Construction and repair work cannot be done without materials such as sealants. They are necessary for sealing seams and holes, the occurrence of which is inevitable at the junction of surfaces made of different materials and when constructing communication passages.

The materials from which building structures are made are varied and have different properties. The purpose of the structure is also of great importance: is it a residential or industrial building, whether it is exposed to temperature changes, the influence of aggressive environments, or vibration. All of these factors determine the selection of the appropriate sealant for each specific situation.

Functions of sealants in construction

When constructing construction projects, various materials must be reliably sealed at their junctions. It can be brick, concrete, artificial or natural stone, glass, wood, metal, ceramics, plastic and others.

At the joints, it is necessary to ensure tightness so that moisture and drafts do not penetrate into the building at this point in the structure.

When carrying out communications, it is also necessary to seal all openings through which utility networks are installed. When installing or repairing a roof, no matter what material it is made of, it is important to make it impermeable to precipitation. Doorways and windows also require sealing; It is also needed when installing plumbing fixtures and finishing damp rooms.

There are different types of joints in concrete structures:

- temperature, which compensate for changes in size that occur due to daily and seasonal temperature fluctuations.

- shrinkage, which are designed to compensate for stress in hardening concrete to prevent cracks;

- structural, necessary when pouring concrete in several stages;

- insulating ones, which are installed along all vertical fences to compensate for deformation.

In all these cases, you cannot do without sealants that perform the following functions:

- gluing materials;

- sealing joints of materials and various types of seams;

- sealing connections.

In each specific situation, it is necessary to decide which sealant to choose.

Requirements for sealants

Sealants must meet the following requirements:

- high adhesion to various materials;

- ease of application;

- water resistance;

- durability for the entire period of operation;

- resistance to adverse environmental factors;

- resistance to chemicals;

- resistance to temperature changes and solar radiation.

An additional advantage may be the possibility of painting or choosing a sealant by color.

Important!

One of the main necessary qualities of sealants is their adhesion, in other words, the ability to adhere well to other materials that may have different properties and surface features. The higher the adhesion, the better the sealant performs its functions.

We will look at what types of sealants there are in this article.

Types of construction sealants

Sealants are classified according to different criteria:

- composition;

- properties;

- type of condition;

- purpose.

Single-component and multi-component sealants

There are two large groups of sealants - single-component and multi-component.

One-component sealants, as the name suggests, consist of one component and are ready for immediate use. They are packaged in cartridges, which are convenient to work with without the use of special equipment.

Multicomponent sealants most often consist of two, less often three components. They are packaged in separate buckets and mixed before use. To work with such sealants, special mixing equipment is required, as well as a construction gun for application.

Classification by type of condition

Based on the type of condition, sealants are divided into three groups:

- Drying (drying) sealants. As they dry, they remain elastic, although they harden.

- Hardening. These sealants become rubber-like.

- Non-hardening. They remain elastic throughout their entire service life.

Classification of sealants by composition

Modern sealants can be made from various components; Depending on the type of base, sealants are distinguished:

- acrylic;

- polyurethane;

- silicone;

- rubber (butyl rubber);

- polysulfide or thiokol;

- bituminous.

as well as some types of special sealants.

Acrylic sealants

Acrylic sealants are among the most environmentally friendly. They are made on the basis of a water emulsion of acrylic polymers and do not harm human health.

They also contain:

- elastomers, which act as plasticizers;

- antiseptics that prevent the growth of bacteria and mold;

- defoamers, which prevent the sealant from foaming upon contact with moisture from the air and increasing its volume;

- thickeners to increase thixotropy;

- fillers;

- pigments, thanks to which sealants can have different shades.

Acrylic sealants are drying compounds. After its application, the moisture evaporates, causing hardening to occur.

Properties of acrylic sealants:

- due to the water base, after drying they remain vapor permeable, so they can be used in areas where condensation forms;

- UV resistant;

- small deformations (in some cases below 15%);

- after deformation, they strive to restore the original state;

- high adhesion to various types of materials, both porous, such as foam concrete, plaster, wood, and dense, such as brick and ceramics;

- available in various shades (initially transparent acrylic);

- do not support the growth of fungus and mold;

- easy to use, can be diluted with water;

- do not have a strong odor;

- inexpensive.

Disadvantages of acrylic sealants

The disadvantages of this type of sealants include the poor resistance of non-waterproof types to water and aggressive chemicals. Therefore, they are not used where there is constant contact with water.

Waterproof acrylic sealants are resistant not only to water, but also to negative temperatures.

Acrylic sealants are not resistant to large temperature changes and significant deformations.

Scope of application of acrylic sealants

Various types of acrylic-based sealants are used to seal cracks and cracks and seal seams. Acrylic wood sealants are widely used; they make it possible to seal the joints of logs and beams, for which in the old days moss and tow were used.

Due to their low deformation, they are excellent for fixed joints and joints, for example in wooden structures or the junction of walls and tiled floors.

Application of acrylic-based sealants

Acrylic sealants are easy to use. They are sold in cartridges, tubes or buckets, and can be applied either with a gun or with a spatula. To seal deep cracks, acrylic-based sealants can be diluted with water. Before drying, they are easily leveled and, if necessary, removed with warm water.

Peculiarities

In practice, sealing compounds are not always used in their pure form. Mixed reagents are often used, such as “Titanium”, formed by combining rubber with resin, bitumen, synthesized fibers and even a solvent. This composition has proven itself to be effective in roofing work. Judging by the assessments of professional and amateur builders, this sealant is characterized by increased viscosity and perfectly withstands harmful atmospheric influences.

Basically, such a mixture is needed for the following purposes:

- closing the junction points of blocks;

- eliminating gaps;

- renewal of previously formed joints;

- combating leaky places;

- increasing the rigidity of gutters and roof windows.

Classic rubber-based sealant, along with bitumen analogues, is used in the following:

- in the renovation of rooms and utility rooms with excessive moisture;

- when holes appear in inflatable boats and rubber boots;

- when restoring the integrity of roofing materials;

- for fixing roofing felt and other bitumen coatings;

- for attaching polystyrene foam or polyurethane to any base.

Polyurethane sealants

These are one-component sealants; they are made on the basis of polyester resins and are most often used for outdoor work. This group of sealants is very diverse; in it you can find materials for different types of seams.

Hardening of these types of sealants occurs due to air humidity.

Main characteristics of polyurethane sealants:

- high adhesion to various materials;

- low shrinkage;

- constant high elasticity under various temperature and atmospheric influences;

- resistance to humidity, solar radiation, exposure to aggressive environments (alkalies, acids in concentrations up to 10%);

- thixotropy, which allows sealants to be applied to vertical walls and ceilings;

- resistance to sudden temperature changes, freezing;

- resistance to vibrations caused by the operation of mechanisms (for example, machine tools) or seismic vibrations;

- resistance to mechanical stress;

- possibility of painting with paints, including water-based paints;

- Possibility of application at subzero temperatures;

- no corrosion of metals upon contact with polyurethane sealants;

- the ability to bond various materials in different combinations (glass, plastic, wood, concrete, ceramics, metal);

- ease of use.

Important!

Polyurethane sealants include weather-resistant sealants, such as ClearFixa All-Purpose Polyurethane Sealant ]CEMMIX[/anchor].

An important property of polyurethane sealants is their high elasticity. Some types, for example, ClearFixa, break only when stretched more than 4 times in length; The deformability of the seam is within 30% of its width. This allows them to be used on flexible connections.

Disadvantages of polyurethane sealants

When working with polyurethane sealants, personal protective equipment is required.

Scope of application of polyurethane sealants

Resistance to moisture, sun, and temperature changes makes polyurethane sealants an ideal choice for exterior, roofing and facade work, mainly for joints 20–50 mm wide, as well as in wet rooms and for sealing double-glazed windows.

The seams can be painted and they will be invisible. Resistance to vibration allows them to be used in production shops and in other cases where structures are subject to vibration.

Features of application

When using polyurethane sealants, it is important to remember that they should be in contact with the material on only two sides, so an insulating layer of material that does not have adhesion to the polyurethane sealant is installed deep in the seam.

Main nuances and parameters

Such substances are excellent for closing on bases that are in any position.

The main advantage is considered to be rapid hardening when exposed to moist air. Therefore, rubber compounds immediately begin to harden as soon as they are squeezed out of the container.

In stores you can buy one-component or two-component substances that have good performance characteristics.

The hardening process is quick, but you can still have time to trim the sealing layer.

The resulting coating looks like rubber: it has high elasticity and reliability. It is not afraid of sunlight - this is the main indicator of new sealants, which are based on artificial rubber material.

Rubber clamps also have the following features:

- High resistance to mechanical loads (the seam is not damaged, very elastic for a long time).

- Not afraid of various atmospheric loads (tolerates different temperatures, any precipitation).

- High level of adhesion (sealant can be used with different materials).

- Frost resistance (do not lose their strength even at -50°).

Complete polymerization occurs in approximately 48 hours, this depends on the components in the composition. These substances are very similar to silicone ones, but they have many more advantages.

There are substances of different colors: white, brown and red, but usually buy a black fixative. The dark shade is obtained through chemical processes between the main components.

Silicone sealants

Silicone sealants are neutral and acidic. They are made on the basis of synthetic rubber with the addition of vulcanizing impurities and additives that increase adhesion and strength. Silicone sealants cure using moisture from the air.

Important!

Acidic silicone sealants are not used on metals as they are corrosive.

Properties of silicone sealants:

- high elasticity (some of them stretch up to 250%);

- resistance to ultraviolet radiation;

- good adhesion to different surfaces without the use of a primer;

- maintaining elasticity at high and low temperatures;

- Possibility of application at high and low temperatures.

These properties make silicone sealants suitable for outdoor use, sealing joints that are subject to temperature changes, moisture and vibration. Most often, silicone sealants are used to seal seams in damp rooms (for example, in the bathroom), as well as to seal cracks on balconies, loggias, and verandas.

Disadvantages of silicone sealants

These sealants are not paintable. Manufacturers, in order to compensate for this shortcoming, produce them in a wide color palette, as well as in a transparent version.

Brands and remarks: which manufacturer to trust

When choosing and purchasing silicone sealant, you should adhere to the rule: a high-quality product cannot be cheap. As mentioned above, unscrupulous manufacturers are cunning and offer low prices due to the same low quality. Of course, trusted brands also have defective batches, but their share is extremely small.

Basically, low quality is assumed from the very beginning - a large percentage of foreign impurities proportionally worsens the quality of silicone: elasticity and strength decrease, resistance to aggressive influences decreases, color changes, and curing is impaired.

When choosing a quality product, you need to pay attention to the following factors:

- Manufacturer - there are quite a few proven brands: “Macroflex”, “Soudal”, “Moment”, “Econ”, “Kvadro”.

- Original branded packaging with all the information (quality indicators and composition).

- Availability of certified copies of certificates from the seller.

You should be wary of the product:

- With a large weight (more than 340 grams with a volume of 310 ml).

- Labeled “100% silicone” - not a single manufacturer uses silicone in its pure form, without additives or plasticizers.

- With a very low price (the production technology is such that the cost of one tube of sealant costs approximately 70–90 rubles. Add to this amount the average trade margins of 20–50% and you will see the real price of a quality product).

- With a worn and especially paper label.

Rubber sealants

These are one-component sealants based on synthetic rubber.

Interesting!

Initially, rubber was obtained from the juice of the Hevea plant, but already at the beginning of the 20th century, artificial rubber was synthesized.

Properties of rubber sealants

The main property of rubber sealants is their water resistance.

In addition, rubber sealants have the following advantages:

- high adhesion to various materials (plastic, metal, brick, concrete, glass);

- the ability to connect dissimilar materials;

- adhesion to oily and wet surfaces;

- compatibility with bitumen;

- possibility of coloring;

- absence of silicones;

- high thixotropy;

- possibility of use in a wide temperature range, from –50°С to +90°С;

- elasticity;

- Possibility of insulating porous materials.

Scope of application of rubber sealants

Rubber sealants are widely used in construction and repair work, including critical facilities such as hydroelectric dams, chemical and industrial enterprises:

- for sealing wall joints;

- for gluing window sills;

- in roofing works;

- for roof repairs (gluing, gluing, sealing joints between dissimilar materials);

- in facade works;

- for sealing joints of ventilation and air conditioning systems;

- for sealing seams in damp rooms;

- in chimneys and drains;

- when working with non-ferrous metals.

Important!

Composite bitumen-rubber sealants have been created for roofing work.

In addition, rubber sealants are widely used in shipbuilding and the automotive industry.

Features of the use of rubber sealants

Rubber sealants are produced in cartridges, so they can be applied with any construction dispenser guns. The sealant can be applied only at positive temperatures, but it is not demanding on the surface: it can be wet. This is a serious advantage when doing roofing work, as it allows you to avoid waiting for dry weather.

Due to its high adhesion, working with rubber sealant requires care, because it is not easy to clean surfaces stained with it. Therefore, the use of masking tape and film is required.

Peculiarities

The main component of any rubber sealant is synthetic rubber. Like mixtures based on modified bitumen, such substances resist moisture very well. Thanks to such valuable properties, they can be used in sealing roofs and facades, as well as for interior work, even in the dampest rooms.

Sealants that protect surfaces from water adhere well to the surface of a wide variety of materials, including rubber. With their help you can repair an inflatable boat, waders and much more. Roofing felt and other roofing products are glued on top of the sealing layer.

The main advantages of rubber sealants:

- good level of elasticity;

- the operating temperature range is a minimum of -50 degrees and a maximum of +150 degrees;

- the ability to paint the sealing composition after application in any suitable tone;

- immunity to ultraviolet radiation;

- Possibility of use for up to two decades.

Thiokol sealants

These sealants are two-component or three-component. The components are mixed, then polymerized over several hours or days to form a durable film.

Properties of thiokol sealants

Thiokol sealants are considered the most durable and strong, as well as resistant to aggressive chemicals (including gasoline, organic solvents, alkalis, and inorganic acids). They tolerate temperatures from –55°C to +130°C.

Important!

Their service life is more than 20–30 years.

Disadvantages of thiokol sealants

The disadvantages include the high cost of this type of sealant.

Scope of application

Thiokol sealants are used in the production of double-glazed windows, in hydraulic engineering, in concrete and reinforced concrete products.

Questions

Recommended application temperature is from -10 to +40. Clean the surfaces to be joined from dust and solid particles. Non-porous surfaces can be damp, porous surfaces must be dry. The surfaces to be joined may be slightly oily.

Place the cartridge in the gun and apply sealant. After application, immediately smooth the sealant with a damp spatula.

Storage: at temperatures from +5 ºС to +25 ºС.

The main task of rubber sealant is to fill cracks, potholes, chips, cracks and other defects. Possessing a special composition, this product allows you to create a sealing seam that does not allow the penetration of moisture and dust.

Bitumen sealants

This is the oldest and most popular type of sealant. They are made on the basis of modified bitumen polymers.

Bituminous materials are very affordable; they are obtained during the processing of petroleum products and are, in fact, production waste.

Properties of bitumen sealants

The main property of bitumen sealants is their insolubility in water. In addition, bitumen sealants:

- durable;

- durable;

- chemically resistant;

- cheap.

The advantages of this type of sealants include their long-term use in construction, due to which there is now a large number of developments in this area. This is a proven, reliable material, and modern technologies make it possible to create new types of bitumen sealants, devoid of the disadvantages inherent in their predecessors, for example, bitumen sealants are produced not only black, but also in other colors, thanks to the addition of light pigments based on aluminum compounds, which is white. .

Disadvantages of bitumen sealants:

- low resistance to heat;

- low resistance to solar radiation.

Important!

Bituminous materials can destroy foam. This can be a serious barrier to their use, however there are modern asphalt sealants that are compatible with foam, such as CEMMIX Roofing Asphalt Sealant.

Scope of application of bitumen sealants

Bitumen sealants have long been successfully used in almost all joints and seams of external and underground structures:

- walls;

- floors;

- foundation slabs;

- buried structures of port and transport facilities;

- in sewer and water supply networks;

- flat and pitched roofs;

- engineering networks;

- drainage systems;

- at the joints of drainage system elements.

Features of application

Bituminous sealants polymerize quite quickly, making them suitable for urgent repairs.

What sealant to use for the roof

Both the comfort of living and the safety of all property located in the building depend on how strong and airtight the roof of the building is.

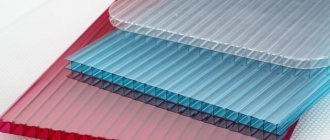

Roof structures vary; for example, they can be made from piece materials:

- tiles;

- slate;

- polycarbonate;

- metal profile.

Another option is a roof made of fused or glued roll materials, polymer or bitumen.

The roof can be flat or pitched. In the first case, its tightness is especially important, but in the second, one cannot do without reliable sealing of all seams. It only takes one leak to cause problems.

Any seams, abutments and joints can cause leakage. Although the parts of the roofing structures are equipped with rubber seals and gaskets, they do not provide complete sealing; sealing materials in the form of paste or mastic are required.

Reliable sealing is also needed for holes that appear from the installation of various equipment, antennas and cables.

Another problem is the effect of weathering on the roof.

This is why roofing sealants must meet the following requirements:

- waterproof;

- strength and reliability;

- durability;

- high adhesion;

- resistance to precipitation, weak acid solutions, temperature changes and UV radiation;

- possibility of use in any weather conditions, which in Russia can be very different;

- ease of use, no need to use special equipment.

For the roof, special roofing sealants are chosen, which can be bitumen, thiokol, or polyurethane, for example, CEMMIX roofing bitumen sealant.

Why do you need to seal your roof?

Sealing the roof will protect the rafter system, as well as the roofing pie, from moisture penetrating inside and from getting the insulation layer wet. It is also worth noting that this process protects the most unprotected places from the effects of aggressive reagents falling along with precipitation. If water gets inside the roof, the rafters will quickly rot and become covered with fungus, even if they are well treated with protective compounds. The thermal conductivity of the roof will also increase, so the house will be too cold in winter and too hot in summer.

No matter how carefully the cracks on the roof are sealed with other materials, the sealant will complete the job Source repairblog.ru

Thus, sealing is a very important process that increases the reliability and durability of the entire structure.

What sealants exist for external seams, and what should you consider when choosing

In what cases is sealing needed:

- Structures that are assembled from homogeneous elements and require tightness of joints and seams. For example, structures made of wooden blocks, logs, timber; concrete elements such as stairs, panels, parapets; roofing materials; metal and composite sandwich panels.

- Connections to the walls of door and window blocks.

- Joints in wet rooms (bathrooms, kitchens).

- Connections of dissimilar elements made of bitumen, concrete, plastic, metal, etc.

- Places where utilities pass through walls.

- Structural, shrinkage, temperature, insulating joints in concrete parts.

Which sealant is better? It is impossible to answer this question unequivocally. Sealant for external seams must meet the following requirements:

- strength and elasticity;

- high adhesion to various types of materials;

- ability to withstand vibration;

- resistance to temperature changes, solar radiation, moisture;

- chemical resistance;

- ease of use;

- durability and preservation of properties throughout the entire period of operation;

- no shrinkage;

- possibility of gluing parts and elements;

- possibility of coloring.

Most often, one-component polyurethane sealants are used for this work, such as CEMMIX Seam Adhesive, which is available in different colors.

How to choose a sealant

You always want to choose the best material, but there is no universal solution. When choosing sealants, the following factors are taken into account:

- base material and surface condition;

- work will be carried out indoors or outdoors;

- will there be a load on the seam or joint;

- whether the joint is flexible or rigid, movable or fixed;

- are there any external influences;

- what is the ambient temperature;

- Will painting be required?

The price of the material and ease of use play an important role.

Mistakes when working with sealants:

- incorrect choice of sealant;

- lack of surface preparation;

- the use of sealants without taking into account temperature and humidity, as well as other unfavorable environmental factors.

Main characteristics of hermetic substances

When choosing a sealing substance, it is necessary that its composition has sufficient strength, can withstand various chemical influences, it must be elastic, be resistant to corrosion and interact well with various types of materials. It should also withstand various weather conditions well. When filling seams, it should not allow voids or cracks.

Safety precautions when working with sealants

When storing sealants, it is important to follow the manufacturer's requirements. Typically, sealants are stored at room temperature in their original packaging, out of the reach of children.

Some sealants may be caustic to the hands or produce harmful fumes, so it is necessary to comply with hygiene regulations and use gloves and, in some cases, goggles and a respirator. Acrylic sealants that do not emit toxic substances are safe in this regard.

The right sealant is an integral part of any construction or renovation project. Which sealant to use depends on the situation. The strength and tightness of the structure depends on how correctly it is selected and applied. But it is equally important to choose a high-quality, affordable product from a well-established brand, such as CEMMIX sealants.