No flooring lasts forever. It wears out, and in order for the room to return to its fresh look, it will need to be replaced. The most common coating for this is linoleum, which is attractive due to its price, wear resistance, design and practicality. However, not everyone knows how to glue linoleum.

- Which is better to choose linoleum for an apartment?

- Where can you glue linoleum

- On concrete

- On a wooden floor

- To plywood

- Instructions on how to glue

- How to glue linoleum at joints: several methods

- Glue gun

- Soldering iron

- Hot welding

- Cold welding

- Adhesive mastic

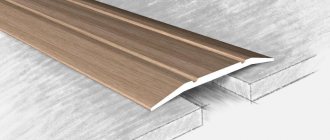

- Overlay strip for linoleum

- Common mistakes when gluing

- Care instructions

You can glue linoleum to the floor yourself, without repair specialists. Before doing this, we recommend watching video tutorials in order to properly glue the material together and make the joints completely invisible and airtight.

This article is devoted to the rules for gluing linoleum so that it lasts for several decades. It covers:

- types of coverage;

- where can you glue;

- what glue for linoleum is needed in the work;

- methods of gluing at joints;

- recommendations for proper care.

Methods for laying linoleum

Without fixation

The easiest and fastest installation method. Most often used in small rooms that can be covered with one sheet of linoleum. The covering is cut to the size of the room and placed on the concrete floor. After shrinkage, the edges of the linoleum are simply pressed with baseboards.

Fixed with double-sided tape

This method uses adhesive tapes designed specifically for gluing linoleum to a concrete floor. The tape is laid along the edges of the room and at the joints, and only after that the covering is laid. To remove air bubbles and improve fixation, the surface of the linoleum is rolled with a heavy roller.

Fixed with glue

The most labor-intensive and reliable method. Before laying, linoleum adhesive is applied to the entire area of the concrete floor with a special notched trowel. After some time, the coating is carefully laid on it, and then excess glue is removed if necessary.

Before laying, you need to unroll the roll and let it rest indoors for several days. This is necessary for any installation method. When laying out the linoleum to shrink, leave a small distance between the edges of the covering and the walls. This technique will allow the coating to shrink and expand with fluctuations in humidity inside the house without deforming the main part of the canvas. The cracks themselves need to be covered with plinths so that they do not spoil the appearance of the room.

Is it necessary to glue linoleum: expert advice.

- Small room. If the room has an area of less than twenty square meters, the flooring is laid in one piece. It is fastened along the edges with rigid plinths, in the area of the inter-door joint it is connected with double-sided tape, a strip, or “cold welding”. No gluing required.

- Old concrete. When the screed is loose and prone to crumbling, gluing will be impossible. The glue will simply seep into the screed.

- Availability of paint. Usually the paint reacts chemically with the adhesive, causing stains on the decking.

- Coating made of wood-based materials. The material is not glued to plywood, thin fiberboard, chipboard - this causes impregnation and deformation, delamination of the base.

- Base made of parquet, laminate. It is recommended to remove the slats, which will diverge and begin to creak and move, which reduces the quality of the floor.

Advantages of laying linoleum with glue

Despite the complexity of the process, fixing with glue has many advantages that other installation methods do not have:

- Tight connection to the concrete floor. Thanks to this, the likelihood of wrinkles and tears on the surface of the linoleum is significantly reduced.

- Elasticity. Modern adhesives allow linoleum to naturally expand and contract without severe deformation.

- Noise suppression. Some adhesives can absorb vibrations from the floor surface. That is, your neighbors below will not hear you walking around the apartment or moving a chair.

- Save time without losing quality. Some additional properties of the adhesive help simplify the process of laying linoleum. For example, many moisture-proofing compounds do their job without a backing.

Fixing linoleum to a concrete floor with glue is a great way to extend the life of the coating

Advantages of adhesive installation

The main thing that sets linoleum apart from the spectrum of all finishing materials for flooring is its unpretentiousness. This coating is appropriate in rooms with high humidity, since the artificial material does not allow or absorb liquids. In addition, it is durable and wear-resistant, so it is suitable for public institutions and simply rooms where there are a large number of people. These qualities make linoleum an ideal floor covering. However, in order for all its advantages to be realized in practice, it is necessary to firmly fix the material to the surface.

Adhesive installation is the most preferred method of installing linoleum indoors. Experts note several key factors determining this choice:

All this makes adhesive installation of this type of coating the most preferable option. However, it should be noted that this method also has a drawback: linoleum installed in this way will not be easily dismantled.

On the other hand, with properly selected and glued linoleum, the need to change the coating will disappear for a very long time.

What types of glue are used to lay linoleum on a concrete floor?

Water based

The most environmentally friendly and safe type. Due to its composition, it has a very low emission of volatile organic compounds. However, water-soluble glue cannot always provide a strong enough hold. Most often, problems with its use arise in damp rooms.;

Acrylic

The most common type. Acrylic-based adhesives provide high bond strength, are resistant to sun and moisture, and also withstand small temperature changes. A universal option for all types of premises. Not recommended for outdoor use, as in severe frost it hardens and begins to crumble.

Polyurethane (reaction)

The strongest type in terms of fastening. The polyurethane-based composition creates a very strong bond between the coating and concrete. When dried, the composition does not lose elasticity and becomes moisture resistant. Reactive adhesives have an unpleasant chemical odor and can be toxic. Not recommended for residential use.

The choice of type of glue depends on the characteristics of the room where the linoleum is planned to be laid

Is gluing of the product necessary?

Sometimes residents or premises owners wonder about the appropriateness of using glue when installing linoleum not on top of a concrete screed, but on materials such as hardboard, chipboard, OSB and fiberboard. These slabs, like, for example, wooden floors and crumbling concrete, are not the most durable and reliable basis for applying linoleum strips. They are unstable in terms of microclimate because they can accumulate dust and moisture. Therefore, in such a situation, applying glue is prohibited; it is better to limit yourself to glue-free methods.

In general, it is necessary to take into account that all types of glue are applied only to an absolutely flat, thoroughly cleaned and prepared surface.

How to choose which glue to attach linoleum to a concrete floor?

To prevent installation of new linoleum from becoming a nightmare, consider the following factors when choosing an adhesive:

- Type of linoleum. It's always best to choose an adhesive specifically formulated for the flooring you're working with. For example, for linoleum with a natural base, a water-dispersed material is suitable, and for a synthetic base, acrylic is suitable.

- Purpose of the room and its features. In rooms with high humidity, moisture-resistant glue is used, and in rooms with high traffic levels, high-strength glue is used.

- Ease of use of glue. While there are many tools available to help minimize the mess when working with glue, it's likely that you'll have to make some adjustments. Therefore, it is better to make sure that the adhesive you choose can be removed if necessary. Water-based materials are the most practical in this regard.

- Environmentally friendly composition. All materials you can buy in a store are officially considered safe for use at home or work. However, some do produce more harmful emissions than others. If this worries you, carefully study the composition of the glue before purchasing.

A few words about choosing linoleum

It is necessary to highlight several positions regarding the flooring, which will allow you to immediately identify several features. When choosing a material, you should choose a thicker product - this will make the floor warmer and softer. On the other hand, there is a problem that indicates the possibility of dents and other marks due to furniture legs.

It is important to understand another feature - thickness is not an indicator of quality. It is used only to improve comfort and eliminate minor surface problems.

When assessing quality criteria, you should pay attention to the protective layer, which will indicate strength, resistance to wear and various negative phenomena

It is recommended to choose not the thinnest linoleum - it can quickly stop performing its functions and lose its beautiful appearance

Typically, finishing materials are divided into classes where commercial, semi-commercial and household are located. Products are presented in descending order of wear resistance. Next, we present the main positions and their features.

To provide additional noise and heat insulation, it is better to choose variations of linoleum with a felt base

Please note that the situation with cold floors cannot be solved with felt alone. Therefore, it is necessary to take care of additional insulation using glass wool or similar products

You should not buy products with an unpleasant, pungent odor. This is a feature of low quality products that release toxic substances.

This is interesting: What kind of floor tiles are there for parquet: we describe in detail

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

The two pillars on which all home renovation problems rest are the desire for unhealthy savings and philistine misconceptions. If you want to clarify something, please contact me!

Features of laying technology

Every building material has its weak points, and linoleum is no exception. Therefore, we have prepared a step-by-step guide for laying linoleum on a concrete floor, taking into account its main features.

Required tools and materials

- utility knife,

- floor scraper,

- roulette,

- Master OK,

- pliers

- notched spatula,

- masking tape,

- damp cloth or mop,

- linoleum,

- glue.

Laying linoleum does not require special skills or professional equipment - with the right approach you can do it yourself

Step 1: Prepare the room

If you are replacing old flooring, remove all furniture, appliances, plumbing fixtures and other items from the room. Use a pry bar to remove the doors and baseboards. If necessary, take pliers and remove the remaining nails.

Step 2: Prepare your work surface

It is very important that the floor is level, dry and clean. After dismantling the old covering, sweep away all debris from the floor, remove any remaining adhesive and wipe it with a damp cloth. Wait until the surface is completely dry.

On a concrete floor, it is necessary to seal all cracks through which moisture can seep. Otherwise, the linoleum may become deformed, peel off, lift, or crack. To correct defects, use a special sealing solution. Apply it carefully using a trowel and level it across the floor.

Once dry, sand the entire floor surface with coarse sandpaper wrapped around a block of wood. This will not only make the concrete surface smooth, but also rough. This effect will improve the bonding of linoleum and concrete.

Step 3: Let the linoleum sit

You will make a big mistake if you start laying linoleum immediately after purchase. It takes time for shrinkage, approximately 24-48 hours. The covering must be unrolled so that it can gradually adapt to the temperature and humidity of the room. This is necessary to prevent deformation of the linoleum after installation.

Before installation, you need to let the linoleum adapt to the conditions of the room.

Step 4. Begin installation of the coating

Before cutting linoleum, take the necessary measurements. Determine exactly how the coating will be laid and in what places the excess needs to be removed.

Using a notched trowel, spread the adhesive onto the floor following the instructions on the package. Lay out the linoleum and use a floor roller to thoroughly smooth the sheet to remove wrinkles, bubbles or waves. Start from the center of the room, pushing the air out to the edges.

After this procedure, you can attach the skirting boards.

Step 5: Do the finishing work

Remove excess glue from the instrument and linoleum with a soft cloth if it has not yet dried. Cured material can be removed using a swab moistened with water and floor cleaner.

Don't rush to put up furniture and walk on the new linoleum. Wait a while for the coating to firmly adhere to the floor.

Furniture can be placed on a new surface only after the glue has completely hardened.

How to glue to metal?

Sometimes you have to fix linoleum on completely different surfaces, for example, on metal. Many people choose double-sided tape in such cases, since it sticks the linoleum quite firmly and does not have to bother with applying glue. However, this method has a number of disadvantages. Double-sided tape does not provide proper adhesion to such a complex surface as metal, so after some time it will probably move, and waves and creases will appear on the outside of the linoleum.

The most successful gluing method in this case is considered to be liquid nails, for example, Moment glue. This is a modern method of installing coatings, which allows you to attach them to almost any material and guarantees high fixation strength. Liquid nails are not used when working with natural materials, however, they are quite appropriate when interacting with all others. So, they are not suitable for fixing a solid piece of linoleum on a fabric base, but they can handle materials such as PVC. In addition, they are very economical: they do not require application to the entire surface, a few “snakes” are enough.

Before applying glue, as always, you need to make sure that the surface is prepared for gluing: smooth and unpainted.

But in the case of this material, you need to be prepared for the fact that the linoleum in these places will quickly wear out.

How and with what to glue the edges (joints) of linoleum when laying on a concrete floor

The instructions described above are intended for small rooms where one sheet of linoleum is sufficient. If the width of the roll is not enough, the linoleum is laid end-to-end.

In general, the seams and edges of the coating wear out faster than the main part. To extend its service life, these places need to be glued as tightly as possible.

For these purposes, hot and cold welding technologies are used.

Hot welding of linoleum

It is produced using special equipment and is intended for industrial coatings with a high wear resistance class and an increased level of strength.

Cold welding of linoleum

This is filling the seams with a special glue to give additional strength and wear resistance to vulnerable areas. The process is simple and you can do the job yourself.

For new coatings, class A cold welding should be used. It has a liquid consistency that quickly fixes the edges of linoleum, preventing them from coming apart. Class “C” welding is denser and is intended for repairing old coatings.

Cold welding is a great way to firmly glue the edges of linoleum

You can firmly connect the edges of linoleum using cold welding in four steps:

- Prepare the seam for welding: clean and dry it well.

- Cover the joint with masking tape to avoid deformation of the coating. At the junction, make a neat cut with a utility knife.

- Wear gloves and a respirator to avoid poisoning from chlorine vapors contained in the glue.

- Apply a uniform layer of cold sealer to the joint of the linoleum. Avoid getting glue on the canvas to avoid damaging it.

- The seams will be firmly welded after 30 minutes. If necessary, you can remove the tape within 15 minutes after applying the composition.

Instructions on how to glue

How to lay linoleum correctly? You need to follow step-by-step instructions that describe in detail the principles of operation. This will help you avoid basic mistakes in your work.

The master, who is faced with the task of gluing linoleum, must choose one of several working methods. Their distribution is based on the type of adhesive used in the work.

How long will it take to walk on new linoleum?

This directly depends on the characteristics of the glue you used for installation. Therefore, the best decision would be to look for the answer to this question on the packaging of the material.

Drying time also depends on the humidity and temperature in the room. For example, most acrylic flooring adhesives will fully cure within 12 to 20 hours after installation, depending on environmental conditions.

And although the time varies from manufacturer to manufacturer, it is generally not recommended to walk on new surfaces for 12-15 hours. Heavy furniture should be placed on a new floor even later - no less than 24 hours after installation.

Proper installation of linoleum looks beautiful and neat

Linoleum - to glue or not to glue?

I read all sorts of articles on linoleum - my head was swollen, but I still didn’t understand.

Some say - you can just lay it down, you just need to stick it a little from the edges with 2-sided tape, others - definitely glue it over the entire surface, and still others - glue it with two stripes crosswise. I would like to glue it, honestly, I wouldn’t want to - the floor is made of gypsum fiber board, if you peel it off later, the surface will most likely be ruined. Tarkett semi-commercial linoleum produced in Russia, there will be no joints, the area is small. Please tell me. 05/28/2006 at 23:42

I too was tormented by this issue at one time. If you do it according to science, then you need to glue it. But according to another science (life), you don’t have to glue it. I have friends whose linoleum has been left unglued for years and nothing has happened - it just sits there and doesn’t swell. So about three months ago I laid linoleum on a flat base. So far so good. The only thing I did was create centimeter gaps from all the walls and did not clamp them with a plinth. Although there is a refrigerator, stove and cabinet on one wall, that is, the linoleum is jammed there. But I think that modern linoleums are not very susceptible to compression and stretching.

05/29/2006 at 10:27

A small area - you don’t have to glue it, but if you have a powerful vacuum cleaner, it will be a little annoying that the linoleum gets sucked in and moves away from the floor.

If I'm not mistaken, there are adhesives that do not stick dead - that is, they will not damage the floor when you remove the linoleum.

05/29/2006 at 22:43

It’s better to glue it, I just have cheap linoleum (sinteros) thrown on half of my apartment (without glue), and when reflected in the light you can see that it’s full of waves and swellings. My backing is MDF, so there are no flaws. This summer I’ll buy a new one (already finished) and I’ll definitely glue it on

05/29/2006 at 23:32

Well, we’re not talking about the cheapest linoleum. And probably not the subtlest.

05/30/2006 at 17:29

In theory, it's better to glue it. Because linoleum that is not glued can crawl on the floor, for example, when trying to move furniture. Also if the base is uneven, too. It’s easier to make un-glued linoleum into a bubble. and then you look and tear something good. On the other side. Linoleum does not last forever and will have to be replaced someday. And you will hate to change the glued one. And the furniture can be carefully lifted and moved without touching the linoleum. And the floor can be flat. So. as always in life: if you don’t stick it, if you do it right, if you stick it, well done too

05/31/2006 at 22:26

We glued linoleum for 5 years. Afterwards we started gluing only the joints of the two halves. and at the threshold. The vacuum cleaner is attracted to the account. did not notice. Bubbles form precisely on glued linoleums. or poor foundation under linoleum. Lately there has been no glue and there have been no complaints from clients.

06/01/2006 at 13:29

I have it glued. Kitchen 14 sqm and hall 15 sqm. Both here and there are solid pieces. Tarkett Discovery Kyoto 2. I won’t mention any pros, because... they are taken for granted and not gluing the linoleum is not a fact that everything would have been much worse. But I will note a MINUS. The floor is a screed and small irregularities that were not noticeable at the subfloor stage became clear after the stickers were applied. To one degree or another, the linoleum is glossy, and from here all the bumps and depressions are visible. So if the screed is not perfect, then I would not glue it.

06/10/2006 at 21:25

I decided not to glue it, after a year it swelled in those places: where the child was rolling on a chair near the desk (chair on wheels); where the sofa (on wheels) was falling apart. I thought that I had ruined the linoleum, but I glued nothing, the swelling disappeared. I smeared the floor completely.

08/21/2006 at 01:37

lel wrote: I decided not to glue it, after a year it swelled in those places: where the child was rolling on a chair near the desk (chair on wheels); where the sofa (on wheels) was falling apart. I thought that I had ruined the linoleum, but I glued nothing, the swelling disappeared. I smeared the floor fully.

a chair on wheels will destroy any covering.

08/21/2006 at 02:56

Vas12 wrote: I read all sorts of articles on linoleum - my head was swollen, but I still didn’t understand. Some say - you can just lay it down, you just need to stick it a little from the edges with 2-sided tape, others - definitely glue it over the entire surface, and still others - glue it with two stripes crosswise.

The glue is applied in a uniform layer, and then, depending on the linoleum, glue and requirements, a special notched trowel is selected (as for tile adhesive, but only the shape of the depressions is different, smaller, more frequent), which is leveled over the surface. What to apply to also depends on the properties of the coating (porosity, etc.), i.e. sometimes it is enough only for the base, only for the linoleum. At least this is what is written in the instructions of manufacturers of adhesives for floor coverings such as FORBO, HENKEL, MAPEI, ARDEX. It's better to trust, i.e. read the instructions for the selected glue

Vas12 wrote: I would like to glue it, to be honest, I wouldn’t want to - the floor is made of gypsum fiber board, if you tear it off later, the surface will most likely be ruined. Tarkett semi-commercial linoleum produced in Russia, there will be no joints, the area is small.

Why tear off linoleum if it is of high quality, harmonizes with the interior, does not irritate and is installed with high quality?? If the GVL is proven, then you can level it with a thin layer of self-leveling mixture, the edges can be used on deformable bases

Types of coating

Based on the material used, there are two types of coating: artificial and natural. The first is made from natural ingredients. Recognized as safe for health, there is practically no smell. Among the additional advantages it is worth highlighting: high wear resistance, ease of maintenance, fire resistance. Disadvantages - low plasticity (causes inconvenience during transportation).

The second type contains rubber, alkyd resin and polyvinyl chloride. Sometimes the product has some unpleasant odor, but due to its plasticity it can be transported well.

Types of material according to wear resistance:

- household (the most common and cheapest);

- technical;

- specialized (thicker layer);

- semi-commercial.

The structure is also different:

- Homogeneous. It is distinguished by the integrity (homogeneity) of the material.

- Heterogeneous. Has several layers (2-4). There is a protective layer, a main layer, an insulating layer and a backing layer.

Base difference:

- Lack of foundation. The canvas is quite thin and requires a high quality subfloor.

- Foam base. Linoleum is elastic and can be glued in rooms with high humidity. The total layer thickness is 3 mm.

- Fabric base. Contains a felt (most often) backing, the outer layer is made of PVC. The positive thing is that this material has the properties of insulating heat. Layer thickness - 5 mm.

Now, we should answer the questions - how to glue linoleum? What compositions should I use?