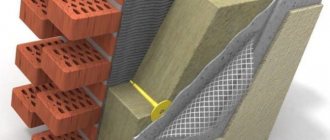

Cross insulation is one of the best ways to insulate a frame house. With its help, you can block all cold bridges, which are represented by wooden structural elements, cracks, and nail joints. This approach will help reduce home heating costs by 4-5 times.

Such insulation allows you to better protect the double top trim, double pillars of openings, and corners from low temperatures. For this purpose, an additional thermal insulation layer of at least 5 cm thick is laid on the outside. The final density of the thermal insulation layer can reach 25 cm, in which case even severe frosts will not be terrible. It is important to lay the mats with the seams staggered to avoid overlaps - this way you can protect the house from blown cracks.

A little about construction technologies.

The most common method of constructing frame houses is the so-called “Canadian technology”, in which sheet insulation is installed between the frame posts.

Other methods are less commonly used, for example, the use of ready-made sip panels (more expensive, although the materials are the same), the use of hollow blocks, which are then filled with sawdust, a concrete mixture based on crushed foam or expanded clay (a controversial issue regarding energy efficiency).

When building using “Canadian technology”, the following types of insulation are mainly used:

- Mineral wool

- Styrofoam

- Glass wool

- Ecowool

- Extruded polystyrene foam

Cross insulation

In addition to the main insulation, additional insulation of the frame house from the inside can be used during construction. It is made with a layer of insulation of less thickness, placing it on top of the frame supports on the inside. In this case, the plates of heat-insulating material are placed in a cross direction. If in the main insulating layer they were mounted with the long side up, then in the additional layer they were mounted with the long side horizontal.

Note: A similar technology is used for cladding interior walls. For example, when covering a frame wall with plasterboard, it is hung in two layers, placing the slabs in different directions.

This technology is called cross-insulation.

It has an important advantage. Cross insulation of a house allows you to place utility lines (wires, pipes) between the main and additional layers.

We cover the racks with insulation.

It also increases the overall layer of thermal insulation and improves the energy efficiency of the walls of the building. For subsequent installation of wall cladding, a sheathing is installed on the inside of the additional layer. Wall sheathing is attached on top of it.

Expanded polystyrene sheets (penoplex)

The material is lightweight

This quality is important if additional insulation is not planned at the construction stage. There will be no additional load on supporting structures

Among other advantages, we highlight:

- immunity to temperature changes. Numerous freeze/thaw cycles do not lead to changes in the internal structure;

- water does not penetrate inside the cells, does not freeze there and does not cause cracks or deformation.

But it is important to understand that polystyrene foam and its modifications are not flawless. Among the negative qualities we highlight:

- instability to high temperatures, rapid ignition;

- under mechanical shocks, polystyrene foam is deformed, the sheets will have to be changed;

- the room will become a kind of thermos due to low air permeability.

Expert opinion

Sergey Yurievich

Construction of houses, extensions, terraces and verandas

Ask a Question

Expanded polystyrene and its varieties are used only for external insulation when appropriate fire retardant treatment is carried out.

Installation of insulation

So, when the choice in favor of one or another insulator has already been made, the following questions arise: how to insulate a frame house with foam plastic or penoplex? How to correctly install insulation?

It is especially preferable to use polystyrene foam as insulation for a frame house on the outside, given the fact that mineral wool, with its low moisture resistance, is much less suitable for this and is used more for internal insulation of walls.

Expanded polystyrene boards are mounted on the wall in several different ways, namely:

- Using special glue for polystyrene foam. There are two types of such glue: in the form of a dry mixture and in the form of foam. Dry adhesive, similar in appearance to tile adhesives, is diluted with water (according to the instructions) and then applied to the wall. Foam adhesive is similar to regular polyurethane foam and is usually used for smooth walls. This glue is applied using a regular foam gun. When insulating frame walls with polystyrene foam, you must be extremely careful, since this material is quite fragile and the edges of the slabs break off easily. If you plan to further plaster the walls, then during installation it is preferable to apply the adhesive not in slaps or strips, but rather distribute it over the entire joining surface of the polystyrene foam board.

- Using fasteners (“fungi”). To install slabs when insulating the walls of a frame house with polystyrene foam, fastening elements are used, which are ordinary dowel-nails for concrete, but with a special cap that holds the foam plastic in the frame wall. Made of plastic, such “fungi” are not subject to corrosion and eliminate the formation of cold bridges.

Installation of polystyrene foam in a frame house using “fungi” is reliable and quite simple. The steps are as follows:

- Holes are made in the wall corresponding to the thickness and length of the “fungi”.

- Apply a sheet of polystyrene foam.

- The plastic part of the “fungus” is inserted, and then the special nail that comes with the “fungus” is hammered in, thereby pushing apart its part located in the concrete

- Using a frame. When insulating a frame house with penoplex and polystyrene foam, an additional wooden frame is sometimes used, which is a lattice or strips that are attached to the wall, after which insulation is attached inside the frame itself.

Otherwise, due to the same thickness of the slats and polystyrene foam, insulation in a frame house may turn out to be ineffective, since unique cold bridges will form.

For better fastening of slabs to the wall when insulating a frame house with polystyrene foam, several options for fastening polystyrene foam can be used simultaneously. In a frame house, for example, there is a frame and “fungi” or “fungi” and glue.

Regardless of what material you prefer to use for thermal insulation: polystyrene foam or polystyrene foam, your frame house will be warm and cozy. And by insulating a frame house with polystyrene foam yourself, you can also save a lot of money.

See more on this topic on our website:

- How to insulate a timber house from the outside with polystyrene foam and polystyrene foam. After building a house made of timber, many people are faced with the question of how much its walls can save heat, because in our conditions of harsh winters this is the case.

Insulation of a frame house from the outside with environmentally friendly insulation Since insulation of a frame house from the outside is a task of paramount importance during the construction process, it is recommended to approach the choice of a heat insulator with particular seriousness. In addition to such characteristics. Do-it-yourself insulation of the walls of a frame house from the inside Manufacturers of SIP panels and people who understand how the walls of a frame house are insulated say that well-mounted walls can fully replace a half-meter

Do-it-yourself insulation of the walls of a frame house from the inside Manufacturers of SIP panels and people who understand how the walls of a frame house are insulated say that well-installed walls can fully replace a half-meter wall.

Insulation of a wooden house from the outside with polystyrene foam. The effectiveness of the external insulation of a wooden house equally depends on the correctness of the chosen thermal insulation material and on the correctness of the installation. One of the most widely used.

Insulation for a frame house - reviews and which one to choose If you are planning to build a frame house, then, in all likelihood, you are asking yourself the question: “What material is best to use for its thermal insulation?” Choosing insulation for frame.

How can you insulate a concrete floor?

To insulate concrete, you can use any modern thermal insulation materials. Moreover, both in a single version and as a combination of several types of insulation into one sandwich.

The most popular are polystyrene foam slabs; it can be laid directly on the ground or earthen floor and then filled with concrete mixture. If the load on the concrete floor is small, then light grades PSB35 will be sufficient for insulation. If a private house has a garage, then the floor will require denser polystyrene foam PSB50. To insulate concrete floors in warehouses, extruded polystyrene foam such as penoplex is used under screed.

In addition to foamed polystyrene boards, you can use mineral fiber in mats or rolls. Mineral wool is used in the insulation of concrete floors in limited quantities and often only in foil or hydrophobic versions, always paired with penofol.

Mineral wool in an apartment as insulation for a concrete floor is good only until the first flood

A good result is obtained by insulating the concrete base with penofol brand “A-LP”. It is a completely normal option if you need to insulate concrete floors in a country house heated by ceiling infrared heaters or a regular potbelly stove.

You can quickly make insulation by backfilling with expanded clay or sealing the concrete floor with polyurethane foam. In the first case, a fraction of 5-10 mm is used, with the obligatory drying of the rough base with lime; before insulation, excess moisture leaves the concrete floor and at the same time the nutrient medium for the proliferation of bacteria is destroyed.

If you blow out the insulation with foam, then it is better to choose special brands for laying polyurethane foam on the floor of a private house using a generator. All other insulation schemes are either too expensive for private households or are susceptible to the formation of cold bridges on the concrete floor.

Concrete floor insulation thickness

The selection of the main parameters of thermal insulation is made depending on the method of installing the insulating layer, the material, the characteristics of the foundation and the climate. It is clear that the more severe the climate in the area where the private house is located, the more powerful the insulation of the concrete floor should be.

The simplest calculation involves the use of ready-made data, for example, SNiP No. 2.01.01-82 and SNiP No. 11-3-79 have already collected data on the recommended value of thermal resistance of insulation of private housing constructions used for permanent residence.

In order to calculate the thickness of insulation for a floor, you need to select from a reference book, SNiP, or at least from a map the recommended thermal resistance indicator in a given climate zone and multiply it by the thermal conductivity coefficient for a specific material used on the concrete floors of a private house.

As a result, we obtain the thickness of the required insulation in meters. For the middle zone, the thickness of polystyrene foam under the concrete screed should be at least 50 mm. If the foundation is made in the form of a slab, then the thickness of the thermal insulation should be increased to 100 mm of EPS sheet.

When insulating with mineral wool, a thickness of at least 100 mm is recommended, even if the concrete floors in the house are raised above the basement line. Specific options are selected based on the conditions specific to each particular case.

Materials for cross insulation

Cross insulation eliminates the appearance of cold bridges

Cross insulation (CI) of a frame house is a way to reduce heating costs. The level of costs is reduced by 4-5 times compared to other insulation options.

The main feature of PU is the absence of cold bridges, which allows you to stop the circulation of cold air flow inside.

The main material is a thermal insulation layer, the thickness of which is set to 15-25 centimeters. The thicker the insulation, the higher the percentage of resistance to extreme frost. However, not only this parameter affects the quality of the product. Other requirements are put forward for thermal insulation raw materials:

- environmental friendliness;

- resistance to mechanical damage;

- high fire safety;

- low level of thermal conductivity;

- strength of the structure.

Various types of construction wool and sawdust meet these standards.

Mineral, basalt and ecowool

Mineral wool

Mineral wool is used for thermal and sound insulation of buildings for various purposes: industrial, public and residential. Has undeniable advantages:

- low thermal conductivity;

- low density;

- high vapor permeability, which facilitates ventilation loads;

- service life – 25-70 years;

- environmental friendliness.

However, there are disadvantages to using the described product. When exposed to water, cotton wool loses its thermal insulation properties. During installation, dust and microfibers are formed due to mineral wool, which, if they enter the human respiratory tract, cause irritation.

Basalt wool is a type of mineral insulation. When interacting with moisture, basalt is not saturated with it, so its thermal insulation properties are preserved. During operation, dust and micro-splinters are also generated. Therefore, during repairs it is necessary to use a respirator.

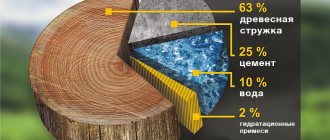

Sawdust

Sawdust must be treated with antiseptics and fire retardants

Sawdust is particles of processed wood. Outwardly they resemble dust. The main advantages of raw materials:

- no harm to the external environment;

- relative cheapness;

- satisfactory level of heat-saving parameters.

When choosing sawdust as insulation, you should take into account some points:

- To maintain heat, sawdust must be mixed with gypsum or lime.

- The material must be treated with antiseptics and fire retardants.

- There is a risk of fire.

- There is no resistance to biological influences, attacks of rodents and pests.

Frame house insulation cake

The cake is the layers that make up the insulation of a home. Their minimum number is five, while the maximum can be about 10. As for the thickness of the insulation, the ideal would be a layer of 200 mm (with a stand of 40 mm) or in a cross lathing with dimensions of 50x50 mm. But these parameters are good only for insulating a residential building. If you need to make thermal insulation at the dacha, 100-150 mm will be enough (although if you make 200 mm insulation, then this will also be good).

So, what does the insulation pie of a frame house consist of? This:

- vapor barrier film;

- insulation;

- waterproofing;

- wind protection;

- outer wall cladding.

You can easily do the insulation of the walls of a frame house with your own hands. First of all, decide on the type of insulation (correct or cross), insulation material, hydro-, steam- and wind insulation, thickness of the thermal insulation layer, as well as the number of these same layers

When cross-insulating, it is also important to know where the thermal insulation work will be carried out, from the inside or outside. Only when all these parameters are taken into account is the correct insulation pie scheme drawn up.

Master classes from professionals

Master classes organized by professionals allow you to obtain the latest and adequate information on all problems of insulation and related topics. As a result of the consultation, it will become clear what the width of the frame board should be in a certain case, and how to calculate the thickness of a fundamentally new material.

Experienced craftsmen understand safety measures and the storage and transportation of each insulating coating better than ordinary amateur builders. Many mistakes are made when attaching structures, drawing up diagrams and determining the sequence of layers in the “pie”. But communicating with knowledgeable people helps correct this situation.

When mineral wool is used, try to prevent condensation coming from warm rooms from getting on it. But waterproofing and vapor barrier are also fraught with many pitfalls.

The choice of material for cladding is often dictated by tradition, personal tastes or stereotypes - but meanwhile, a thoughtful design is much more pleasant. Professionals will tell you when you can use natural insulation, and when it is better to use artificial ones. It is very important to understand the compatibility of materials with each other: master classes again help here

To find out which insulation retains heat better, see the following video.

The importance of using high-quality insulation insulation from steam and wind

In order for mineral wool-based insulation to retain heat as best as possible, they need to be properly equipped with effective protection from wind, steam and moisture.

- Vapor barrier is a reliable barrier against moisture, which is present in any room in the form of vapor. If there is no such protection, the mineral wool will absorb water and become much worse at retaining heat in the house.

- Hydrowind protection. Its operating principle is reminiscent of a windbreaker worn over a sweater. The protective membrane retains warm air well in the room. It consists of several layers that allow it to retain heat and not interfere with the release of water vapor to the outside, as well as prevent atmospheric moisture from entering inside.

- The latest generation of protective membranes can protect the heat insulator and wall structure to the maximum from the negative influences of the external environment. Ordinary polyethylene film does not have such qualities, and it cannot be used in tandem with modern insulation materials. Neglecting this advice will certainly lead to the formation of a thermos effect inside the wall. And due to the lack of ventilation throughout the entire volume of the walls, the insulation will simply deteriorate and will not work.

Diffuse vapor barrier membranes

This vapor barrier has the property of changing (slowing down or accelerating) the penetration of vapors through its structure. Such membranes are usually used where the risk of moisture entering the frame wall pie is too high. For example, you have chosen a wet façade as an external finish, which is finished with impenetrable façade materials (clinker tiles, stone, etc.).

Scheme of the principle of operation of a vapor barrier.

Water vapor from the air that gets into the cake, or atmospheric moisture that gets behind the exterior finish, will cause destruction of the insulation and frame of the building due to high humidity. For a frame house, a humidity level above 19% is considered fatal. Moisture cannot escape due to the vapor-impervious properties of these façade materials. In this case, you will need to purchase diffuse films.

In normal mode, diffuse film is a classic vapor barrier that blocks the passage of air vapor from inside the premises to the outside through ceilings and walls. But if the humidity inside the frame house increases, then the diffuse film allows the steam to return inside the house from the insulation, thereby saving its structure. If your home is indicated for installation of a diffuse vapor barrier, the interior plasterboard sheathing should be installed through a ventilation gap made from a plasterboard profile or wood sheathing.

This is where the steam from the wall insulation will escape. Diffuse membranes cost several times more than a simple vapor barrier. Also, for its installation you will need branded mastics and adhesive tapes.

In order for a cheap or expensive vapor barrier to fulfill its direct functions, it must be installed correctly, carefully gluing all overlaps and joints. Only in this case will a durable vapor barrier layer be formed. Thanks to high-quality vapor barrier at home, any insulation will perform its functions for many years.

Problems in the construction of frame houses are very often associated with errors in the construction of this simple structural component - the vapor barrier. It is best not to allow anyone to participate in this process, but to do everything yourself, with the help of relatives or friends. It will only take a few days, but you are guaranteed to avoid the problems of poor-quality and incorrect installation of vapor barriers.

389

Vapor barrier in a frame house is carried out to protect thermal insulation materials from moisture, which can affect them indoors. It is worth noting that the main requirement for installing any insulation is its high-quality and maximum tight fit to the walls and floor of the frame. If water gets on it, the material will lose its positive properties, change its shape and its effectiveness.

Naturally, the overall insulation of the home will also suffer. The only correct and reasonable solution to eliminate such situations is to use a vapor barrier. The article describes in detail how to lay it, the features of construction work and what, in fact, this component is.

Insulating the roof of a frame house with your own hands

Very often, instead of the ceiling, and sometimes together with the ceiling, the roof of a frame house is also insulated with mineral wool. This is usually done in cases where the attic space is residential and heated.

The insulation technology is practically no different from the thermal insulation of the ceiling, with the exception that a waterproofing material must be stretched over the insulation to protect the insulation from the external aggressive environment.

This is how the thermal insulation layer of mineral wool on the roof of a frame house looks like in the diagram:

Here are a few features that will help make the DIY insulation process easier:

- It is more convenient to insulate the roof, as well as the ceiling, from the outside, because installing mineral wool from the inside is, firstly, inconvenient, and secondly, this material tends to fall on the head and face.

- After installing the rafter system, it is necessary to hem a vapor barrier layer from below, onto which, just as in the case of the ceiling, fill the inside with sheathing material, board or plywood.

- Now lay sheets of insulation on the outside, adhering to the same rules as when insulating other parts of a frame house.

- A waterproofing membrane is laid on top of the insulation, onto which the counter-lattice, sheathing and roofing material are already placed.

It is worth noting that the roof can also be insulated from the inside if it is fully assembled. But this is much more inconvenient, because you will have to come up with some kind of temporary fastenings, before stretching the vapor barrier material, so that the insulation does not fall out.

Frame wall insulation pie - what elements does it consist of?

There are several main options for building a frame house, the first is a factory one, when ready-made blocks are initially purchased, it is called frame-panel. Another method is to arrange and assemble the panels on site, essentially by hand.

Both options must contain several important layers, each of which has its own specific function. In fact, there are only 5 main layers:

- So, naturally, the facade cladding comes first, this also includes the external insulation, so the function is an attractive design and protection from temperature changes;

- Next, the windproof membrane protects the house from drafts, removes moisture and thereby retains heat;

- The frame itself always contains some kind of insulation;

- The vapor barrier layer protects the insulation from the penetration of water vapor, which in turn ensures the durability of the building;

- Internal lining. There are no longer any special standards here; you can use internal insulation, a variety of decor and anything that seems appropriate to the owner.

Insulation pie

IMPORTANT!

Layers of vapor barrier and wind protection must be secured using lathing. It is a mesh, usually made of wooden blocks, which fixes the necessary films and internal insulation, preventing deformation of the structure.

How to connect a steel battery

Installation and connection of steel radiators requires the step-by-step implementation of a number of procedures

It is important to securely mount the battery on the wall using suitable brackets and connect it to the heating system in the house or apartment

Craftsmen carefully drill holes in the wall, hammer in dowels and screw fasteners into them, and hang the battery on them. After this, shut-off valves are connected and pipes are supplied.

When the installation of a steel radiator is completed, pressure testing and a test run of the heating are carried out. After making sure that there are no leaks at the joints, the master hands over the work to the customer.

If the radiator is installed to replace an old battery, the specialist turns off the taps, drains the coolant from the sections, and then begins dismantling work. A new panel radiator is attached to the same place and connected to the harness.

We care about our clients and provide a variety of discounts on our services:

- We offer a flexible system of discounts from 5 to 20%, depending on the total cost of plumbing services ordered from us.

- Discounts for pensioners, disabled people, WWII and Labor Veterans - 10%.

- 5% discount when ordering heating radiator connections through the online form on the website.

How to build a frame house with your own hands - step-by-step diagram

Step 1: Preparatory stage

First of all, you should decide on the amount of building material. To do this, a diagram of the walls is drawn, the necessary measurements and calculations are carried out. It would also be useful to be careful when it comes to tools, so that unnecessary distractions do not arise later during the work process. So, we will need a drill, a screwdriver, a plumb line, a level, a construction ruler, a square, a hammer, and quite possibly a jigsaw and metal scissors will also come in handy. In addition, do not forget to purchase special antiseptic agents, which should be used to treat all wooden elements in order to give them fire-resistant properties and protect them from termites.

Step 2: Frame Construction

It has already been said that the thickness of the walls of a frame house largely depends on the purpose of the building, and it is influenced by the cross-section of the racks. Therefore, the area of supports for residential premises must be at least 50 cm2. First of all, the lower trim is installed on the foundation waterproofing, and then the logs are installed in its grooves. Naturally, all angles must be right, and the horizontal is also aligned. To further simplify the work, it is recommended to maintain a distance between the logs equal to the thickness of the insulation. Then, having thoroughly treated all the elements with antiseptic agents, you can install the corner posts and secure them with the top trim, and only after that install the intermediate beams.

Step 3: Processing the corners and installing the top floor

The next step in the construction of the correct “pie” of the walls of a frame house is the careful processing of all corners, including window and door openings. We secure them with special metal corners, which are fixed with screws. Next, the floor joist is installed; the technology is similar to the installation of floor elements, only in this case their length should be slightly longer. All racks should be strengthened with jibs.

Step 4: Exterior finishing

In the first paragraph it was already mentioned that the walls of frame houses must also include thermal insulation material, for example, mineral wool, although in principle, you can choose a different insulation material. So, to keep your home warm enough even in the harsh winter, be sure to secure a layer of thermal insulation material between the frame posts. Next comes the installation of waterproofing. Make sure that each subsequent layer overlaps the previous one, while laying it in the direction from bottom to top. It is advisable to fill thin blocks on top of it, with the help of which a ventilation gap is formed. Finally, we lay down a layer of exterior finishing material.

Step 5: Interior Work

The structure of the inner side of the walls of a frame house consists of a smaller number of layers - only vapor barrier and the finishing material itself. The latter is plasterboard, plywood, chipboard

If the room is residential, be sure to pay attention to whether the composition of the finishing material is harmful to health, because some types of chipboard are poisonous and unsuitable for such use

- https://stroychik.ru/strojmaterialy-i-tehnologii/karkasnyj-dom-svoimi-rukami

- https://obustroen.ru/stroitelystvo/steny/pirog-steny.html

- https://nastroike.com/stroitelstvo-doma/931-pravilnyj-pirog-dlya-sten-karkasnogo-doma

- https://remoskop.ru/pravilnyj-pirog-steny-karkasnogo-doma-ustrojstvo.html

Work order

Pie of the insulated wall of a frame house

The results of the work performed are influenced not only by the materials, but also by the installation scheme.

External insulation

Installation of the PU is carried out as standard in the following steps:

- 50*50 mm bars are placed horizontally in the bottom-up direction. The pitch is 60 cm, but it is recommended to measure 59 cm.

- A five-centimeter layer of thermal insulation is placed in the formed spacer.

- A membrane is placed on top of the created structure to protect it from moisture and wind.

- Another windproof film is laid overlapping at a distance of 10-20 cm.

This arrangement gives access to ventilation ducts and is convenient for the final interior covering.

Internal insulation

After external insulation, the craftsman proceeds to treating the room from the inside. The work proceeds as follows:

- A 5 cm layer of insulation is laid flush between the jibs. The second layer completely covers the wooden frame.

- Vapor barrier structures are being installed.

- The sheathing is installed to accommodate the final covering.

Do not push or compact the insulation. The amount of air inside the wool affects the thermal conductivity.

The attic floor, roof and roof are completely insulated according to the same scheme. In the case of the floor, additional installation of a strapping beam with a windproof and heat-insulating membrane is required.

Insulation of a frame house: materials

To provide protection from the cold of a frame building, it is necessary to lay several layers of thermal protection. The main filler for walls is mineral wool, but the range of fillers is represented by different types of materials. They differ not only in the degree of thermal protection, but also in the type of installation, care, and can affect the design of the entire house.

What is the best way to insulate a frame wooden house from the inside? It's a difficult question. To answer, it is better to consider all available options:

- Mineral wool and varieties;

- Sandwich panels;

- PPU;

- Styrofoam.

Mineral wool sheets are a dense product that is placed inside the frame, between the outer and inner walls. Cotton wool takes the shape of the figure in which it is located, and therefore ensures maximum adherence to the walls of the house.

Mineral wool has several varieties: glass wool, basalt stone, slag wool, etc. To insulate a frame house, it is better to choose a material with a density of more than 35-50 kgm3. This way you can avoid its subsidence and the appearance of unnecessary cold bridges.

Sandwich panels combine the qualities of sound insulation and powerful insulation. They are a complex combined insulation system that folds onto the wall like a construction set and immediately provides cross-insulation of the wall. Unfortunately, the cost of sandwich panels is quite high.

Instead of mineral wool, polyurethane foam is sometimes used - a water-based material that fills space well, hardens quickly, and provides a high level of protection from the cold. Working with polyurethane foam is not too difficult - its qualities are similar to polyurethane foam, and therefore applying it to walls, trimming, etc. will not be a problem.

The most common type of external insulation is polystyrene foam. Thick sheets of dense material can protect the house from the wind and retain up to 5° of heat that can escape through the walls. The polystyrene foam is attached to the external wall using construction adhesive, mushroom nails, and putty mesh. Covering the external wall of the house with foam plastic guarantees the so-called. cross-insulation of a house, where cold bridges (boards, beams) are covered with a layer of insulation.

Another task of foam plastic is to protect the frame from the harmful influences of the environment. Excess moisture, damage to the sheathing, and bacteria can greatly harm your home. Frame repair is a very expensive proposition. Polystyrene foam will protect the frame from most adverse factors. In addition, if the outer skin is damaged, the damaged slab is very easy to repair or replace.

How are they insulated?

In frame houses, mainly the same heat retention methods are used as in other buildings.

Thermal protection using mineral wool is deservedly very popular. According to some experts, it accounts for at least 50% of the entire market of heat-insulating materials. This popularity is primarily due to its high efficiency and lack of fire risk. At the same time, mineral wool weighs relatively little and allows steam to pass through perfectly, which allows you to maintain a good microclimate. It is necessary to understand that the quality of wool is directly affected by the type of binders used. They are created:

- based on bitumen;

- based on bentonite clay;

- from synthetic raw materials;

- based on a mixture of dissimilar components (most often synthetic resins are combined with hydrophobic substances and other additives).

Ecowool - also known as cellulose wool - is completely safe in environmental and sanitary terms, fully justifying its name. By nature it is a loose gray material. Ecowool can be used to insulate any part of the house. However, it is quite expensive. Such thermal insulation can only be installed using special equipment. Most often, ecowool is used by dry blowing. This method is very fast and produces excellent quality. Blowing equipment can be used for work. The wet-adhesive scheme allows you to insulate a large space. You will also need a blow molding machine for the job.

As for the rather popular penoizol, it is technically correct to call it urea-formaldehyde foam. This heat insulator has a low density and effectively protects against heat leakage. Penoizol is usually simply poured into the desired positions in foam format.

You can often find frame houses insulated with polyurethane foam. In different cases, both slabs (sheets) made from it and self-foaming mixtures are used. Using polyurethane foam, you can insulate the entire building - from the bottom to the top edge. This material is cheap and adheres well to a wide variety of substrates (in the form of foam). PPU slabs can become a support for waterproofing and facade cladding.

List the main types of insulation and their brief description

Insulation materials are divided according to their properties and method of application, but today the variety of materials is so large that it is very difficult to describe all the options, so only the most popular methods will be discussed.

Comparison of thermal insulation

Stone wool

Stone wool is a material that is used everywhere; it is preferred by many construction companies. The popularity of cotton wool is based on easy installation, since no special skills are required and you can get by with improvised tools.

NOTE! It is used in frame houses that are built with one’s own hands, that is, not of a factory design. Thermal insulation is used to fill the openings between the beams of the frames. Due to its distribution, cotton wool can be found in almost every large hardware store, and transportation is possible even in your own car

The main requirement for installing wool is its installation density - there should be no gaps

Due to its distribution, cotton wool can be found in almost every major hardware store, and transportation is possible even in your own car. The main requirement for installing wool is its installation density - there should be no gaps.

Stone wool

Styrofoam

Polystyrene foam is a cheaper and moisture-resistant insulation material, but it is also quite fragile. Installation of foam plastic is somewhat more difficult and requires some experience in this area. Since the material does not absorb moisture, there is no need for moisture/vapor protective membranes, which reduces the cost of the project.

The performance characteristics of polystyrene foam somewhat repel many people, which is why serious disputes flare up around the material. As negative aspects, they note that the material is not at all environmentally friendly and people complain about a deterioration in their health after insulation.

Styrofoam

Mineral wool

Mineral wool is often used in construction due to its high thermal/sound insulating properties, and mineral substances are increasingly gaining popularity in private construction.

Cotton wool has the form of fibers that are several times smaller than hair, and all this is in compressed form. The fiber length is 10-15cm.

Due to the presence of a huge number of air cavities, the material retains heat well, and along with it, sound. Installation of wool is as simple as possible due to the flexibility and elasticity of the blocks, and there is no tendency to deform. There is no risk of fire.

Mineral wool

There are many other types of insulation, such as:

- Styrofoam;

- penoplex;

- penofol;

- penoizol;

- polyurethane foam.

Vapor barrier of roof and walls. Where is it installed and why is it needed?

Let's look at another situation. Steam has entered the structure and moves outward through the layers. I went through the first layer, the second... and then it turned out that the third layer was no longer as vapor-permeable as the previous one.

As a result, the steam that gets into the wall or roof does not have time to leave it, and a new “portion” is already supporting it from behind. As a result, before the third layer, the vapor concentration (more precisely, saturation) begins to increase.

Remember what I said before? Steam moves in a direction from warm to cold. Therefore, in the region of the third layer, when the steam saturation reaches a critical value, then at a certain temperature at this point, the steam will begin to condense into real water. That is, we got a “dew point” inside the wall. For example, at the border of the second and third layers.

There was an obstacle in the way of the steam. Steam saturation has increased and condensation is likely to form

This is exactly what people often observe when the outside of their house is covered with something that has poor vapor permeability, such as plywood or OSB or DSP, but there is no vapor barrier inside or it is made poorly. Rivers of condensation flow along the inside of the outer skin, and the cotton wool adjacent to it is all wet.

Steam easily enters the wall or roof and “slips through” the insulation, which usually has excellent vapor permeability. But then it “rests” on the outer material with poor permeation, and as a result, a dew point forms inside the wall, right in front of the obstacle to the steam path.

There are two ways out of this situation.

- It takes a long and painful time to select materials for the “pie” so that the dew point under no circumstances ends up inside the wall. The task is possible, but difficult, given that in reality, the processes are not as simple as I am describing now.

- Install a vapor barrier from the inside and make it as airtight as possible.

It is along the second path that they go in the west, making a hermetically sealed obstacle in the path of the steam. After all, if you don’t let steam into the wall at all, then it will never reach the saturation that will lead to condensation. And then you don’t have to rack your brains over what materials to use in the “pie” itself, from the point of view of the vapor permeability of the layers.

In other words, installing a vapor barrier guarantees the absence of condensation and dampness inside the wall. In this case, the vapor barrier is always installed on the inner, “warm” side of the wall or roof and is made as airtight as possible.

Moreover, the most popular material for this “they have” is ordinary polyethylene 200 microns. Which is inexpensive and has the highest resistance to vapor permeation, after aluminum foil. Foil would be even better, but it's hard to work with.

In addition, I pay special attention to the word hermetically sealed. In the west, when installing a vapor barrier, all joints of the film are carefully taped. All openings from communication wiring - pipes, wires through a vapor barrier - are also carefully sealed

The installation of overlapping vapor barriers, popular in Russia, without gluing the joints, can give insufficient tightness and, as a result, you will get the same condensation

All openings from communication wiring - pipes, wires through the vapor barrier - are also carefully sealed. The installation of overlapping vapor barriers, popular in Russia, without gluing the joints, can result in insufficient tightness and, as a result, you will get the same condensation.

The vapor barrier does not allow steam into the wall and, accordingly, the likelihood of getting enough steam for condensation is greatly reduced

Untaped joints and other potential holes in the vapor barrier can cause a wet wall or roof, even if there is a vapor barrier itself.

I would also like to note that the mode of operation of the house is important here. Summer country houses, in which you visit more or less regularly only from May to September, and maybe several times in the off-season, and the rest of the time the house is without heating, can forgive you some flaws in the vapor barrier.

But a house for permanent residence, with constant heating, does not forgive mistakes. The greater the difference between the external “minus” and the internal “plus” in the house, the more steam will flow into the external structures. And the greater the likelihood of getting condensation inside these structures. Moreover, the amount of condensate can ultimately amount to tens of liters.

Choosing the optimal insulation

Mineral wool heat insulators are the most acceptable option for insulating a frame house. The materials are made from different raw materials, which determine the basic characteristics and scope of application. The general advantages of all types of mineral wool include: light weight, fire safety, resistance to pests and the necessary vapor permeability.

The main disadvantage of fiber insulators is hygroscopicity. To preserve the insulation properties, mineral wool needs high-quality vapor and waterproofing.

Basalt wool - environmentally friendly and fireproof

The main component of the insulation is rocks of volcanic origin: basalite, diarite and basalt. Stone wool is a completely non-flammable material that can withstand temperatures of 1000 °C. The heat insulator retains its physical properties for 40-50 years. The main advantages of basalt-based mineral wool:

- low thermal conductivity – 0.36-0.42 W/m*C;

- resistance to mechanical stress;

- good noise insulation characteristics;

- resistance to temperature fluctuations.

The insulation contains hydrophobic additives that ensure rapid removal of moisture. Basalt heat insulator is produced in slabs, the density of the material is 35-50 kg/cubic. m. The disadvantage of stone wool compared to fiberglass counterparts is less elasticity and susceptibility to rodents.

Glass wool – elasticity and moisture resistance

The basic components of the heat insulator are broken glass and sand. The addition of binding components makes it possible to form rolls from the finest glass fibers. Approximate dimensions of the mats: thickness – 100 mm, width – 1200 mm, length – 10 m.

It is equally important to calculate what density of insulation should be used. For thermal insulation of frame buildings, this glass wool parameter should be at least 15-20 kg/cube

m.

Features of glass wool:

- high elasticity – the material easily takes on and quickly restores its given shape, which is very convenient during installation;

- vibration resistance;

- not susceptible to mold and unattractive to rodents.

Like rock wool, fiberglass is fire resistant. However, in comparison with the previous insulation, glass wool loses on several points:

- Unsafe material - installation is carried out in a respirator and protective clothing. The fibers are very fragile and when cutting, a lot of “glass” dust is released.

- Shrinkage of the heat insulator - over time, the risk of the formation of cold bridges increases.

Ecowool – versatility of use

A new word in the segment of thermal insulation materials is ecowool. The material is 80% recycled paper. Additional components: boric acid and sodium tetraborate. Minor ingredients provide protection against microorganisms and reduce flammability.

Distinctive features of ecowool:

- Ecowool is a loose insulation material, and therefore the technology for its application is fundamentally different from working with sheet mineral wool. To create a thermal insulation layer, special equipment is required - a pneumatic inflatable device.

- If the walls of a frame house are insulated poorly, there is a risk of ecowool shrinkage, which can lead to the formation of uninsulated zones.

- The material is not recommended for use near open fire sources, fireplace pipes and chimneys. A protective layer of basalt foil-clad fireproof mats or fencing made of asbestos-cement slabs is required.

The main advantages of ecowool: environmental friendliness, the ability to insulate hard-to-reach places and high sound insulation qualities.

“Warm wood” - an alternative to mineral wool

This group includes mats and slabs made of wood fiber materials. The technical and operational characteristics of the insulation are at a fairly high level:

- good thermal insulation - thermal conductivity is comparable to that of mineral wool;

- preservation of the structure even when wet - the properties of the insulation do not change when absorbing moisture in a volume of 20% of its own weight;

- high strength and excellent sound insulation – protection from impact and “air” noise;

- sufficient density and elasticity - the insulation is attached between the frame posts without additional fasteners;

- environmental friendliness of the material and safety of installation work.

Wood fiber insulation “breathes” and helps maintain a comfortable microclimate in the house. The disadvantages of a heat insulator include: high cost and flammability.

A variety of methods for using ecowool

The second most popular material for thermal insulation of frame buildings is ecowool. But here it is better not to experiment and entrust the work to professionals. Mechanized backfilling will ensure the required density and uniformity of laying. There are three methods of using ecowool:

- dry "spray";

- wet application;

- glue method.

The dry method is applicable for horizontal surfaces, inclined closed cavities, filling interfloor ceilings and non-demountable structures. The packing density of ecowool using this method is 45-65 kg/cubic meter. m depending on the slope.

Wet technology is suitable for vertical open walls. Ecowool flakes are moistened and applied to the surface under pressure. The density of the thermal insulation layer is about 65 kg/cu.m. m.

The adhesive method is similar to the previous one, but instead of water, an adhesive component is added. Advantages of the technique: high adhesion of the insulation to the wall, elasticity of the material and low deformation after drying. The adhesive method is indispensable for thermal insulation of flows from below; this option is also suitable for treating walls.

The issue of insulating a house needs to be thought through at the construction stage. This is more profitable from a financial point of view and technically correct. Structural elements are insulated as the building is erected, and there is no need to carry out major repairs to the building after commissioning.

Review of manufacturers

Reviews allow us to appreciate not only various types of insulation materials, but also the professionalism and conscientiousness of individuals who supply fireproof thermal insulation made of stone wool to the market. It places emphasis on ensuring the highest environmental and sanitary performance of its products. You can use this mineral wool as part of thermal protection:

- pipes;

- facade walls;

- room partitions;

- roofing structures;

- areas experiencing intense loads.

100 mm of such a slab is enough to replace almost 2 m of brickwork.

The French corporation Isover sells glass wool to its consumers in roll, slab or matte configurations. Of course, environmental safety is somewhat less, but the cost of the products is noticeably lower and optimal fire-fighting properties are guaranteed. The level of thermal conductivity also meets the necessary requirements. The company's line includes pressed materials that are easy to install even without the use of fasteners.

Glass wool is also supplied under the URSA brand, which uses significantly less phenol in production, and in some cases has gotten rid of it altogether. The product range includes:

- slabs of moderate rigidity;

- products adapted for medical and children's organizations;

- hydrophobic structures of increased density;

- products resistant to deforming loads.

Existing insulation technologies

Insulation is not the only thing that needs to be chosen correctly when it comes to insulating a wooden frame house. What is important is the correct choice of technology, which is dictated by the insulation material, as well as its careful adherence.

Leading technologies:

- Thermal insulation with slabs. This is the laying of mineral wool, polystyrene foam and similar materials.

- Spraying. This technology for insulating a frame house is not yet so widespread, although it has significant advantages: a thin layer does not “steal” space and has excellent characteristics. Application requires special equipment.

- Backfill insulation of frame house walls. This refers to bulk materials, when cellulose fiber or similar insulation is poured into the cells of the frame (dry method).

- Combined option. This insulation scheme is optimal. For example, to insulate the walls of a frame house from the outside, they are lined with foam plastic and plastered, and to insulate the frame house from the inside, mineral wool is used.

Common questions and answers

Q: Are there ready-made house designs that take into account the parameters of interior or exterior finishing with thermal insulation?

A: Yes, they are abundantly present on our website in the appropriate section. If you can’t find a suitable option, adding additional characteristics to the design of a ready-made project is much easier and cheaper than developing it from scratch.

Q: What type of insulation is best for a beginner?

A: If a small building is being constructed, the most profitable option for the builder - amatera - will be cross-laying mineral wool.

Internal frame: 150 mm wide (for warm latitudes 120 mm is possible).

External frame (or internal) - 50 mm.

Layering of layers: perpendicular.

Q: How long does it take to install insulation for a house?

A: For a team of 3-5 builders, it will take about 12-20 hours to install insulation in a one-story house.

Speed plays an important role here: weather changes and rain can damage the insulation and cause financial damage to the home owner.

What to do after thermal insulation

Frame construction technology is good because it allows you to get a comfortable, cozy and warm home at a minimal cost. A layer of insulation is placed inside the structure and prevents heat loss

Therefore, after installation, it is important to create a supporting system and a plane for subsequent decorative finishing

In other words, the frame is sheathed with available finishing materials. Now all that remains is to choose what material to insulate your house with and start working with your own hands. With insulation, the frame system will delight the owners for many years.