorBatteries

Video selection: using different types of drywall tapes and profiles.

source: //gipsokarton-blog.ru/instrument-i-materialy/lenta-uplotnitelnaya-dlya-gipsokartona.html

Sealing tape

in construction and repair work it refers to component materials for drywall along with such elements as various profiles, lintels, hangers, connectors, screws, etc. It's easy to use. It is necessarily used for tightly sealing seams between sheets and for fastening metal profiles and mounted partitions to load-bearing walls and ceilings.

Compactor roll

Supplied in the form of rolls of building material with dimensions:

- strip width from 3 to 95 mm (if necessary, rolls of other widths can be purchased upon request);

- thickness 2-4 mm;

- length from 30 m.

Installation of the door frame

The frame for the opening is made in two versions:

- In a regular PS rack profile, reinforced with a wooden beam, which is placed in the middle of the profile.

- Using a special UP profile, the metal thickness of which is 2 mm.

Doorway frame

Usually the first option is used by amateurs. In this case, the PS profile is attached to the floor and ceiling to conventional PN profiles with an opening 20 mm wider than the door frame. A wooden block 50 mm x 50 mm is inserted into it. The beam is also inserted into the upper lintel, which is also 20 mm higher than the doorway. The door frame is attached to the frame with ordinary wood screws through a metal profile into a wooden beam.

In the second and technologically correct option, special profiles with a metal thickness of 2 mm are used. This is a reinforced profile and is designed to withstand the loads of doors. They are also mounted in the opening under the door frame with a gap of 20 mm in width and height. But they are fastened to the floor and ceiling using special connecting metal corners 2 mm thick.

Fastening the corner to the floor and ceiling using the usual dowel-nail pattern. The profile should be fastened to the corner only with special bolts with nuts and washers, which are included in the kit. The transverse jumper can be made from a regular PS profile. It is necessary to insert a wooden beam into it to secure the door frame, but it would be more correct to install it from the UP profile.

Types and brief characteristics of sealing tapes

Before we begin finishing work on the interior decoration of apartments and offices, we will understand what types of sealing tapes exist and for what work they are preferable to use.

Reinforced tape

- Reinforcing. It is a fiberglass self-adhesive mesh. The tape is used to strengthen building structures. Used to eliminate cracks and various defects. Width starts from 100 mm;

Serpyanka (construction bandage)

- Serpyanka. This is a self-adhesive reinforcing tape, whose structure resembles a bandage in appearance, and consists of synthetic fiber. It is used to seal the joint seam between plasterboard sheets. Available in 5 cm width;

Installation using bandage tape

- Bandage (non-woven). This is a thin, durable fiberglass material that is attached to a wet putty solution at the joints of the sheets. Prevents chips and cracks in sheet joints;

Perforated paper tape

- Perforated paper. This type is recommended to be used specifically for fastening gypsum board sheets, since paper tape and drywall are similar materials in composition. An exception is the case when it is necessary to connect multilayer sheets of plasterboard. A roll of paper sealing strip is produced 5 cm wide;

Example of damper tape installation

- Damper. Made of polyurethane foam, either with one adhesive side and a protective film, or without an adhesive layer, and 30-50 mm thick. Due to this composition, it has soundproofing and water-repellent properties. Used to prevent the formation of cracks that occur due to vibrations of load-bearing structures;

Corner protection with metal liner

- Corner protection with metal liner. Its device is a five-centimeter perforated paper strip with two centimeter strips of galvanized steel. It protects the outer corners of drywall from chipping and deformation.

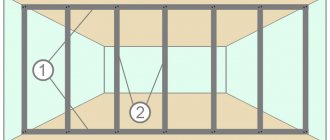

Installation of wall sheathing

There is almost always a debate about what to do with an uneven wall - plaster it or it is easier to build a frame from metal profiles and then cover it with gypsum and putty. If the sheathing wins the dispute, then the work ahead is as follows:

- We mark the floor and ceiling, stepping back the required distance from the wall, so as not to take away excess space from the room. We connect the marked risks with lines using a painter's cord. Along the lines we begin fastening PNP profiles, that is, ceiling guides. Why this profile, because with it we can win space. Don't forget to put soundproofing tape on the bottom of the profile. We fasten it with 6 mm x 40 dowels. If we attach it to wood, for example in the ceiling, then we drill it with wood screws.

- We attach straight hangers to the wall, which are used for wall and ceiling profiles with a pitch of 600 mm.

- We install PP profiles into PNP profiles, i.e. ceiling ones, because the guide profile is intended only for this size with a thickness of 27 mm. You can build the sheathing from 50 mm wide profiles from PN and PS, but this will not be economical and will take up excess space from the room. We install in increments of 400 mm or 600 mm.

- We attach straight hangers to the sidewalls of the PP profiles and secure them with fleas. The size of the step depends on the thickness of the wall - it will be sewn into one sheet of drywall or two. The profiles are fastened to each other using small screws, popularly called fleas. But it is also possible to fasten it using a cutter by making holes in the places where the profiles are double connected.

- If the height of the wall is higher than 2400, the length of the gypsum board sheet, then it is necessary to install horizontal jumpers at the joints of the plasterboard sheets. The lintels are made from the same PP profiles in each span. Using metal scissors, cut mustaches on narrow shelves at an angle of 90 degrees. These mustaches are used to attach the profile jumpers to the racks using the same fleas. It should be taken into account that the gypsum board sheets are attached in a checkerboard pattern. This makes it possible to obtain a rigid and reliable structure, therefore the jumpers must be arranged for such a system.

Ready-made sheathing for fastening drywall

Conditions for using sealing tape

The sealing tape is simple and durable to use if the technology for repair and construction work is followed.

List of necessary tools for sealing joints:

- level or plumb line;

- spatulas (preferably two for different types of joints - one wide, the other narrow);

- construction knife for cutting chamfers;

- primer brush;

- sandpaper (or other sanding tool).

First of all, it is necessary to ensure the necessary heat and humidity microclimate in the room where work is being carried out. To do this, before drywall work, it is necessary to complete the plastering work, laying the screed on the floor and all structures must dry. So, for high-quality installation, the temperature in the room must be maintained at least 10 degrees Celsius and there must be no drafts.

Conditions for using sealing tape

Before gluing the sealing tape, all work on installing and fastening gypsum board sheets to the frame must be carried out efficiently, since “walking” sheets cannot be fastened with a sealant. The screw heads must be flush with the surface of the plasterboard structures.

Selection and installation procedure:

- first you need to decide what functions this material should perform (only as sealing the joints of drywall sheets or, for example, also as sound insulation), read the installation instructions;

- prepare the surface for gluing - plaster, degrease and dry the metal profile, clean off dust, apply chamfers for better adhesion, if they were not there initially;

- select the seal according to the width of the profile, unwind it before directly gluing it and remove the protective film.

- Apply putty into the seam gap. The putty must be mixed well until it has a homogeneous consistency, so that cracks do not appear later. Press the adhesive side firmly onto the seam, gap or profile without pulling;

- putty tape is applied exactly in the center of the seam, and the remaining putty is removed with a spatula;

- then level the surface with a top coat of putty and sand.

source: //gipsohouse.ru/questions/943-uplotnitelnaya-lenta-dlya-profilya-gipsokartona.html

Drywall is convenient and practical. The only difficulty is the need to carefully seal the seams between the sheets. Reinforced tape is suitable for these purposes.

Several types of this building material have their own characteristics and advantages. So, the separating tape for plasterboard sheets has good soundproofing properties; it is glued to the junction of the plasterboard wall and the load-bearing wall.

Serpyanka, which is a synthetic fiber intended for subsequent application of a layer of putty, hides the joints.

The best damper tapes in the middle price segment

SoundGuard 211222

Compared to other top participants, it stands out due to its material of manufacture. The company abandoned the classic option and opted for environmentally friendly polyester fibers. In addition to them, jute is observed in the composition. This product is focused on metal profiles for the frame and cladding with supporting structures at the points of contact, absorbing vibrations. In addition, the tape acts as a lining when installing wooden joists, beams and base flooring made of boards.

It consists of an elastic layer of randomly intertwined polyester fiber, which is evenly distributed over the entire surface.

SoundGuard 211222

Advantages:

- environmentally friendly material;

- high sound insulation properties;

- tightness;

- vibration damping qualities.

Flaws:

- narrow specialization (combined with wooden floors).

MaxForte 150 mm

Chemically cross-linked polyethylene foam eliminates structural noise, and also compacts and levels out unevenness in the floor and connecting wall. Due to its cellular structure, it acts as a good sound insulator and absorbs expansion caused by temperature fluctuations.

MaxForte 150 mm

Advantages:

- does not lose elasticity within the range from - 80 to + 100C;

- long-term storage will not lead to loss of properties;

- modulus of elasticity Unit: 0.17 MPa at a load of 2 kPa;

- moisture resistance;

- light weight;

- easy installation.

Flaws:

- thickness only 3 mm;

- short roll length (30m).

KNAUF FE 40m 0.1m 8mm

The product is a double tape made of elasticized polystyrene foam and polyethylene film. It reduces the likelihood of the screed cracking as it dries and gains strength. Absorbs the pressure exerted on it and reduces the noise level. The FE prefix notifies that the width has increased to 8 mm (standard 6 mm). Aprons speed up installation, since there is no need to add separating layers to the walls.

KNAUF FE 40m 0.1m 8mm

Advantages:

- durability;

- versatility (suitable for heated floors and interior work in residential and public buildings);

- The polyethylene apron simplifies installation.

Flaws:

- no self-adhesive layer.

Why do you need reinforcing tape?

Drywall tape with metal inserts is used to protect the corners of plasterboard sheets from Knauf or any other manufacturer. The use of such material prevents accidental damage to the sheets.

The main advantage that Knauf offers in this product is its high adhesion, due to which it easily sticks to any type of drywall.

In addition, experienced builders and complete beginners purchase Kurt reinforcing tape. Compared to other materials, Knauf tape is convenient, and labor costs when using it are minimal.

After using the reinforcing tape, you can easily begin painting or wallpapering; the surface is smooth and even.

In addition to convenience, reinforcing tape is used if you do not want to get cracks at the joints of sheets some time after completion of the work.

Types of reinforcing tape

Several types of such tape:

- The first is self-adhesive - easy to use;

- The second, ordinary one, is made from fiberglass and is characterized by increased strength.

They buy any and select them depending on the type of work. Kurt tapes are available in rolls ranging from fifty to one hundred meters in length.

But in any case, the tape is secured with gypsum plaster or starting putty is used for these purposes. To prepare them, use a mixer to knead the composition to the desired condition, make it homogeneous and moderately thick.

A simple type of tape is serpyanka. The reinforcing strip is solid - this is already a plus. If you tear the Knauf tape, you can see that it has long fibers; such material can withstand the load and will last a long time.

The reinforcing option is easy to install and does not leave any unevenness on the surface, which will come in handy if the sheet of drywall remains to be finished with a finishing layer.

Even a beginner will not have problems with installation. The process is simple and does not require special skills or experience in similar work.

No matter how the tape is used, it is difficult to lay it in such a way that waves appear. This has a positive effect on the final appearance of the finished plasterboard wall.

How to choose?

There is a wide assortment on the shelves. It is so huge that it can cause stupor in an unprepared beginner. Knowing certain nuances will greatly facilitate the task and minimize the risk of purchasing a product that does not meet certain requirements.

- Decide on the width. It is chosen based on a simple rule, which takes into account the thickness of the multi-layer structure of the floor. The rise above the surface is 10-15 mm.

- Material. The basis of a quality product is polyethylene foam raw materials. The choice is due to the fact that it is neutral to all chemicals, practically does not burn, is environmentally friendly and has a closed cellular structure. It will provide full heat and sound insulation, and will not deteriorate when exposed to direct sunlight.

- Examine the condition of the packaging. Distributed in rolls, which are usually packaged in sealed boxes. Less often in films. Dents and holes indicate violation of recommendations for storage and transportation of goods. It's better not to take it.

- External data. The canvas is clean, without visible defects.

- Density. There should be no gaps or voids! The presence indicates possible problems with the sticky surface.

- Studying the winding density will reveal possible unwinding of the tape from the coil.

- The cut line is perfect and without flaws. Roughness and unevenness indicate a fake.

- When purchasing self-adhesive options, pay attention to the adhesive surface. Delaminations are strictly excluded.

- Purchase only from verified and certified stores and market outlets. This reduces the risk of running into a fake. Since the damper tape is quite vulnerable to forgery. Anyone can download and print the information insert. And the damper itself is cut, at best, from a rolled substrate, which does not completely correspond to the declared characteristics. To avoid this type of problem, it is not recommended to buy from other people or from untrusted places. If in doubt, immediately request a certificate of quality and conformity of the product from the seller.

Laying rules

Knauf reinforced is applicable in work where maximum strength is achieved, as well as when putties based on artificial resins are used. A similar material is also used for sealing horizontal joints.

- Before starting work, dilute a small amount of putty, then apply the prepared mixture to the joints. When finished, glue the reinforcing fabric onto the applied layer.

- For better adhesion, slightly moisten the glued strip.

Gluing strips

- The strip is laid on the applied solution, but with the condition that the center is on the line of connection of the plasterboard sheets.

A simple method is to glue one side of the strip and then slowly glue the remaining length. The ideal solution is to hold the already fixed end with one hand and continue gluing and leveling with the other using a spatula.

- After the strip is completely pasted, check the quality of work and remove excess solution.

If everything is done according to the instructions and correctly, then the strip will lie exactly at the joint of the plasterboard sheets and will not protrude above the surface, or, conversely, will fall into the seam.

Before starting gluing, complete all wet repair and construction work. The fact is that Knauf reinforced tape, like any other, does not hold well if the room is humid.

Do not use this material for fixing drywall sheets if they are loosely secured. This use of tape will not eliminate the defect; the only solution in this case is to re-fix the drywall with high quality and only then use Kurt tape.

At the stage of installation of the frame, no attachments were made for hanging things

If you plan to use drywall in finishing work, then you need to immediately think about hanging heavy things, because to secure them inside the frame you need to make embedded parts from wood or plywood. Embeds are a reliable guarantee that a TV or shelf will not fall off the wall.

An example of using mortgages to install a TV.

Subtleties and nuances when working

It is not necessary to use tape for small cracks and joints, even if the gap is wide or long, tape is used. The only caveat is that it is overlapped (its width is 3-5 cm). After the plaster has dried, treat the surface with finishing putty, which is used specifically for painting (or use another mixture whose main task is to prepare the surface).

If the edges of the sheathing of Knauf plasterboard sheets, which are adjacent to the enclosing structures, are glued, Kurt dividing tape is better suited, which is suitable for most sheets, including KGL, GKLO, GKLV, etc.

The separation tape offered on the market today is suitable for working with walls and ceilings. It is distinguished by a convenient width (about 65 mm and a length sufficient for any type of work - 50 meters). The reinforced tape is easily applied to sheets installed as walls and to ceiling coverings.

If you need to properly seal the cracks and joints between sheets of Knauf plasterboard, then the best solution is to purchase reinforced tape from the same manufacturer. The use of this material will ensure high quality of the finished surface and compliance with Knauf technology.

source: //gipsohouse.ru/materials/6654-armiruyushhaya-lenta-dlya-gipsokartona.html

The gypsum board itself (plasterboard sheet) is the result of the genius of human thought. It’s difficult to put into words how much it speeds up and facilitates the process of finishing the premises. This material, durable and reliable, always perfectly smooth and easy to use, rightfully occupies first place in the finishing materials market.

Sealing tape for drywall, subtleties and nuances when working

Drywall is successfully used for leveling surfaces, creating unusual arches, multi-level ceilings, partitions, full partitions between rooms, decorative niches and other works.

In order to work with this material, you don’t need to be a genius; it is simple and easy to use, and components such as, for example, sealing tape for gypsum plasterboard profiles and slab joints, special profiles and connectors make working with it convenient , and the result is impressive in its accuracy. Not to mention the huge financial benefits, if you compare the leveling of walls with gypsum board and plaster - the first is always cheaper, and the result, as a rule, cannot be distinguished from the outside. There is only one thing that gives drywall indoors: always perfectly flat surfaces, as if drawn with a ruler.

One of the necessary materials for the work is a special tape, which is used to effectively insulate frame elements, as well as tape for sealing joints of gypsum board slabs. Let's talk about them in detail.

Insulating and sealing tape

Conventionally, all tape for drywall profiles is divided into tape used for rough finishing work, and tape that is used at earlier stages. This type is called sealing

drywall tape.

Insulating and sealing tapes

Sealing

The tape allows you to suppress the occurrence of noise from contacts between the metal profile, drywall and the wall.

This tape is designed to provide the following conditions for the further operation of products made with its use:

- Suppression of noise resulting from contact of the metal frame of a gypsum plasterboard structure directly with the base surfaces of the room, which can lead to vibrations, hum, rattling and other unpleasant sounds.

- Protection of the entire structure from vibrations and shifts resulting from slight changes in the geometry of the base planes due to increased vibration loads on the structure where the structure is installed, or due to seasonal climate changes. In other words, to protect supporting surfaces from heat shrinkage.

- In cases where partitions are constructed from double reinforcing elements between these elements to prevent the formation of condensation and improve the thermal insulation properties of the finished product.

- At the corner joints of slabs located in damp rooms, for additional protection from moisture penetration.

KNAUF insulating and sealing tapes

There are several types of such tape , which can be divided into the following basic classes depending on their area of application:

- High density tape, self-adhesive

. Used for gluing the guide profile before installation on the base surface. Serves to reduce the noise of the structure, as well as to protect against vibrations. - Medium density tape - used for laying between the profile and gypsum board sheets in places where it may be required, and for internal insulation of structures.

The use of tape with sound-proofing and heat-insulating properties is typical for luxury facilities, but can also be used for mid-budget finishing work.

It is important to remember that the use of this insulator provides the following undeniable advantages, which, at relatively low costs at the installation stage, will pay for themselves many times over during further operation:

- Reduced noise levels. The frame of walls, arches and other plasterboard structures is made of galvanized steel profiles, regardless of whether filler is used for the inter-wall space, metal is a rather loud material, and if it is not muffled with insulating tapes, the wall will hum, resonate, rattle and generally bring discomfort to residents.

- The seal provides the necessary construction allowances, which means that in the event of a slight change in the geometry of the base walls, the frame, and therefore the entire structure, is not deformed.

- Thermal insulation properties. Metal is a good conductor of both heat and cold. Not insulated from external walls, it can draw heat out of the room and, conversely, conduct cold into it.

KNAUF insulating tape

As can be understood from the above, sealing tape for gypsum plasterboard profiles plays an important role in the overall design of plasterboard structures. You should not ignore its use in order to get a good, high-quality and durable result.

Ceiling frame installation

The ceiling is assembled from PP and PNP profiles. First, markings are made on the walls. The best way to do this is with a laser level. But, if there is no such thing, you can work with a water spirit level. The next step is to install it according to the markings of the PNP profile using dowels along the entire contour of the room (dowel pitch 500 mm). Don't forget to attach the soundproofing tape to the profile shelf. The next step will be to install PP profiles into PNP profiles with a pitch of 600 mm and attach them to the suspension systems. There are two options here:

- Using direct hangers, as in the case of installing sheathing. But this option is possible if the space in the section between the frame and the base ceiling is no more than 200 mm.

- If the distance is less, then it is necessary to use a hanging anchor to fasten the profiles through the crab-anchor system. This system consists of:

- Cross-shaped connector for PP profiles (popularly called crab).

- Anchor suspension for quick installation.

- Double connecting piece for wire with loop.

- Wire with loop

This system allows you to make a ceiling frame with a clearance of up to 1500 mm.

Jumpers with a pitch of 600 mm from the same profile are attached to solid PP profiles and installed at the joint in crabs and secured to them with metal-to-metal screws. After the work has been done over the entire area of the room, you can begin installing the gypsum board. This is how the frame for a single-level ceiling is prepared.

Frame for installing plasterboard on the ceiling

The technology for manufacturing walls, ceilings and partitions from plasterboard on a metal frame makes it possible to implement both simple plans and very complex designs.

Finishing tape

Many people think that there is only tape for drywall profiles, but in fact there are many more options, all of them are widely represented on the market, for example the so-called “serpyanka”. And if you work with the specified material every day or just want every element to be in its place, you need to know about all the options presented not only for sealing joints, but also for finishing work:

- Serpyanka. This tape is in first place for a reason. Indeed, in terms of the area of application and the amount of tape that is spent during repairs, it is the leader of the list. This tape has one purpose: sealing the joints of sheets in the longitudinal plane of the work.

Serpyanka is the most popular type of tape used when working with drywall.

Finishing tape for drywall

Method of operation. In advance, before installation on the frame begins, the edges of the sheets are cut with a special gypsum board plane or a painting knife at an angle of forty-five degrees. The sheets are sewn onto the frame staggered so that the joint lines are not in one line, leaving a gap between them of three to five millimeters. After sheathing, the joints of the slabs are puttied with starting putty, then, without waiting for the material to dry, they are glued on top along the seam with serpyanka and sealed with a layer of finishing putty.

This finishing method allows you to obtain a smooth surface in the future.

- Reinforcing tape. It looks almost the same as serpyanka tape, only it has increased density and larger sizes. This tape is used to strengthen some elements built with plasterboard, for example, on the bends of figured arches. Features an increased safety margin; Before giving the tape the desired shape, it is recommended to soak it a little in hot water.

Reinforcing tape for drywall

Reinforcing tape is similar to sickle tape, but has a greater density and size.

- Ribbon made of thick paper with perforation. Used in the same places as reinforcing tape. It differs from it in that it does not require pre-soaking and grips drywall well, since it itself is made of thick paper.

- To seal joints, fiberglass tape is also used; it is mounted on a damp layer of starting putty and leveled with a spatula.

- Tape reinforced with metal corner. Used at corners to provide additional rigidity to the structure.

These tapes must be used regularly if you want your work to look great and last for a long time.

Assembling a metal frame for a suspended ceiling in stages

The first stage of work is project development. Even if you are planning a simple single-level ceiling frame made from a plasterboard profile, it is worth drawing the sheathing on paper, to the correct scale. This is the only way to calculate the exact number of required elements. Especially when the layout is more complex than the following example (3 * 4 m room, located perpendicular to the window wall):

- PN (27 * 28 * 3000 mm) – 5 pcs;

- PS (27 * 60 * 4000 mm) – 10 pcs;

- “Crabs” - 26 pcs;

- Straight hangers – 54 pcs;

- Dowel-nails 6 * 40 mm – 150 pcs;

- Self-tapping screws for metal, sharp 3.2 * 13 mm – 350 pcs.

Dowels and screws often fail during installation or turn out to be defective. Therefore, they are purchased with a reserve of 10–30%. Pendants are a universal element, so their supply (10%) will not be superfluous. Most likely, it will not be possible to buy the exact quantity of metal profiles due to the length being a multiple of 3 or 4 meters. Therefore, they are also brought in more than needed.

Drywall, as a rule, is placed so that the longitudinal joints “run along the light,” that is, perpendicular to the window. The transverse joints are shifted by 60 cm. This serves two purposes. Firstly, they “get into the grid” with a cell of 60 * 60 cm, and secondly, they eliminate the formation of long joints “across the light”.

The dimensions of the gypsum board are 1200 * 2500 mm, and the dimensions of the mesh cells are 600 * 600 mm. Therefore, the sheets are trimmed, leaving 1200 * 2400 mm, or the “squareness” of the outer cells is sacrificed, making their size 600 * 700 mm.

Drawing the wireframe

Before making a frame from a drywall profile, you need to draw a work plan. Drawing begins with the “tapping” of the level, in our case, the horizon. The most convenient way is to use a laser building level. When it is turned on, a horizontal line is visible on the walls, located at an arbitrary height from the floor. In the corners of the walls, along this line, mark with a pencil. They are then transferred to the desired height using a tape measure.

To connect the marks, use a “beating” paint cord, into the body of which colored chalk is poured. It is difficult to perform this procedure alone, but it is possible by screwing the end of the cord to the wall - at the level of the mark. Then, stretching the cord to the end of the wall and pulling it to the height of the second mark, a “click” is made. As a result, the chalk leaves a noticeable mark along which the guide profile will be screwed.

In addition to the laser level, hydraulic and bubble levels are used. They give approximately the same results, but have their own advantages and disadvantages.

Having drawn the “directions”, they place Fr. Solid products are usually installed along long longitudinal plasterboard seams. Therefore, they start from the window or the opposite wall, marking every 60 cm from the corner. Then they place marks on the remaining two walls, also starting from the corner. It should be remembered that the size of the outermost (for the sheet) cells is 60 * 70 cm.

Many installers draw a frame made from a metal profile under plasterboard on the base ceiling in order to immediately attach the hangers. However, this is not necessary, especially since sometimes during the installation process you have to move something and change the diagram. However, attaching guide profiles and hangers is the dirtiest and noisiest part of the job. Therefore, it is advisable to do it all at once.

Installation of hangers and guides

If a decision is made to secure hangers at an early stage of work, their location is marked on the base base. In our case - on the surface of the interfloor ceiling. Technologically correct placement - on each rack profile, every 40 - 60 cm. The displacement associated with the installation of “crabs” and jumpers should be taken into account. Holes are drilled about the profiles and the spaces between the hangers, nailing these elements with dowel nails.

They make frame lintels for drywall on the wall from the profile. Essentially, jumpers are pieces of a stand that form two (or one, if the cell is extreme) sides of a grid cell. As a rule, their length is 52 – 53 cm, and they are fixed using “crabs”. It is advisable to “hang” each jumper. Especially those that will become the basis for the gypsum board joint. The more suspensions, the more reliable the design will be.

It is advisable for two people to secure the guides, although an experienced installer can easily do it alone. Assembling a frame from a drywall profile can be a difficult task for one person with minimal repair experience.

The profile is held along the line and “drilled”, immediately driving in the dowel-nails. To make it smoother, fixation should begin from the edges. Then they “drill” the center, and then the rest of the nails, every 40-50 cm. A total of 6-8 holes are required per metal profile.

Having secured one “stick”, the next one is mounted end-to-end with the first one. The important point is their connection. In order to maintain a straight line, the metal profiles are connected with a piece of the same “guide”, 20-30 cm long, inserting it into the nailed “sticks”. These “extensions” can then be removed. It is not necessary to connect the guides to each other at the corners, but it is advisable. For this, metal screws are used.

Installation and adjustment of the rack profile

Having a reliable horizontal frame and screwed hangers, you can begin installing the racks, without which not a single installation of a frame made from a profile for plasterboard is complete. To level the plane, fix the cord by pulling it between the walls perpendicular to the window. Screw the cord to the underside of the “guide” with a metal screw, roughly dividing the room into 3-4 parts.

- The stand is slipped under the cord, and its ends are inserted into opposite “guides”, “centered” along the drawn marks. One - central - metal profile will be enough for a start.

- To prevent it from pulling the lace down, the middle is raised above the thread by 5-10 mm and temporarily fixed with a suspension. The remaining hangers are attached to the profile, placing it 1-2 mm above the cord. When all the fastenings have been made, the middle is unscrewed and fixed again - “catching” the level along the thread. As a result, the central rack metal profile is “perfectly” adjusted relative to the guides. For control, you can use the building level and the “rule” (a trapezoidal paint strip taken as a standard). A deviation from the level within 1 mm per 1 m of surface is considered acceptable.

- Installation of the remaining racks of the wall frame from the plasterboard profile is now simplified. After all, you don’t have to look at the lace, using a “rule” or a profile placed on the edge for control. One end of the “rule” is pressed from below to the “guide”, and the other - to the adjusted stand.

- The remaining racks are fixed with hangers, guided by the “rule”.

- Looking at the drawing, install the “crabs” without screwing them in first.

- Jumpers, cut in advance or along the way, are inserted into the “crabs”.

- The jumpers are “suspended”.

- Screw 8 metal screws into each “crab”. Sometimes they are passed “through one”, saving screws, but this should not be done.

- As a rule, a control check is carried out “for the sake of the soul”, because hardly anyone will redo anything. The “rule” or stand, turned edgewise, is applied to the sheathing at different angles.

The worst thing is when making a frame from a profile for plasterboard leads to the appearance of significant bumps. Theoretically, you can try to hit the frame in those places where the “rule” swings, but it’s better to partially touch it. If a hole is found, you should not pull the sheathing down - the reliability of the fastenings will be impaired. It will be easier to then level it with plaster (on drywall).