Linoleum is a universal coating that can be laid in a variety of places and conditions, as well as on various types of substrates. It is often used to cover wooden floors made of boards or lined with plywood. Linoleum perfectly protects the surface from excess moisture, and at the same time it looks very nice, because the material can have any color, and choosing the color you like is not difficult. And it’s not at all difficult to lay it yourself. Today we’ll talk about how to lay linoleum on a wooden floor.

How to lay linoleum on a wooden floor

Laying linoleum

Features of a wooden floor

Before we talk about the linoleum flooring itself, it is worth noting several specific features of a wooden floor. This will help you understand why this type of finish and this type of base are absolutely compatible.

Wooden floor

The floor, made of wood, has a multi-layer structure. It consists of joists on which wooden floorboards are laid. In the space remaining under the boards, various communications can be located, as well as layers of insulation and waterproofing. Thus, the floorboards are protected from moisture coming from below. On top, a layer of linoleum, which is not afraid of water, will help protect them from it. In general, of course, the wooden floor itself is breathable, it has good vapor permeability, but still excess moisture is harmful to it.

Options for plank flooring in a private house

Not only the owners of newly built country houses, but also the owners of city apartments of old housing stock are puzzled by the problem of laying linoleum on the floor.

But linoleum can also have a negative impact on a wooden floor. If ventilation is not provided under the floorboards, then moisture willy-nilly will accumulate in the area where the joists are located, because linoleum will not allow it to escape outside and will disrupt the microclimate created under the floor.

However, the linoleum-wood floor combination is one of the best finishing options. Very often, it is this type of finishing coating that allows you to restore the former beauty of the base again. It's simple - boards lose their appearance over time; if they are painted, they constantly need to update the paintwork, which peels off. And thanks to linoleum, you can get a beautiful appearance of the floor quite quickly. At the same time, the coating is durable and will not require updating for many years, unlike the same paint.

The paint on the floor needs to be renewed periodically

On a note! Wooden flooring is considered environmentally friendly; it is optimally suited for installation in apartments where people who take responsibility for their health live. And linoleum, although it is a synthetic material, will never be a source of harmful substances. Therefore, these two materials - wood and linoleum - may well be neighbors.

Wooden floor in the apartment

Floor condition assessment

Before laying linoleum, it is necessary to assess the condition of the wooden floor and the need for preparatory work.

Walk energetically around the room, or better yet, jump.

If the floor does not wobble underfoot and does not make any sounds, then such a floor will be the easiest to work with, even if it does not have a perfectly flat surface.

Inspect the surface: the color of the boards should be natural. Try to pierce areas with discoloration with a screwdriver or an awl - healthy wood, regardless of age, will be strong enough.

The good condition of the floor and a normal level of humidity is indicated by the absence of fungus or mold on the boards and rust on the heads of the nails.

Another problem with wood flooring is wood-boring insects. Their presence is indicated by eaten grooves on the surface and inside the boards. Rotten boards must be replaced, otherwise the rot will spread to other wooden elements.

If there are traces of the presence of insect pests, then treatment with bioprotective preparations is mandatory.

It is advisable to lift one or two boards and assess the condition of their undersides and the joists on which they are laid. Tap them with a hammer - a distinct wooden sound should be heard, and a dull sound indicates the presence of pockets of rot.

Particular attention should be paid to load-bearing joists if the floor creaks or sag: most likely, they cannot withstand the load and you will have to place bricks or bars under them, and additional boards are nailed to the joists.

The squeaking noise can also be caused by friction between the floorboards. To solve this problem, it is recommended to pour talc or graphite powder into the cracks between them.

In addition, it is necessary to evaluate the evenness and horizontality of the surface. Performing all these actions is the key to long service life and good appearance of the coating.

What kind of linoleum is used on wooden floors?

Any type of linoleum is distinguished from other materials used for finishing by the following positive characteristics. This type of coating is quite durable, has a long service life, is easy to maintain, is not afraid of water, and has a reasonable price with a wide variety of colors and textures. And there are quite a lot of types of linoleum, among them it is easy to choose the type of coating that will be optimal in terms of price and quality.

Linoleum on wood floor

Table. Main types of linoleum.

| View | Characteristic |

| PVC linoleum | An artificially created polymer is used to make this type of coating. The material may have several layers, a different base or not have it at all. The thickest version of this linoleum usually has a foam base and consists of four layers. Its thickness is at least 4 mm. The bottom layer is made of foamed vinyl, followed by a reinforcing layer made of fiberglass. The PVC layer sets the selected color of the material, and also protects the material from negative influences from the outside. This material has improved heat and sound insulation characteristics. |

| Rubber | This linoleum is called “relin”. This is a multilayer material with a thickness of about 3 mm. It is made on the basis of bitumen, crushed rubber or rubber. The upper part is made of thin colored rubber. The material is elastic and not afraid of water. |

| Alkyd | This type of coating can have a thickness from 2 to 5 mm. Special pigments, fillers and alkyd resins are used for production. The material is resistant to abrasion, can have different colors, and has excellent sound and heat insulation properties. But in general it is a rather fragile species that can be easily damaged at a break. |

| Colloxylin | Material that does not have a base. Nitrocellulose is used in its production process. The coating is highly resistant to moisture, does not burn, and is very elastic. |

Glyphtay (alkyd) linoleums

Examples of rubber linoleums (Relin)

Laying linoleum on a wooden floor

Note! There is also thinner PVC linoleum on sale, up to 3 mm thick. Usually in this case the bottom layer is represented by felt. It also has a fiberglass layer covered with PVC film. If linoleum is fabric-based , it does not have a fiberglass layer. The material is not afraid of abrasion and is quite resistant to various factors. Baseless linoleum is the thinnest. It does not have any backing and is usually installed where the floor surface will experience maximum moisture exposure.

Examples of natural linoleum

Of course, linoleum made from PVC is most often used. Compared to other types, it has a relatively low cost, but at the same time has high quality indicators.

Different types of polyvinyl chloride linoleum (PVC)

Any type of linoleum can be laid on wooden floors. But it is still recommended to take material with sufficient thickness. If you look at the classification of linoleum, then for use at home it is recommended to purchase a semi-commercial version.

On a note! There are also household linoleum, characterized by the smallest thickness, and commercial , which is the thickest and hardest type of coating, ready to experience maximum loads.

The structure of household polyvinyl chloride linoleum (PVC): a) multilayer; b) single layer

When choosing a material, it is important to take into account the operating conditions. For example, in high-traffic areas in residential buildings, only a semi-commercial option is installed - the household option will quickly lose its appearance. But in the bedroom or nursery, the first one can be the best solution, especially if you want to save money. In any case, it is not recommended to buy a coating less than 3 mm thick.

Commercial linoleum

Classes of application of linoleum

Table of main criteria for choosing linoleum

Positive qualities of the material

Linoleum has always been popular as a finishing coating for floors of any type. This is a consequence of its many advantages over other materials. The positive qualities of linoleum can safely include its following properties: wear resistance and elasticity, water resistance and strength, a variety of shades and patterns, simplicity and speed of installation, which can be done independently, without calling or paying specialists, and, of course, an affordable price, which for many it is a decisive factor in their choice.

Methods for laying linoleum

Linoleum on a wooden base - just like on another type of base - can be laid in several ways. In general, they are divided into adhesive and non-adhesive. In the first case, the material is simply rolled out on the base and fixed around the perimeter of the room with plinths. But this option is only suitable for small rooms with low traffic, otherwise the material can easily move and waves will appear on its surface.

Linoleum rolls out on the floor surface

The adhesive method can be divided into two subtypes - using glue or using double-sided tape. In both cases, the fixation will be quite reliable, but still, for rooms where the floors are under significant load, only the option using an adhesive composition will be optimal.

On a note! Typically, linoleum is laid with glue only in rooms with an area of more than 20 m2.

Laying linoleum with glue

Technology of work execution

There are three main ways to lay the material:

- without glue with fixation only on skirting boards for small rooms;

- on double-sided tape around the perimeter;

- on glue.

The latter method guarantees the greatest strength. It is especially relevant when covering large areas.

Fastening without glue:

- lay out the covering on the floor;

- wait a few days;

- fix it with baseboards, making sure there are no bubbles.

Fixing the canvas to the baseboard

Fastening with double-sided tape:

- glue tape around the perimeter of the wooden floor;

- lay linoleum, measure all dimensions again;

- roll the roll to the middle of the room;

- tear off the protective layer from the tape;

- unwind the roll, gluing it;

- control the absence of bubbles and irregularities;

- cut off the excess, install baseboards.

Fastening the canvas with tape

Fastening with glue:

- lay out the roll on the floor;

- cut the corners for a tight fit;

- roll half of the coating into a roll;

- gradually unroll the roll, applying glue to the surface (after applying the glue, you should wait 20 minutes, and only then fix the material on the flooring);

- repeat the work with the second half;

- cut off excess;

- install plinths.

When laying linoleum from two strips, tape or cold welding is used to connect them at the junction.

Before using cold welding, apply masking tape to the joint and cut it along the seam with a utility knife. This will prevent excess adhesive solution from getting onto the front side of the linoleum.

Rules for laying linoleum on a wooden floor

In order to properly lay linoleum on a wooden floor, it is recommended to follow several rules:

- It is recommended to lay the material so that it lies along the direction of the boards;

- when joining individual sections of the covering, you need to ensure that the joint is in the middle of one of the floor boards;

- the temperature in the room while laying linoleum should not exceed 20 degrees. But it shouldn’t be too cool here either;

- material with a marble pattern should run perpendicular to the window, then the joints will be less noticeable. In general, linoleum must be laid taking into account the direction of incidence of light rays;

- if the coating will stick to the base and there will be joints on it, then it is important not to forget to leave an overlap of about 8-10 cm. Only in this case will it be possible to beautifully and neatly connect two pieces of material.

Linoleum pieces should be laid with overlap

Advantages and disadvantages

The choice of lining material is determined by its characteristics, pros and cons when used. Let's determine the main strengths and weaknesses of each type of bedding for linoleum.

| Type of position | Advantages | Flaws |

| Jute |

| high price |

| Cork |

|

|

| Linen |

| softness |

| Combination of natural materials |

|

|

| Foamed polymer substrates |

|

|

| Wood-based materials | inexpensive products. |

|

| DSP and GVL |

| installation features |

| Akuflek |

| |

| Infrared Film Substrate | additional heat source |

|

Next, watch a video on how to lay a roll underlay on a concrete floor yourself.

Required tools and materials

To lay linoleum on wood floors, you will need to purchase not only the coating itself, but also certain tools and materials. This could be a tape measure and other measuring materials, a knife for cutting the coating, a notched trowel (if using the adhesive fixation method), a roller for rolling the surface, putty for sealing the seams between the boards.

VX75 - knife for cutting linoleum

To implement the adhesive fixation method, you will need to purchase special glue or double-sided tape. For additional leveling of the floor, plywood, as well as nails or screws, can be useful. If installation involves joining individual strips of linoleum, then you need to buy cold welding to connect them inconspicuously.

Cold welding for linoleum

Linoleum seam welding technology

Calculator for calculating the area of a quadrangular room

Go to calculations

Main stages of finishing work

Preparing the base

The first step is to test the wooden floor for defects, rotten or rotten boards, etc.

The correct technological scheme provides for a flat floor, the absence of sudden changes in level, as well as adaptation of the boards to further operating conditions.

If installation is done without additional laying of intermediate material, it is necessary to carefully prepare the rough base. To do this, it is advisable to remove the old paint and check the condition of the boards. If necessary, defective ones are replaced.

It is necessary to remove paint from the base and check the condition of the places where the boards are attached. If the fasteners do not hold them in place tightly enough, they must be additionally secured to the joists. Most often, nails are used for this. Thus, the work on preparing the foundation can be reduced to the following:

- Deepen all the nails with which the floor is attached to the beams by 6-7 mm using a hammer. In places where the boards squeak or move, nail them to the joists with additional nails;

- Remove all irregularities (slabs) using a hand plane or an electric sanding machine;

- Finally clean or lay down plywood (7 to 12 mm thick).

If the material will spread on an old wooden base, it is best to completely wash it, dry it and vacuum it.

Advice

It will be much easier to remove the paint with a spatula if the surface is first heated to the desired temperature.

As for boards that have become unusable, they are replaced with new ones. Gaps and cracks are usually sealed using putties and mastics specially designed for these purposes. They resort to uniting the sexes much less often.

Linoleum can be laid on a completely flat base. The extent to which the surface obtained after repair meets these requirements is checked using a level. Detected irregularities are eliminated using a plane or by sanding.

True, it is impossible to achieve the required result in this way if there are significant potholes in the wooden covering.

Leveling the base in such cases is carried out by laying sheets of plywood, chipboard or moisture-resistant fiberboard under linoleum on a wooden floor, 7–12 mm thick. But at the same time, differences in the rough surface should not exceed 8-12 m per 1 m². Otherwise, a “spring” effect will appear while walking.

For their fastening, adhesives and self-tapping screws are used. For gluing, compounds that are used when laying parquet or PVC glue with a special filler that increases viscosity, for example, building gypsum, are suitable.

On a note

The elements of the leveling coating should be laid staggered and offset, which helps to evenly distribute the load over the entire floor surface.

Self-tapping screws are recessed into the body of the leveling layer, protecting the finishing coating from damage by the heads of the fasteners. Joint seams and places where sheets are attached should be puttied, after which these areas should be sanded.

How to prepare material for installation

A laying diagram is drawn up in advance to calculate the required amount of decorative material. Not only the length of the room is taken into account, but also the width of the roll. You should try to use a monolithic piece without joints. The correct technology for laying linoleum on a wooden floor is to spread the roll. After this, it must remain indoors for about 24 hours to take shape.

Not only the base needs preparation, but also the finishing material itself.

Linoleum must be rolled out on the floor and left for several days. He must adapt to the conditions of the given room and “rest.”

If the rolled out roll does not fit tightly enough to the floor in certain places, it should be pressed down by placing heavy objects on these areas: books, boards, etc.

Attention

If strong kinks or large dents/bulges are found on the surface of the material, then it should be discarded and replaced in the store, since no effort or tricks during installation will help to obtain an even plane of the finished floor.

If your choice fell on laminate flooring, then read how to lay laminate on a wooden floor here.

A prerequisite is that the work must take place in a room in which the air temperature is at least 16 ° C and the humidity is about 40%.

Uncover

Is it possible to lay linoleum on a wooden floor not in one piece, but in component parts? To do this you will need to make a pattern. Cut lines are drawn on the inner surface of the material according to a previously drawn up diagram. Then they check the dimensions again and make the cuts. It is best to use a special sharp knife with a thin blade for this. Regardless of what was laid on the wooden floor under the linoleum, you must first spread the blanks and wait until they take on their final shape.

Skirting boards must first be dismantled. Having spread the canvas overlapping the walls, the contours of all protruding elements, for example, heating pipes, are outlined on it, after which these areas are cut out.

Trimming around the perimeter is carried out with a margin. Excess material will later be covered with baseboards.

Laying technology

There are several options for installing such a coating.

- Laying without gluing is the simplest, although ineffective, technology. It is carried out in two stages:

- linoleum rolled out on the floor is left in this form for a couple of days;

- after straightening, press it along the perimeter using plinths.

The risk of resulting in an insufficiently even coating is quite high, so this method is not suitable for rooms with an area larger than 12 square meters. m.

- Gluing with special tape . Using double-sided tape is an excellent opportunity to extend the life of the coating, as it prevents the canvas from wearing out prematurely. As for reliability, it is largely determined by the quality of the tape used.

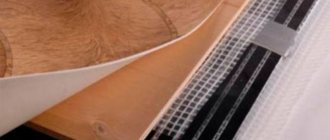

- Installation with adhesive composition . Despite its relative labor intensity, this method is the most popular and is considered the most reliable option. The underlay will help eliminate small defects in the wooden floor that require mandatory leveling.

Anticipating the question of what to put under linoleum, we note that the best option is a cork backing. It not only improves the quality and reliability of fastening, but at the same time serves as additional insulation for wooden floors.

Let us highlight the main stages of installation:

- the wooden base is covered with an adhesive composition and evenly distributed over the entire surface - a notched trowel is recommended for this work;

On a note

Carefully read the instructions for the composition - as a rule, it indicates the time that you need to wait before proceeding directly to gluing.

- the cork backing is rolled out on the plank floor. Particular attention should be paid to the corners where it is pressed especially carefully;

- the adhesive composition is then applied to the substrate and also leveled with a spatula;

- linoleum is spreading.

How to prepare a rough foundation

The base must be level, strong and reliable. Preparing the subfloor includes testing it for strength. It is important to inspect all the boards, walk around them and understand whether they need to be replaced or maybe it’s time to change the joists as well. Floors should not sag or creak, and there should be no mold or mildew on them.

Advice! Even if the boards look quite reliable, it is recommended to additionally screw them to the joists with self-tapping screws. Then they will be fixed as securely as possible.

Old wooden floor

Old paint, if any, must be removed before laying linoleum. It can be heated with a hair dryer and then scraped off with a spatula. It is also recommended to remove absolutely any old flooring so that it does not spoil the work done.

Leveling the floor is also an important task. It is recommended to cut down all the bumps (or plan them with a plane), but if the floors are completely uneven, then it is best to cover them with sheets of plywood or OSB. This will make the base as level as possible. Leveling the floor also includes puttingtying all the cracks and gaps between the floorboards. Copes well with the task of correcting the base of the scraper.

Before installing OSB or plywood, baseboards, nails, etc. are first removed.

Wood floor scraping

The floor should also be thoroughly cleaned of debris. There should be no dust or sand on the surface. If there is a need for wet cleaning, then it is carried out, but the floors must dry thoroughly before laying linoleum, otherwise mold may appear under the already laid covering.

Advice! If the linoleum will be laid using glue, it is recommended to pre-prime the base. PVA glue can be used as a primer.

In what cases is a linoleum underlay necessary, and when is it overkill?

There are a number of significant arguments in favor of linoleum underlay. In particular, its use is mandatory in the following cases:

- a cold floor is the main precondition for laying an additional base before laying linoleum. The high degree of thermal insulation of the material serves as a protective barrier against the cold that comes from the basement or lower floors where non-residential premises are located. Therefore, experts do not recommend saving on the comfort and health of loved ones by neglecting the layer between the floor and linoleum. It is worth purchasing a good substrate, preferably made from natural raw materials;

Substrates are laid on uneven or cold floors, as well as under single-layer linoleum

- uneven floor surface. Only an experienced craftsman can make a perfectly even screed, therefore, to avoid unevenness, it is better to use a backing that will hide all imperfections;

- single-layer linoleum. A coating without a base, although it costs much less, will not be able to provide the necessary thermal insulation; in such cases, a special base is required - a substrate.

You can do without an additional layer in a number of cases listed below:

- linoleum is laid on the old covering. In such a situation, the base should be as smooth as possible, without flaws, otherwise it is better to dismantle the old material;

- multilayer linoleum with a foam or jute base, which in its properties is in no way inferior to the substrate, greatly simplifies the installation process. This multi-layer material consists of fiberglass, a layer impregnated with PVC paste with a fabric backing, jute, polyvinyl chloride foam and polyester;

The backing may not be laid if multilayer linoleum is used.

- despite the fact that Tarkett commercial homogeneous linoleum is single-layer, it creates reliable insulation. This option is the best choice of linoleum for the hallway. Photos show different types of such material.

Preparation of linoleum

The linoleum itself also needs preparation before final fixing to a wooden base. To begin with, the newly arrived rolls are placed in the room where the material will be laid. They must lie down for a while to get used to the microclimate of the room. This procedure is especially important if the coating was transported in winter. The room temperature should be at least 16 degrees, and the humidity should be between 40-65%.

After this, the rolls need to be unrolled and the linoleum left to lie in this position for a few more days. The procedure will allow the material to straighten and stretch a little. Sometimes it is even recommended to press it down with something heavy so that it quickly takes the desired shape.

On a note! If strong kinks or breaks are visible on the unfolded linoleum, it is recommended to return the coating to the store where it was purchased and exchange it for a whole one. If it is not possible to return it, then you can try to heat the fractured area with a hairdryer and straighten it out. But the procedure is not always effective.

Severe kinks in linoleum cannot always be eliminated with your own hands.

The next stage of preparation is correct cutting. The material must be cut according to the geometry of the room. A small reserve of material (about 10 cm) is usually left along the edges, which is removed immediately before attaching it to the base. The necessary cuts are immediately made in the places where pipes and other elements pass. The main thing is not to cut off the section completely, but to make a hole of exactly the same diameter so that the linoleum fits tightly to the pipe. The cut, without which it is impossible to put the coating on the pipe, must be located behind it and, upon completion of the work, is carefully sealed with cold welding.

Important! You need to cut out linoleum very carefully and carefully, since it’s simply not possible to correct mistakes made.

It is easy to determine that linoleum is ready for fixation - there will be no folds or irregularities on the coating.

Is a substrate needed?

Preparing the floor for linoleum does not always end with leveling. In some cases, it is necessary to additionally lay the substrate. This material is needed for sound and heat insulation. It is especially necessary if plywood is not laid on the flooring. The underlay can correct minor unevenness if there is no need or time to do a full leveling.

There are five types of substrates:

- Jute. They have the ability to absorb excess moisture. The material will provide excellent additional insulation. Jute is rot-resistant and does not grow mold. In addition, it has good fire resistance.

- Cork. If you do not plan to install heavy furniture in the room. Cork would be a great option. It becomes a good additional insulation, natural and safe for humans. Disadvantage: low strength. Also, the material may have a relatively high cost.

- Linen. If you need to prevent the occurrence of mold and mildew indoors, then flax will be the best material for the substrate. It is not susceptible to the influence of various microorganisms.

- Combined. There are substrates made from several materials: linen, wool, jute. They are dense and do their job well. But during operation, their quality decreases significantly.

- PVC. Suitable for different types of surface, low cost.

The simplest option, which allows you to simplify your work, is to buy linoleum with a backing already glued on (check with the store salesperson).

Laying linoleum on a wooden base

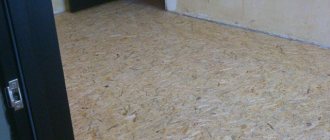

Step 1. The wooden base is prepared in the traditional way - tested for strength, cleaned of debris, and dried if necessary. If puttying the joints between the boards is not an adequate leveling measure, then the base is covered with plywood or OSB sheets. The thickness of these materials should not be less than 7 mm. A building level will help determine the evenness of the floor.

The evenness of the floor is checked using a building level

Step 2. The sheet leveling material is fixed using self-tapping screws or nails. They are simply screwed to the boards in increments of 20-30 cm.

Self-tapping screws are used to fix sheet material

Step 3. Linoleum is brought into the room, where it stands for several hours and acclimatizes.

Roll of linoleum indoors

Step 4. After this, the coating is rolled out on a wooden base.

The roll is unrolling

Step 5. The material is cut in accordance with the geometry of the room. Trimming is carried out with a special knife for linoleum. After this, the coating is cured for several days.

Cutting linoleum

Cutting linoleum

Step 6. Next, the linoleum is adjusted to the exact dimensions of the room. The stock of material that is currently preventing the linoleum from being laid flat is being cut off.

Linoleum is cut along the walls

Step 7. The final stage of the glueless method is the installation of skirting boards around the perimeter of the room and thresholds at the entrance. This way the linoleum will be fixed to the base.

Laying skirting boards on linoleum

Prices for Tarkett linoleum

linoleum tarkett

Leveling the surface

Plywood is laid for leveling on a concrete and wooden base.

Leveling a concrete base with plywood will save time and effort compared to screeding. Before leveling work, you need to assess the level of elevation differences using a level or rule. In a damp room, lay a layer of waterproofing. On concrete, plywood is either glued to the floor or fixed with anchor bolts and nuts.

When gluing, the initial complete layout of plywood sheets is carried out over the entire area of the room. For ease of installation, the large panel is cut into 4 parts. Then the adjustment is made, not forgetting about the compensation gaps of 1 cm. The sheets are placed in such a way that there is no contact of four corners at once.

All plywood is removed and the concrete is primed for better adhesion. After drying, begin gluing. Gradually, in small areas, a layer of bitumen mastic or universal polyurethane glue is applied with a spatula, and sheets of plywood are laid on it in accordance with the diagram.

The glueless fixation method involves drilling holes in the concrete for anchor bolts in accordance with the layout diagram.

A sheet of plywood of different sizes requires up to 16 anchor bolts, but not less than 9 per 1 square meter. An anchor is installed into a hole in the concrete, a bolt with a washer and a nut are screwed into it. A sheet of plywood is placed on top of the washers in the drilled holes. Using nuts, the level is adjusted strictly horizontally. The remaining sheets are laid using the same technology.

Before laying plywood on a plank floor, check it for strength and evenness. The condition of the boards is assessed and rotted floorboards with traces of mold are replaced. Additionally, fragile and creaking boards are secured with nails or 5-7 cm screws. The nails must go right through the board and be secured in the joist holding the floorboard. All protruding nails must be sunk into the floor so that they do not stick out. All protrusions and knots are trimmed off with a plane or grinder.

There are two ways to lay a plywood base - without using joists and with joists. Without logs, plywood is laid directly on a wooden base. Plywood sheets are cut into 2-4 parts in advance to avoid deformation when humidity changes. Pieces of plywood are laid in a checkerboard pattern with an offset, not forgetting about a gap of 0.2-0.5 cm between the sheets and between the wall of 1-1.5 cm.

Using a screwdriver, screw the screws at a distance of 25 cm. The screws are taken from wood, 3-4 cm in size. They need to be deepened so that they do not protrude above the surface and tear the soft material. These recesses must be filled with wood putty.

When the height of the ceilings allows the use of logs and the wooden base is too uneven, then wooden beams are laid. For the logs, take a beam measuring 50 by 70 mm, the distance between them is 40-60 cm. Check that all the logs are at the same level and attach them to the boards.

The thickness of the plywood sheet should be from 18 mm, it depends on the distance between the joists - the larger it is, the thicker the sheet.

The sheets are fixed with self-tapping screws, deepened by 2 mm, then puttied. At the end of all work, the plywood floor is covered with a fire and moisture retardant compound.

Useful tips

- Before starting work, you should check all linoleum for bubbles, swelling and other defects.

- If such deviations are detected, the best solution is to exchange the roll for a better one. Because in this case it will still not be possible to obtain a flat surface.

- You should start work from the corner farthest from the doors. Laying the canvas this way will be more convenient because you will always, at any stage of laying the material, have access to the front door.

- If you want to achieve not only an aesthetic effect when laying linoleum, but also improve sound absorption or insulate floors, you should use a special underlay. It can be made from jute, cork or polymer.

Subscribe to our Social networks

Methods of applying protective agents

There are two methods for treating wood with protective agents:

- Surface treatment. This method allows you to preserve all the decorative properties of the tree and at the same time protect it from various influences. This operation is carried out in any private construction, from finishing wooden beams in houses to any wooden buildings.

- Deep processing. The implementation of deep coloring is possible only in production, where there are special industrial devices. The essence of this treatment is to penetrate the product deep into the wood fibers, thereby ensuring high-quality protection of the entire part.

What to lay on the floor in the kitchen requirements for flooring

Of course, when deciding which is best to choose for the flooring in the kitchen, we first talk about comfort. And only then do we think about how the floor we have chosen will last as long as possible. What does this depend on?

That's right, it depends on what the product was made from and what the properties of these materials are. Plus, don’t discount the appearance of the floor. Because kitchen design can either win or, on the contrary, lose.

What properties do manufacturers give their kitchen flooring? So they should:

- be resistant to wear;

- do not absorb moisture;

- be easy to clean and maintain;

- not be subject to mechanical stress;

- respond normally to cleaning products;

- be beautiful in appearance.

It is important to remember that each type of floor covering has its own additional conditions (such as, say, requirements for increased aesthetics, etc.). After all, someone may limit themselves to the practicality of the solution, while others may not have enough money. It seems that the requirements are not enough? Are there materials that fully correspond to them? Are you choosing what kind of flooring you want in your kitchen? Let's look at the possible flooring options for the kitchen:

It seems that the requirements are not enough? Are there materials that fully correspond to them? Are you choosing what kind of flooring you want in your kitchen? Let's look at the possible flooring options for the kitchen:

- Ceramic tile

- Cork coverings

- Natural wood

- Laminate

- Polymer self-leveling floor

- Porcelain tiles

- Linoleum