Coloring methods

There are two main ways of painting aluminum products: with anodizing and aniline, and also without it, but using metal enamel and primer.

Thanks to these methods, you can paint aluminum products with your own hands right at home. If you have not encountered anodizing before, it is a chemical process that is performed to ensure that aluminum does not oxidize and the paint adheres normally to its surface. It is this procedure that guarantees the highest quality painting both at home and in industry. However, even without it you can achieve acceptable results if you follow all the instructions. After all, anodizing large objects with your own hands is a very, very difficult process.

Do-it-yourself anodizing

Painting aluminum surfaces using anodizing is done as follows. You will need:

- for electrolyte solution - soda and salt;

- aluminum dishes;

- current source;

- sandpaper;

- aniline and vinegar;

- degreaser.

First we need to make the electrolyte. To do this, you need to prepare solutions of salt and soda. To do this, you need to mix them in one vessel in a proportion of 9 parts salt to 1 part soda. Mixing must take place in a glass container!

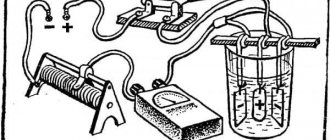

We process the product to be painted with sandpaper and degrease its surface. After this, it should be dipped into water, being careful not to touch the surface of the profile with your hands. You need to pour an electrolyte solution into an aluminum dish and put the object to be painted in it. Next, connect the current source with the positive pole to the product, and the negative pole to the cookware. Let's leave it for 2 hours.

After this, you can proceed to painting with aniline dye. To prepare it, you need to add 1 ml of vinegar, 15 g to a liter of water. dye and heat about 75-80 degrees.

Next, we place the object to be painted in this solution for about a quarter of an hour. Now you know how to paint anodized aluminum.

Alternative technology

How to paint aluminum without anodizing at home? You will need:

- sandpaper;

- primer;

- epoxy or acrylic paint for metal (aerosol is more suitable than standard powder paint if painting is done at home);

- degreaser.

First you need to properly sand the product. Next, the profile should be degreased. After this, you need to start priming the profile surface as quickly as possible. After complete priming, you can begin applying paint. It is better to use an aerosol.

After painting, leave the profile to dry for 6 hours, after which its surface can be coated with an additional layer of varnish. This is exactly how painting aluminum at home ends up if you do it yourself.

But there is an even easier way to dye at home! To implement it, you just need to sand the product well and then degrease it. Afterwards you need to apply a special enamel paint on it. Be careful to follow all instructions on the enamel can exactly! The painting will be finished after drying.

Painting with powder paint

If you have the opportunity to use some production tools for painting, then an excellent option for you would be to give the aluminum a new color using powder paint.

This method of painting requires treating the part with a special solvent that will not leave previous layers of paint on the object. Next, a powder coloring agent is applied. This is done evenly and carefully so that the color is rich and permanent.

Immediately after applying powder paint, the part will not seem too perfect, but then the item must be placed in a special industrial heat chamber.

There, the part and the coloring powder are heated to a high temperature, due to which the powder begins to melt, uniformly coloring the surface to which it is applied.

This method of painting aluminum parts is the most durable and reliable, because this paint is of high quality. But carrying out a similar process at home is more than difficult.

Painting non-ferrous metal surfaces is a difficult process, but if you approach it competently, it can be easily accomplished even at home. The main thing is to follow the rules!

Features of aluminum anodizing

Although some of you prefer lighter colors, in practice they are difficult to reproduce on some alloys such as silicone castings and 2000 series aluminum-copper alloys.

- Another problem is organic paints, which are prone to fading when exposed to too much sunlight.

- Some colors, such as red and blue, are particularly prone to discolouration.

- Black and gold paints produced for inorganic purposes (ammonium oxalate) are much more prone to discolouration.

- Anodizing with paint usually reduces or eliminates paint bleed.

- Alternatively, the metal (usually tin) can be electrolytically stored in the pores of the anodic film to ensure that those colors most prone to losing brightness are retained.

- The color range of metal paints varies from various shades of white to black. Bronze colors are used for architectural metals.

Alternatively, the color can be applied entirely to the film. This can be done through an anodizing process with organic acids mixed with sulfur electrolytes and pulsed current.

The "splash" effect is created by painting an uncovered porous surface in light colors and then spraying darker colors over them. Water-based mixtures and solvent-based paint can be applied alternately as they stick quite well and leave stains.

Images that will have the quality of photography and graphics in vibrant colors can be printed in open pore oxide film using dyes through screen printing, sublimation or digital printing.

Electrochemical painting method

It is better to paint aluminum using the electrochemical method, but it is not accessible to everyone and is quite labor-intensive. The process goes like this: first, electrochemical oxidation is performed, then a primer is applied, then paint. Before oxidation, the surface is chemically cleaned. After oxidation, a protective oxide film is obtained on top. To increase the resistance of such a film to corrosion, before priming, the part is placed in a chromium solution.

The oxidation process is performed electrochemically or chemically.

With the electrochemical method, the appearance of an oxide layer is achieved by passing current through an acidic electrolyte solution. And after that they are treated with chromium and covered with paint or varnish.

During chemical oxidation, aluminum is treated in special solutions of sodium bichromate, chromic anhydride, and potassium fluoride.

Read also: Grades of aluminum alloys and their applications

At home, oxidation is quite difficult. It is necessary to have certain skills and strictly adhere to safety rules when working with chemicals.

After obtaining a layer of oxide by oxidation, you can begin painting the aluminum. To do this, purchase aniline dyes in the store - powders used for dyeing woolen fabrics. The aluminum part is placed in a hot (50-60°C) solution of aniline dye and kept there for no more than 20 minutes. After painting, the part is removed from the water, dried and coated with colorless varnish.

Where is the aluminum anodizing method used?

Anodized aluminum alloy parts are most commonly used in aircraft manufacturing, a number of architectural components, as well as consumer products (refrigerators, microwaves and grills), sporting goods (baseball bats, golf carts and equipment), etc.

The most well-known anodizing processes, such as sulfuric acid on aluminum, create a porous surface that easily accepts paint. The number of colors in paints is almost endless; however, the resulting colors tend to vary depending on the base of the alloys.

Painting aluminum at home

If you need to paint aluminum at home, you should follow all painting steps very clearly and consistently. An aluminum product must first be cleaned, then degreased and primed, and only then applied paint. The quality of the primer and paint is of great importance in this process. It is important to choose a good primer “for stainless steel, galvanized coatings and aluminum.” Special two-component epoxy/polyester paints can be used for painting. Use sandpaper to remove all old paint and white powder. Apply the first coat of primer as quickly as possible before the aluminum becomes dull. The oxidation process of aluminum in air occurs very quickly, so it is important to apply the first layer of primer as quickly as possible, before oxides form. After applying the first layer, wait the time specified in the manufacturer's instructions. When applying the second layer, there is no need to rush.

Even if the primer package says that no surface cleaning is required for its application, it is better to do so. Freshly cleaned aluminum will adhere better to paint. The sooner painting is done after mechanical cleaning, the better the adhesion.

Varieties of suitable paints for painting

There are four types of aluminum paints that meet the requirements to varying degrees. Coatings have their pros and cons, so when choosing, you should take into account the purpose of the part to be painted.

Aniline

The main area of application of aniline dyes is the textile industry. They are available in powder and liquid form.

Aniline is a toxic substance, but after drying the product is safe for health.

Epoxy

Resins form the strongest compounds.

Durable epoxy paints typically consist of two components—a base compound and a volatile hardener.

Acrylic

The paint base is a polymer that adheres firmly to the surface.

Aerosol paints are easy to use. The sprayer can be used to paint hard-to-reach corners and small elements. Acrylic paints are also more varied in color. White compositions can be colored.

Powder

Another advantage of powder coating is the absence of toxic emissions from the composition or solvent, more economical consumption. Most often, to fix the dye, parts are subjected to heat treatment in a special heat installation, so the technology cannot be reproduced at home.

How to paint aluminum yourself

The process of painting aluminum at home will not be easy. This is a complex event that requires compliance with all conditions. Even with minimal damage or scratches, the applied coating will easily peel off the metal. Only specialized paints and primers are used for aluminum. However, the anodizing process is most often still necessary.

There are various DIY painting methods. But we cannot say that the painting is carried out with very high quality, since the procedure must be carried out under appropriate conditions. This is explained by the properties of aluminum, which is easily oxidized by air.

The ideal painting method would be anodizing under special conditions and applying paint using professional equipment. It is in this case that the surface receives a high-quality and durable coating.

It will be no secret for any specialist who knows the properties of aluminum that there are 3 ways to paint it without specialized equipment. But you still can’t do it without special devices or reagents. Using regular paint and primer will get you nowhere. Only these three methods are effective:

- Powder painting;

- Anodizing or using aniline dyes;

- Use special primers or enamels, having previously degreased the surfaces. This method is also called “painting without anodizing.”

Historical reference

The first and most important of these was the development of the anodizing process, which transformed the aluminum surface into an extremely strong, durable and corrosion-resistant material.

Aluminum alloys are highly valued as low-maintenance materials that, due to their high temperature control and versatility, can be used in a wide range of applications, from the kitchen segment to aircraft and spacecraft.

These are not very hard materials. However, unlike pure aluminum, they are not passivated, so they are more susceptible to corrosion and rust. To maximize the benefits of aluminum and improve its durability, hardness, and corrosion resistance, these and other industries resort to the process of anodizing aluminum.

Powder coating

Powder painting of aluminum involves treating the metal surface with special chemical compounds, and then applying a layer of powder paint. The part is then treated with high temperature, causing the dye to melt, ensuring the strength and durability of the polymer layer. The advantage is a wide range of colors, i.e. you can create a golden color or chrome without any problems. Defects that arise can be easily removed with a special coloring pencil. The widespread use of the method eliminates the need for specific equipment.

Powder painting is carried out in two stages. The first is the use of special solvents to remove previous layers. The second is treatment with a coloring composition. If everything was limited to this, then there would be no difficulties.

However, in order for painted, for example, alloy wheels or profiles to acquire the required attractiveness and be reliably protected, their surface must be additionally heated. This can be done using a thermal camera. In it, prepared surfaces are treated at high temperatures so that the applied powder paint spreads in an even, durable layer.

It is not always possible to use powder coating of aluminum. The price of specialist help can also be considerable. Therefore, for self-processing, you can use other staining methods.

Anodizing

This method involves applying a protective layer using the galvanic method. The most durable coating is obtained using this method. Most often, other methods achieve only temporary results.

Anodizing is a process of improving the appearance and providing protection against oxidation. Upon completion of the procedure, the metal can be painted with the necessary material, for example, aniline paint.

To work you will need the following:

- Salt, soda - to prepare the electrolyte.

- Aluminum cookware.

- Current source.

- Sandpaper.

- Vinegar.

- Aniline.

- Degreasing agent.

This electrochemical method requires strict adherence to operating technology. It looks like this step by step:

- To begin, prepare your own electrolyte solution from salt and soda. The required volume of water to fully accommodate the workpiece should be determined in advance.

- The water is divided into 2 equal portions, from which a solution with soda and salt is prepared separately. Then they are mixed. The percentage should be approximately: 9 parts salt to 1 part baking soda. Mix in a glass container.

- After this, the part must be thoroughly sanded and degreased (for example, with acetone).

- Immersed in water. It is advisable not to touch the prepared surface. Then the workpiece is placed in an aluminum vessel with a solution.

- The current source is connected. “Plus” - for the part, “minus” - for the dishes. The power source can be a 12 V car battery with a current of 2 A. The current density should be based on a calculation of approximately 15 mA per 1 cm2.

- It remains turned on for about two hours, or rather, until the solution turns grayish-bluish.

Read also: Analyzers of the chemical composition of metals and alloys

Upon completion of the process, aniline dye should be prepared with water and acetic acid. The proportions are as follows: for 1 liter of water add 1 ml of vinegar and 15 grams of paint. The composition must be heated to 75 – 80°C. This solution must be poured into a vessel with an anodized element. Many automotive and other parts often need to be painted black or other colors. This can be done quickly and cheaply in a similar way.

This method, despite its apparent complexity, is the simplest and least expensive of all. It has gained well-deserved popularity, as it allows you to obtain the most durable, water-resistant surface on such a finicky material.

Special primers and enamels

In order not to use the anodizing method, but not to reduce the quality of the created surface, you can use a special primer that provides high adhesion. To do this, the following tools and materials are needed:

- Painting equipment - brushes or sprayers.

- Sandpaper.

- Special alkyd primer.

- Suitable paint for aluminum.

- Degreasers – acetone, white spirit, kerosene.

This staining method requires some preparation. To find special dyes and primers for painting aluminum elements (bumpers, boats or corrugated sheets), you will have to study the assortment of more than one hardware store. The dye is worth buying epoxy or acrylic. For home processing, it is better to choose an aerosol than a powder dye. However, searching and purchasing materials is one of the initial stages of processing. Alternative painting of aluminum involves performing the following operations:

- Surface treatment with sandpaper. You should get a uniform matte surface. It is optimal to use sandpaper with 1200 grit.

- Removing dust and dirt.

- Degreasing with special compounds.

- Treatment with a special primer. Moreover, it is necessary to complete priming after the degreasing effect ends.

- Uniform application of paint from a can onto a primed surface. Apply in 2-3 layers with a short interval necessary for the previous one to dry.

- Drying of the part within 6 hours.

- Applying protective varnish to the dry surface.

- If necessary, polish the finished surface.

You can use a less complex version if you have a grinding machine. After careful sanding, the surface is quickly treated with special enamel. In this case, you must strictly follow the instructions for using the coloring composition. If you have the necessary materials and tools, then this method is very simple.

To carry out all the activities with your own hands, you need to tune in to quickly carry out all stages, acquire basic knowledge of chemistry and reactions, as well as available tools. To study the process in detail, you can use the video provided and study the photos, which explain all the nuances of the procedure. In this case, high-quality painting will not be difficult.

We also recommend reading:

Casting aluminum yourself at home

What is aluminum anodizing

The process of painting aluminum at home will not be easy. This is a complex event that requires compliance with all conditions. Even with minimal damage or scratches, the applied coating will easily peel off the metal. Only specialized paints and primers are used for aluminum. However, the anodizing process is most often still necessary.

There are various DIY painting methods. But we cannot say that the painting is carried out with very high quality, since the procedure must be carried out under appropriate conditions. This is explained by the properties of aluminum, which is easily oxidized by air.

The ideal painting method would be anodizing under special conditions and applying paint using professional equipment. It is in this case that the surface receives a high-quality and durable coating.

Tips and Cautions

How to paint aluminum correctly so that it does not peel off:

- Metal that has been sanded must not be left in the open air. The reaction with oxygen will cause the part to oxidize, and the primer will not be taken. The work will have to start again. Therefore, after sanding and degreasing, you need to immediately start priming;

- if the spray bottle is clogged, you need to shake the bottle and spray paint on the rough surface until the layer lies evenly;

- suitable sandpaper fraction for sanding is 600, 800 and 1200;

- the aluminum window profile is sanded with 500-grit sandpaper, primed and painted using a spray gun, and the glass is first wiped with alcohol and covered with masking tape over plastic film;

- Automotive aerosol paint is suitable for painting aluminum profiles in sliding furniture;

- The old coating from an aluminum boat is removed with a grinding machine or a remover; it can be painted with a roller or spray gun. It is better to use epoxy compounds to paint the bottom;

- The specialized paint Hammerite has proven itself well. This is a durable anti-corrosion coating that is applied to rust without priming. But it requires a solvent from the same manufacturer, which is difficult to find on sale.

Safety precautions for home painting aluminum:

- work in a ventilated area;

- Before painting, carry out wet cleaning so that dust does not settle on the parts and does not mix with the paint;

- Do not paint near heat sources - near a radiator, stove, or in direct sunlight;

- remove chemicals, gasoline cans, medical solutions, and household chemicals from the work area;

- Use lamps for lighting.

When working with powder dye, you need to wear protective clothing:

- thick medical gown;

- gas mask or respirator with safety glasses;

- gloves.

During painting, it is important to maintain cleanliness: thoroughly clean the surface of dust after sanding, avoid drips and drops of paint, and when working in a garage or shed, ensure that midges do not get into the composition. The coating on a flat surface lasts longer.

Coloring methods

It will be no secret for any specialist who knows the properties of aluminum that there are 3 ways to paint it without specialized equipment. But you still can’t do it without special devices or reagents. Using regular paint and primer will get you nowhere. Only these three methods are effective:

- Powder painting;

- Anodizing or using aniline dyes;

- Use special primers or enamels, having previously degreased the surfaces. This method is also called “painting without anodizing.”

Powder coating

Powder painting of aluminum involves treating the metal surface with special chemical compounds, and then applying a layer of powder paint. The part is then treated with high temperature, causing the dye to melt, ensuring the strength and durability of the polymer layer. The advantage is a wide range of colors, i.e. you can create a golden color or chrome without any problems. Defects that arise can be easily removed with a special coloring pencil. The widespread use of the method eliminates the need for specific equipment.

Powder painting is carried out in two stages. The first is the use of special solvents to remove previous layers. The second is treatment with a coloring composition. If everything was limited to this, then there would be no difficulties.

Read also: How to sharpen drills for metal using sandpaper

However, in order for painted, for example, alloy wheels or profiles to acquire the required attractiveness and be reliably protected, their surface must be additionally heated. This can be done using a thermal camera. In it, prepared surfaces are treated at high temperatures so that the applied powder paint spreads in an even, durable layer.

It is not always possible to use powder coating of aluminum. The price of specialist help can also be considerable. Therefore, for self-processing, you can use other staining methods.

Features of the material

An oxide film forms on the surface of aluminum, like any metal. On aluminum it has the following features:

- the surface is covered with a thicker layer than on other metals, regardless of the processing method and environmental conditions;

- the film prevents moisture from reaching the surface, so water-based paints do not adhere to aluminum;

- oil paint also peels off - slower from smooth parts, faster from shaped parts.

Surface particles of the material come into contact with oxygen from the atmosphere. As a result, aluminum oxide is formed, covering the product with a dense layer. The metal appears to be dusted with white dust and is slightly rough to the touch.

Anodizing

This method involves applying a protective layer using the galvanic method. The most durable coating is obtained using this method. Most often, other methods achieve only temporary results.

Anodizing is a process of improving the appearance and providing protection against oxidation. Upon completion of the procedure, the metal can be painted with the necessary material, for example, aniline paint.

To work you will need the following:

- Salt, soda - to prepare the electrolyte.

- Aluminum cookware.

- Current source.

- Sandpaper.

- Vinegar.

- Aniline.

- Degreasing agent.

This electrochemical method requires strict adherence to operating technology. It looks like this step by step:

- To begin, prepare your own electrolyte solution from salt and soda. The required volume of water to fully accommodate the workpiece should be determined in advance.

- The water is divided into 2 equal portions, from which a solution with soda and salt is prepared separately. Then they are mixed. The percentage should be approximately: 9 parts salt to 1 part baking soda. Mix in a glass container.

- After this, the part must be thoroughly sanded and degreased (for example, with acetone).

- Immersed in water. It is advisable not to touch the prepared surface. Then the workpiece is placed in an aluminum vessel with a solution.

- The current source is connected. “Plus” - for the part, “minus” - for the dishes. The power source can be a 12 V car battery with a current of 2 A. The current density should be based on the calculation of approximately 15 mA per 1 cm 2.

- It remains turned on for about two hours, or rather, until the solution turns grayish-bluish.

Upon completion of the process, aniline dye should be prepared with water and acetic acid. The proportions are as follows: for 1 liter of water add 1 ml of vinegar and 15 grams of paint. The composition must be heated to 75 – 80°C. This solution must be poured into a vessel with an anodized element. Many automotive and other parts often need to be painted black or other colors. This can be done quickly and cheaply in a similar way.

This method, despite its apparent complexity, is the simplest and least expensive of all. It has gained well-deserved popularity, as it allows you to obtain the most durable, water-resistant surface on such a finicky material.

Other Anodizing Methods

In addition to the classic method described above, hard anodizing, micro-arc and color anodizing can also be used. These methods of metal processing will be briefly discussed below.

The goal of hard anodization is to obtain a particularly strong microfilm. The technique is widely used in aircraft, automotive and construction industries. The peculiarity of the technology is that not one, but several electrolytes are used at once. For example, oxalic, sulfuric, citric, tartaric and boric acids can be used in one process. During anodization, the current density gradually increases, and due to structural changes in the cells, the film acquires increased strength.

Micro-arc oxidation scheme

Microarc oxidation is an electrochemical process in which the surface of aluminum is oxidized, and at the same time electric charging phenomena occur between the anode and the electrolyte. The technique makes it possible to obtain particularly high-quality coatings with a high level of wear resistance and adhesion.

Another method of anodizing is color. As the name suggests, the main task of the process is to change the color of the part.

There are four methods of color anodizing:

- Coloring by adsorption method. It is carried out by immersing the product in an electrolyte bath. It is also possible to dip the part into a solution with a dye heated to a given temperature.

- Electrolytic painting (another name is black anodizing). First, a colorless film is obtained, and then the metal is dipped into an acidic saline solution. The final color of the product can vary from black to a faint bronze tint. Black tones of aluminum are especially in demand in the construction industry.

- Interference staining. The technology is similar to electrolytic dyeing, but due to the creation of a special reflective layer, the color shades are much more varied.

- Integral coloring. The technology involves mixing an electrolyte with organic salts.

Special primers and enamels

In order not to use the anodizing method, but not to reduce the quality of the created surface, you can use a special primer that provides high adhesion. To do this, the following tools and materials are needed:

- Painting equipment - brushes or sprayers.

- Sandpaper.

- Special alkyd primer.

- Suitable paint for aluminum.

- Degreasers – acetone, white spirit, kerosene.

This staining method requires some preparation. To find special dyes and primers for painting aluminum elements (bumpers, boats or corrugated sheets), you will have to study the assortment of more than one hardware store. The dye is worth buying epoxy or acrylic. For home processing, it is better to choose an aerosol than a powder dye. However, searching and purchasing materials is one of the initial stages of processing. Alternative painting of aluminum involves performing the following operations:

- Surface treatment with sandpaper. You should get a uniform matte surface. It is optimal to use sandpaper with 1200 grit.

- Removing dust and dirt.

- Degreasing with special compounds.

- Treatment with a special primer. Moreover, it is necessary to complete priming after the degreasing effect ends.

- Uniform application of paint from a can onto a primed surface. Apply in 2-3 layers with a short interval necessary for the previous one to dry.

- Drying of the part within 6 hours.

- Applying protective varnish to the dry surface.

- If necessary, polish the finished surface.

You can use a less complex version if you have a grinding machine. After careful sanding, the surface is quickly treated with special enamel. In this case, you must strictly follow the instructions for using the coloring composition. If you have the necessary materials and tools, then this method is very simple.

To carry out all the activities with your own hands, you need to tune in to quickly carry out all stages, acquire basic knowledge of chemistry and reactions, as well as available tools. To study the process in detail, you can use the video provided and study the photos, which explain all the nuances of the procedure. In this case, high-quality painting will not be difficult.

We also recommend reading:

LMB selection

The quality of painting aluminum with your own hands depends not only on the skill of the artist, but also on the properties chosen by the paintwork material. There are several paint options suitable for aluminum surfaces:

- Aniline. It is used to add color to textiles. Although this paint material has the slight disadvantage of being susceptible to UV light and moisture, it is excellent for creating a coating on anodized aluminum products. This coating material is available not only in powder, but also in liquid form. Using the second option will save effort and time.

- Epoxy. The basis of this material is resin of the same name. They provide the following paint properties: strength, durability and immunity to the influence of negative factors.

- Acrylic. It is resistant to high temperature, moisture, and mechanical damage. Aluminum painting technology allows the use of this material after applying a special primer to the metal surface.