With the help of finishing materials, which are presented in a huge range on the market, you can bring any design solutions to life. Natural materials are safe for health, but sometimes they are too heavy and “eat up” space, and their cost is not affordable for everyone. Fortunately, with the help of modern technologies, materials are produced that not only look natural, but also simplify repairs. One of the interesting and relevant options in modern design is decorative brick panels for interior decoration.

PVC panels

Made from modern artificial material - polyvinyl chloride - with the addition of softeners. The untreated material is white. After giving the product a textured pattern that matches the brickwork, a special technology is used to paint it in the desired shades. Polyvinyl chloride has excellent sound-proofing and heat-insulating properties.

Decorating the walls with PVC brick panels allows you not to think about extraneous sounds and noises.

The material is absolutely safe for the health of others, which is why brick-like wall slabs for interior decoration are gaining popularity. The surface of PVC panels is easy to clean, which allows them to be used for finishing work in the kitchen.

Varieties

The production process involves the use of different materials. Taking this into account, the panels are divided into two groups:

- PVC. The basis is polyvinyl chloride, which is considered an artificial raw material. First, the panel receives a white tone, after which it is painted;

- panel for brick material. It is immediately distinguished by its external characteristics and increased level of reliability. Wood shavings are used in production.

The panel has a rectangular shape, its area ranges from three to eight square meters. After manufacturing, the plates are cut to a specific size and sent for sale.

MDF panels

Such products are made from wood chips, which are pressed under high pressure. Processing under high temperature makes the material more durable and reliable. Thanks to this, MDF panels have high quality characteristics. This finishing material is not afraid of temperature changes and even moisture accumulation, therefore it is considered an ideal option for cladding the kitchen area, hallway and bathroom.

Installation

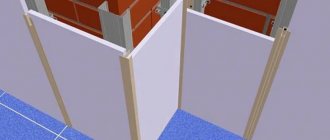

It is very easy to mount such parts on walls. True, unlike PVC analogues, you will have to use a frame or lathing, but this does not complicate the task too much. A primitive sheathing is assembled in such a way that each of the attached parts is fixed at least at two points. This is enough to create a strong and reliable structure.

The remaining details of the installation of such coatings can be seen in the illustration presented and no additional explanations are required - everything is very simple and anyone can cope with such operations.

Gypsum products

Gypsum panels that look like brick look especially good in the interior; they most accurately convey the texture of this material, so such an imitation is practically indistinguishable from a real brick wall. Another advantage of gypsum products is absolute fire safety.

USEFUL INFORMATION: Do you know enough about vinyl wallpaper?

However, it should be remembered that gypsum is afraid of moisture, so this finish is only suitable for dry rooms.

Another feature of gypsum boards is their fairly considerable weight. So, for example, a 50 × 50 × 3 cm slab weighs 4 kg.

Preparation

PVC is polyvinyl chloride, simply put, a type of plastic. Panels made from this material are especially popular because they are not afraid of moisture and do not rot, are quickly installed, do not change under the influence of ultraviolet rays, retain a decent appearance for a long time and, when using a frame, create additional sound insulation. Finally, they are relatively cheap.

Installation of PVC plastic panels always begins with the preparatory stage. First, the material is selected and purchased, observing several important points. While in the store, you need to inspect the cut of the panel. If there are thick layers, both external and internal, and a thick lintel, then the finish will be reliable. The thickness of the panel can also be determined by weight - the heavier, the thicker. Then the uniformity of the plastic is considered. The entire sheet should have a uniform thickness without too thick or too narrow places - this is a guarantee of good quality.

When you have chosen a brand and manufacturer (it is better to pay attention to European companies), you also need to calculate how much material will be needed. Otherwise, there will be unused fragments (and you will be overpaid), or, on the contrary, there will not be enough material and you will have to urgently buy it in the store (excessive time will be spent)

PVC panels are placed either vertically or horizontally. In the first case, you need to measure the length of the room along the perimeter, then subtract the width of the doors and windows from this figure and divide the remainder by the width of one panel. This will give you the number of elements needed to renovate the room. It is better to add a couple of units to this figure in case of unforeseen situations.

If the panels are placed horizontally, then the first step is to calculate the area of the room. Next, the area of doors and window openings is subtracted from this figure. Finally, the resulting number is divided by the area of one panel (usually this figure is indicated on the packaging by the manufacturer). An additional 10% is also added in case of unforeseen situations. If the sheets are mounted horizontally, then you should be prepared that the material will have to be cut, which means there will be scraps left.

Once you get rid of the packaging, you can get a good look at the edges and individual cells. The panels should not show any dents or damage. The more complex the image, the more important it is to study the quality of its application - blurred fragments and uneven coverage should cause concern. Also, if you are going to purchase several packs of sheets that must match in color, it is wise to unpack and check whether the shades match. Finally, the material should be tested right in the store. One sheet is bent about 30% and then unbent. If there is no damage, then everything is in order with the purchase.

Having purchased the material, you need to prepare the walls. The first step is to remove old paint, tiles, wallpaper and layers of old trim. Then the surface is leveled using plaster. In addition, it would be a good idea to try to seal existing recesses or eliminate protruding elements. Having finished leveling the wall, you can begin priming. It is recommended to choose a composition with additives against mold and mildew. While the primer dries, you can start assembling the sheathing, as well as bring the panels into the room - they need to stay inside for about 12 hours to adapt to the existing conditions.

The sheathing elements should be positioned perpendicular to the plastic sheets. This means that if the sheathing runs horizontally, the panels will run vertically, and vice versa. The distance between the lathing strips should be from 30 to 50 centimeters; the first number is still optimal. The planks must be secured near window openings, near doorways, as well as at the beginning and end of the wall.

The sheathing is most often attached to dowels. The length for a concrete wall is 40 millimeters, and for a brick wall – 60 millimeters. The distance between the dowels varies from 50 to 60 centimeters. In order for the polyvinyl chloride panels to be evenly laid, the sheathing must also be in the same plane. To do this, you can use pieces of plywood or wooden spacers pre-treated with an antifungal compound.

Variety of shapes

Brick wall panels can be of different shapes:

- The typesetting form of products imitating brick is a rectangular tile. Ideal for partial wall cladding when precise selection of patterns is required.

- The slatted panel is available in the form of planks of various widths.

- Sheet products are produced in the form of slabs with an area of 3 to 8 m2. This option is more technologically advanced during installation, as it allows you to simultaneously cover a larger area.

Advantages and disadvantages of wall panels

The popularity of brick panels for interior wall decoration is explained by their high quality characteristics, including:

- Resistance to high humidity.

- Ability to withstand sudden changes in temperature.

- Resistance to solar radiation, the color of the facing material does not change even when directly exposed to the sun's rays.

The listed parameters provide many advantages to finished products:

- Acceptable price.

- High-quality imitation of real brick.

- Versatility of application, which makes it possible to organically combine panels with different facing materials.

- Easy and simple installation.

- Maintainability.

- High sound and heat insulation.

- Long-term operation.

But, like all building and finishing materials, brick wall slabs have their drawbacks:

- At high temperatures, the material can be deformed, so you should not use such cladding near sources of open fire.

- Despite the declared strength, brick slabs are not able to withstand strong mechanical stress, which can lead to dents or scratches.

Price

The price of brick panels depends on several factors, which include:

- Material – MDF is usually more expensive than PVC.

- Manufacturer - Chinese and Malaysian products are the cheapest, Russian ones are somewhat more expensive, products from Europe and the USA can be 2 or more times more expensive.

- Brand awareness.

- The complexity of the drawing.

- The quality of the paints used.

USEFUL INFORMATION: Improved wall plaster: we follow the requirements of SNiP

Features of choosing panels for brick

When using the described products that imitate brick, it is important to take into account the advice of experts:

- Brick-like wall panels are often used when decorating recreation rooms. However, the brickwork of an ancient castle can exert emotional pressure due to the lack of comfort.

- In one-room apartments, one wall is lined with materials imitating brick, choosing soft, non-aggressive tones. This option does not overload the interior.

- When partially cladding walls, you can use brick-like slabs in bright colors. This will help highlight any area and create an interesting accent in the room. It is worth remembering that you should not use products made of MDF and PVC when finishing fireplaces in order to avoid deformation of the material.

- It is not recommended to use red brick cladding material for finishing living rooms. This can disrupt the calm emotional atmosphere in the apartment.

- Brick wall panels in white and light gray shades fit perfectly into an interior dominated by pastel colors. However, in the bedroom, the walls of which are lined with such panels, you will feel “chill”.

- When choosing a finishing color, you should take into account the area of the room, its lighting and the chosen style solution.

Application in different styles

Brickwork is decorated in different ways in the interior. The most commonly used technique is when all rooms in the house are lined with brick-like MDF panels intended for interior decoration. This finishing method implies the presence of large rooms with high ceilings.

The interior in the Scandinavian style involves white tones. The clarity of spatial geometry is emphasized by dark ceiling beams, door blocks, and baseboards. Monotonous brickwork can be effectively diluted with spotlights. In these cases, it is recommended to use brickwork panels with a relief surface.

If the apartment is small, solid brick cladding looks a little heavy. In the absence of partitions, brick finishing is used to zone the space. Light, as if sun-bleached brick, will be an excellent accent for the Provence style.

The shiny facing material will transform the hay with the familiar laying of brick rows. The use of the technique of imparting special properties to simple objects is typical of high-tech, which implies ergonomics, comfort and manufacturability of the interior.

If the interior is dominated by red tones, the ideal combination for them would be white paneling. A light high ceiling, snow-white furniture and other items will add luxury to the entire interior. This is an art deco style, the sophistication of which is not disturbed by the brick finish, which only highlights the elegance and chic of the overall style.

Another option for small rooms is the minimalist style. White masonry is used so that the walls do not receive additional volume, but visually expand.

Black tone is a solution for neo-Gothic. The simplicity of the forms is combined with unusual details in the form of false columns or a fireplace area.

The beauty of the room is added by arches trimmed with MDF panels. The material bends easily, taking the desired shape, for which the strip should be heated and bent to the required radius.

An arch made of a panel under brick laying is a favorite in a country style solution.

Pay attention to the finishing of the niches. The panel is cut along a broken line; it is used to trim opening areas for doors and adjacent walls near the corner area. The remaining surface is painted, covered with wallpaper or plastered. This is a grunge style, the basis of which is light bricks with elements of plaster mortar and ordinary furniture.

Wall decoration with brick panels

Installation of panels can be carried out in two ways:

- In the first case, the slab is glued directly to the wall surface. At the same time, due to the flexibility of the product, minor irregularities are hidden. The adhesive composition is selected depending on the material from which the slabs are made. Pasting begins from the corner, checking the evenness of the location using a building level. If necessary, the wall panel can be easily trimmed with a fine-toothed file.

- The second method is to install the slab on the frame. This option is especially relevant when finishing walls that have significant curvature. To mount the frame, you can use wooden slats or a metal profile. Assembly of the frame begins with attaching the guide profile to the floor and ceiling. Then, maintaining a certain step, vertical wall profiles are attached to the wall. Brick-like wall panels for interior decoration are fastened using self-tapping screws.

Important! To prevent premature damage to the finishing boards during operation, it is recommended to place the profiles at a distance of 40 cm. You can first fasten a sheet of plywood to the frame and place a wall panel on top of it.

A brick wall in the interior is an excellent design solution. A decorative panel imitating brick allows you to create the desired interior at low material and time costs. Convenient and practical panels transform the room, reproducing the structure of natural material and simplifying repairs.

MDF panel Brick white 2440x1220 mm, 2.98 m2

We deliver goods directly from partners from all over Russia. These products are not presented in stores and are only available for ordering on the website.

Art. 18046875 In the shopping list In the shopping list In comparison In comparison

Description

MDF based panel, used for interior decoration in dry rooms.

Preparing Panels: Like all wood products, panels will expand or shrink in size with changes in humidity. Therefore, before installation, place the panels horizontally around the perimeter of the room for at least 48 hours.

Installation:

- The surfaces on which the panels will be installed must be smooth, clean and dry. — — Panels are cut with a hacksaw from the front side, and with a circular saw - from the inside. Use construction adhesives that do not contain aggressive solvents and apply using a notched trowel.

- The back surface of the panel must be completely covered with glue, the grooves from the spatula must be left.

- Press the panels firmly, leaving gaps at the top and bottom, as well as between the panels.

- All gaps are carefully filled with sealant to prevent moisture from entering the non-facial surface of the panel.

- If profiles are used (joint, connection, internal and external corners), then they must first be installed in place and filled with silicone sealant.

- The glue must dry before applying sealant.

- It is important to carefully follow the instructions for applying the adhesive/sealant.

Care: Clean with mild detergents and water (wipe with a damp cloth). Do not use abrasive cleaners as they may scratch the surface and dull it.