Icer

11300 1 4

Icer November 29, 2016Specialization: master in the construction of plasterboard structures, finishing work and laying floor coverings. Installation of door and window units, finishing of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

In the photo: finishing the facade of a house in the half-timbered style appeared in Germany, but gained popularity all over the world

Many people associate the half-timbered style with the charm of small towns in Western Europe. But if you wish, you can decorate your home in detail. Read this review and you will see how simple and easy it is to create a corner of Bavaria in your yard.

In our country you can increasingly see such houses

Selection of material for façade arrangement

The service life, ease of installation and practicality of operation of the cladding largely depend on correctly selected materials. Particular attention should be paid to the base of the half-timbered façade and the printed strips.

Natural wood or imitation

The choice lies between wooden or polyurethane boards. Each material has pros and cons.

Distinctive features of wood beams :

A worthy alternative to wood is polyurethane beams . The main advantages of polymers:

An important argument in favor of simulating half-timbered timber with polyurethane beams is the affordable cost of polymer materials.

Options for the base for half-timbered frames

The beams are installed on a prepared base. Three options are popular in frame house construction:

The most practical method is the use of cement-bonded particle boards (CSB). The material has a high density, tolerates longitudinal loads well and is not afraid of precipitation. DSP sheathing gives the frame additional strength.

Composite slabs are the best basis for half-timbered timber. The ratio of price and technical qualities of the material is optimal.

Plastering walls is a labor-intensive process. In addition, given the characteristics of prefabricated houses, this method is not recommended for cladding. Temporary movements of the frame can lead to cracking of the plaster layer.

OSB boards are a budget technology. It is advisable to use the material in the construction of country houses and small buildings.

The nuances of using OSB boards:

A little history

A house is a structure erected for living.

Over the course of historical time, the requirements for housing increased, which led to the appearance of houses of different proportions and type of construction. In order to adapt to the environment, terrain and climate. Due to these factors, names are formed: castle, palace, villa, chalet, cottage and so on. For the medieval cities of Central Europe - the German states, in particular, the architectural model of the so-called half-timbered house is typical.

Half-timbering, in German, is a load-bearing wooden frame assembled from supports and beams connected vertically, horizontally and diagonally. The resulting spaces, of various shapes and sizes, were filled with adobe, brick, and sometimes wood. Then they were plastered flush with the beams, leaving the geometry of the frame structure visible, giving the latter also decorative properties.

Thus, there is a combination of functional and aesthetic motives. Both solutions are extremely successful: houses of this type have been standing for several centuries, and the elegant simplicity of the facades and walls is elegant and beautiful.

Photos of half-timbered houses have become widespread among those who have never seen them, along with images of other “beauties.” Including in the form of wallpaper for PC screens. Which once again emphasizes the originality and even some fabulousness of these creations of human hands.

Step-by-step instructions for finishing the facade

Let us describe the sequence of finishing the facade of a house in the half-timbered style with your own hands. The entire course of work can be divided into several stages.

Design and sketch development

The first step is to draw up a layout plan for wooden beams . It is necessary to build on the working drawing of the house itself.

When drawing up a sketch, you should adhere to the following rules:

Required materials and tools

To implement the half-timbered façade you will need the following materials:

The tools you need to prepare are: a hammer drill, a screwdriver with attachments and drills, a grinder for cutting slabs, a level, a tape measure, a spatula, a roller, a square and a pencil.

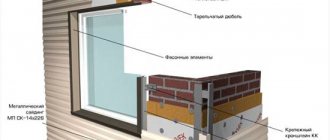

Cutting and fastening of CBPB boards

Comparing the dimensions and configuration of the walls with the dimensions of the facing slabs, you should cut the DSP. Before installing the panels, it is necessary to “fill” the frame with heat-insulating material, and attach a windproof membrane .

Priming and painting walls

At this stage, the walls are finished before attaching the beams. Work progress:

As a rule, one layer is not enough to cover gray DSP boards. To achieve color uniformity, it is advisable to repeat the staining.

Preparation and installation of beams

Boards for finishing the facade must be well dried. Next, the material is sanded and treated with fire-retardant impregnations and protective compounds.

Such measures are aimed at reducing the wood’s ability to ignite and increasing its resistance to precipitation and solar radiation. Antiseptic impregnation protects beams from rot and insect infestations. The final stage of preparation is painting the boards in a dark color.

The procedure for working with polyurethane strips is somewhat simpler. They do not require pre-treatment and are fixed to the CBPB with liquid nails.

Modernity

Fachwerk began to be revived en masse. The reason for this is practicality plus the development of the building materials industry.

Modern designs of half-timbered houses visually have little in common with traditional ones, but the principle from which the name comes is the same - a visible wooden frame that stands out in color from the rest of the wall area.

The changes have gone towards making the design lighter and simpler, thanks to the quality of the materials and fasteners used.

The areas of the cells of the entire supporting structure have expanded, in other words, there are fewer elements. Diagonal braces, which played an important role in constructing the façade pattern and strengthening the frame, were no longer needed. Lost their functionality.

Laminated timber, which replaced solid logs, is much stronger and stronger; beams made from this material require fewer supports. The fillers of the spaces between the beams are not heavy bricks and clay, as in the old days, but light panels that have all the necessary strength, insulation and energy-saving characteristics. There was no longer any need for a deep and solid foundation.

Characteristics of a facade made of DSP and its installation method

Cement particle board (cement particle board) is a well-proven material in the facing materials market. Cement particle boards (CSP) appeared in construction about 30 years ago; in recent years, due to the high pace of construction of low-rise buildings, they have become very popular in the design of facades. Thanks to the structural monolithic nature of the slabs, a facade made of fiberboard combines the best qualities of cement and wood - resistance to dampness and low temperatures. Thanks to the addition of chips of various types of stone (marble, granite and others) to the DSP, such a facade looks modern and attractive.

Secrets of decor in the half-timbered style

The facades of houses in the German half-timbered style have some common features in their design:

- Floors are visually delimited by one or two rows of horizontal beams.

- There are sashes in the window frames.

- Entrance doors are mostly solid wood, without glazing.

- The downspouts, chimney and vents match the color of the beams.

- The foundation of the house is decorated with natural or artificial stone.

- In the half-timbered tradition, window sills are decorated with flowerpots and flower pots.

Facade decoration in the medieval European style has taken root in modern frame housing construction. Imitation half-timbered structures can radically change the appearance of a building, giving it originality and presentability.

Advantages and disadvantages of DSP facades

DSP facades have characteristic features associated with the structure and manufacturing technology of DSP boards. The dimensions of the material (2,600 by 1,250 and 3,200 by 1,250) allow them to cover large areas, which distinguishes them favorably from the board coverings previously widely used in individual construction.

The structure of the slabs consists of wood chips bonded with cement mortar and a layer of stone chips

Thanks to these and many other advantages, cement particle board is one of the most common options in facade interiors.

The advantages of such facades include the following qualities:

Domestic manufacturers use only environmentally friendly materials

Construction

For the customer, construction begins with viewing catalogs of half-timbered houses, on the website of the nearest company, or in the office itself. If you have your own project, the terms for adapting existing developments to the client’s wishes are discussed.

The technology of a half-timbered house allows the implementation of any shapes and outlines, from simple and unpretentious to the most complex and bizarre. This also applies to the internal layout - the frame is voluminous.

The solidity of the structure is achieved by careful and tight fitting of the parts to be connected. This requires extreme precision in measuring and maintaining the distances and sizes of grooves and tenons. Most often, this condition is achievable only with stationary equipment.

For this reason, it can be argued that the construction of a half-timbered house takes place on the production site of a construction company.

Facade installation

If the walls of the house are not wooden, then the sequence of installing the DSP is as follows:

DSP facades are very popular and allow many design solutions to be implemented

Then the sequence of actions is as follows:

Stone chip coating can be made from various rocks

Seam processing

Cement particle boards can be used to finish the base

In another case, metal or wooden planks are placed at the joints of the slabs. A tree of contrasting color looks very impressive on the façade.

DSP facades are widely used in frame construction of low-rise buildings and have their own advantages:

Source

Recommendations

Some useful tips for building a private house:

- Do not join two panels at the seam. The material consists partly of wood chips; they can increase in size if water gets into the joint;

- It is much faster and easier to sheathe a house and only then make windows, rather than start cutting in the slab and adjusting window openings in advance;

- It is better to use white self-tapping screws in construction; they are much stronger than their black counterparts and also have excellent corrosion resistance;

- It is necessary to seal each seam with sealant; this is a necessary step, because the slabs can swell.

It’s better to entrust the construction of your future home to professionals who have been building frame structures for many years, such as.

DSP facade for siding

Judging by the reports of portal users, such a facade based on DSP is also popular.

But, having chosen this option, you should prepare in advance for a large amount of work on cutting cement-bonded particle boards.

I like DSP, but I decided to do something more original and cut the slabs into “boards” using a circular saw, and then install them like siding.

After installing the facade, the user plans to prime it and paint it with acrylic paint.

If you paint the “siding” in advance as the façade is being covered, then it will be difficult to choose the same color on different walls.

So far it turned out like this.

I thought for a long time about how to decorate a large area of the facade of my frame house. The tree disappears because it is too exposed to negative weather factors. Then I turned my attention to fiber cement siding. The material is interesting, but I have to pay the entire amount for it right away - about 300 thousand rubles. If I make a mistake in the quantity + allowance for framing corners, cornice boards, platbands, etc., then I’ll have to buy more later. Take it immediately with a reserve - what to do with the surplus later, and this is an extra expense. Well, the color that I liked has already been discontinued.

In addition, when sawing fiber cement siding, you may end up with chips and scratches that will have to be painted over with expensive paint. You also get expensive scraps (the price of fiber cement siding in 2015 was about 930 rubles per 1 sq. m versus 200 rubles for DSP), which then, unlike DSP, cannot be put into use. Another argument that weighed in favor of cement-bonded particle boards was that the width of fiber cement siding was 19 cm, and the user wanted “boards” on the facade about 31 cm wide. This reduces the number of horizontal planks, which means the speed of work increases, installation time is saved and the expenses.

As a result, the user loosened the slabs using a circular saw, onto which he placed a diamond blade from a grinder through an adapter ring (since these tools have different mounting diameters for saw blades).

I bought a 1 cm thick DSP with dimensions of 1250x3200 mm. I unrolled the slabs into 4 strips, about 30 cm wide, attached them to the sheathing and painted them in place. The façade fully justified itself; nothing fell off during use, and the paint did not peel off.

At the end of the article, we will present the economic benefits of such a facade, which were calculated by Yegor Shilov. So, the cost of making homemade siding from DSP , which included: the cost of the slabs + their sawing + painting, including the purchase of paint - 480 rubles. for 1 sq. m.

Let us remind you that fiber cement siding cost 930 rubles. for 1 sq. m. The total difference was 450 rubles. The area of the façade of the house is about 300 sq. m. m. The total savings were 135 thousand rubles.

You can learn all about facades based on cement bonded particle boards in the topic: facades made of cement-bonded particleboard, fastening, processing and finishing.

We recommend articles on the topic: finishing the facade of a stone house with concrete “brick” tiles, how to properly install flexible tiles on the facade and finishing an aerated concrete house with porcelain stoneware.

The video shows an example of the correct installation of a “wet facade” on polystyrene foam.

Source

Floor-to-ceiling window. Or a glass wall

Features of modern architecture are straightforwardness, some even angularity, with a predominance of vast flat surfaces, and large windows. Fachwerk incorporates both of these directions.

Panoramic glazing of a half-timbered house is an integral part of the style; it simply suggests itself. A full-wall window in a private house is an unusual phenomenon in the post-Soviet space; a lot of attention is paid to describing the benefits and advantages.

First, a lot of daylight is captured. Secondly, the dimensions of the room extend to the nearest trees, or to the horizon - depending on the location of the house. And the opposite effect - the appearance becomes part of the interior.

In a cottage community, only the facade remains glass, behind which the living room, dining room and kitchen are located - common spaces. The remaining walls facing the fence or neighbors are blank.

It is possible to locate the house in the depths of the plot, with a view overlooking the surroundings that have been personally furnished. Or a “turn” in the direction of the patio. There are many options - if only there was a plot.

Glazing is made using frameless three-chamber double-glazed windows, the formula of which can be selected depending on the climate and geographic region. Tempered glass is usually installed on the outside, which is several times stronger than ordinary glass and is difficult to break. On the inside there is sun-protection or energy-saving glass. Protects against excessive heat in summer and heat loss in winter. From this point of view, a modern window can be of any size.