If the owners of an apartment in an apartment building decide to make repairs that may affect the walls, then they should definitely become familiar with the question of how to work with load-bearing walls in the room. After all, a load-bearing wall is an important element responsible for the reliability of the entire structure, therefore there are certain safety rules that stipulate what types of construction work are permissible to perform on a given surface and what are not. What a load-bearing wall is and how to calculate it in different houses will be discussed further.

What is a load-bearing wall

Load-bearing walls include those surfaces onto which the weight of the higher part of the structure is transferred; these include floor slabs, other walls, and beams. In some buildings, the load-bearing elements are not walls, but columns and beams.

Therefore, if it was decided to redevelop the building, it is so important to accurately determine the location of the load-bearing surface. After all, the safety of the residents of the apartment, as well as all the residents of this house, will be in great question. Thus, making changes without approval from the authorities is fraught with serious consequences. In addition to the long running around to legitimize the finished redevelopment, one should not forget about the possibility of making changes that could lead to destructive actions in relation to the building.

The owner of the apartment cannot know what changes were made by the owners of other apartments; only the BTI authorities know this, where all the changes are indicated, and they can say for sure whether it is possible to make any other changes to each specific load-bearing wall or not.

Load-bearing walls include those surfaces onto which the weight of the higher part of the structure is transferred.

For this reason, any replanning begins with the following steps:

- inviting BTI workers to the apartment so that they indicate the design of which walls can be changed;

- It is better to legitimize changes in the layout of the premises in advance, then it will require less time and effort;

- Also, to make it easier to plan the repair yourself, you can independently determine the location of the load-bearing surfaces. Accordingly, the project can be prepared in advance, and official representatives will only document and confirm the possibility of carrying out the work.

It is better to legitimize changes in the layout of the premises in advance, then it will require less time and effort.

Requirements for load-bearing structures:

- they are necessarily distinguished by their strength and reliability, because they are responsible for the durability of a large number of building elements;

- fire safety refers to their properties;

- meet other safety requirements;

- In addition to pressure from above, there is pressure on them and on the sides; all these factors are taken into account when restructuring the surface in a living room.

Load-bearing walls are elements of a building that are subject to strong pressure, so their thickness is greater than that of other types of walls, which are responsible only for their own weight. This indicator differs from the type of house, materials used during construction work, it is determined by standards, so this factor makes it easier to determine which wall is load-bearing.

Standards, including those prescribed in SNIP. And it is according to them that organizations carrying out construction are guided; if they are not observed, the building will not be allowed to be delivered, and the relevant documents will not be drawn up.

In many cases, it is better to do without affecting this surface, and create a project according to which changes will be made on non-load-bearing walls.

But each type of house has its own characteristics.

Load-bearing walls are elements of a building that are subject to strong pressure, so their thickness is greater than that of other types of walls.

Essential characteristics of any wall materials

Before we begin to consider the characteristics and features of the use of the most popular materials belonging to the groups presented above, it is worth noting that for any wall of the house, regardless of the materials used and design features, there are a number of mandatory functions and requirements:

- Structural strength . This criterion is one of the most important, since for several decades the walls must bear the load not only of their own weight, but also the weight of the roof and ceilings, communications and engineering units, and interior decoration of the premises. That is why all erected walls must have a certain margin of safety. To build the walls of the house we are considering, you need to focus on the strength of the material, which does not exceed 150 kg/cm2 .

- Minimizing loads on the foundation . This parameter is no less important than the previous one, since neglecting this factor can lead to the destruction of the entire building or to a significant increase in the cost of the zero cycle.

- Thermal resistance . This factor characterizes the thermal comfort indicator indoors. It directly depends on the thermal conductivity of the wall material and their thickness. For the material of the walls of our house, we can focus on the value of 2.5 m2 K/W .

- Water absorption . The ability of a particular material to absorb and retain moisture is determined precisely by this criterion, which characterizes the percentage ratio of the mass of water absorbed by the wall to the mass of dry matter of this wall. The water absorption of wall materials used for the construction of the house we are considering should be in the range from 6% to 15% .

- Fire resistance . This criterion characterizes the ability of walls to limit the spread of flame.

- Frost resistance . This parameter characterizes the ability of wall materials and various structural elements to withstand alternate freezing and thawing. Most modern building materials have a frost resistance coefficient of 25-35 cycles. This value fully satisfies the requirements for the construction of the walls of our house. Experts do not recommend using materials with a frost resistance coefficient of less than 15 cycles, since in this case it is necessary to carry out additional processing that will prevent the penetration of moisture from the facade.

How to find out where the load-bearing wall is in an apartment

Determining the location of the wall responsible for the reliability of the structure is allowed in a number of ways. The first option is to look at the floor plan, it is requested from the capital construction department.

Every homeowner has a technical passport of their home, but if a person does not have knowledge of construction issues, then it will be difficult for him to understand the drawings, and this document is unlikely to help him.

More convenient and easier, to a certain extent, methods are recognizing the load-bearing surface by the thickness and location of the walls. To distinguish a load-bearing surface from a non-load-bearing one, you first need to get rid of all surface finishing, right down to removing the plaster layer. Having eliminated excess layers from the surface, proceed to measuring its thickness. But each material has different width indicators:

- brick walls have a minimum thickness of three hundred and eighty millimeters when it comes to the load-bearing side;

- a house made of panels is distinguished by the presence of many foundation walls, having a thickness of one hundred and forty millimeters. It should be noted right away that changing the walls of such a house is permissible only in rare cases;

- monolithic buildings have a load-bearing structure index of twenty centimeters.

This method is quite complicated, for this reason you can request data from the person responsible for building a house floor plan, which will simplify the task.

To distinguish a load-bearing surface from a non-load-bearing one, you first need to get rid of all surface finishing, right down to removing the plaster layer.

According to their location, such walls are built in certain parts:

- all surfaces that are external are responsible for the strength of the house, and of course, are considered load-bearing;

- overlapping surfaces between 2 adjacent rooms also belong to this category of walls;

- all surfaces facing the landing belong to the foundation walls.

All surfaces that are external are responsible for the strength of the house, and of course, are considered load-bearing.

Having determined that the wall where you plan to make changes is load-bearing, you need to understand whether the planned actions are permissible. Such structures cannot be demolished; usually, niches and openings can be created in them.

But here it is also forbidden to do anything, the number of changes is limited and there are subtleties in creating them. It is not recommended to carry out such repair work on your own; you should contact a specialist. Without this, they may simply refuse to remodel the room. Which will lead to danger to life, because then no one will give a guarantee that the work was carried out correctly. Also, the sale of such an apartment will become impossible.

If the project involves demolition of part of the surface, then it is absolutely impossible to do without a professional. At the same time, he must have the appropriate permits; all other activities will be illegal.

A specialist will be able to properly strengthen the surface so that it stands firmly and does not collapse in the future.

Such structures cannot be demolished; usually, niches and openings can be created in them.

Option No. 1: wooden walls

The most widely used materials belonging to this group are the following:

- Log.

- Beam (simple and profiled).

- Glued laminated timber.

The construction market does not stand still. New building materials appear with enviable frequency. However, despite all the newfangled trends, houses made of logs and beams not only have not lost their popularity, but are also becoming increasingly relevant. Wood used to build walls has a number of advantages. Durability, strength, light weight, ease of processing - this is not a complete list of the advantages of this building material.

The technology of construction of modern wooden houses is greatly influenced by the emergence of the latest technologies and equipment. Solid wood is practically no longer used. It was replaced by a wooden beam, which is a log hewn from all sides. It is the preliminary processing of the logs that ensures their almost perfect fit to each other. This technology helps improve the quality of housing and reduce construction costs.

However, construction logs used for the construction of walls have their own advantages:

- Strength.

- Ease of construction.

- Natural beauty.

- Environmentally friendly.

- Ease of machining.

The ability to ignite quickly, the need for additional processing to prevent rotting and uneven drying are the main disadvantages that characterize the use of construction logs.

Houses built from wooden beams (simple, profiled or glued) have a number of general advantages:

- Reduced costs (compared to the use of other building materials).

- Fast home assembly. The two-story house (150-200 m2) described at the beginning of the article can be assembled in two to three months.

- Creation and preservation of a special indoor microclimate.

- Multiple design options.

- Ecological cleanliness.

- Low thermal conductivity. An unheated house warms up completely in just a couple of hours and retains 6 times more heat than a brick house, and about 1.5-2 times than a foam concrete house.

- Resistance to deformation.

- Ability to remove excess moisture.

- Excellent frost resistance. Houses can last more than a hundred years.

- High strength and elasticity.

- Virtually no interior or exterior finishing is required (especially for houses made of profiled and laminated timber).

- Aesthetic appearance.

In addition, houses built from simple, profiled or laminated timber have a number of individual features and advantages. So, to build walls from a simple wooden beam, you can use a columnar foundation or “floating columns”.

Profiled timber ensures increased durability of the building, high solidity, excellent steam and air permeability, ease and speed of house assembly, and maximum environmental friendliness. The low weight of the timber can significantly reduce the load on the foundation, and the low cost of the material (about 2-3 times cheaper than laminated veneer lumber) and the aesthetics of the building sometimes tip the scales in favor of profiled timber.

Houses built from laminated veneer lumber are characterized by high strength, improved thermal insulation and higher (compared to natural wood) fire resistance. The advantages of laminated veneer lumber include a fairly short construction period and, of course, the natural beauty of the wood and its texture.

Walls made of wooden beams, like those made of other materials, also have their disadvantages:

- Anisotropy of wood. This indicator characterizes the heterogeneity of strength, vapor conductivity, thermal conductivity and other properties depending on the direction of the wood fibers.

- Limitation of use depending on ambient temperature. Thus, houses made of laminated veneer lumber are not recommended to be used in conditions of prolonged heating above 35°C, all others - above 50°C. A temperature of 35°C is not typical for the temperate climate zone (which is where our house is conventionally located), but in recent years it has not been such a rare occurrence. This fact makes us think once again about the use of laminated veneer lumber.

- Possibility of cracks (except for laminated timber). To be fair, it is worth noting that this drawback is quite easily eliminated by rubbing with special mastics.

- The need to use additional finishing materials when using simple timber. This will prevent moisture from getting into the space between the beams.

Thus, houses and walls made of wood quite successfully combine excellent consumer qualities and a relatively low price, and the environmental friendliness and beauty of this material cannot be overestimated. That is why wooden buildings continue to be erected for many centuries, despite the advent of modern building and finishing materials.

How to find out which wall is load-bearing in a panel house

Panel houses are distinguished by the fact that they have special design codes, which can be used to understand how they were built. There are special databases in which, knowing the code, you can find a house plan and the required apartment, where it will be indicated which wall is load-bearing in it.

You can also find such a wall by measuring the thickness of surfaces. Non-load-bearing walls in panel houses usually have eighty millimeter or meter walls. And the underlying surface of interest has a thickness of one hundred and forty to two hundred millimeters.

If you decided to check the thickness of the wall before removing the finishing coating, then it can affect the obtained indicators; they take about fifty millimeters.

Demolition of a wall in a house made of panels is guaranteed to lead to the collapse of the structure.

You can find such a wall by measuring the thickness of the surfaces.

Brick walls with insulation from thermal insulation panels

Characteristic

Brick walls with insulation from heat-insulating panels (Fig. 19) consist of a load-bearing part - masonry, the thickness of which is determined only from the conditions of the strength and stability of the wall, and a heat-insulating part - foam concrete, gypsum or gypsum slag panels.

Advantages and disadvantages

Lightweight concrete stones, compared to ordinary bricks, have a lower volumetric weight and lower thermal conductivity, so the use of ceramic stones for the construction of external walls makes it possible to reduce their thickness. The disadvantage is that lightweight concrete stones with a lower volumetric weight have less strength and resistance to weathering.

Characteristic

Three-hollow stones with large voids have dimensions of 390x190x188 mm. In bonded rows, a bonded stone with a smooth end surface is used.

How to find out which wall is load-bearing in a brick house

It is worth finding such a surface in a house built of bricks in terms of thickness, given that between them there are layers of special mortar that secures them. The total thickness thus depends on the number of bricks stacked. And it can range from 120 centimeters to 380, although it can be thicker.

In this matter, only surfaces thicker than 380 centimeters are considered load-bearing; anything thinner does not apply to them.

It is more difficult to find a brick house in the database using the code, so you should not waste time on this; perhaps there is no house in the database at all.

In this matter, only surfaces thicker than 380 centimeters are considered load-bearing.

What are they?

The main distinguishing feature of self-supporting walls, in comparison with loaded ones, is that they have a small thickness. Accordingly, less material is used during their construction. The thickness of the walls of this type, depending on what they were built from, can range from 50-380 mm.

During the construction of the rear, among other things, non-load-bearing enclosing structures can also be assembled. Such walls also do not take the load from the elements of the house located above. In another way, structures of this type are called hinged. They are always built within the same floor. However, if their height exceeds 6 m, they can already be considered self-supporting. Their design and calculations are carried out accordingly.

How to find out which wall is load-bearing in a monolithic house

These premises are distinguished by their various structural options in architectural solutions. They may have load-bearing walls, as well as columns and beams.

If the wall surface is thicker than two hundred millimeters, this means that it is load-bearing. Columns are often much thicker than walls, but the main thing to understand is that any structure thicker than two hundred millimeters is considered a load-bearing structure.

In new monolithic houses, it is even easier to recognize such walls. To do this, you just need to look at them; all these surfaces in these houses are built from reinforced concrete. In addition, you can see the armholes treated with the solution.

In new monolithic houses, these surfaces are constructed from reinforced concrete.

How to find out which wall is load-bearing in a Khrushchev building

Khrushchev buildings have the same construction plan, so determining the required wall is easy. You just need to know that in such houses, load-bearing structures include all external walls, and inter-apartment surfaces, as well as surfaces facing the landing.

But, to be sure, you can also focus on the thickness; all surfaces on the inside that are thicker than one hundred and twenty millimeters are load-bearing surfaces.

Which walls can be demolished in a Khrushchev building, the answer is those that are thinner than this indicator can be eliminated. But it is not advisable to touch the dividing wall between the balcony and the room. After all, it was erected so that excess cold did not enter the room. Such a project will not receive permission from the authorities responsible for this issue.

Another way to note is the use of surface drilling; ordinary walls can be easily drilled, but load-bearing walls will be broken by drills.

Khrushchev buildings have the same construction plan, so determining the required wall is easy.

Option No. 2: walls made of blocks

The most popular and widespread are the following building materials belonging to this group:

- Cinder blocks.

- Foam blocks.

- Gas blocks.

- Sand-lime brick.

- Ceramic blocks.

- Arbolit.

Wall masonry made from a wide variety of blocks has become widely used and very popular. Walls built from one type of block or another have different physical properties and features inherent in the block filler material.

However, most buildings built from block building materials are characterized by excellent heat and sound insulation properties, increased fire and frost resistance, environmental friendliness, lightness, strength, durability, resistance to mold and mildew, and ease of processing. In this section we will dwell in detail on the advantages and disadvantages of various types of this building material.

Cinder blocks

Slag, which is the flux-containing components of waste rock, is the main filler of cinder blocks. A wide variety of materials can be used as building stone fillers: cement, expanded clay, cullet, broken brick and concrete, gravel, sand, granite screenings, crushed stone. Cement is the main binder of cinder blocks.

The main advantages of cinder blocks include the following:

- Low cost due to the low cost of the components used. As a result, the cost of masonry and construction of the entire house is significantly reduced.

- Easy to use. No special skills are required to build cinder block walls.

- Strength and durability.

- Fire resistance and frost resistance.

- Possibility of self-production.

- Low consumption of binder solution.

However, cinder blocks also have some disadvantages, among which are the following: poor sound insulation properties, high thermal conductivity, the need for double-sided plastering of walls and the difficulty of laying various communications.

Foam blocks

This type of building material is made from foam concrete, which is a type of cellular concrete. Cement mortar, sand, water and a foaming agent are used to make foam blocks. Foam block is an artificial porous stone that can float in water. A wall made of this material is able to “breathe”, creating an ideal indoor microclimate. Approximately the same microclimate is created in houses built from wood. However, foam blocks, unlike wood, do not rot or burn.

Advantages of foam blocks:

- Low specific gravity.

- Low hygroscopicity.

- Ease of processing.

- High durability.

- Environmentally friendly.

- Cheapness. Foam block is one of the cheapest materials.

- Good sound insulation.

- Cost-effective due to low weight. Thanks to this, you can significantly save on the construction of the foundation and the thickness of the plaster layer. Foam blocks can even be laid with glue.

- High fire resistance.

- Low shrinkage rate.

- High thermal insulation properties.

The only disadvantage of foam blocks is that the construction of walls is only possible using a frame method, and a synthetic foaming agent can enhance the hygroscopicity of concrete.

Gas blocks

This building material has unique characteristics and is becoming increasingly popular. It is aerated blocks that provide real competition to classic brick due to their natural origin and excellent performance qualities. Sand, lime, cement, water and aluminum powder are used to produce aerated blocks. Depending on the binder component used (lime or cement), a gas silicate or aerated concrete block can be obtained. Both types of gas blocks, due to their high porosity (up to 85%), have excellent performance properties inherent in both wood and stone:

- High strength.

- Ease of processing.

- Low thermal conductivity.

- High fire resistance and frost resistance.

- Excellent sound insulation properties.

- Excellent vapor permeability.

- Durability.

- Environmentally friendly.

- Ease.

- Resistance to fungi, bacteria and mold.

- Moisture resistance.

- Quick installation.

However, gas blocks also have a number of negative properties. In particular, additional cladding of external walls or protective plastering may be required; sound and heat insulation properties decrease with increasing density and strength. It is impossible to build high-rise buildings (more than 3 floors) from aerated concrete blocks. However, in our case (construction of a two-story house), this factor has absolutely no influence on the choice of material.

Sand-lime brick

This building material is made from sand, lime and some additives. Sand-lime brick is used for the construction of external and internal walls and for cladding. It is not recommended to use sand-lime brick in places with high humidity and for masonry that may be exposed to elevated temperatures. These features of the use of sand-lime brick are due to its ability to absorb moisture well and decompose hydrate components with a significant increase in temperature.

The main advantages of sand-lime brick include the following:

- Reliability and durability.

- Environmentally friendly.

- Resistance to the influence of aggressive factors.

- High fire resistance.

- Possibility of use for a wide variety of architectural solutions.

- High noise absorption coefficient.

However, sand-lime brick also has a number of negative properties that limit its use:

- Increased construction time and high labor intensity of work. This state of affairs is possible due to the small size of sand-lime brick.

- High ability to absorb moisture.

- Heavy weight. Sand-lime brick is one of the heaviest building materials.

- Low adhesion to cement mortar.

- Limited application (temperature and humidity).

Ceramic blocks

Ceramic blocks or “warm” ceramics are an environmentally friendly building material made from high-quality clay with the use of certain additives. Many builders use the expression “warm block” in their everyday life, which indicates one of the main characteristics of this material - ceramic blocks are distinguished by excellent thermal insulation qualities. In addition, these blocks have almost all the positive properties of ceramic bricks:

- Resistance to aggressive factors.

- High strength.

- Light weight.

- Environmentally friendly.

- Ease of processing.

- High adhesion achieved due to the corrugated surface of the blocks.

- Durability.

- Frost resistance.

- Excellent heat and sound insulation properties.

- Light load on the foundation.

- Optimal indoor microclimate.

- Reduced construction time (compared to brickwork).

- Saving mortar when laying.

Ceramic blocks have few disadvantages, but they do exist: high price, the need to plaster the walls to protect them from moisture, and fragility during transportation.

Arbolit

This building material is a type of lightweight concrete. To make it, a mixture of organic fillers (woodworking waste, fires, reeds, etc.), a binder and water is used. The mixture also contains some additives. For example, to accelerate the hardening of cement and mineralization of the aggregate, calcium chloride and alumina sulfate are added.

Arbolite very successfully combines the best qualities of stone and wood. This unique building material is characterized by excellent heat capacity (the thermal conductivity of wood concrete is 4-5 times lower than brick), high strength, and resistance to rotting. It is environmentally friendly and fireproof. A negative quality of wood concrete can be called high water absorption, which can be successfully overcome by creating a reliable protective coating.

The positive qualities of this unique material more than compensate for this drawback:

- Low thermal conductivity, which allows you to significantly save on heating your home during the heating season.

- Environmentally friendly.

- Plastic.

- Ease of processing.

- High strength.

- Low specific gravity.

- Fire safety.

In addition to the block building materials discussed above, you can use ceramic bricks, expanded clay blocks, twin blocks, gas silicate blocks, sand concrete blocks, polystyrene concrete and sawdust concrete blocks to build houses. These building materials have almost the same performance qualities as all block building materials.

How to distinguish a load-bearing wall from a non-load-bearing one

So, there are several methods that can be applied in certain cases, these include:

- Studying the documentation received from the BTI is not an easy process, given the fact that you need to have knowledge in this area, otherwise you can easily make a mistake. And in such a matter, a mistake can be fatal. It is better to turn to professionals;

- The tapping method has not been described previously; it involves determining the type of surface, focusing on the sound it produces when tapping on it. Of course, such a technique hardly meets the reliability parameter. After all, some walls, even not being load-bearing, can emit a sound similar to them;

- determining a wall by its thickness. We should not forget that finishing also makes adjustments to the thickness of the surface; the correct measurement will be the surface cleared of finishing materials. For each type of structure, which differs in the materials from which they are built, there are specific standards for the thickness of such surfaces. They are described above;

- drilling a wall to understand how thick the surface is, or even the material and its reaction, a drill can tell what type the surface is.

Of course, particular moments can also make adjustments to the correctness of the surface definition.

Drilling into a wall to understand how thick the surface is, or even the material.

Option No. 3: heterogeneous (multilayer) walls

Among the building materials belonging to this group, the following are most widespread:

- SIP panel.

- Permanent formwork.

- Multilayer heat blocks.

The materials listed above have a number of undeniable advantages, among which we can highlight such as a significant reduction in construction time, light weight, cost savings, excellent combination with other building materials, and long service life. Below we present in more detail the main performance qualities of each material separately.

SIP panel

A SIP panel is a structure that consists of two oriented strand boards or OSB, between which there is a layer of insulation glued under pressure - solid polystyrene foam. Expanded polystyrene has a number of excellent physical and performance properties.

It is resistant to aggressive environments, environmentally friendly, durable, and easy to use. This material is characterized by a low degree of thermal conductivity and vapor permeability.

Houses built from SIP panels have the following qualities:

- Strength.

- Durability.

- Energy efficiency.

- Relatively cheap.

- Beauty.

- Fire resistance.

- Environmentally friendly.

- Practicality.

In addition, houses made from this material are very quickly assembled. Thus, the two-story house with an area of 150-200 m2 discussed in this article can be assembled in 12-15 days on a prepared foundation, and the full construction cycle, including interior decoration, will take no more than three months.

The relative cheapness of constructing buildings from SIP panels is achieved due to the following factors:

- Inexpensive foundation.

- Short construction period.

- Simplicity of finishing work.

- No additional insulation is required.

- Significant savings on heating and home maintenance.

However, ideal building materials that have absolutely no disadvantages do not exist. SIP panels are no exception, the main disadvantages of which include the following: fire hazard, the need to use a ventilation system, and the possibility of rodents entering.

Permanent formwork

Permanent formwork consists of panels or blocks made of various materials that are mounted into a formwork structure. The use of permanent formwork can significantly speed up and simplify the construction process by combining several operations into one technological cycle.

The main advantages of using permanent formwork include:

- High speed of construction. For example, the box of the house discussed in this article can be erected in just a week.

- Light weight of blocks.

- Variation of architectural solutions.

- Low cost of material.

- High fire safety.

- Environmentally friendly.

- High strength.

- Excellent heat and sound insulation.

- Can be used in any climatic conditions and on any soil.

This material also has its drawbacks. The use of permanent formwork is characterized by the difficulty of compacting the concrete mixture and constructing door and window openings, the need to use protective finishing materials and install a grounded circuit that protects the building from lightning.

Multilayer heat blocks

Multilayer heat blocks are made using the injection method from expanded clay concrete and contain a thermal insulation liner made of expanded polystyrene. The decorative front surface, made of expanded clay concrete painted with iron oxide pigment, represents the third layer of this building material.

Multilayer heat blocks are practically free of disadvantages, but they have many advantages:

- High speed of construction.

- Significant cost savings.

- No additional heat and sound insulation is required.

- Excellent thermal efficiency.

- Durability.

- Aesthetic appearance.

- Environmentally friendly.

- Fire safety.

- Possibility to increase living space.

- Light weight.

Brisolite and insulated laminated veneer lumber, like the heterogeneous (multilayer) building materials discussed above, have found wide application in the construction of houses and have many similar physical and operational properties.

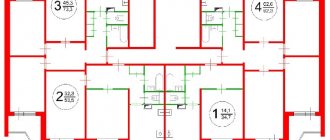

How a load-bearing wall is shown in plan

These walls can be designated completely differently in plan, which is why it is so difficult to identify them. This becomes a task that is difficult for a non-specialist to solve. This is especially true for old houses, when different developers could designate the walls at their discretion in the plan; there was no unified system. Most often they are indicated by shading, or a thicker line.

But since it is impossible to simply find out for sure whether a thickened or highlighted line indicates its relationship to the carrier, it is impossible to do without contacting the regulatory authorities. You can contact the BTI, where employees must provide clarification and explain which wall in the apartment is load-bearing, and whether changes can be made to its structure.

Sometimes an employee must come to the apartment for this. This is one of the best methods to know exactly what adjustments are allowed in a room.

And yet there will be a list of documents that can show the location of these walls:

- BTI technical passport, which details the materials used in the construction of the building, the location of room partitions (more precisely, the type of their designation), and all possible nuances of the design;

- a step-by-step plan, but its quality of preparation may be low, it all depends on the master who created it.

Therefore, if the documents do not provide a clear answer to the question posed, they resort to the methods described above to accurately calculate the location of load-bearing walls.

In modern houses everything is much simpler. Plans are usually filled out more clearly, developers highlight supporting structures in the plan with a red line, and are ready to tell the owners about them.

In modern houses, developers highlight supporting structures in the plan with a red line.

As a result, we can say that it is necessary to coordinate all changes made, and this is definitely done. After all, the lives of not only the residents of a particular apartment, but also everyone else living in this house depend on this. If the redevelopment is carried out and approved on time, the process of legalizing it will be long and complex. If the load-bearing wall is incorrectly calculated and changes are made to its design that are not permissible, it will still eventually have to be restored. And it’s good if they don’t have time to lead the building to irreversible consequences. Such repairs require turning to professionals.

Studio apartment we demolish walls without damage!

In modern designs, small open space apartments called studios are extremely popular. This layout is convenient for a family of 2-3 people. Many people want to remodel large apartments in a studio, dividing the interior space with furniture. This option requires complete or partial demolition of the walls, leaving only the box of the apartment.

It is necessary to understand that such redevelopment requires the creation of supporting structures to distribute the main weight of the upper floors. Many professionals offer clients the use of frame technologies and the creation of decorative columns and built-in niches. This option harmoniously delimits the space and does not violate the requirements of higher authorities of technical bureaus.

Let us remember that the older the structure, the more significant the fragility of the main walls. In old-type buildings, the main structures are not allowed. Therefore, dismantling is prohibited without additional supports and a detailed calculation of the weight of the floors. Masters recommend seeking help from professional architects who will help resolve the issue of redevelopment without additional costs or violations of requirements.

Renovating old-style apartments is always a difficult task, requiring the involvement of third parties. We do not recommend carrying out large-scale demolition activities on your own at one time. Remember that by turning to professionals, you preserve not only your own comfort, but also the comfort of your neighbors.

We recommend watching the detailed installation of the load-bearing wall in the video: