Aluminum objects are widely used in everyday life. Over time, they lose their attractiveness. Painting the aluminum will help restore it. You can do this yourself, but there are some nuances in the work. When the material comes into contact with air, it oxidizes and a plaque that is difficult to remove appears. To ensure that the dyeing results are not negative, the paint lasts a long time, all actions are performed according to the instructions.

If in production for applying paint to aluminum, conditions are created so that there is no oxidation of it, components are introduced into the composition of the CM, then painting the material at home will work if you use the advice of craftsmen who have gone through all the stages of preparation and got a good result.

Self-painting with anodizing

Materials are prepared before painting aluminum using anodizing and aniline:

- baking soda and ash salt - for electrolyte solution;

- aluminum container;

- power point;

- sandpaper sheet;

- vinegar 9% and aniline;

- degreasing agent.

The electrolyte is being prepared. A solution of salt (9 parts) and baking soda (1 part) is mixed in a glass container.

Before painting aluminum, it is sanded with a sheet of sandpaper and degreased. An object is immersed in a liquid. You cannot touch it with your hands.

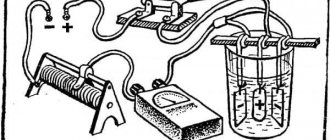

The electrolyte solution is poured into an aluminum container. The product to be painted is immersed in it. The power supply point is connected to it with the positive pole, and to the container - with the negative pole.

Everything is left in this state for 2 hours.

Next, aniline CM is used. Its components: liquid - 1 liter, vinegar, 9% - 1 ml, dye - 15 g. all components are mixed and heated to 75-80 degrees. Painting an aluminum profile immersed in the solution will take 15 minutes. The longer the item is in the solution, the richer the shade will be.

At-Home Painting Instructions

In addition to choosing durable paint, the method of painting aluminum is important. There are three main methods of painting a specific metal. The most durable result is obtained after anodizing - keeping the part in an electrolyte solution under voltage.

Anodizing technology

To increase aluminum adhesion you will need:

- salt or soda;

- distilled water;

- glass and aluminum basin;

- fine-grained emery;

- battery with a current of 2 Amperes and a voltage of 12 Volts;

- electrodes;

- acetone.

- prepare a concentrated solution of salt or soda in different dishes;

- leave the concentrate for 15 minutes and strain;

- mix part of the solution with nine parts of water in a glass container;

- sand the aluminum part with sandpaper;

- degrease with acetone;

- rinse in water;

- Do not touch the washed part with your hands so that stains do not remain;

- dip in each solution in turn for 30 minutes;

- connect the anode to the part, the cathode to the container, connect the electrodes to the battery;

- give voltage for 1.5-2 hours.

To prepare the coloring composition you will need:

- 15 grams of aniline dye;

- 1 milliliter acetic acid;

- liter of water.

- mix dye and acid in water;

- heat to 80 degrees;

- lower the prepared aluminum part into the mixture;

- take it out after 15 minutes.

For intense coloring, the part is kept in the solution longer, and for light tinting - less.

The color of anodized aluminum can be changed by holding the product in chemical solutions. The following table shows how to prepare them and obtain a certain shade:

| Solution 1 | Solution 2 | Color | ||

| Name of salt | Dosage in grams per liter of water | Name of salt | Dosage in grams per liter of water | |

| Hexation-(II)potassium ferrate | 10-50 | Iron(III) chloride | 10-100 | Blue, light blue |

| Hexation-(II)potassium ferrate | 50-100 | Copper(II) sulfate | 10-100 | Brown |

| Potassium dichromate | 50-100 | Lead acetate | 100-200 | Yellow |

| Potassium chromate | 5-10 | Silver nitrate | 50-100 | Orange |

| Barium chloride | 10-50 | Sodium sulfate | 10-50 | White |

| Cobalt acetate | 50-100 | Potassium permanganate | 25-30 | Black |

Techniques without anodizing

At home, painting aluminum profiles is carried out using other practice-tested methods. For this you will need materials:

- sandpaper sheet;

- primer composition;

- degreaser;

- epoxy or acrylic CM for metal. For self-use, an aerosol formulation is recommended.

The surface is sanded, degreased, coated with primer and CM. The product is ready for use after 6 hours. Additionally, painted aluminum is varnished for protection.

Acid primer technology

To make painting an aluminum profile less problematic, new surface treatment products are being developed and produced that enhance the adhesion of CM to the surface. At the car market you need to purchase a special acid primer, regular and spray paint.

Before painting aluminum, the metal is cleaned, degreased, and covered with 2 layers of acid primer. A regular primer is applied to the dried base, powdering it so that it is transparent. This is aluminum painting, technology using aerosol compositions. Therefore, the dye will be aerosol.

Enamel paint coating

For the simplest method of painting metal, you need: sandpaper, degreaser and enamel paint. It is cleaned, degreased and painted with special enamel. KM is applied strictly according to the instructions prescribed by the manufacturer on the container. Such conditions ensure that enamel paint for aluminum will adhere to high quality.

Tips and Cautions

How to paint aluminum correctly so that it does not peel off:

- Metal that has been sanded must not be left in the open air. The reaction with oxygen will cause the part to oxidize, and the primer will not be taken. The work will have to start again. Therefore, after sanding and degreasing, you need to immediately start priming;

- if the spray bottle is clogged, you need to shake the bottle and spray paint on the rough surface until the layer lies evenly;

- suitable sandpaper fraction for sanding is 600, 800 and 1200;

- the aluminum window profile is sanded with 500-grit sandpaper, primed and painted using a spray gun, and the glass is first wiped with alcohol and covered with masking tape over plastic film;

- Automotive aerosol paint is suitable for painting aluminum profiles in sliding furniture;

- The old coating from an aluminum boat is removed with a grinding machine or a remover; it can be painted with a roller or spray gun. It is better to use epoxy compounds to paint the bottom;

- The specialized paint Hammerite has proven itself well. This is a durable anti-corrosion coating that is applied to rust without priming. But it requires a solvent from the same manufacturer, which is difficult to find on sale.

Safety precautions for home painting aluminum:

- work in a ventilated area;

- Before painting, carry out wet cleaning so that dust does not settle on the parts and does not mix with the paint;

- Do not paint near heat sources - near a radiator, stove, or in direct sunlight;

- remove chemicals, gasoline cans, medical solutions, and household chemicals from the work area;

- Use lamps for lighting.

When working with powder dye, you need to wear protective clothing:

- thick medical gown;

- gas mask or respirator with safety glasses;

- gloves.

During painting, it is important to maintain cleanliness: thoroughly clean the surface of dust after sanding, avoid drips and drops of paint, and when working in a garage or shed, ensure that midges do not get into the composition. The coating on a flat surface lasts longer.

Source

Powder coating technique

Aluminum powder paint is used if there is access to special thermal equipment.

The old layer of CM is removed with a special solvent. The powder composition is applied. Accuracy in work is the key to uniform surface coverage. The color will then be rich and lasting. The appearance of the part at this stage will be far from perfect.

The aluminum part is subject to heat treatment: it is placed in a special industrial chamber. The covering layer melts under the influence of high temperatures and spreads evenly on the surface.

The absence of such a heat chamber at home reduces the possibility of using powder paint painting techniques.

Methods for painting aluminum at home

Aluminum painting at home can be done with or without anodizing. Anodizing is a special processing of non-ferrous metals using chemical or electrochemical methods that stop the oxidation of the material. After this treatment, aluminum is much easier to paint, since its adhesion to the primer and paint mixture increases. However, this process is not the simplest, so you can paint metal at home without it, but be sure to take into account all the nuances of the process.

Please note: Can acrylic paint be applied to alkyd paint?

Anodized

In this case, the surface undergoes long-term anodizing and aniline dyes are used. The method is good when it is necessary to process a small part, since it must be completely immersed first in an electrolyte solution and then in a dye. For this painting technology, it is necessary to prepare aluminum dishes into which the object to be painted can be immersed, fine-grained sandpaper, aniline paints, concentrated acetic acid for them, a 2A/12V current source, boiled water, soda and salt for anodizing, any solvent for degreasing the part. Painting aluminum parts looks like this:

- First you need to prepare the electrolyte. There should be enough of it so that the part can be completely dipped into the solution. To do this, first separately make two concentrated solutions with boiled water: soda and kitchen salt in a ratio of 1:5. Then in a glass jar you need to mix 9 parts of soda with 1 part of brine.

- Sand the product to be painted thoroughly with fine sandpaper to remove the oxide film.

- Degrease the cleaned surface with a suitable solvent, then rinse the product in plain water.

- Pour electrolyte into an aluminum vessel, place the product there, and connect the current. Connect the current source, for example, a car battery, with the plus to the object and the minus to the metal container. So you need to hold the product for 1.5 to 2 hours for the anodizing process to take place. Upon completion, a bluish-gray color will appear on the surface of the aluminum.

- Now comes the turn of coloring. This requires aniline dyes. To prepare the composition, you need to mix 15 g of pigment with 1 liter of water and 1 ml of vinegar, heat the solution to 80 degrees. The product must be immersed in the pigment solution for 15 minutes.

Modern offers from manufacturers

Manufacturers are developing coatings of different compositions, which are used taking into account painting methods, the required protective and aesthetic qualities of an aluminum structure.

CMs for metal with direct adhesion to the base have been developed. Using them reduces painting time. Aluminum painting begins without pre-treatment with primers. Due to this, less time is spent on the entire process. Manufacturer LECHLER, Italy produces such compositions. Their products with strong anti-corrosion protection for aluminum structures operating in aggressive environments are in demand: Epoxy anti-corrosion primer EPOFAN PRIMER 29175 (LS175) is applied in one layer, followed by a two-layer coating of gloss paint for metal ISOLACK 29144 (LS144) or matte paint for metal ISOLACK PUR OPACO 29141 (LS141). A coating resistant to mechanical and chemical influences is formed. Over a long period of operation, the brightness of the color is maintained under the influence of external factors. Orders are accepted by Industrial Coating Systems LLC in St. Petersburg, contact by mail or 8-812-902-502-8 - placing orders, selecting paint from the RAL catalog (for example, in tandem with epoxy anti-corrosion primer with zinc phosphate 5204 in 1 layer is used Metal paint 2285 in pastel colors or in silver, gold or metallic.

CMs for metal of the LECHSYS brand allow you to work using the technology: “wet” application.

How to paint aluminum

Any compositions are not suitable for this metal. Only those suitable for use on non-ferrous metals should be used. Since painting aluminum is quite difficult, it is best to choose products that are marked “for aluminum” on the label.

Acrylic mixtures

The basis of these paints is acrylic polymer. Due to this, the coating is resistant to temperature fluctuations, it is not afraid of water, and is highly resistant to scratches. Acrylic-based compositions require mandatory preparation of the metal surface - anodizing. It is better to use aluminum paints that come in cans. Due to spraying, it is much easier to apply the composition evenly than using a brush, because it often leaves unsightly stains.

Paint for aluminum

Aniline dyes

When deciding what to paint aluminum with, pay attention to dyes with aniline. Such compositions are in demand when dyeing yarn, fabrics, clothing, and leather. They are used both in production and at home. They are inexpensive. If you prepare the solution correctly, it will also be useful for imparting color to aluminum. Aniline dyes are sold as liquid or powder in a variety of colors. Pigments are toxic compounds, so precautions must be taken when working with them. After drying on metal, aniline dyes do not pose any danger; they are suitable for processing aluminum parts without prior anodizing.

Aniline dyes

Epoxy composition

Epoxy resin paints are a good solution for processing aluminum profiles. However, they are not so easy to work with, especially if you don’t have the skills, because painting requires skill and quick completion of the procedure. But the coating is strong and durable, it is resistant to various factors.

Epoxy enamel

Powder paints

Powder paint for aluminum is one of the most modern and effective compositions for processing various metals - from steel to aluminum. The surface is first prepared, and then the composition is applied using a sprayer. In order for powder paint to adhere well to the material, the mixture must literally be melted, so painting is more suitable for production conditions. It requires special equipment (thermal chambers), so this option is useful only for constant work (repair shop, small production).

Powder painting

What affects the effectiveness of dyeing?

All actions for preparing and painting aluminum structures will be effective if certified materials are used in the work. This is necessary both for self-dying and for specialized companies. Powder dyes from the international concern based in the Netherlands, Akzo Nobel, and a brand from France, Bichon, are in demand on the Russian market.

If you contact a company that organizes a full cyclical process, the painting of the aluminum profile will be done quickly and with the highest quality. Price for painting aluminum profiles according to the price list: from 189 rubles per 1 m2.

Many companies that sell paints and varnishes for metal offer them in an assortment of colors. Moskovskaya offers a wide selection of paints according to the RAL catalog. There is contact by phone or by mail

Features of aluminum

Aluminum is widely used because it is easy to process, lightweight and does not rust at all. But coloring it is a bit complicated. This is due to the fact that silver metal oxidizes very easily. Even under normal conditions, it interacts with oxygen in the air, which is why it becomes covered with a coating, a film to which the paint practically does not stick. Therefore, without special preparation and specific painting techniques, the decorative layer will simply fall off after drying.

Aluminum products

Adviсe

Recommendations from experts will help you obtain a high-quality painted surface:

- The even distribution of the dye released by the can will be ensured by frequent, strong shaking. The action provokes constant mixing of the components, acquiring homogeneity.

- Before applying paint, clean the nozzle to ensure an even spray. Turning the can upside down, press the spray until the spraying liquid becomes clear.

- It is recommended to sand the surface with coarse sandpaper. 600 material number will do an excellent job of treating the surface before applying the last protective layer.

Choosing any method, following the recommendations, technology, sequence of actions will allow you to obtain a high-quality painted part, protected from oxidative processes. For work, it is important to choose high-quality materials, paint and varnish products, and degreasing solutions, then the result will be positive.