Non-flammable panels made from SML glass-magnesium sheet are used for high-quality fire protection of concrete and load-bearing structures of various public and industrial premises and buildings, construction of roofs and creation of a base for floors.

To counteract the spread of flame, a huge number of different materials are used, glass-magnesite is one of them.

When a decorative coating is applied to it (acrylic painting, PVC film lamination, hpl / spl plastic sticker), modern fire-resistant panels are obtained, widely used as a means for finishing walls inside and outside buildings.

This material is often ordered from us to organize safe escape routes in buildings with a high number of visitors.

Price for non-combustible wall panels

The cost of non-combustible panels depends on:

the thickness of the SML slab, the type of decorative coating applied (painting, PVC film, hpl plastic), the number of panels in a one-time order, the need for cutting to customer dimensions, the cost of delivery from our production to the customer’s site. All these parameters are important for calculating the final cost!!!

Please send your request to the email address listed on the website, or fill out the convenient electronic form below.

Also select the color and type of coating from the catalogs of decorative coatings in the next section, indicate the selected article in the request.

paints and varnishes

Fire-resistant paint combines protection and decorative properties. It forms a film that keeps objects from burning. Water-based and organic-based paints with swelling effect are used for metal surfaces. One of the advantages is that it can be removed from the surface.

Fire-resistant fillers in paints:

- vermiculite;

- perlite;

- stone wool;

- basalt fibers.

During testing, the fire protection group of the product is determined. When interacting with fire, the intumescent layer increases 70 times. This creates a coke layer that protects the object. As the paint disintegrates, it releases components that slow down the combustion process.

When choosing paint, pay attention to the cost and material of the surface used.

The following paints are available for sale:

- NEOMID for metal (6 kg) costs 1,714 rubles.

- NEOMID for air vent (6 kg) – RUR 1,714.

- NEOMID for cable (6kg) – 1985 rub.

- NEOMID for wood (25 kg) – 8039 rub.

- Thermal barrier for metal structures – 375 rubles/kg.

- FRIZOL-OK for metal (25 kg) – 5750 rub.

- Protect F for metal structures (20 kg) – 4050 rub.

- Pirocor for metal – 250 rub/kg and others.

Fireproof paint Source nebezopasno.com

All paints are applied with brushes, rollers, and sprayers. The manufacturer indicates the layer thickness and recommended primers on the packaging.

CATALOGS OF BASIC COATINGS (painting, PVC film, HPL plastic):

Catalog of acrylic wall panels

Catalog of wood-coated wall panels

Catalog of PVC coatings (lamination) of wall panels

Catalog of HPL plastics for wall panels

We carry out TURNKEY INSTALLATION of decorative panels of our production. 9 years of work experience / 236 objects completed. Design/technical consultation. Tel.

Use EXPRESS APPLICATION or mail

Modal with text

Non-flammable panel SML 6 mm, 1220x2440 mm 127014702

Application: for external and internal work Sheet format: 1220x2440x6 mm

LSU painted according to RAL (one side): from 1270 rub.

Order

Non-flammable panel SML 8 mm, 1220x2440 mm 134015402

Application: for external and internal work Sheet format: 1220x2440x8 mm

One side: 1340 rub.

8 mm

Non-flammable (one side)

Order

Non-flammable panel SML 10 mm, 1220x2440 mm 155017502

Application: for external and internal work Sheet format: 1220x2440x10 mm

One side: 1550 rub.

10 mm

Non-flammable (one side)

Order

Non-combustible SML panel 12 mm, 1220x2440 mm 155017502

Application: for external and internal work Sheet format: 1220x2440x12 mm

One side: Check

12 mm

Non-flammable (one side)

Order

PRICE REQUEST

Types of heat-resistant wallpaper

For final finishing of the walls, you can use heat-resistant wallpaper. They are produced using several technologies. There are metallized roll materials that are made as follows.

The interlining, which is a product made from cellulose and synthetic fibers, is covered with thin aluminum foil. The top is coated with non-electrically conductive paint or embossed. Non-flammable wallpaper has interesting patterns and performs decorative functions. The material is durable.

Another type of non-flammable wallpaper is made from fiberglass. All components are of natural origin. The material washes well, has a beautiful appearance, and is suitable for premises of any purpose. The fire safety certificate confirms the high fire-retardant ability of non-combustible wallpaper.

Properties and scope of application of fire-resistant SML panels

Due to the properties of the raw materials for the production of SML panels, the material acquires excellent characteristics of increased resistance to moisture and resistance to high temperatures, due to which non-flammable SML panels are used in rooms with high fire safety requirements.

In addition, this material is reliably protected from various forms of mold or mildew. This allows us to recommend wall cladding using SML panels in children's, school, and medical institutions.

Non-combustible wall panels, as the name suggests, have high resistance to open fire, 10mm thick sheets mounted in two layers, staggered, that is, no seams are applied - more than 120 minutes. Fire-resistant panels are an irreplaceable building and finishing material. During production, SML undergoes thorough testing, and its quality is confirmed by relevant certificates.

In the event of a fire, the flames will engulf the entire house quite quickly. However, if the internal walls are made of fire-resistant SML panels, then the colossal damage that fire can cause can be avoided.

Modern fire-resistant panels made of glass-magnesite sheets are reliable and resistant to various mechanical damages.

LSU contains exclusively environmentally friendly substances and components. Toxic impurities such as asbestos, phenol and formaldehyde are not used in the manufacture of this material. Thanks to this, the panels do not emit odors or harmful substances. This expands their scope of application, allowing the use of LSU in all places of life and permanent residence of a person without exception.

The material has a reasonable price. This is achieved due to the efficiency of the components included in its composition.

Furnace lining materials

Lining is the lining of the furnace surface that is in contact with the flame. But since, in addition to protection, it can reduce heating efficiency, it is important to calculate the thickness of the layer.

Heat-resistant materials are installed during the construction of the stove or during its finishing.

Examples of furnace lining Source yandex.net

Lining material:

- fireclay products;

- leaf kaolins;

- mullite mats;

- basalt wool;

- vermiculites;

- fire-resistant compounds.

The same applies to cast iron stoves - they get very hot, so the walls near them must be protected, especially if the stove is installed in a wooden house.

Decorative non-combustible, fire-resistant wall panels

It is possible to order decorative fire-resistant panels. Decoration of non-flammable SML panels is carried out by applying an acrylic coating on an industrial line under the conditions of a factory production cycle. In addition, natural veneer, PVC films or HPL plastic can also serve as decor.

Non-flammable LSU panels have a long service life due to the use of durable, high-quality materials.

Fire-resistant panels based on SML are easy to install and technologically convenient (suitable for sawing, planing, cutting and milling). If necessary, they provide quick and easy access to utilities due to the ease of dismantling.

Tips for choosing

For finishing the foundation in country houses, it is recommended to choose non-mineral insulation (foam glass), and for roofing and facades - basalt materials (mineral wool).

When purchasing, you need to read the information on the label . All characteristics of the panels should be described there.

Roofing materials can only be considered truly reliable when, in addition to good performance characteristics (strength and durability), they have a high level of fire safety.

When choosing, you can seek help from a consultant . It is necessary to carefully check the product to ensure there are no cracks or other damage. The packaging must be sealed. The price depends on the company, type of material, its composition and degree of fire resistance.

Installation of non-combustible wall panels

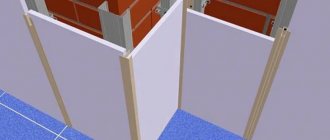

Installation of non-flammable panels based on SML is carried out quite quickly and only requires care when performing the work. Aluminum profiles are used for installation. Their design allows you to hide corners and joints between connected sheets. Profiles can be painted in different colors, which increases the aesthetic qualities of the installed material. Installation does not require the use of any liquids or solutions. This allows you to get rid of dirt that is usually formed during finishing work using water-based mixtures. The profile installation method prevents subsequent possible destruction of the panels or the appearance of cracks in the event of transportation or settlement of the building. Thanks to these qualities, the material is suitable for the construction of new houses.

Fire resistance of building materials

Facing materials differ in chemical composition, structure, thermal insulation, and hygroscopic properties. Depending on the raw materials from which they are made, the following materials are distinguished:

- organic;

- inorganic;

- mixed.

Non-flammable (NG) are inorganic materials: stone, brick, glass, asbestos cement and others. When organic and polymeric substances are added, the properties of the product change. NG include:

- inorganic materials permitted in construction;

- metals;

- gypsum boards containing 8% organic matter;

- mineral wool boards - 6% binder components.

Refractory materials contain 8–15% filler. All other organic materials are considered flammable.

Composition of non-flammable SML panel

The composition of the non-flammable SML panel includes various non-toxic substances that give the material certain characteristics. To increase protection against bacteria and fungus, as well as resistance to various chemicals and reactions, magnesium chloride is used. Fire resistance, as mentioned above, is achieved through fiberglass and magnesium oxide. Wood shavings act as insulation, and perlite sand is used for improved sound insulation.

Minerite slabs

Cement-fiber board is used for cladding building facades. The impact-resistant plate is safe for health. Minerite - fireproof materials for walls around stoves are often used in baths and saunas. The composition of mineralite includes:

- cement;

- cellulose;

- mica;

- limestone.

Several types of fiber cement boards are produced:

- Windproof windshields are installed in façade frames.

- HD are universal products that are used for interior and facade work. They produce HD slabs of different thicknesses from 3.2 to 10 mm.

- “Pastel” slabs have a polished surface and are painted.

- The PC model is covered with façade primer and painted.

- Fire-resistant boards - for lining and protection of heating equipment.

Non-flammable sheet material is used for thermal insulation of the floor, walls, ceiling, and roof in the bathhouse. The dimensions of the mineralite sheet are: 1200x630; 1200x845; 1200x1275mm. Maximum heating up to 400 degrees. Price of sheets: 945, 1265, 1885 rubles.

Fiber cement boards Source stroyfora.ru