Mineral wool for wall insulation and its sizes: 11 options

When choosing insulation, carefully study the characteristics of mineral wool so that it meets all the requirements. You can insulate the house yourself. This can be done easily and simply if you decide on the type of thermal insulation material and become familiar with the nuances for its installation. When choosing insulation, special attention should be paid to the properties of the material. Mineral wool dimensions are an important issue that needs to be resolved before laying the material. Mineral wool of different lengths, thicknesses and widths is suitable for a specific type of work.

Standard insulation sizes

The leader in the market of thermal insulation materials is. It produces plates, mats, rolls and cylinders. Varieties of mineral wool are used to insulate a specific type of structure. To insulate the frame structure, mineral wool is usually used, in which the thickness is 46-213 mm, the width ranges from 566 to 612 mm, and the length is 1175 mm.

For thermal insulation of walls, roofs, facades and other parts of buildings, as well as for insulation of equipment, mineral wool with a thickness of 50 to 150 mm is used

For high-quality sound insulation of multilayer walls, mineral wool of the following sizes is used: thickness - from 51-101 to 205 mm, width - from 613 mm, length - from 1175 mm.

Flat roofs are usually insulated with wool, which has the following dimensions: thickness - from 55 to 175 mm. Width – from 1195 mm, length – from 1280 mm. All sizes of mineral wool can be found in special catalogs. The most common method of insulation outside and inside is laying mineral wool mats on frame structures.

Wool sizes:

- ISOVER M34 – 40 mm by 200 mm, 610 mm by 1220 mm. 3000 mm by 9000 mm;

- Frame-M37 – 42 mm by 203 mm, 610 mm by 1220 mm, 3000 mm by 22000 mm;

- ISOVER M40 – 50 mm by 200 mm, 610 mm by 1220 mm. 3000 mm by 9000 mm;

- Frame-M40 – 50 mm by 200 mm, 50 mm by 1200 mm, 7000 mm by 14000 mm.

To insulate the pipelines, it is necessary to use cylinders of mineral wool. Typically, for thermal insulation of roofs, facades, walls and other parts of a building, Knauf mineral wool is used, which is presented in the following variation: thickness - 55-155 mm, while its length and width can vary. The latter characteristics should be selected based on ease of use.

general information

Mineral wool is produced using a technology that has already become a classic. This is the use of raw materials from rocks such as basalt, which are processed at high temperatures.

After melting, the result is combined with special chemicals to produce stone wool fibers. From the fibers themselves, cotton wool is already created as a full-fledged building material.

As you understand, this initial structure affects the properties of mineral wool. So, its thickness must be quite impressive so that the fibers can stick to each other. Also, cotton wool has a high density, does not react to many external influences, etc.

Moreover, the density of mineral wool is really high. Especially if slab insulation is taken into account. Here the density of the slab can be equal to the density of the foam. And at the same time, the thickness of the material will have little effect on its density, as well as its size. But this factor still needs to be taken into account.

This insulation is almost ideal for finishing walls and insulating the walls of an apartment from the inside, since its installation is carried out using the simplest technology. If desired, it can be combined with other materials. For example, laying drywall, siding, etc. over mineral wool.

Sizes and shape of mineral wool

Mineral wool insulation is produced in two main types or forms. Vata is found in:

- Rolls;

- Slabs.

Cotton wool in rolls are long strips of mineral insulation that are rolled into a small roll. Its length when unfolded can reach up to 7-10 meters, but its width rarely exceeds 1.2 m.

Mineral wool slabs

The thickness of the roll is a maximum of 50 millimeters. This size of the workpiece allows you to safely transport rolls of insulation without spending too much space on its placement.

Cotton wool in rolls is most often cheaper. It absorbs moisture faster, can settle over time, and its installation on walls is not carried out using the easiest technology. The density of wool in rolls is also, as a rule, lower than the density of insulation in slabs.

To secure the roll and insulation to protect the walls of the house efficiently, you will have to seriously tinker. After all, first you need to spread it (and doing this on a vertical wall is not so easy), and then also fix it. It seems impossible to cope with such work alone.

And the size of the roll, or rather its length, must also be taken into account. If it has a length of more than 6 meters, then using the material in this form for wall decoration will simply be unproductive (it will have to be additionally cut).

But mineral wool in slabs was specially created for finishing walls and other vertical structures.

The size of the slab is on average 1000×1200 mm. Its width can vary, but a length of 1200 mm is considered almost a standard.

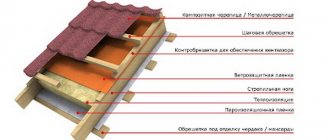

The thickness of the slab may vary depending on its purpose. Thus, the thickness of the slab for floor insulation can be only 30-40 mm. But the thickness of the facade slab or insulation for thermal insulation of a flat roof can reach up to 80-100 mm or even higher.

The size of liquid thermal insulation boards allows them to be conveniently laid anywhere. You can even install them yourself, and you only need a few tools from the available tools.

The density of the insulation in the slabs also changes significantly. Insulation for roof slopes has an extremely low density. For this type of slab, this parameter is a real necessity.

Plates for finishing walls or flat roofs, on the contrary, have an increased density. You can actually walk on them with a load, without fear that the mineral wool will bend or become deformed.

Properties of mineral wool

Let us turn directly to the properties of mineral wool, for which it is so valued in the construction industry. And by the way, it has just a huge number of positive properties.

Mineral wool in rolls: types and sizes

The modern market offers a wide variety of all kinds of innovative thermal insulation materials. This includes liquid-ceramic heat insulator, polyurethane foam, and silica mats. However, mineral wool is still the most popular of them.

Today, thermal insulation with mineral wool is one of the most popular construction services.

Mineral wool is characterized by a low thermal conductivity coefficient, a wide temperature range, high fire safety and absolute environmental friendliness.

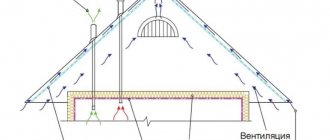

Rock wool rolls are usually used to insulate horizontal surfaces. This installation requires careful handling and avoidance of too much stress on the surface. Rolls are used to insulate floors between floors, floors, attics, and roofs with a slight slope. They are also used to insulate pipes, fireplace covers and home stoves.

Roll dimensions (width, thickness, length in mm):

- Ursa M-11 – 1150 by 53 by 9000;

- Isover Classic – 1220 by 50 by 8200;

- Isover Sauna – 1200 to 50 to 8200;

- Heat Knauf Dacha - 1220 by 50 by 7380.

Bulk mineral wool is inconvenient to roll, so its thickness usually does not exceed 50 mm. Mineral wool in rolls can be used to insulate large areas where the surface is subject to significant load. For laying rolls, logs, rafters and other building elements are usually used.

Why is thermal insulation needed?

Many people do not fully understand how the thickness of insulation affects the durability and technical characteristics of a structure. In simple terms, thermal insulation allows you to save on utility bills, because heat loss is reduced by almost a third, and in some cases by half.

Another important side effect of thermal insulation is sound insulation.

This is especially important for apartment buildings in urban areas, where sounds from the street can cause unnecessary discomfort. Panel houses also have extremely low sound insulation

If we are talking about personal construction with your own hands, for example, your own mansion or a country home, then thermal insulation materials make it possible to reduce construction costs by replacing materials for building walls.

So, using thick polystyrene or mineral wool slabs (within 10 cm wide), it is possible to replace brick walls with them. The load on these walls must be small, so this method is suitable for one-story buildings, building verandas or houses for guests.

Suitable sizes of mineral wool in slabs

The many advantages of mineral wool contribute to its widespread use in the construction process. To accurately calculate the required amount of material, you need to be informed about the size of the slabs. If when choosing thermal insulation materials you need to know the number of squares, then when choosing wool you need to pay attention to the dimensions of the slabs.

Mineral wool slabs are used for external and internal construction work.

Standard slabs have the following dimensions: 1000 by 500 mm. In each specific case, you can select the appropriate thickness of the slabs. The number of slabs is determined by the size of the structure being finished.

Slab sizes:

- Izover Frame P-32 – 1170x610, while the thickness can vary from 40 to 150 mm.

- Izover Frame P-34 – 1170x565, while the thickness can vary from 40 to 200 mm.

- The rigid Izover plate is 1550x1180, with a minimum thickness of 30 mm.

You can calculate the required number of slabs in a hardware store, having previously measured the area of the room. You can calculate the number of mineral wool sheets in advance. Find out in advance how many sheets are in one package or pack. If the sheets do not fit, they can be carefully cut. Wadding trimmings can be used to insulate cracks and joints. The density of the sheets is selected depending on the required quality of thermal insulation.

Features of mineral wool for insulation

Modern construction cannot be imagined without the use of mineral wool as a thermal insulation material. It has a wide range of uses, which makes it especially popular among builders. The most common way to use mineral wool is to insulate building structures.

Manufacturers produce products of different types and purposes: plates, mats, rolls, cylinders

Typically, mineral wool is used to insulate roofs, floors, walls and ceilings: the dimensions of the materials depend on the area of the room and the type of insulation.

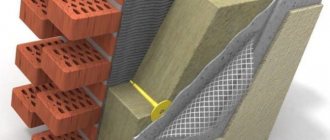

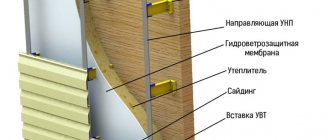

Often mineral wool is used to lay the middle layer. At the same time, the load on the insulation of various types of surfaces in any buildings, houses and structures is avoided. Vertical laying of mineral wool is used to insulate facades and walls. The inclined and horizontal installation method is chosen for insulating the ceiling, roof and roof.

What is mineral wool used for:

- For equipping facade systems that are ventilated, as well as for installation in curtain wall facades.

- Mineral wool is used to insulate building sandwiches of panels and blocks, which are used to build multilayer walls with different types of cladding. They can be metal, concrete, fiberboard and OSB.

- To insulate various industrial structures, equipment and pipelines.

Related article: How to hang a poster on a wall without a frame

Modern manufacturers offer consumers different types of general building insulation. Cotton wool can be presented as a lightweight heat and sound insulating material that does not have a coating. Another option: cotton wool with one-sided caching using aluminum foil. The wool can be equipped with special sound-absorbing material.

Main categories

Wall insulation is divided into 2 groups:

- For internal insulation.

- For external insulation.

These categories differ from each other only in their ability to pass steam or retain it. Mineral wool, packaged in slabs, mats, rolls, is easy to use, easy to cut and fills the most inaccessible corners, leaving virtually no waste after cutting.

TechnoNIKOL

- Technofas. Available in the form of a slab measuring 600*1200*50/100 with a density of 145 kg per 1 m3.

- Technoven Standard. Plate. Dimensions 600*1200*50/100, density 80.

Knauf

- Insulation FKD. Slab (600*1200* 20-160, density 140 -150.

- Insulation FKL, plate. 200*1000*20-200, density 85.

- Insulation FKD-S, plate 600*1200*60-180, density 140-160.

- Insulation HTB, plate 1000*500*20-180, density 35-150.

Rockwool

- Fasrock, roll 1000*600*100, density 135.

- Wentirock max, roll 1000*600*50, density 50-90.

- Panelrock, plate 1000*600*50-100, density 65.

ATTENTION! The fine-fiber structure of mineral wool contains formaldehyde, and therefore is classified as a carcinogenic building material. For safe installation, it is necessary to have special protection for the worker performing insulation or insulation. To prevent fibers from scattering throughout the room, the pressed slabs should be protected with membranes. And only after that begin finishing work.

Mineral wool. Types, properties. (video)

The use of basalt insulation is a fairly popular method of insulating premises. The service life of mineral wool is very long, so it is used to insulate industrial buildings and residential buildings. Construction foil and stone wool is intended for various types of insulation. The volume of materials used depends on the area of the insulated room. Cotton wool is used to insulate walls, ceilings, floors and other surfaces. For each of them it is better to use cotton wool of a certain quality and composition.

Peculiarities

The main property of any thermal insulation material is its thermal conductivity. In order to achieve optimal temperature in the house, it is necessary to either reflect heat from the surface or prevent transmission along the wall of the building. According to this criterion, all insulation materials are divided into two categories:

- preventive type - in these products the thermal conductivity is very low;

- reflective type - here the level of infrared radiation is reduced several times.

Classification

Depending on what criterion is used as the basis for the classification, insulation materials are divided into different groups. In this article, we are interested in differentiation by density. In this case, the following types of thermal insulation materials are distinguished:

- Lungs. They have low weight and low thermal conductivity. This group primarily includes mineral wool materials.

- Average. An example of such insulation is foam glass. Such thermal insulation materials are usually produced in the form of slabs and blocks that have high thermal and sound insulation properties.

- Tough. This is a dense insulation material, usually obtained by pressing, for example, mineral wool mats. In addition to low thermal conductivity, they are characterized by moisture resistance and the ability to withstand heavy loads.

Dimensions of mineral wool: release form and dimensions

The production volume of the Russian mineral wool market is constantly increasing. The maximum figures dating back to 2013 are admirable - 52.5% increase compared to 2009.

The share of mineral wool used in construction has increased from 46% in 2010 to 60% today. Starting from mid-2017 and beyond, an increase in the production of mineral wool products is predicted.

This success is due to many factors. This includes an increase in multi-apartment construction, the growing popularity of suburban housing, and the growth of industry in general. However, an important factor is the thoughtful study of the needs of the construction market by product manufacturers.

Knowledge of the required technical and operational characteristics, sizes and dimensions of mineral wool, understanding of what a builder needs to build quality housing allows the manufacturer to produce products that will be in demand.

How does the purpose of mineral wool affect its size?

Insulation is necessary for any building in order to:

- reduce heat loss in winter;

- protect from overheating in summer;

- preserve elements of the building’s supporting structure from the effects of negative environmental factors;

- increase the service life of the structure.

These tasks are entirely within the capabilities of inorganic insulation materials. Of the large list of materials of this kind, mineral wool is in particular demand. Mineral wool has been successfully used in construction for a long time.

Related article: Thermal and noise insulation of walls in an apartment

By giving preference to this type of insulation, the consumer receives the following advantages:

- thermal conductivity index 0.035 W/μ, one of the best;

- high-quality dielectric properties;

- high levels of vapor permeability;

- best fire resistance parameters;

- low hygroscopicity;

- high resistance to aggressive environments.

This material can be used to insulate walls, both inside and outside. It is used for roofs, attics and basements, and internal partitions. Its dimensions have the same standards as the distances between the guides where the mineral wool is laid. If violations of standards occur in construction, there is also a need to adjust the size of the insulation.

Application

Insulation is produced in rolls or slabs. For example, rolls are best for roof insulation, slabs are good for walls.

There are also mats that are necessary for insulating the floor.

Stone wool is often produced in the form of granules, as well as in the form of cords and bundles. These forms of packaging are used in industrial construction.

To effectively insulate a house, the following thickness of mineral wool is used:

- outer wall – 100mm;

- ceiling, attic – 150 mm;

- roof and attic – 300 mm.

The width of mineral wool in rolls and slabs is the same - from 565 cm to 620 cm, length - from 1117 cm to 1380 cm. The data is given using the example of Isover mineral wool.

Another similar insulation, for example Ursa, is also universal in use. Ursa is produced in slabs and mats with a thickness from 30mm to 100mm, length from 1250 to 10000mm, width 610mm -1200mm.

As you can see, the differences in dimensions between different brands are insignificant. The price is also about the same.

And yet, specialists at different sites use different brands of mineral wool insulation.

No matter how similar different types of insulation are in their technical and operational characteristics, sizes and other indicators, advice from a professional on their use will be extremely useful!

Products for easy installation

Foil-coated mineral wool in slabs

Sometimes the size of stone wool in slabs is not enough to thermally insulate a vertical or inclined structure. To simplify installation of the system, mats with additional layers are used:

- Bitumen. Allows you to create an additional base for the roofing sheet.

- Laminated with polymer or fiberglass. They facilitate “dry” insulation or the installation of sandwich systems. Fiberglass prevents fibers from blowing out, and polystyrene blocks moisture from entering.

- With section differences. Used to slope a pitched roof. Water drains faster from such a slab.

- Lamellar. The sheet is distinguished by a perpendicular arrangement of fibers, due to which elasticity is achieved and tensile strength increases.

- Double basalt. They allow you to protect your home using “wet” technology from heat leaks. The top coating is rigid and prevents the product from deforming during installation. The lower elastic part ensures that the material adheres tightly to the wall.

- With foil. Additional fiberglass reinforcement of penoplex models eliminates the penetration of condensate. Using the material you can insulate a residential attic or loggia.

Manufacturers mark the sides for ease of use.

Let's calculate the required amount of insulation

It is useful to consult a professional on any issues. For example, which wool is better for a particular object - stone wool, one that uses basalt rocks, the so-called basalt wool, or another.

Will you need foil wool, what mineral wool materials will be needed at all, and is it possible to optimize costs.

For example, let’s calculate the required amount of insulation for the roof.

Stage one:

- calculate the roof area;

- we add the area of the attic walls and partitions;

- We add 3% to the amount received.

Stage two. We choose the insulation whose roll area most closely matches the insulation area. We consider the material both sheet, and in rolls, and in mats.

Stage three. We divide the roof area by the area of the insulation squares and multiply the unplanned number of layers. The amount received will determine how many sheets, rolls to buy, and how much slab material will be required in pieces.

In order not to waste money on cutting insulation, carefully calculate the dimensions of the room, carefully analyze everything that is written on the packaging of this or that insulation. However, even if the mini-plate or roll tape has been trimmed, there is nothing to worry about. The waste will be useful for insulating adjacent buildings.

Mineral wool is considered almost the best insulation on the country's construction market. The sizes of different brands of these products are almost the same.

The dimensions are dictated by building codes; this standard approach largely optimizes the construction process.

When choosing insulation, it is important to take into account technical characteristics, professional advice on the purpose of a particular material, length, width, thickness and other important indicators.

A significant characteristic is density. Typically it is 11-350 kg/m kV. The highest density wool is used for internal partitions and has dimensions similar to other types of insulation.

Watch the video that explains the nuances of calculating and laying insulation:

Advice from experts

Finding out the size of stone wool is often necessary in order to calculate how much material is needed for insulation. Don’t think that it’s too easy; they often buy too much or, worse, too little material. To avoid making mistakes in calculating quantities, you need to consider the following points:

- Almost every package indicates how much area one “portion” of mineral wool can cover. This information will help determine exactly how many packages are needed.

- Do not forget that stone and any other mineral wool has properties such as shrinkage - it is better to purchase it in excess. Therefore, about 15% should be added to the results obtained. This will help avoid the formation of cracks.

- In order to minimize the consumption of insulation and waste from it, it is necessary to calculate the optimal distance at the stage of construction or installation of the sheathing, often 50-60 cm.

- It is imperative to double-check the size of the roll or sheet of insulation, since even from the same manufacturer they may differ. As well as the area of the roll.

In general, to calculate the required amount of stone wool you need:

- Determine the insulated area. To do this, multiply the length by the width. If the area is not of a standard shape, then it must be divided into its component parts.

- Determining the perimeter of the house if everything is insulated - walls, ceilings, floors. Multiply the perimeter by the height and by the number of floors, if there are several.

- If you also need to insulate the roof, then calculate its area.

- All that remains is to add up the resulting dimensions and do not forget to add about 15% for trimming the seal.

Important! Manufacturers do not take the sizes of rolls and mats from the ceiling; they are determined by building codes that help standardize the process of constructing house insulation.

Mineral wool can be of different thicknesses from the same manufacturer

General characteristics

The product is sold in two forms: slabs and rolls. The dimensions of the sheets are established by GOSTs. In the rolled version, the length of the mat can reach 10 meters, the width - from 1 to 1.5 meters. Slab parameters: 1250*610 mm. Thickness varies from 2 to 15 cm. Density is another important indicator, which indicates the number of fibers per 1 m³. On the packaging it is indicated by the letter P. Values from 35-150 are suitable for working with walls. The higher the value, the greater the load on the base.

Mineral wool differences

As we have already said, there are three types of mineral wool insulation. Each of them is made from different raw materials and has its own properties.

Glass wool

A material consisting of molten glass cullet, dolomite, sand, soda or limestone.

Advantages:

- Breathability.

- Fire resistance.

- Elasticity, vibration resistance.

- Withstands low temperatures.

- Lower cost than other mineral wool.

Minuses:

- Short shelf life - 5-10 years.

- Shrinkage 80%.

- Strongly absorbs moisture.

- If it comes into contact with the skin, it causes itching or even an allergic reaction.

As for the scope of application, it is usually mineral wool for insulating walls inside the house.

Slag

Produced from metallurgical waste. Inferior in characteristics to other types of insulation.

- Does not provide adequate sound insulation.

- Does not withstand strong heat. It does not burn, but it sinteres and loses its thermal insulation qualities.

- Does not tolerate temperature changes.

- Protective clothing and a respirator for installation are also required.

- It is impossible to insulate damp rooms with metal fasteners, since under the influence of moist air, slag will promote corrosion.

- High hygroscopicity.

Related article: Finishing panels for external walls

Plus, such a layer in the wall does not attract rodents and insects. Most often used on dry surfaces of temporary buildings or non-residential buildings.

Stone

The most expensive material. It is usually chosen for exterior work in private houses, including frame wooden houses. Rocks are used in production. Thanks to this, the final product has many advantages:

- High density and therefore strength.

- Fire resistance. Does not ignite at any temperature.

- Minimum shrinkage (5%).

- Long service life (up to 50 years).

- Provides excellent sound insulation.

- Almost does not break during operation, which happens with other types of products.

- Vapor permeability. The fibers repel moisture.

The downside is the high cost. Despite all the advantages, it is not always rational to insulate with these slabs.

Types depending on material of manufacture

The 3 options for thermal insulation slabs made of mineral wool are glass wool, stone wool and slag wool.

These varieties have a specific mineral wool width, fiber length and technological parameters that determine their popularity for use in a particular area.

Slag

Slag wool is produced from electric blast furnace slag and has a fiber size of 4 to 12 microns and a length of 16 mm. Thermal conductivity is 0.48 W/mK with increased hygroscopicity. Mineral wool dimensions - 500x1000x50 mm. This modification is hydrophobic and, more than others, has a predisposition to humidity, which does not make it possible to use it on external roof insulation, and its low level of fire safety precludes use in attic spaces.

Another disadvantage is that the fibers are quite brittle, and it is possible to work with such material only with gloves. Despite all this, given the good flexibility and uniform thickness, working with such material is quite convenient. In addition, slag wool is not heavy; even a decent amount of mats does not create a load on the roofing system. It has a very light structural structure, thermal conductivity 0.048 W/mK.

Due to its texture, it has high vapor permeability and hygroscopicity, and therefore, with this type, it is necessary to use waterproofing.

Glass wool

Glass wool is a budget building material for thermal insulation. At the same time, it has very good density and elasticity, with a thermal conductivity coefficient of 0.050 W/mK. It is made from the same consumable materials as ordinary glass - sand, soda, dolomite and limestone rocks. Fiber size up to 15 microns. The dimensions of mineral wool insulation in slabs are 1250x600x50 mm.

Permissible temperature +450C. The main advantage is the relatively low price. The disadvantages are low performance characteristics and a high risk for the human respiratory organs and skin, which forces you to quickly perform insulation work, with dense protection of the laid layer with surface material, while the worker must use special clothing, respirators and goggles when working.

Advantages and disadvantages of mineral wool for wall insulation

Let's summarize. The advantages of almost all types of mineral wool include several qualities:

- Non-flammability.

- Easy processing. Plates and rolls are cut with a knife or saw.

- Good noise and heat insulation.

- Easy installation.

- Long service life (from 5 to 50 years, except for material made from slag).

- The need to work in protective clothing and a respirator.

- Fiberglass may require additional vapor barrier.

There is also an opinion that when heated, the insulation emits fumes that are harmful to health. Manufacturers claim this is a myth. In addition, after installation, the thermal insulation layer is covered with plasterboard, boards or other finishing.

Particles released into the air when cutting products can be harmful. To do this, it is recommended to close the airways, and if fibers get on the skin, wash them off only with cool or cold water. This is necessary so that the pores do not expand and cutting dust does not get into them.

Overall, this is a modern, easy-to-use, effective material for protecting your home from high and low temperatures.

How to choose mineral wool products

First you need to pay attention to several characteristics:

- Thickness of mineral wool for wall insulation. The thicker the insulating layer, the higher its fire safety, sound insulation and strength. For interior partitions and frame structures, mats of 5 cm are suitable. For facades - from 5 to 10 cm.

- Density (P). We wrote about it above. The rigidity of the structure and its ability to withstand loads depend on it. For facades, the indicator should be in the range of 100-125 kg/m³. If plaster is chosen as finishing, then 150 kg/m³. For interior partitions - 75-90 kg/m³.

- Thermal conductivity. The smaller it is, the better. In this regard, basalt and fiberglass products have proven themselves well.

- Vapor permeability. The coefficient suitable for private buildings is that of stone wool. Designated MU1. The larger it is, the better the product.

- Fire resistance. The fire resistance level of fiberglass is 600⁰ C, material made of rock alloys is 1000º C.

What else to pay attention to

If you are planning work on the outside of the building, choose basalt slabs. When it is necessary to insulate from the inside, fiberglass coating is also suitable. When purchasing, look at the storage conditions.

- If the product gets even a little wet, there is no point in purchasing it. Check that there are no tears in the packaging.

- Blocks and rolls should be kept under cover and not outdoors.

The most famous manufacturers of mineral insulation are Isover, URSA, Rockwool, Knauf. Their products are certified and quality tested.

Other important markings

In order to understand in what form the insulation will be presented, you should consider the additional markings on the packaging. Namely:

- P-75. The number means density; the less dense the mineral wool, the more convenient it is to roll it. This is exactly the case. Such types are used for walls that will not take on a load-bearing load.

- P-125. These are already slabs, they are used for the ceiling and floor. It has increased sound insulation properties.

- PPZh-175. In addition to the fact that the density of this stone wool is 175 kg/m³, it also has increased rigidity, as indicated by the “F” marking.

- PPZh-200. The densest mineral wool, which is also fire resistant.

Mats are convenient to use on the floor

How to properly insulate walls with mineral wool

Let's first talk about what can ruin all your work.

Errors in installing mineral wool slabs

- Lack of surface preparation. It should be smooth, clean and treated with an antiseptic (if it is wood).

- Carrying out work during rainfall or leaving finished work unprotected from rain.

- Insufficient application of glue. It is correct when it is distributed over the entire surface, including the perimeter. The most suitable glue is polyurethane foam or dry mixture. The first product is easier and faster to work with, but it is a little more expensive. Both products are resistant to external influences and guarantee good adhesion.

- Unfilled seams between insulation parts. They can only be closed with inserts made of the same material. The maximum gap is 2 mm.

- Intersection of slabs at window and door corners. There should be no joint in these places.

- Lack of mechanical fastenings. Anchors and dowels are used as additional connections for heavy sheets. The optimal quantity is 3-4 pieces per piece (two in the corners, 1 or 2 in the center).

- Smooth mounting, joint to joint. Craftsmen advise installing elements in a checkerboard pattern - this makes it easier to avoid gaps in the structure.

These are the main mistakes that people make when doing thermal insulation at home on their own.

Instructions for insulating the walls of a house with mineral wool from the outside

You will need a metal profile or timber to create the sheathing, accompanying tools for building the frame, a knife or saw, fasteners and a membrane film for vapor barrier. There are two methods. Let's consider one of them. The work is carried out in several stages.

- Surface preparation. You need to remove all old layers of plaster and other finishing from it, clean off dirt and mold, carry out processing and remove all unevenness with a primer.

- Installation of the frame. After the primer has dried, mount the guides at a short distance from the facade - approximately 10-15 cm in increments of 60-100 cm, 1-2 cm less than the width of the block or roll.

- A film is placed under the first layer - with the smooth side facing the stove and the vapor-absorbing side inside. It is attached with double-sided tape or a stapler.

- The first layer of cotton wool is attached on top. Usually a softer one is chosen so that it hides any depressions or bulges if they remain after leveling. The slabs are laid from bottom to top, and the rolls from top to bottom.

- Next, more rigid elements are installed. For reliability, they can be secured with a construction stapler or mushroom dowels.

- Another layer of vapor barrier is placed on top (the film is not stretched), lathing and cladding.

In the case of mounting under a frame, it is important to know in advance the size of the mineral wool insulation for the walls in order to correctly calculate the distance between the profiles.