Home Construction of the Wall

Modern houses must meet fairly high requirements for thermal protection. External walls made of brick have excellent load-bearing properties. However, if you calculate what thickness of brick walls should be made in accordance with the requirements, the result is unrealistic - about 3 m.

The problem is that materials that have excellent thermal resistance characteristics have low load-bearing capacity, and vice versa. At the moment there is no material that would meet all the necessary requirements in all areas. So, what is the optimal thickness of a brick wall?

Secrets of the right choice

When choosing solid bricks for construction, you should be especially careful, since your safety will be directly related to its quality.

It is no secret that a good brick can be recognized by its red-brown color and characteristic ringing sound when struck. Thus, if you have a mustard or black sample in front of you, it is better to immediately refuse the services of this company. The same should be done if you see any cracks or chips in the brick. For high-quality solid bricks, the volume of voids should not exceed 13%, since this characteristic directly affects the water absorption coefficient (at least 8%). In turn, if there are absolutely no voids in a solid brick, the interior of an object built using it will not be protected from temperature changes (too high thermal conductivity will “release” heat).

Thus, the choice of one or another type of brick directly depends on the characteristics of the structure (whether it is a load-bearing wall, whether you want the room to retain heat or this indicator is not of great importance to you), and experienced consultants will always help you decide on the final option .

The construction of brick buildings and structures does not lose its popularity. Like many years ago, brick is the main building material. Today, the construction industry produces a wide range of such products. Which type is better to use for the construction of load-bearing walls, foundations, basements, columns, and which for partitions? To do this, you first need to decide on the main types of bricks.

This type is used for the construction of a foundation base, columns, plinth, vaults, partitions, columnar structures, load-bearing walls, etc. It can be used when laying a smoker, stove, fireplace. You can use the relief material to build both walls and partitions, partitions, which will be plastered in the future. If this solid building material was chosen for the external walls of the building, then they must be additionally insulated.

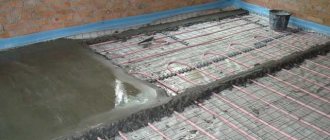

How to build aerated concrete walls with your own hands

How to lay out the first row - features

Important! Aerated concrete is a hydroscopic material and with increased humidity the quality of its properties decreases. Therefore, it is important at the stage of preparation for masonry to carry out work on cut-off horizontal waterproofing. Most often, roofing felt or similar rolled material is used for this; a polymer solution is also suitable.

The quality of the future structure depends on how well the first row of masonry is laid out, so it is important to level the surface using cement mortar and a trowel (or comb), and evaluate the absence of any distortions using a building level.

Aerated concrete can be laid in one or two rows. For double-row masonry, you can use ordinary cement mortar, since the cold bridges will be covered by the second row. For single-block masonry, experts recommend using a special adhesive solution and mixing it in accordance with the manufacturer’s instructions. The consistency of the masonry mortar should be similar to thick sour cream. Apply it with a special ladle or trowel, and then level it with a comb. If the glue protrudes, it is removed with a trowel, but under no circumstances is it rubbed over.

Important! The thickness of the seam between the foundation or ceiling and the first row of masonry must be at least 20 mm! The thickness of the seam between the rows should be no more than 3 mm, otherwise it will worsen the heat and sound insulation qualities of the masonry.

Each new row of masonry is carried out from the same angle. The rows relative to each other should be laid with dressing (that is, with an offset of 8-10 cm). The ends of the blocks can be smooth (budget option) or with grooves. In the second case, there is no need to coat it with the solution, but if the blocks are smooth, glue must be applied to their joints.

At the end of the row, an additional block is laid, the edges of which are coated with adhesive solution on both sides. The blocks are cut with a special hacksaw. After laying, it is necessary to treat the surface with a special plane. Upon completion of laying the row, its evenness is checked with a building level.

Important! The construction of walls on subsequent floors is unacceptable without installing an interfloor ceiling.

In order to protect the blocks from rain, it is recommended to unpack them as needed, and cover the laid out rows with film. It is also important to observe the temperature regime; the optimal range is considered to be from +5 to +35 C.

Laying gas silicate block Ytong - video

Tools required for laying gas silicate blocks:

- wall chaser

- building level

- Master OK

- plane

- carriage for adhesive solution

- rubber hammer

- hacksaw

- grater with metal teeth

- square

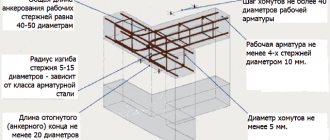

Reinforcement of gas silicate masonry

To strengthen the masonry, as a rule, reinforcement of at least 8 mm is used; to improve the quality, it is pre-treated with an anti-corrosion compound.

Types of reinforcement

A brick partition in a wooden bathhouse, as in a room for any other purpose, must be reinforced. Depending on the location of the elements, such strengthening can be:

- vertical;

- longitudinal;

- transverse.

In the latter case, a mesh is laid into the brick partition. The grille can be purchased or made independently. For this purpose, rods are used, which are connected to each other by the principle of welding or using wire. The side of the cells should not be more than 120 mm. There is also no need to increase the size of the mesh itself too much, as this will reduce the strength of the brick partition.

In order to protect the reinforcement, it is first placed in cement mortar, which will increase the thickness of the rod, as well as the width of the seam, which can be 14 mm. Partitions erected in 2; 1.5 or half a brick, must be reinforced every 4 rows.

Even if the partition is two bricks thick, but the structure is being operated in a region where there is a seismic hazard, internal reinforcement should be carried out vertically or longitudinally. Strengthening the wall using the latter method can be done outside or inside the structure.

Plaster for insulation

Wall chipping tools and process features depending on the wall material

Plastering is a good opportunity to both insulate and finish a room.

In order to insulate using this method, you need to prepare the surface by applying a special mesh of metal or fabric to the walls. The plaster itself is applied in several layers.

One of the longest, dirtiest, but cheapest ways to insulate walls is to plaster them.

Wall insulation begins with the first layer - “spray”. This is done so that the solution is evenly applied to the entire surface and gets into all the cracks. When first applied, the solution must be liquid; it is applied by vigorous rubbing into the surface. To do this, use a brush with a brush. The solution is applied to the brick wall evenly, up to 5 millimeters thick. The treatment of the walls from the inside of the room must be carried out carefully so that there are no dry spots. This will allow you to apply the second layer more efficiently and thereby enhance the insulation.

The second layer is soil. It will be the main one and should be evenly applied to the surface to be insulated. It is applied with a special spatula with a flat end. The thickness of the soil should be approximately 50 mm. The second layer should be applied in two stages. First, one layer is applied, and after drying, a second is applied. This is done so that the solution, which has a large weight, does not separate from the surface.

The third layer is the finishing layer. The solution is prepared from sifted sand so that when applied it does not leave grooves and holes on the already applied base. The solution is applied in a layer of up to 5 millimeters, completely leveling the wall from the inside. In order to insulate the walls with plaster, you will have to put up with dirt in the house for some time. In addition, this method is the most expensive of all.

Tools:

- brush with a stiff brush;

- flat spatula;

- ladle;

- grater;

- level.

Materials:

Requirements for building materials

Brick is the most popular material for building houses; there are hundreds of manufacturers producing products with distinctive characteristics. Before purchasing it, the developer will need to familiarize itself with its production parameters so that they comply with GOST requirements.

The most important of them:

- Strength characterizes the ability of a brick to withstand external natural factors without destroying the structure. This characteristic is marked “M”. For wall structures of residential buildings, bricks of M - 150 and M-200 are allowed, which corresponds to a compressive strength of 150 and 200 kg/cm2, respectively. The brand of brick is also characterized by bending strength, which for the above modifications is respectively 22 and 34 kg/cm2.

- Thermal resistance should be from 0.5 to 0.8 W/m*K and characterizes the ability of the wall to retain heat in the house.

- Moisture absorption is set at 6-14%, this is a high figure, but the porous structure of the brick cannot guarantee less, therefore, during the construction of walls, waterproofing will be required, which, as a rule, is performed in the process of thermal insulation of external walls.

- Frost resistance is set at F50 and must provide at least 50 freezing/thawing cycles of the walls.

- The vapor permeability of brick corresponds to 0.14-0.17 Mg/(m*h*Pa).

- The shrinkage of bricks is no higher than 0.1 mm/m; for this reason, cracks in brick buildings are quite rare.

- Sound insulation of walls of 1.5 bricks provides protection of 50 dB, which corresponds to SNiP.

- The fire resistance of a brick should provide resistance to direct flame exposure for more than 5 hours; in practice, this figure is higher and reaches 10 hours.

Scheme

Laying walls of 1.5 bricks can be done with single-row or multi-row ligation. The first is considered stronger and more durable and involves swapping the tie and spoon rows from the outer part of the wall being built, while observing the following basic rules:

- the rows at the top and bottom are laid with pokes from the outside;

- longitudinal seams in the following rows are shifted by 1/2 bricks, transverse seams by 1/4;

- the blocks of the upper row overlap the vertical seams of the lower one.

This laying method has a significant drawback, since it will require many incomplete bricks, which leads to increased labor intensity of construction work and increased mortar consumption.

Multi-row dressing is performed according to the following row scheme:

- the first is “spoon-poke”;

- the second is “poke-spoon”;

- from 3 to 6 - laying only with spoons with dressing of seams in 1/2 brick;

- from the 7th row the action is repeated from the first row.

Corners are considered the basis for the construction of walls of any object, therefore even the slightest mistakes made during their laying will lead to damage to geometric shapes, and, consequently, to a decrease in the load-bearing capacity of the structure and the duration of its operation.

When using the 1.5 brick technology, the construction of corners is carried out 4 rows ahead. This is required so that it is possible to install the order and expose the cord. In this case, it is possible to maintain horizontality as accurately as possible when laying rows.

The correct layout for laying one and a half bricks is in the video:

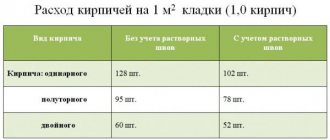

How many pieces will you need?

To calculate the volume of building material for a two-story house in a 10x10 m plan:

- The perimeter is determined by the outer walls: 10x 2+ 10 x2 = 40 m.

- At a height of 3.00 meters, the area of the wall structures is: 40 x 3.0 = 120 m2.

- The area of windows and doors is 11 m2.

- When laying 1.5 bricks, the wall thickness is 380 mm.

- According to the table, it is chosen that 1 m2 of walls with 1.5 bricks requires 189 bricks

- Brick consumption: (120-11)* 189 = 20601 pieces.

- Mortar consumption taking into account a 5mm thick mortar joint: 5.263 m3.

Stages of work

Since the load-bearing walls are laid on the foundation, it is necessary to waterproof the base before starting work.

Most often, roofing felt or a membrane is used, which covers the base of the building in a single, overlapping layer. The joints are treated with bitumen mastic to prevent moisture from penetrating through the foundation to the walls.

The choice of masonry depends on the average temperature in the region . In the northern and central zones of Russia, options of 2-2.5 bricks are more often used; in the southern regions, 1.5 bricks are acceptable.

There are several methods of dressing, each of them is reliable and is used along the entire length of the wall. Before starting work, masons must have a plan with openings marked on it and points of connection with adjacent walls.

Preparation of the solution

A rigid mortar mass is used for joints so that shrinkage is minimal. How to prepare the joining solution:

- you will need a cement mixture of grade M400 and pure river sand without impurities, the dry components are combined in a ratio of 4:1;

- water is added to the resulting mixture to make it homogeneous and plastic;

- prepare the solution in portions so that it does not have time to harden during the work.

Creating a structure with insulation

Stages of work to create a full load-bearing wall with insulation:

- Form the first row of rough masonry. For example, an option of 2 bricks, lay them dry, taking into account the additional distance at the seams. Before installation, the brick is moistened in water. This is done to prevent the porous and dry material from absorbing water from the solution before it hardens.

- Start rigidly fixing the wall from the corner; further compliance with the horizontality of the walls depends on it. The system for bandaging the corners depends on preference; the physical properties of the wall do not change depending on the choice.

- The corner is initially built in 4 rows.

To form the frame of the structure, the press-on masonry technique is used. The mortar mass is placed at a distance of approximately 1 cm from the outer edge of the brick. Stretch the mixture over the surface with a trowel, then place the brick on top, pressing it to the base. The trowel handle is tapped on the material, horizontal and vertical are checked using a building level. During the process, the solution will be partially squeezed out of the seams; it is used to form new ones. - Then continue the first row of walls until they connect along the entire perimeter, taking into account openings and access to the combined partitions. The starting row is the most important, it forms the direction of the wall. Before forming the next one, it is recommended to strictly check all horizontal and vertical lines and repeat the check every 4-5 rows.

- To create the required rigidity, you can add reinforced mesh to the seams every 4-5 rows.

- After the walls rise to the required height, the ceilings take their place, and insulation is laid on the outside of the house. The procedure is not necessary if the house is located in warm regions.

- Next, a facing masonry is formed, rigidly connected to the rough masonry. The cladding is laid in 1 row of beautiful bricks (red, silicate, clinker, etc.).

Between rough masonry and cladding, the house goes through all stages from the appearance of the roof to the laying of communications. Windows and doors are often installed immediately, and the final design of the facade, cladding and insulation of load-bearing walls is the final stage of construction.

Design Features

Not everyone knows the intricacies of construction technology. A completely legitimate question is: what is a monolithic brick building? This is a building constructed from solid concrete, with external cladding and internal partitions made using brick.

In most cases, in order to improve thermal insulation characteristics, the gap between bricks and concrete is filled with waterproofing material and insulation.

Using formwork, which is an auxiliary equipment, builders pour various structural elements of the building:

- capital walls;

- base;

- interfloor coverings.

When constructing monolithic houses, panel formwork is used, made of durable steel sheets, light aluminum, non-metallic materials, and wood.

By monolithic concrete we mean the technology of its production directly on the construction site, by pouring concrete into the formwork

The following types of formwork are used:

- Removable design.

It is dismantled after the reinforced concrete has hardened. The panels are moved to the next work area, where the frame is formed, reinforcement cages are installed, and concrete is poured. It is used in the construction of residential buildings and high-rise industrial buildings. - Stationary type.

After pouring, the panels remain as an integral structural element of the building. This type of formwork technology, in addition to the formation of a reinforced concrete monolith, performs a waterproofing function, additionally insulates the building, and insulates it from extraneous noise. It is better to carry out private construction of a building using such formwork.

Let us dwell in detail on the positive aspects of the technology for constructing monolithic buildings lined with brick on the outside.

In Khrushchev/Stalinka

Load-bearing walls in such buildings are a diagram of their three load-bearing (green) and transverse (blue) walls; in the diagram they look like this:

In this case, the partitions marked in blue are also load-bearing for the flight of stairs.

As you can see, in this case the standards apply. The structural design of Khrushchev or Stalin buildings does not change, although the layout of the apartment may differ.

Benefits of brick

This building material is widely used in many countries around the world. This is due to a number of its advantages over other materials. Its main advantages include:

- strength;

- durability;

- environmental friendliness;

- versatility;

- appearance;

- frost resistance;

- fire safety;

- soundproofing.

In terms of strength, the material comes in several grades: M175 and M150, M125 and M100. The number after the letter indicates the load that the product can withstand. For example, M125 can withstand 125 kg/cm². It is quite possible to build three-story buildings from M100 bricks. Such a house will have decent durability with the correct thickness of the brickwork. It will last 100 years without any problems. This material is made from natural, environmentally friendly substances. It consists of clay, to which sand and water are added. As a result, he is able to breathe and let air through. However, it does not rot.

The block sizes are usually the same. This allows you to build the most unusual architectural structures. Such elements give an individual style to the building. The material has frost resistance, which is indicated by letters and numbers. The number indicates the number of freezing and thawing conditions for which the material is designed. Frost resistance is indicated by the symbols: F50, F35 or F25. Brick is a fireproof material. Buildings made from it prevent fire from spreading indoors. The thickness of the load-bearing brick walls protects residents from noise from the street. This is an excellent soundproofing material.

Load-bearing brick wall, construction rules

This article describes what a load-bearing brick wall should be like. If you are interested in this question, read to the end.

The video at the end will help you correctly calculate the thickness of the load-bearing wall.

- 1 Laying load-bearing brick walls 1.1 Indicators

- 1.2 Material calculation

- 1.3 Masonry

- 1.4 Determination of the load-bearing part of the structure

- 1.5 Summary

- 1.6 How to make the correct calculation of a load-bearing wall

Laying load-bearing brick walls

The construction of residential buildings, dachas and other structures made of brick will not surprise anyone for a long time.

After all, this material has excellent indicators for:

- Strength.

- Frost resistance.

- Durability.

- Environmentally friendly.

- Soundproofing.

In addition, brick is a non-flammable and versatile material.

Of course, brick buildings have their drawbacks, but with the right approach to construction, they can be played out so that they become insignificant.

Indicators

It is worth considering a couple of parameters that will help in choosing a material for a particular design.

So, when choosing a brick, you can see the letter “M”, and next to it are not the numbers 100, 125, 150, 175 or 200.

So the strength is designated “M100” and so on. The number after the letter indicates the load that the material can withstand.

That is, the number 100 indicates that the brick can withstand a load weighing 100 kg/cm2.

The second, no less important indicator is frost resistance, which is also a combination of the letter “F” and a number, for example 25, 35, 50.

Builder tips

Experienced professionals can almost always give some useful tips for beginners, without which they would be guaranteed to make one of the common mistakes. For example, a fundamental point is the correct calculation of the foundation, taking into account the hydrogeology of the selected area. You should understand where the groundwater is located, how much there is, how much its quantity is affected by normal precipitation, and whether the soil under the future home is equally stable throughout the year. If this is not taken into account, then even a correctly calculated foundation, supposedly of sufficient strength, can “float”, especially if it is also made of brick and has limited bending strength. In such a situation, it will only contribute to the stretching of the walls above it and the bending of individual blocks, because cracks in the walls will appear too quickly and the building will not survive for long, posing a real threat to its inhabitants.

A separate point is the insulation of the external walls of the house or lining the main wall with facing materials. Many beginners do not take into account that it is necessary to leave a small gap between these two layers, because if there are temperature changes, condensation will still appear there, which can destroy the structure. If moisture gets inside, fungus can also penetrate there, which over time destroys the structure of building materials and increases the wear and tear of the house.

To avoid such phenomena, it is necessary to properly organize the ventilation of the space between the walls, for which special ventilation boxes are used. This device is made of very durable materials that can normally withstand any humidity and temperature changes without deformation. Thanks to them, thermoregulation inside the wall occurs naturally, and excess moisture gets out, so it does not accumulate inside and does not destroy the structure so much.

To learn how to properly make brickwork with your own hands, watch the following video.

Defects that reduce the strength and stability of walls

Violations and deviations from project requirements, construction norms and rules,

which builders allow (in the absence of proper control on the part of the developer),

reducing the strength and stability of the walls:

- wall materials (bricks, blocks, mortar) with reduced strength compared to the requirements of the project are used.

- metal anchoring of the floor (beams) to the walls is not performed according to the design;

- deviations of the masonry from the vertical, displacement of the wall axis exceed the established technological standards;

- deviations in the straightness of the masonry surface exceed established technological standards;

- The masonry joints are not filled completely enough with mortar. The thickness of the seams exceeds the established standards.

- excessive amounts of brick halves and chipped blocks are used in the masonry;

- insufficient connection of the masonry of internal walls with external ones;

- omissions of mesh reinforcement of masonry;

In all of the above cases of changes in the dimensions or materials of walls and ceilings, the developer must contact professional designers to make changes to the design documentation. Changes to the project must be certified by their signature.

Your foreman’s “let’s make it simpler” suggestions must be agreed upon with a professional designer. Control the quality of construction work done by contractors. When performing work on your own, avoid the above construction defects.

The norms of the rules for the production and acceptance of work (SNiP 3.03.01-87) allow: deviations of walls by displacement of axes (10 mm), deviation by one floor from the vertical (10 mm), displacement of supports of floor slabs in plan (6...8 mm ) etc.

The thinner the walls, the more they are loaded, the less safety margin they have.

The load on the wall multiplied by the “mistakes” of designers and builders may turn out to be excessive (pictured).

The processes of wall destruction do not always appear immediately, but sometimes years after the completion of construction.

Tips for the developer

It is certainly advisable to choose a wall thickness of 200-250 mm made of bricks or blocks for a one-story house or for the top floor of a multi-story house.

The house has two or three floors with a wall thickness of 200-250 mm. build if you have a ready-made project at your disposal, tied to the ground conditions of the construction site, qualified builders, and independent technical supervision of construction.

In other conditions, for the lower floors of two- or three-story houses, walls with a thickness of at least 350 mm are more reliable.

Read about how to make load-bearing walls only 190 mm thick here.

Next article:

Previous article:

The relationship between the thickness of brick walls and different parameters

It is necessary to understand that the load-bearing and external planes of the building are simultaneously experiencing more than one load variant. Highlight:

- Horizontal - under the pressure of air masses and the expansion of the roof rafter structure.

- Vertical - under the influence of walls and floor slabs.

Based on the types of loads, the thickness of external, load-bearing and internal walls must be correctly selected. Naturally, increased parameters allow increasing the load on the building structure. But you shouldn’t make the vertical planes too massive - this is an extra waste, you will have to buy brick elements and mortar components. Also, this irrational approach reduces the space of the rooms.

Therefore, when during construction it is important that the thickness of the walls in a brick house is calculated correctly, they rely on:

- The components used for manufacturing and the shape, or rather the presence of internal cavities in this building material.

- The way in which individual elements will be laid out in relation to each other.

Based on the types of loads, the thickness of external, load-bearing and internal walls must be correctly selected.

From the type of brick

Ordinary (also called construction) is used for walls, both those outside and those that provide internal division of space. This type can be used in the construction of a private house. But the thickness of the brickwork of the outer wall in this case will be insufficient to provide thermal insulation parameters. In this case, insulation is used. Externally, such bricks have small chips or irregularities that do not affect the level of strength created.

This type can be used in the construction of a private house.

Facing type - smooth, textured or shaped. They are used exclusively for cladding, which increases the width of the wall.

They are used exclusively for cladding, which increases the width of the wall.

This classification is given depending on the direct purpose of the brick. But there are also 3 standard sizes:

- Single has overall dimensions of 250x120x65 mm. Its energy efficiency is not very significant, since thermal conductivity indicators are only about 0.6 W/mS.

- One and a half truck – 250x120x88 mm. It has higher thermal conductivity, which allows it to be used for the construction of external walls of a building.

- Double – 250x120x138 mm.

As can be seen from the presented figures, only the height of the product unit changes. But it is the one-and-a-half and double ones that have higher effective indicators, due to which they are used for those parts that experience increased loads and impacts.

It is the one-and-a-half and double ones that have higher effective indicators.

From the type of brickwork

The thickness of the load-bearing brick wall is determined by the laying method. The following options exist:

- Construction of a tray row, when the laying is carried out in 1/2 brick. The vertically formed seams are displaced by approximately 1/4 or 1/2 of the length of the brick.

- Creating a chain ligation allows you to create a strong wall that is embedded in the monolith of the entire structure.

- Multi-row option - no strict requirements are imposed and no restrictions are imposed on the use of a poke in each row of laid bricks.

- The lightweight version has the following feature. In fact, 2 strips of walls are being built here, the middle space between which is filled with various insulating materials.

- The reinforced method of creating a dressing allows you to strengthen the overall structure, which is often used as a private type of construction of walls when it is necessary to increase rigidity.

- The decorative version of masonry is used when it is necessary to decorate the facade or create a certain composition.

Creating a chain ligation allows you to create a strong wall that is embedded in the monolith of the entire structure.

Also, the size of the load-bearing walls is influenced by which option from the following is chosen:

- Half a brick.

- Into one.

- At 1.5.

- In 2 elements.

- 2.5 pieces.

The last 2 options are suitable for the construction of buildings that demonstrate high thermal insulation characteristics in harsh winter conditions.

The following rules also apply:

- When erecting external walls, they often use 1.5 or 2 bricks.

- In order for the load-bearing, central internal walls to have sufficient rigidity, it is necessary to use a masonry of 1.5 bricks.

- For partitions, it is recommended to reinforce the masonry with 0.5 bricks of additional reinforcement.

- Further plastering of brick walls requires not filling the seams to a depth of approximately 1 to 2 cm. It is mandatory to bandage the seams.

Plastering brick walls requires not filling the joints to a depth of approximately 1 to 2 cm.

D1628 Project of a brick house with a corner terrace and a spacious balcony on the attic floor

The total area of a country house is calculated as the total area of the apartment (SNiP 2.08.01-89), that is, by the sum of the areas of all premises. For balconies and porches, various reduction factors are used. The areas of premises with inclined walls (under roof slopes) are also calculated with reduction factors, depending on the angle of the roof slope.

Such a project is not sold as a separate album of drawings. There is a specific construction company that is ready to carry out all the construction work for this project. She has working drawings of this project. The fixed price of construction includes all works and materials of the general construction cycle. This fixed price includes a specific type of foundation, walls, roofing and exterior finishing. As a rule, the fixed price does not include delivery of materials to the site.

The total area of a country house is calculated as the total area of the apartment (SNiP 2.08.01-89), that is, by the sum of the areas of all premises. For balconies and porches, various reduction factors are used. The areas of premises with inclined walls (under roof slopes) are also calculated with reduction factors, depending on the angle of the roof slope.

The composition of the family puts forward certain requirements for the number of bedrooms and living rooms. We consider living rooms to be both those that are called “bedrooms” by the author of the project, and those that are called “office”, “children’s room” or “guest room”. The living room and kitchen are not included in the number of living rooms. We also do not include premises in living rooms that are labeled by the author as “technical” or “storage rooms”.

The bedroom can be small, even 5-6 m². But it must have a window, as well as space sufficient to accommodate an adult’s bed, with a bed size of at least 2.1 x 0.9 m.

Types and dimensions of bricks

Building material with this name is produced from different types of raw materials, and therefore can have completely different sizes, but we will discard adobe and other blocks, focusing on brick in the classical sense - the one that is white and red. Theoretically, blocks of any size can be made to order, but there are also standard dimensions, which in table form look like this:

- a simple single brick is 25 cm long, 12 cm wide and 6.5 cm thick;

- the thickened version has all the same parameters, except for the thickness, which here is already 8.8 cm - by the way, in the usual horizontal masonry it is perceived rather as height;

- a single brick of modular dimensions is slightly larger than a simple brick in length and width - 28.8 cm and 13.8 cm, respectively, but in thickness it is 2 mm less - it is 6.3 cm;

- a thickened brick of modular sizes has the length and width of a single modular size, and the thickness of a simple thickened one;

- the thickened version with a horizontal arrangement of voids has dimensions completely similar to the simple thickened one - 25 by 12 by 8.8 cm.

Basic provisions

There are several ways to determine whether there is a load-bearing wall in front of you or not. For example, by location. All external walls are always load-bearing, as well as those located on the side of the staircase. These could be walls that border your neighbors. In addition, you can determine by its thickness and what it is made of. If brick is used, then the supporting structure in this case will be more than 380 mm. As for reinforced concrete structures, this is 140–200 mm, and in the case of monolithic walls, the load-bearing wall will be 200–300 mm or more. You can also find the supporting structure by the location of the floor slabs. All walls that are perpendicular to the slabs are load-bearing. Although there are houses where there are exceptions to the rules, for example, Czech buildings.

These are the basic provisions that will help you determine which walls are load-bearing and which are not. Now let's take a closer look at where and what kind of walls are in a panel house, Khrushchev, brick and monolithic house.

How to reduce the thickness of buildings and improve thermal insulation

People planning to build their own housing with their own hands may be interested in the answer to the question: “What thickness should the structures have in order to maximize the thermal performance of the building and its insulating properties?” As you know, constant noise has a bad effect on a person’s overall well-being. The problem of good sound insulation is most pressing for those who live near a train station, airport or factory.

Brick walls with an air cushion provide effective protection against noise. The technology is called well masonry. Between the walls of the house, 25 cm each, an empty space is left, which is filled with porous material:

- light concrete mixture;

- slag;

- organic insulation;

- expanded polystyrene;

- expanded clay.

well masonry with insulation

A cavity filled in this way makes it possible to reduce the overall weight of the structure and increase the level of thermal insulation.

To create an insurmountable barrier to cold from the street, you will need to make a ventilated façade. For this purpose, special heat-insulating panels, plasters and various facing materials are used.

Installation of a ventilated facade

The masonry of the 25 cm external wall is finished with facing bricks from the outside, and the structure must be insulated on the inside.

The following scheme is proposed:

- On the inside, the brick walls of the house are sheathed with insulation.

- The insulation layer is covered with a vapor barrier film.

- A metal mesh is laid on top and plastered. Alternatively, you can use drywall.

- Perform interior decorative finishing. Its task is to close all previous layers of the “pie”.

Insulating the wall from the inside

The result is cheap and cheerful. With the right approach, a practical owner will be able to reduce the initial cost of the property by 20%.

Building materials should not be used in areas of high seismic hazard. During a strong earthquake, the masonry is destroyed to the foundation.

Possible errors and their consequences

What can go wrong:

The masonry has deviated.

To prevent this from happening, it is necessary to constantly check the angles, horizontal and vertical. If it was not possible to keep track, the wall must be disassembled and rebuilt, since compliance with the geometry is necessary for the strength and stability of the house frame.Small deviations are leveled out later using plaster.

- The dressing was performed incorrectly. The bricks must be laid out so that the load from one of them falls on the two lower ones. The seams should not match, otherwise the strength of the structure is greatly reduced. Those who create masonry for the first time need to familiarize themselves with the technology and dressing options and practice dry.

- Poorly sealed seams significantly reduce the thermal insulation properties and structural strength. The solution should lie smoothly, without gaps. Therefore, they use the principle of pressing, when the mixture under pressure fills the voids.

When creating rough walls, some builders do not pay attention to the cleanliness of the process, are in a hurry, and do not observe the uniform distribution of the solution. Load-bearing walls are the most important element of the structure; you need to pay time and attention to each brick.

How to save on masonry

how to save money on bricklaying

The thickness of any brick wall is a parameter that is determined during the design process of the house. Being selected according to all the rules, it will help save both time and money, ensure reliability and durability in maintenance, and play a positive role in the wear resistance of any structure. However, such an event is often costly for the budget. There are some options to help deal with this problem:

- In low-rise construction, it is quite possible to use lightweight masonry. It is made like a well: that is, two different walls will be built at a short distance from each other (0.5 bricks are used in each).

- The resulting air gap will be a good heat insulator. This will happen due to the fact that the air does not conduct heat very well.

- Additionally, you can “fill” such a cavity with expanded clay, foam concrete and similar materials.

- In order for the structure to be more rigid, it will be necessary to connect the walls using diaphragms. This decision will make the construction of such a building more economically profitable.

Brick partitions - little secrets and subtleties of masonry

When erecting a single or half partition, you need to take into account the construction features. They will help you avoid mistakes and make a reliable design:

- a partition can only be built on a prepared foundation; before its construction, a reinforced concrete screed is laid out;

- the solution should be plastic, viscous, but not too liquid, otherwise it will come out of the seams. The thickness of the seam is from 10 to 12 mm. One of the best compositions: 4 parts sand, 1 part M500 cement, part water;

- a layer is laid between the floor and the wall that prevents the spread of vibration and hydration of the room (2 layers of roofing material);

- In order for the partition to hold firmly, you need to secure it with grooves up to 5 cm deep. The outer parts of the structure are inserted into these holes;

- It is necessary to bandage the seams when constructing a brick structure. If this is a partition of 0.5 bricks, then a vertical bandage is made (the seams are in the middle above the bricks of the previous layer);

- In order for the structure to be durable, it must be reinforced with wire rods;

- For processing, before applying the decorative layer, be sure to cover the brick with plaster. With this technology, you need to take into account the width of the joints - it should not protrude beyond the boundaries of the brick;

- When building a partition, it is better to use wet bricks, previously soaked in water.

To follow these simple recommendations, you do not need specific work skills.

Thermal insulation protection

Some insulation materials require protection from getting wet, blowing or, for example, direct sunlight. Some of these tasks may be assigned to the finishing layer, but the main protection is provided by special membrane materials.

One of the most commonly used insulation materials in Canadian frames, stone wool, has the ability to sharply reduce the resistance to heat transfer when wet. The source of moisture can be precipitation or condensation of water vapor. In the first case, special synthetic burlap is used that allows air and water vapor to pass through, but retains water droplets.

The penetration of steam from the inside cannot be completely limited, because the building must carry out natural gas exchange with the environment. However, it is possible to limit the amount of water vapor to such a level that it is not enough to raise the relative humidity in the cooled indoor air to 85–90%. Typically, such a calculation is carried out for the point of separation of the rows of a frame or supporting system with external insulation. However, the same method can also be used to calculate layer-by-layer the dew point displacement throughout the year inside homogeneous walls.

Panel houses

Conventional interior partitions in such houses have a thickness of 80-100 mm; they can be constructed of gypsum concrete. Standard load-bearing walls in panel buildings are 140 mm, 180 or 200 mm. If during the measurement the owners received less than 120 mm, then this is also a partition that is not a supporting structure.

The layer of plaster present in such buildings must also be taken into account when measuring, but it is usually 50 mm, no more, and this figure will not have a big impact. If possible, it is better to take correct values that completely exclude the thickness of finishing materials.

Features of calculating wall thickness

- The thickness of the walls according to thermal engineering calculations does not always coincide with the calculation of the value based on strength characteristics. Naturally, the more severe the climate, the thicker the wall should be in terms of thermal performance indicators.

- But in terms of strength, for example, it is enough to lay out the outer walls in one or one and a half bricks. This is where it turns out to be “nonsense” - the thickness of the masonry, determined by thermal engineering calculations, often turns out to be excessive due to strength requirements.

- Therefore, laying solid brick walls from the point of view of material costs and subject to 100% use of its strength should only be done in the lower floors of high-rise buildings.

- In low-rise buildings, as well as in the upper floors of high-rise buildings, hollow or lightweight bricks should be used for external masonry; lightweight masonry can be used.

- This does not apply to external walls in buildings where there is a high percentage of humidity (for example, in laundries, baths). They are usually built with a protective layer of vapor barrier material on the inside and solid clay material.

Now I’ll tell you about the calculation used to determine the thickness of external walls.

It is determined by the formula:

B = 130*n -10, where

B – wall thickness in millimeters

130 – size of half a brick, taking into account the seam (vertical = 10mm)

n – integer half of a brick (= 120mm)

The calculated value of the solid masonry is rounded up to the whole number of half-bricks.

Based on this, the following values (in mm) of brick walls are obtained:

- 120 (a brick floor, but this is considered a partition);

- 250 (in one);

- 380 (one and a half);

- 510 (in two);

- 640 (at two and a half);

- 770 (at three).

In order to save material resources (bricks, mortar, fittings, etc.), the number of machine hours of mechanisms, the calculation of wall thickness is tied to the load-bearing capacity of the building. And the thermal component is obtained by insulating the facades of buildings.

How can you insulate the external walls of a brick building? In the article insulating a house with polystyrene foam from the outside, I indicated the reasons why brick walls cannot be insulated with this material. Check out the article.

The point is that brick is a porous and permeable material. And the absorbency of expanded polystyrene is zero, which prevents the migration of moisture outward. That is why it is advisable to insulate a brick wall with heat-insulating plaster or mineral wool slabs, the nature of which is vapor-permeable. Expanded polystyrene is suitable for insulating concrete or reinforced concrete bases. “The nature of the insulation must correspond to the nature of the load-bearing wall.”

There are many heat-insulating plasters - the difference lies in the components. But the principle of application is the same. It is performed in layers and the total thickness can reach up to 150mm (for large values, reinforcement is required). In most cases, this value is 50 - 80 mm. It depends on the climate zone, the thickness of the base walls, and other factors. I will not go into detail, since this is the topic of another article. Let's return to our bricks.

The average wall thickness for ordinary clay bricks, depending on the area and climatic conditions of the area at the average winter ambient temperature, looks in millimeters something like this:

- — 5 degrees — thickness = 250;

- — 10 degrees = 380;

- — 20 degrees = 510;

- - 30 degrees = 640.

I would like to summarize the above. We calculate the thickness of external brick walls based on the strength characteristics, and solve the heat-technical side of the issue using the method of wall insulation. As a rule, a design firm designs external walls without the use of insulation. If the house is uncomfortably cold and the need for insulation arises, then carefully consider the selection of insulation.

What factors need to be considered when choosing the type of masonry?

When determining how thick a wall should be, it is advisable to focus on the following points:

- Estimated load. This is a determining factor, including the number of storeys of the building, as well as its functional purpose.

- Climatic nuances. The building being constructed must provide comfortable conditions for people, this is especially important for a winter home where people live permanently. The thickness is considered sufficient if the walls do not freeze.

- Accepted standards. When calculating the thickness of walls, it is important to focus on the standards prescribed in the current GOST. Only under this condition will the house be safe to live in.

- External attractiveness. The aesthetic component is very important for an external wall, so it cannot be ignored either. Thin masonry looks most preferable, but is not always acceptable.

Insulation inside and outside

In modern houses, the wall is a multilayer structure made of various materials. The main rule of combining them is: the vapor permeability of the layers increases from the inside to the outside. Insulation from the inside is considered the worst option, since it is very difficult to fulfill this requirement.

Insulation scheme

The second major drawback of this solution: if you insulate the wall from the inside, then the dew point - the conditions for the formation of condensation - will be inside the room, and not outside. The third drawback is that thermal insulation takes up at least 15 cm of internal space.

You have to take this step in cases where you need to insulate a finished, tiled house. Moreover, if the cladding is made with siding, it is recommended to donate it and insulate the building from the outside.

If we are talking about a project, or about a house that is at the stage of building a foundation, then the issue of thermal insulation must be resolved in favor of another method.

Definition

A load-bearing wall means a structure on which the floor of the next floor rests. Also, such walls can be replaced with columns or beams that support the entire structure.

If during the repair process the load-bearing wall is incorrectly identified, then if it is damaged, cracks may appear in the building; in the worst case, the ceiling may collapse.

What is needed to demolish walls?

This is the approval of a redevelopment project. Such issues are resolved by the Bureau of Technical Inventory (BTI). The list of required documents includes:

- a plan developed by representatives of the BTI, separately for each specific case;

- a technical report has been drawn up allowing the demolition of the partition;

- approval of actions by the housing inspection.

It will take a considerable amount of time to collect documents and obtain permission for redevelopment, which apartment owners need to remember.