One of the most practical solutions in designing the interior of a kitchen or hallway is the use of ceramic tiles under laminate. Choosing ceramic tiles and then laying them correctly as in the photo allows you to get an excellent result - an externally “warm” floor, which also has excellent waterproofing characteristics. The advantages of such material are obvious, but are there any disadvantages? Laminate floor tiles are a new development in modern industry that have an interesting exterior. Its outer side perfectly imitates wood, which allows you to give the floor a look that is entirely similar to a wooden covering. In turn, everyone knows that wood goes perfectly with any decorative items in the interior.

Tiles for laminate from the Freedom collection of the Italon factory close up

Stone laminate - what is it?

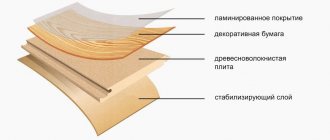

The composition of SPC is similar to flooring options such as quartz-vinyl tiles or “rigid” linoleum. In terms of manufacturing features and functional characteristics, this material is very different from other types of flooring. The fact is that classic floor coverings are multi-layered. They consist of a base (made of HDF board), a paper covering with applied decor and a wear-resistant protective outer layer that protects the coating from damage. Laminate, familiar to owners of residential and industrial premises, has become an attractive installation option thanks to the use of a clear system of locking connections between individual panels.

It was extremely difficult to find a waterproof coating that also met consumer requirements for safety and a pleasant appearance in stores. Therefore, modern manufacturers have developed and introduced into the range a fundamentally new version of flooring, called SPC (Stone Plastic Composite). If we translate the name, then it is translated from English: stone-polymer composite. What does this coating consist of:

- The slab at the base of the plank has a high degree of density. It consists of 75% calcium carbonate and 25% PVC. This composition is necessary to increase the strength of the load-bearing layer, while also performing reinforcing functions. Due to this, the service life of the coating increases and the resistance to mechanical damage increases. During production using hot press forming technology, a Click connection system is applied to each plank using a milling cutter. A number of brands that produce SPC laminate add a high-rigidity substrate to the bottom layer of the PVC board, which helps improve damping properties and sound insulation;

- The small thickness of modern high-strength composite material is not an obstacle to creating an attractive visual effect, which can be decorated with a pattern similar to natural stone or wood cut. Depending on the type and type of collection, the surface of the flooring can be textured or completely smooth, rough or patterned. In the premium segment, full-color photo printing is used on the top layer for complete imitation;

- The protective layer over the layer of stone or composite can range from 0.2 – 0.7 mm. It increases the resistance of the laid laminate to scratches, chips, or other mechanical damage. Most often, a special polyurethane is used as such a layer, which hardens after UV treatment. It is this version of the outer protective layer that is also used on HDF laminate, quartz-vinyl tiles, and dense linoleum. It has already proven itself to be an excellent solution against abrasion, compression and exposure to negative external environmental factors.

The material is cut and sold in the format of tiles of the same size or planks. Most often, SPC is manufactured in factories located in mainland China. The different options differ from each other due to a number of factors. Among them: features of the collection in terms of appearance and color scheme, the type of material used for external decoration, the thickness of the tiles and their size, the presence and type of chamfer. The price of the material varies depending on the quality, brand and appearance features and ranges from 1250-3500 ₽/m2.

Professionals in the field of finishing work and laying flooring argue that collections sold at a higher price differ from the budget segment. How? Excellent geometry of the planks, a small number of defective or substandard elements, and the quality of the external finishing of the material. For example, the color scheme will look more natural, and after correct installation, you can create a pattern that resembles real wood without repeating elements.

Recommendations for choosing tiles

When starting to select tiles for laminate flooring, it is imperative to familiarize yourself with the composition of the material.

Give preference to tiles that contain quartz sand, thanks to which the tiles become more resistant to mechanical stress and abrasion. To install a floor in a kitchen or hallway, experts recommend choosing a rectangular tile shape, which will not only shorten the installation process, but also completely imitate a wooden floor. The fashion for wooden floors will never go away. However, such material is considered expensive and requires careful and systematic care. Therefore, modern industry produces building materials that can visually resemble wood, giving them high technical characteristics. Understanding the advantage of laminate tiles, everyone will be able to create a beautiful design in the kitchen, giving it a special coziness and comfort. The ability to install heated floors under ceramic tiles not only raises the rating of the material, but also allows home owners to significantly save on heating costs.

Advantages

In terms of positive aspects, SPC has all the same features that durable linoleum, parquet boards and high-density laminate have:

- High rigidity and strength. For this reason, composite SPC can be installed in any room with high traffic and heavy furniture installed;

- 43 stability class. With this indicator, the material can easily be used both at home and in commercial or industrial premises;

- Excellent level of resistance to moisture or temperature changes. Therefore, this option will serve you well in the bathroom and toilet, in the kitchen and on the loggia. Also in other places where high resistance to these environmental factors is required. The maximum water absorption rate was only about 0.03%;

- A large selection in terms of external decor and texture features - you will definitely find an option suitable for your interior and the implementation of ideas;

- The slip resistance coefficient of this type of finishing material complies with the R9 standard. For this reason, the material is recommended for installation in rooms where families with small children live or spend time, as well as people with limited mobility;

- The small thickness of the material (from 3.5 to 7 mm) will help you easily combine this coating with any other floor covering option, so that you do not have to level the floor level in different rooms;

- The level of material fluctuations, even with significant temperature differences, is up to a maximum of 0.003%. For this reason, threshold-free installation is possible in large areas;

- Easy installation options without the use of glue or other connecting materials, jigsaws, saws, etc. For laying on a flat and durable base, you only need a special high-density substrate with a thickness of 1-1.5 mm;

- Compatible with any “warm” floor systems. It is best to use such design options as film mats with an infrared heating system or water systems integrated into the concrete screed;

- Easy to clean and maintain. In order to remove dust or dirt from the surface of the laminate, you only need warm water and a special mop attachment. All types of dirt, including the most serious ones, can be easily removed using warm soapy water. To remove complex multi-component contaminants, you will need special household chemicals, which you can buy at any specialty hardware store;

- Service life - up to 25-30 years with normal care and proper installation.

Joint location

When thinking about the future interior, you must immediately decide on the area where the border between tiles and laminate flooring will be placed in the kitchen. These two types of coating differ significantly in the way the base is laid, its technological characteristics and requirements. Therefore, at the stage of installation of products, care should be taken to clearly differentiate them.

There are different methods to solve the problem with the joint:

- Use an aluminum strip to secure linoleum near walls and thresholds;

- Apply vinyl overlay for masking;

- Organize a podium at the point where the two materials separate.

White tiles and laminate Source stroy-podskazka.ru

You can create a seam in any of the following ways, but the most important thing is to choose the right location. The main condition is to place the joint in such a way that it does not interfere with movement and does not pose a danger during active movement of residents and guests in the room. The border should either run parallel to the movement of people or be located in an area that is rarely visited. Otherwise, the risk of injury to occupants and damage to the coating increases.

Most often, the tiles are laid in the shape of the letter L, with most of it located under the set, and in front of the furniture a work area one and a half steps wide is formed. This arrangement will allow you to move freely around the kitchen without fear of catching a joint or hitting the podium. The rest of the space is laid out with laminate, this will give the room a more lively and cozy look.

Design of the joint between materials Source climatechange.ru

The boundary between materials is usually formed similar to what is done when laying linoleum. The seam is located parallel to the kitchen unit, its line runs along the facade. When arranging the podium, the area with tiles is placed 2-3 cm below the main surface.

Flaws

- High price compared to other types of coatings - from 1250 ₽/m2 only for the material, excluding the cost of work and additional materials for installation;

- Average fire resistance. According to the international classification, the material has a stability class of KM2, which guarantees an acceptable option in terms of finishing and building materials. In the event of a possible fire, such a laminate does not emit toxic substances or smoke, catches fire with difficulty and does not burn well, and does not contribute to the spread of open fire;

- High consumption when laying using the herringbone method - about 10-15% of the amount needs to be purchased additionally in order to be enough;

- Heavy weight (one plank with an area of slightly more than 0.2 m2 will weigh 1.5-2 kg). Therefore, when importing material and unloading, problems with carrying and placement may arise.

Main types

Laminate flooring for tiles has several varieties, differing mainly in the nature of the relief.

In addition, the coating differs in strength class or base material. All these varieties relate to the material as a whole, not just to laminate flooring.

It should be understood that the type of pattern imitation does not yet bring the coating into a special category, which has its own qualities and properties.

From an aesthetic point of view, the number of varieties of laminate flooring for tiles is quite large, since there are options:

- With different colors of individual blocks.

- With an imitation of a set of different types of tiles.

- With an image.

- Having a different surface - from smooth to rough, like natural stone.

IMPORTANT!

All these varieties are constantly being supplemented and changing, the boundaries between them are conditional and insignificant. The main criterion is the decorative value of the material and visual appeal.

Acclimatization of SPC laminate

All manufacturers have their own approach to this point. It is important to follow the instructions on the SPC laminate packaging. It is recommended to strictly follow the instructions only in large rooms. The laminate itself is extremely stable in terms of size and changes with changes in temperature and humidity conditions. For complete acclimatization, the laminate needs to be kept indoors for 24 hours in the warm season, or for two days in winter at a temperature of 17 to 27 °C. Do not place the packaging vertically so that the laminate does not bend under its own weight.

Installation procedure

Anyone can handle installation work. In this case, it is worth taking into account the recommendations of specialists and correctly performing each subsequent step:

- Before laying tiles, it is ideal to level the work surface to avoid subsequent deformation of the tiles.

- Lay tiles only on a dry and clean floor.

- The base for installation must be treated with a primer.

- Remove excess adhesive immediately during installation work, and use a rubber roller to remove air bubbles from under the tiles.

Tiles imitating laminate from the Elm collection of the Kerama Marazzi factory

Laying

- We determine the angle inside the room where the lamellas will touch with 2 spikes at once; installation should begin from here.

- Step back from the wall no less than 0.5 cm, install wedges on the spacer. If the area of the room is more than 60 m2, then increase the gap to 1 cm.

- Lay the laminate according to the instructions on the packaging from the manufacturer. If the length of the last tile in the row does not allow you to lay a whole lamella, then carefully cut off the unnecessary fragment.

- Lay the second and remaining rows following the instructions on the package.

Video description

An ideal joint between laminate and tile without any consequences.

Aluminum threshold Source mada.kiev.ua

Vinyl threshold

If there are curved joints, it will not be possible to use metal thresholds. In this case, you can purchase flexible vinyl tape that can be laid in any direction. This material is affordable and easy to handle, so craftsmen often find use for it in repairs.

During installation, the first step is to prepare the seam. At the depth of the joint there is a special bridge, the width of which is cut to the tiles and laminate. The profile is fixed to the concrete base with dowels and plugs. Before laying the tape on the profile, it must be treated in a hot liquid to soften it. When the plastic has completely cooled, the vinyl product will be firmly fixed inside the joint.

Combination ideas in different interior styles

In the minimalist style, a more restrained finish is assumed with rather modest and laconic color schemes, in gray, black or white colors; for the high-tech direction, choose a combination of glossy ceramic tiles with laminate boards in dark gray, black, anthracite or wenge shade.

Scandinavian design can be decorated using light tile finishes or models with imitation wood, stone or marble, which, in combination with beige, white, limestone or ivory laminate, will have a pristine and natural appearance.

The photo shows a Scandinavian-style hallway with a floor lined with patterned hexagonal tiles combined with beige laminate boards.

In rustic country, they often use laminate fabric in walnut, red, rich brown or beige shades in combination with multi-colored mosaics or patterned ceramics in the patchwork style, and for an industrial loft they prefer laminate that has a shabby and aged look in combination with dark tile cladding or products that imitate brick.

The photo shows a laminate floor combined with patchwork tiles laid in the center in a country-style kitchen interior.

Pros and cons of tile flooring with imitation laminate

The reason for the popularity of laminate tiles imitating natural laminate is the strength and durability of this floor covering.

After laying the laminate, the lamellas do not fit tightly together or come in waves. Laminate flooring requires some time for each element to “settle” on the substrate.

The protective coating on the surface of natural laminate wears off quite quickly; after just a year, the lamellas lose their shine and brightness.

Modern laminate floor tiles are characterized by increased wear resistance due to the presence of a protective layer of silicon and aluminum. Innovative technologies make it possible to accurately convey the structure and pattern of natural wood.

Ceramic coating is moisture-resistant, unlike laminate or parquet, is not subject to corrosion and is easy to clean from dirt.

The service life of tiles is 30-40 years.

Disadvantages of the material

Ceramic coating has a number of disadvantages:

- high price;

- difficulties in replacing damaged elements;

- high-quality grouting of tile joints is required;

- uncomfortable tactile sensations (cold and hard surface).