Paint BT-177 – what kind of product is it?

A highly specialized coating material, popularly called “serebryanka” paint BT-177 is a composition of a mixture of bitumen varnish and crushed aluminum, colloquially called “serebryanka”.

This is a composition of a mixture of bitumen varnish and crushed aluminum, popularly called “serebryanka”.

Purpose of the material, where it is used

It is ideal for protecting and covering various types of surfaces exposed to weathering and aggressive environments. It is possible to use paint for exterior and interior decoration. However, there are a number of restrictions regarding silverfish, namely:

- Use in children's and medical institutions, as well as other facilities subject to high safety conditions is prohibited;

- Not compatible with surfaces that can heat up above 80 degrees;

- Do not paint food products and containers (water containers, food storage containers);

- Cannot be used on material that has constant contact with water.

Not compatible with nitro enamel or alkyd paint. Oil-bitumen paint and enamel are incompatible with each other.

It is ideal for protecting and covering various types of surfaces exposed to weathering and aggressive environments.

Main characteristics and properties of paint, advantages

Silver paint BT-177 and its advantages:

- Anti-corrosion effect and creation of wear-resistant protection;

- Protection from environmental influences;

- Beautiful external (has a beautiful shade, after drying, creating a smooth surface with a metallic shine effect);

- Quick drying after application.

Long-term preservation of original characteristics and appearance, subject to application technology.

Silverstone is not explosive, but may ignite if exposed to fire or heat. The reason for this is the flammable component included in the paint. Safety is not limited to compliance with measures for storing silver or its individual components.

Long-term preservation of original characteristics and appearance, subject to application technology.

When preparing the composition and its use, precautions must be taken, because paint is a substance dangerous to the human body. Work must be carried out in a ventilated area and using a respirator. Otherwise, silverfish vapors can affect the respiratory tract and cause serious consequences.

GOST 5631-79 Varnish BT-577 and paint BT-177. Specifications

STATE STANDARD OF THE USSR UNION

VARNISH BT-577 AND PAINT BT-177

TECHNICAL CONDITIONS

GOST 5631-79

USSR STATE COMMITTEE FOR PRODUCT QUALITY MANAGEMENT AND STANDARDS Moscow

STATE STANDARD OF THE USSR UNION

| VARNISH BT-577 AND PAINT BT-177 Specifications Lacquer BT-577 and paint BT-177. Specifications | GOST 5631-79 |

Valid from 01/01/80 to 01/01/95

This standard applies to BT-577 varnish and BT-177 paint.

Varnish BT-577 is a solution of bitumen in organic solvents with the introduction of synthetic modifying additives and drier. The varnish is intended to protect the surfaces of metal structures and products during short-term storage and transportation (six months in a temperate climate according to GOST 6992-68 for a single-layer coating), as well as for the production of aluminum paint.

BT-177 paint is a suspension of aluminum powder PAP-2 according to GOST 5494-71 in BT-577 varnish and is prepared immediately before application by mixing 80 - 85% BT-577 varnish and 15 - 20% aluminum powder. BT-177 paint is intended for painting structures and products operated in atmospheric conditions.

Coating with BT-177 paint (in two layers over a primed surface) should retain protective properties in a temperate climate for at least two and a half years.

BT-577 varnish is applied to the surface with a paint sprayer, brush, pouring or dipping, and BT-177 paint is applied with a paint sprayer or brush.

(Changed edition, Amendment No. 2).

1.1. Varnish BT-577 must be manufactured in accordance with the requirements of this standard according to the recipe and technological regulations approved in the prescribed manner.

1.2a. (Deleted, Amendment No. 2).

1.2. Before use, the varnish is diluted to working viscosity with white spirit (nefras-S4-155/200) in accordance with GOST 3134-78, solvent in accordance with GOST 1928-79 or GOST 10214-78, turpentine in accordance with GOST 1571-82 or a mixture of these solvents.

1.3. Varnish BT-577 (OKP code 23 1113 0600 09) must comply with the requirements and standards specified in table. 1 .

Table 1

| Indicator name | Norm | Test method |

| 1. Appearance of the film | Glossy, uniform, smooth, without pockmarks or wrinkles, black, shade is not standardized | According to clause 4.3 |

| 2. Conditional viscosity according to a viscometer type VZ-246 (or VZ-4) at 20.0 ± 0.5 ° C, s | 18 — 35 | According to GOST 8420-74 and according to clause 4.3a of this standard |

| 3. Mass fraction of non-volatile substances, % | 39 ± 2 | According to GOST 17537-72 and according to clause 4.3b of this standard |

| 4. Drying time of the film to degree 3 at 20 ± 2°C, h, no more | 24 | According to GOST 19007-73 |

| at 100 - 110 °C, min, no more | 20 | |

| 5. Film hardness according to the pendulum device M-3, conventional units, not less | 0,20 | According to GOST 5233-89 |

| 6. Film elasticity when bending, mm, no more | 1 | According to GOST 6806-73 |

| 7. Film resistance to static action of water at 20 ± 2 ° C, h, not less | 48 | According to GOST 9.403-80, section. 2 and clause 4.4 of this standard |

| 8. Film resistance to static action of 3% NaCl solution at 20 ± 2 °C, h, not less | 3 | According to GOST 9.403-80, section. 2 and clause 4.4 of this standard |

| 9. (Excluded). |

Note: An increase in viscosity during storage is allowed if, when diluting the varnish with a solvent in a mass of no more than 10%, it meets all the requirements of this standard.

1.4. BT-177 paint (OKP code 23 1282 0151 02) must comply with the requirements and standards specified in table. 2.

table 2

| Indicator name | Norm | Test method |

| 1. Appearance of the film | Smooth, without pockmarks or wrinkles, silver | According to clause 4.3 |

| 2. Drying time to degree 3 at 20 ± 2 °C, h, no more | 16 | According to GOST 19007-73 |

| at 100 - 110 °C, min, no more | 30 | |

| 3. Film elasticity when bending, mm, no more | 1 | According to GOST 6806-73 |

| 4. Covering power of undried film, g/m2, no more | 30 | According to GOST 8784-75, section. 1 |

1.2 - 1.4. (Changed edition, Amendment No. 2).

2.1. Varnish is flammable and toxic. Solvent vapors included in the varnish, when concentrated in the air of the working area, have an irritating effect on the mucous membrane of the eyes and respiratory organs. Prolonged work with varnish leads to irritation of the skin of the hands.

(Changed edition, Amendment No. 2).

2.2. The main properties of solvents are given in table. 3.

Table 3

| Solvent name | Maximum permissible concentration in the air of the working area of industrial premises, mg/m3 | Temperature, ° C | Concentration limits of ignition in a mixture with air, %, (by volume) | Hazard Class | ||

| flashes | spontaneous combustion | |||||

| lower | upper | |||||

| Xylene | 50 | At least 21 | Above 450 | 1,0 | 6,0 | 3 |

| Solvent | 50 | 22 — 36 | 464 — 535 | 1,02 | — | 4 |

| White spirit (nefras-S4-155/200) | 100 | 33 | 270 | 1,4 | 6,0 | 4 |

| Turpentine | 300 | 34 | 300 | 0,8 | — | 4 |

(Changed edition, Amendment No. 1, 2).

2.3. Methods for determining solvent vapors in the air of the working area of premises must be specified in the regulatory and technical documentation for painting products.

2.4. During the production, testing and use of varnish, fire safety and industrial sanitation requirements in accordance with GOST 12.3.005-75 must be observed.

2.5. All work related to the production and use of varnish must be carried out in workshops equipped with local and general ventilation. All persons must be provided with special clothing and personal protective equipment in accordance with GOST 12.4.011-89.

2.6. Fire extinguishing agents: sand, felt, carbon dioxide, water in a fine spray, chemical or air-mechanical foam from stationary installations or fire extinguishers.

2.7. Control over the content of maximum permissible emissions (MPE) into the atmosphere - in accordance with GOST 17.2.3.02-78.

(Introduced additionally, Amendment No. 2).

3.1. Rules for varnish acceptance are in accordance with GOST 9980.1-86.

4.1. Sampling - according to GOST 9980.2-86.

4.2. Preparing for the test

Before testing, the varnish is kept at (20 ± 2) °C for at least 2 hours, mixed and filtered through a sieve with mesh 02 according to GOST 6613-86.

The viscosity of the varnish and the mass fraction of non-volatile substances are determined without diluting the varnish.

To determine other indicators, the varnish is diluted with white spirit (Nefras-S4-155/200) at 20 °C to a viscosity of 18 - 23 s using a VZ-246 (or VZ-4) viscometer and applied with a paint sprayer to the prepared plates in one layer.

To test varnish and its mixture with aluminum powder, plates are prepared in accordance with GOST 8832-76, section. 3.

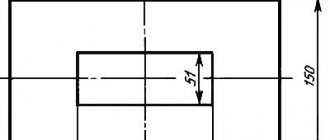

The hardness of the varnish film and the hiding power of the paint are determined on glass for photographic plates measuring 9 ´ 12-1.2 according to GOST 683-85.

The elasticity of the film during bending is determined on plates made of black hot-rolled sheet with a size of 20 ´ 50 mm and a thickness of 0.25 - 0.32 mm.

The remaining indicators are determined on plates measuring 70 ´ 150 mm from black hot-rolled sheet metal with a thickness of 0.25 - 0.28 mm or from steel grades 08 kp and 08 ps with a thickness of 0.5 - 1.0 mm according to GOST 16523-89.

To test varnish mixed with aluminum powder, take a sample of varnish prepared according to clause 4.2, with a viscosity of 18 - 23 s using a VZ-246 (or VZ-4) viscometer at 20 ° C, mix with aluminum powder in accordance with GOST 5494- 71, grade PAP-2 in the ratio indicated below.

Varnish BT-577 - 80 - 85%.

Aluminum powder - 15 - 20%.

The resulting paint is filtered through a sieve with mesh 056 according to GOST 6613-86.

The paint is applied with a spray gun in one layer.

The plates with applied varnish and paint are kept in air at (20 ± 2) °C for 30 minutes, then placed in a thermostat and the varnish film is dried at 100 - 110 °C for 20 minutes, the paint film is dried for 30 minutes.

After drying in a thermostat, the samples are kept in air at (20 ± 2) °C for 3 hours.

The thickness of the varnish and paint film after drying should be 20 - 25 microns.

To determine the resistance of the film to the static effects of water and 3% NaCl solution, the varnish is applied to the plate on both sides.

(Changed edition, Amendment No. 1, 2).

4.3. The appearance of the varnish and paint film is determined visually in natural diffused light.

4.3a. The conditional viscosity of the varnish is determined using a viscometer type VZ-246 (or VZ-4) with a nozzle diameter of 4 mm at a temperature of (20.0 ± 0.5) °C.

(Changed edition, Amendment No. 2).

4.3b. The mass fraction of non-volatile substances is determined according to GOST 17537-72. To do this, a sample of the tested varnish weighing 1.5 - 2 g is placed in a drying cabinet and kept at a temperature of (140 ± 2) °C. The first weighing is carried out after 1.5 hours of exposure in the cabinet, subsequent weighings are carried out every 30 minutes until constant weight.

4.3a, 4.3b. (Introduced additionally, Amendment No. 1).

4.4. The resistance of the varnish film to the static effects of water and a 3% NaCl solution is determined according to GOST 9.403-80, with painted and dried samples placed in the test solution at 2/3 of the height and after exposure in water or NaCl solution for the time specified in subparagraphs 7 and 8 of table. 1, the samples are kept in air at (20 ± 2) °C for 2 hours and the appearance of the film is examined. The film must be unchanged, slight matting is allowed.

(Changed edition, Amendment No. 1).

4.5. (Deleted, Amendment No. 2).

5.1. Packaging - according to GOST 9980.3-86.

5.2. Marking - according to GOST 9980.4-86.

When marking transport containers, a danger sign must be applied according to GOST 19433-88 (class 3, classification code 3313).

5.3. Transportation and storage - according to GOST 9980.5-86.

Sec. 5. (Changed edition, Amendment No. 2).

6.1. The manufacturer guarantees that the varnish meets all the requirements of this standard, subject to storage and transportation conditions.

6.2. The guaranteed shelf life of the varnish is six months from the date of manufacture.

6.1, 6.2. (Changed edition, Amendment No. 1).

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the USSR Ministry of Chemical Industry

DEVELOPERS

V. B. Manerov, V. M. Makarova (topic leader), A. A. Kaverinskaya, E, D. Kazantseva

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee on Standards dated March 13, 1979 No. 895

3. Inspection frequency - 5 years

4. INSTEAD GOST 5631-70

5. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 9.403-80 | 1.3, 4.4 |

| GOST 12.3.005-75 | 2.4 |

| GOST 12.4.011-89 | 2.5 |

| GOST 17.2.3.02-78 | 2.7 |

| GOST 683-85 | 4.2 |

| GOST 1571-82 | 1.2 |

| GOST 1928-79 | 1.2 |

| GOST 3134-78 | 1.2 |

| GOST 5233-89 | 1.3 |

| GOST 5494-71 | Introductory part, 4.2 |

| GOST 6613-86 | 4.2 |

| GOST 6806-73 | 1.3, 1.4 |

| GOST 6992-68 | Introductory part |

| GOST 8420-74 | 1.3 |

| GOST 8784-75 | 1.4 |

| GOST 8832-76 | 4.2 |

| GOST 9980.1-86 | 3.1 |

| GOST 9980.2-86 | 4.1 |

| GOST 9980.3-86 | 5.1 |

| GOST 9980.4-86 | 5.2 |

| GOST 9980.5-86 | 5.3 |

| GOST 10214-78 | 1.2 |

| GOST 16523-89 | 4.2 |

| GOST 17537-72 | 1.3, 4.3b |

| GOST 19007-73 | 1.3, 1.4 |

| GOST 19433-88 | 5.2 |

6. Validity period extended until 01/01/95 by Decree of the USSR State Standard dated 03/27/89 No. 748

7. Reissue (October 1990) with Changes No. 1, 2, approved in June 1934.,

March 1989 [IUS 10-84, 6-89]

CONTENT

| 1. Technical requirements. 1 2. Safety requirements. 2 3. Acceptance rules. 3 4. Test methods. 3 5. Packaging, labeling, transportation and storage. 4 6. Manufacturer's warranty. 4 |

What varieties are there?

Due to its color, the paint was called “silver.” Currently, it is factory tinted with dyes: gold, bronze, copper and others. The composition does not lose its main characteristics, but more opportunities are provided in terms of use for decorative purposes.

According to readiness and structure, silverfish can have several types:

- Aerosol - in the form of a spray can, which you simply need to shake and apply paint to the surface;

- The finished composition is usually produced in metal cans.

Two-component paint contains two substances packaged in a separate container and mixed immediately before use. The proportionality of powder and varnish is 1 to 4. The level of viscosity is determined individually depending on the coating intended to be painted.

Due to its color, the paint was called “silver.”

Mode of application

In order for the paint to adhere well to the product and not lose its decorative or functional properties, it is important to follow a number of rules. They will help to avoid mistakes and extend the service life of the coating.

In order for the paint to adhere well to the product and not lose its decorative or functional properties, it is important to follow a number of rules.

Surface preparation

The key to an excellent painting result is preliminary surface preparation. According to the instructions, it must be dry and clean before painting. Therefore, it is necessary to remove previous paints, rust and, if necessary, treat the surface with a primer.

It is necessary to remove previous paints, rust and, if necessary, treat the surface with a primer.

Is it necessary to breed

Also, BT 177 enamel can be diluted in equal proportions with white spirit, solvent or turpentine. Proportions are related by mass or volume of components. This dilution is necessary to create the desired consistency. If the paint has thickened, then it is diluted using a solvent, toluene or acetone.

Proportions are related by mass or volume of components.

How to apply correctly, recommended scheme

Silver is applied using the scattering method or manually using painting tools. When working, it is necessary to observe the temperature regime, which should be no more than 35 degrees, and the humidity should not be more than 80 percent. It is possible to apply silver also at temperatures below the permissible one.

Silver is applied using the scattering method or manually using painting tools.

Preparing the base for painting

Metal surfaces must be freed from remnants of the old coating. You can use special chemical removers, sandpaper, or a sandblasting machine.

Traces of grease, oil and other stains and contaminants must also be removed.

Puttying and applying primer mixtures are carried out if necessary.

How much paint does it take to make one layer?

According to the technical characteristics of BT-177 paint, the parameter of one layer has a thickness of 20-25 micrometers at a consumption of 110-130 grams per square meter. However, the consumption of any applied composition depends on the method used for painting (spray or manual application), as well as on the professionalism and skills of the specialist. The texture of the material being painted directly affects consumption. When painting wooden, porous plastic or concrete surfaces, the consumption definitely increases by at least 1.5 times than the consumption of silver BT 177 for metal. In addition, depending on the manufacturer, paint consumption may be different. This depends on those components that can be additionally used in the composition of silverware. To accurately determine the required volume, you need to study the instructions for a specific product.

The texture of the material being painted directly affects consumption.

Description and purpose

Silver paint and varnish material BT-177 is a mixture made from aluminum powder and bitumen varnish. Its main purpose is the treatment of metal surfaces on which silver prevents the occurrence of rust. In addition to metal, this paint can be applied to other types of surfaces - concrete, plastic and wood.

Silver paint BT-177 can be used both for interior work and for processing outdoor products. This product has excellent fire-resistant characteristics, so it can be used for application to boilers, furnaces, and other structures made of non-ferrous or ferrous metal that are operated at high temperatures. The composition contains aluminum powder, which is why BT-177 enamel cannot be used in kindergartens, children's rooms, hospitals, and other buildings that must meet high safety requirements.

Silver can be used to color the following products:

- metal pipes;

- gates and fences;

- auto disks;

- garden accessories;

- metal profile fences;

- water pipes and columns.

Attention! It is not allowed to apply BT-177 enamel on surfaces that are heated to a temperature of more than 90 degrees. Also, you cannot paint containers in which water is stored with silver; you cannot apply it to nitro enamel, alkyd paint, oil-bitumen and oil enamel.

How to dry a painted product

There are two schemes for drying products depending on the temperature of exposure to the surface. At a temperature of 20-22 degrees - 16 hours and at 100-110 degrees - 3 hours. If in the first case the varnish BT 177 dries in natural, domestic conditions, then when exposed to artificial heat, certain requirements must be observed. Before using hot drying, keep for half an hour at 22 degrees. Before use, the product must also be exposed to 18-22 degrees for 3 hours.

There are two schemes for drying products depending on the temperature of exposure to the surface.

Coating service life

Manufacturers promise up to 2.5 years of maintaining the original appearance and protective abilities of the composition, but subject to application technology, surface preparation, and drying. The composition of silverfish itself, its preparation and compliance with proportions are also important. Using an expired or improperly stored composition will also shorten the service life of the coating. It is necessary to eliminate the risk of purchasing low-quality goods, therefore BT-177 paint with its own characteristics has a certificate of conformity, which the supplier must have for each batch of goods.

Manufacturers promise up to 2.5 years of maintaining the original appearance and protective abilities of the composition.

Application of the composition

Most often, BT-177 enamel ("silver") is sold in finished form, when all the components of the composition are already combined in one suspension. In this case, before starting work, you just need to mix the paint thoroughly. Coatings are often found in a semi-finished state: when silver powder and varnish are in different containers. Before applying the composition, they must be combined (in a ratio of 85% varnish to 15% powder) and mixed thoroughly until smooth.

The protective coating can be applied using the following methods:

- airless spraying;

- pneumatic spray;

- by dipping the product into a solution;

- using rollers and brushes.

Work should be carried out at temperatures from +5 to +35 degrees. Air humidity should not be more than 80%.

BT-177 paint is applied in one or two layers. If the surface has been previously primed, then a single treatment will be sufficient. Clean and even bases are painted twice. In this case, the guaranteed period of protection of the metal surface will be about 2.5 years.

Rules for storing paint

Silverfish elements should be kept in a well-sealed container, excluding moisture. Storage conditions must provide protection from fire, sun and other temperature influences (heating elements and devices). It is important to store components and finished paint out of the reach of children.

The shelf life of the varnish is 6 months, and the shelf life of the bulk component is 1 year from the date of release. The permissible storage temperature for paint is from -40 to plus 40 degrees. Storing BT-177 at temperatures above the permissible temperature leads to drying out of the composition and the release of toxic fumes harmful to humans.

Silverfish elements should be kept in a well-sealed container, excluding moisture.

With skillful use and following all the instructions from the manufacturer, this material can help out at the right time. This highly specialized coating material has proven itself on the positive side many years ago.