In various articles on our website, two types of sheet material are constantly mentioned: plasterboard (gypsum board) and gypsum fiber sheets (GVL). Feedback from portal visitors showed that not all home craftsmen know the difference between them, and, therefore, do not always choose the right building material for a specific situation.

Therefore, let’s pay closer attention to the topic and consider which is better - gypsum fiber board or drywall when finishing walls, lining the ceiling and leveling the floor. To do this, we will consider the characteristics of the materials, their advantages and disadvantages, which will allow us to understand the difference between gypsum boards and gypsum fiber boards and determine whose set of qualities is best suited under the current operating conditions.

What is drywall (gypsum plasterboard)

Drywall (the word is derived from the term plasterboard sheet) is a building material of varying sizes and thicknesses made from a hardened layer of gypsum dough (core), covered on both sides with cardboard (construction paper). The second name is dry gypsum plaster (in English-speaking countries - drywall).

The material was first obtained in the USA in the second half of the 19th century. It acquired its modern appearance in the 20th century. And again the author of the invention was the American Utsman.

Compound

GKL contains only natural ingredients:

- gypsum (core) - 93%;

- paper (cardboard lining) - 6%;

- water, starch (in gypsum) and sheet coating - 1%.

Attention: the amount of water indicated is in a dry state. During operation, the indicator can change significantly due to the hygroscopicity of gypsum plasterboard.

Kinds

According to established habit, gypsum board is divided into 3 types:

- classic (standard). Denoted by the abbreviation GKL. Cardboard color is gray. The marking is blue. Used for finishing work in rooms with normal operating conditions;

- moisture resistant (GKLV). Resistance to moisture is acquired after impregnation of the gypsum mixture (before molding) with a special waterproofing compound, as a result of which the gypsum absorbs water 10 times less, while quickly releasing it. Recently, antifungal additives have been added to the impregnation. The leaves are green with blue markings. Used in damp areas;

- fireproof (GKLO). The addition of fire retardants, and from leading manufacturers of crystallized water, gives the material high heat resistance - such sheets can resist open fire for up to an hour. The color is pink, the inscription is bright red.

There is another type that is not talked about much: moisture-resistant drywall with increased fire resistance (GKLVO) . It is a combination of moisture-resistant and fire-resistant material. It turns green. The marking is red.

For information: since 2015, the name of plasterboard in construction documentation has been changed to “gypsum building boards” (GSP).

Shapes and sizes

On sale you can find sheets of the following sizes:

- thickness - 8.0; 9.5; 12.5; 14.0; 16.0 mm. The most popular are 9.5 and 12.5 mm;

- width - 120 and 60 cm (rarely 90 cm);

- length - 2.0; 2.5; 3.0; 3.5 and 4.0 m. Sheets with a length of 2.5 and 3 m are in greatest demand, which is mainly due to the height of the ceilings in the house (apartment).

The shape is rectangular sheets. Differences on the side edge. She may be:

- straight - indicated in the marking by a combination of letters PC;

- thinned (UK);

- semicircular (PLC);

- semicircular thinned (PLUK);

- rounded (ZK).

Types of edges.

Purpose

Drywall is used to level walls and ceilings and construct various partitions. You can stick wallpaper and tiles on it, apply decorative plaster, liquid wallpaper. In addition, the surface can be painted with almost all types of paint.

Manufacturers

The best quality gypsum board of the following brands:

- "KNAUF";

- “Saint-Gobain” is a trademark of the Gyproc concern;

- "Lafarge";

- "Volma";

- "BelGips".

GKL and GVL: distinctive features of the material

The material, manufactured under a well-known trademark, traditionally has high performance characteristics. If there is a certificate of conformity, the Knauf gypsum board will have better technical characteristics and a longer service life than its analogues offered by other manufacturers. We invite you to get acquainted with the distinctive features of the material offered by well-known manufacturers.

A certificate of conformity is a must!

Characteristics and dimensions of gypsum boards and gypsum boards "Knauf"

The dimensions of Knauf gypsum board sheets are one of the important characteristics. Manufacturers offer material in standard widths of 1.2 m and lengths of 2, 2.5, 2.7 and 3 m.

Knauf gypsum fiber is relevant when installing interior partitions, installing suspended ceiling structures, wall cladding or floor screeding. Manufacturers offer sheets with straight and folded edges.

When choosing a material for finishing a room with a high level of humidity, you should give preference to moisture-resistant gypsum fiber board. For Knauf flooring, superfloor 1200x600x20mm will be the best choice. Sheets of this size are convenient to attach when performing installation work alone. If you have an assistant, you can safely purchase material measuring 1.2 by 2, 2.5 or 3 m.

Sheet dimensions are in the designation

GKL "Knauf" with special characteristics

In addition to the material with standard characteristics characteristic of drywall, most offer to purchase gypsum plasterboard with special properties. Such sheets can be used for finishing rooms operated in special conditions due to their high performance characteristics.

The acoustic gypsum board "Knauf" is characterized by the following properties:

- The ability to improve the perception of sounds;

- Reduced boominess;

- Reducing background noise levels.

It is used to decorate cinemas, classrooms, recording studios, and conference rooms. They also resort to its help when decorating residential premises located near a busy highway or an apartment building.

Acoustic drywall will create comfortable conditions

The moisture-resistant gypsum board "Knauf" also has fairly high performance characteristics. It is in demand when decorating premises exposed to high humidity: kitchens, bathrooms and toilets.

What is GVL (gypsum fiber sheets)

Gypsum fiber sheets (GVL) are a mixture of building gypsum, fluffed waste paper (cellulose fibers firmly bind the set gypsum in all directions, giving the material high strength and viscosity) and technological additives. The mass is filled with water, stirred, pressed into sheets, and dried.

GVL with an unusual edge.

Compound

The gypsum fiber sheet has a uniform structure, without a cardboard shell. Consists of:

- from gypsum - 80-85%;

- cellulose - 10-15% (most materials indicate 20%, but this is not so);

- special additives (they are also called technological additives) - 5%.

Kinds

Like drywall, gypsum board has 4 types:

- simple (GVL). Used in rooms with moderate humidity and slight temperature changes;

- moisture resistant (GVLV) - thanks to hydrophobic additives, it practically does not absorb water. Recommended by manufacturers for use in wet areas (bathroom, shower, kitchen);

- fire-resistant (GVLO). The material itself does not burn. But in some cases, increased fire-resistant qualities are needed, for example, for lining air ducts, communication shafts, wooden walls when working in a room with an open fire, etc.;

- moisture- and fire-resistant (GVLVO) types are produced for saunas, baths, i.e. for those rooms where there are extreme operating conditions.

It is impossible to determine the type by color - all the sheets are gray. Markings on the back of the plate will help.

GVL marking.

In addition, GVL can be:

- polished (in the marking it is indicated by the letter “Ш”) - the operation is performed for painting;

- unsanded (NS) - for wallpaper, tiles, dry floor screed, etc.

Shapes and sizes

According to GOST, gypsum fiber sheets can be of the following sizes:

- thickness - 10.0; 12.5; 15.0; 18.0; 20.0 mm;

- width - 50.0; 100.0; 120.0 cm;

- length - 1.5; 2.0; 2.7; 3.0 m.

For the population, a sheet of 10 x 1500 x 1200 mm is considered standard.

Please note: products are available in other sizes. For example, floor slabs 120 x 120 x 2 cm. Before purchasing, you need to look at the markings or ask the seller. The edge can be straight (PC) and folded (FC). If necessary (for reinforcing tape), you can thin the edge of the sheet yourself using a carpenter's plane.

Types of edges.

Purpose

Gypsum fiber sheets have a wider range of applications compared to gypsum boards, both in terms of types of buildings and structural elements. GVL is used in residential and non-residential premises, balconies and loggias, baths and saunas for leveling (cladding) walls, installing partitions, lining the ceiling, as a base floor for tiles, linoleum, laminate, parquet and parquet boards.

In addition, the material is widely used in industrial construction.

You can finish gypsum fiber board on the walls using:

- wallpaper - paper, vinyl and textile hold up well. Glue only based on methylcellulose. Problems arise with non-woven trellises;

- paints. Here, firstly, you need polished slabs (putty is expensive and labor-intensive due to several layers), secondly, you cannot paint with silicate-based paints;

- decorative plaster - gypsum solutions with additives from artificial resins are allowed;

- ceramic tiles.

Important: the surface needs to be primed before finishing.

Manufacturers

Main brands of GVL manufacturers:

- “Knauf” - about 70% of the market in Russia and the CIS countries belongs to this product, “Nida Gips”, “Rigips” - another 10% for three;

- "Volma";

- "BelGips";

- "GIFAS" and others.

Types of gypsum fiber sheets by type of edge

In addition to differences in the level of moisture resistance, gypsum fiber sheets differ in the shape of the longitudinal edge. There are two varieties:

- Straight edge(PC). Slabs with this type of edge are used primarily for prefabricated dry floor screed.

- Folded edge (FC). It is used when installing partitions, piers, and leveling walls.

The transverse edge of GVL is always straight.

Advantages and disadvantages

The choice is always easier if you know the strengths and weaknesses of competing materials. This allows you to avoid unpleasant surprises, both during operation and during operation.

GKL

Many years of experience in using gypsum board have formed a complete list of the advantages of the material, where nothing is superfluous, nothing is missing:

- affordable price for mass buyers. This plus is one of the most important for families on a limited budget. At the same time, the quality of work and durability do not suffer;

- low thermal conductivity coefficient - 0.30-0.34 W/ (m×K). According to this indicator, the material is comparable to wood. In combination with insulation, an excellent thermal insulation layer is obtained;

- Easy to install: no experience required. The main thing is to know the principles of working with the material, which can be easily found on the World Wide Web;

- flexibility. Many will be surprised. After all, the material easily crumbles upon impacts or strong bends. On the one hand, this is true. On the other hand, with the help of gypsum plasterboard you can make any semicircular arches and complex installations (as evidenced by the photo below);

Methods for bending gypsum boards.

- fire resistance. The gypsum itself does not burn, but only melts at +1450°C. Only cardboard can burn. But after it is treated with fire retardants, it becomes difficult to burn (painted pink);

- moisture resistance. In fact, gypsum absorbs moisture very well. However, processing sheets with special compounds makes it possible to use the material in rooms with high humidity (kitchen, bathroom);

- high level of maintainability - dents, cracks, and through holes can be easily repaired. As a last resort, the damaged area is replaced;

- versatility. Can be mounted in any room (residential, non-residential) under any finish (wallpaper, paint, ceramic tiles);

- environmental cleanliness. The material contains no additives harmful to health;

- the ability to easily and simply hide communications. But the main thing here is not to overdo it and arrange inspection hatches at the points of connections or adjustments.

The list of advantages of drywall is impressive, but the disadvantages :

- fragility is the main problem of gypsum boards. Sheets may crack during handling (carry only vertically), transportation, or installation. Therefore, special care is needed when working with slabs;

- low strength under weight loads - you can’t hang anything heavy on gypsum plasterboard partitions. It is necessary to provide embedded OSB or plywood boards at the fastening points in advance. You can also use molly dowels. But their weight is limited - for a slab with a thickness of 12.5 mm, such a mount can withstand from 16 to 25 kg of load. This way you can hang a cornice and a TV, but there are no kitchen cabinets or shelves;

- low level of sound insulation, which is important for partitions - even a whisper is perfectly audible. Exit in mineral wool insulation (not polystyrene foam) between sheets of plasterboard.

Another drawback, although common to the materials being compared, is the reduction in space. This is especially noticeable in small rooms or apartments (houses) with low ceilings.

Important: some experts consider the impossibility of covering walls in dachas with gypsum sheets to be a disadvantage—in winter, due to the lack of heating, it will tear. It's hard to agree with this. Firstly, gypsum board is afraid not of frost, but of high humidity (frost tears away sheets that have accumulated moisture). Secondly, you can use moisture-resistant modifications of drywall (GKLV). Thirdly, indoor humidity is lower in winter than in summer. Therefore, after a wet autumn, you can dry the room well and close it for the winter.

GVL

GVL also has its advantages

- high strength allows you to hang heavy objects on vertical structures (a simple self-tapping screw holds up to 30 kg of load), and on the floor to use it as a base under linoleum, parquet, laminate or tiles;

- the presence of viscosity, firstly, allows you to cut the material without dust - it does not crumble, and secondly, you can tighten the fasteners without dowels - it will hold like in wood;

- low heat transfer coefficient, which allows the material to be used as insulation;

- good level of sound insulation - perfectly absorbs air and shock sound waves. This is confirmed by measurements: the noise level drops by 35-40 dB;

- fire resistance - does not burn, but only chars. Therefore it is used as protection for wooden structures;

- the moisture resistance of sheets treated with special compounds (GVLV) is the same as that of cement-sand mortar;

- high frost resistance makes it possible to use it in the country and in unheated rooms;

- hygroscopicity allows, like wood, to regulate the humidity in the room. When the amount of vaporous moisture increases, it is absorbed by the GVL, and when it decreases, it is easily released;

- can be used in a “warm floor” system, but only from below;

- the material is safe in all respects - when heated, it does not emit harmful substances and does not contain allergens;

- there are no restrictions on use: private houses, apartments, cottages, unheated rooms, horizontal and vertical surfaces;

- easy to install - the work can be performed by a home craftsman without the help of specialists;

- not subject to deformation (change in linear dimensions) under the influence of temperature and humidity fluctuations.

There are also disadvantages that you need to pay attention to:

- the price is prohibitive for some segments of the population;

- high specific gravity, as a result of which an assistant is needed during installation. Even though they are smaller in size than drywall, the sheets are much heavier;

- moisture-resistant gypsum fiber sheets can be affected by rot in places with constant high humidity;

- does not bend - can only be used on flat surfaces.

GKL: device types and sizes

GKL stands for plasterboard sheet - a material for dry construction and finishing of walls, ceilings, openings, it is distinguished by its hardness and smoothness of the surface, due to which it is popular in the field of construction modeling. With the help of sheets, the process of installing complex ceiling and partition configurations is simplified.

Drywall installation

GCR is a product consisting of sheets of thick cardboard (performing the function of a reinforcing frame), as well as gypsum, which contains various additives to improve properties. The materials are held together using construction adhesive. Gypsum is not durable, and therefore it is used in conjunction with a reinforcing frame made of cardboard. In addition, the interlayer allows the sheet to retain its shape, since cardboard itself is also not resistant to mechanical damage. There are gypsum boards with a straight end and a tapering section. The last option is recommended for use where it is important to get the most even joints.

Types of drywall edges:

- PC (straight edge) for cladding consisting of several layers;

- UK (thinned edge) is suitable if pasting with reinforcing tape and subsequent putty is necessary;

- ZK (rounded edge) is applied using putty;

- PLC (semicircular edge on the front side) is used only with putty;

- PLUK (semicircular edge and thinned on the front side) is suitable for use with reinforcing tape and putty.

Types of gypsum board edges

| Drywall | Thickness | Drywall sheet size | Leaf area | Drywall sheet weight |

| GKL ceiling | 9.5 mm | 1.2 * 2.5 m | 3.00 sq.m | 22.1 kg |

| 1.2 * 2.5 m | 3.00 sq.m | 26.0 kg | ||

| 1.2 * 2.7 m | 3.24 sq.m | 28.1 kg | ||

| GKL standard | 12.5 mm | 1.2*3.0m | 3.6 sq.m | 31.2 kg |

| 1.2*3.3m | 3.96 sq.m | 34.3 kg | ||

| GKLV ceiling | 9.5 mm | 1.2 * 2.5 m | 3.00 sq.m | 23.3 kg |

| 1.2 * 2.5 m | 3.00 sq.m | 28.9 kg | ||

| GKLV moisture resistant | 12.5 mm | 1.2 * 2.7 m | 3.24 sq.m | 31.2 kg |

| 1.2*3.0m | 3.6 sq.m | 34.7 kg | ||

| GKLO fire-resistant | 12.5 mm | 1.2 * 2.5 m | 3.00 sq.m | 31.2 kg |

| GKL VO moisture-fire-resistant | 12.5 mm | 1.2 * 2.5 m | 3.00 sq.m | 25 kg |

| 1.2 * 2.5 m | 3.00 sq.m | 17.1 kg | ||

| GKL restoration | 6.5 mm | |||

| 1.2*3.0m | 3.6 sq.m | 20.5 kg |

Dimensions and weight of drywall

Drywall is also known as “gypsum board” and can only be heard in certain regions. This was facilitated by the frequent use of Gyproc brand products. As a result, the name “gyprock” became a common noun. Used for various types of plasterboard products.

INTERESTING: Slate: types of sizes, pros and cons

Features of different types of plasterboards

In addition to the above types with different edge thicknesses, there are other materials in this category. They differ in the direction of application, which is due to the difference between the types of additives. Main types:

- GKL is a standard sheet of plasterboard, characterized by a gray color, this feature allows you to determine the type of material by external features; this type of product is used for interior decoration;

- GKLV is a plasterboard sheet that is characterized by moisture resistance, which is due to additives in the gypsum composition; the material can be recognized among others by its light green tint; such products are used for finishing rooms with high levels of humidity;

- GKLO is a fire-resistant plasterboard sheet, recommended for use in facilities where the level of fire danger is increased, flammable finishing materials are used, this material is distinguished by a light pink tint. GKLO is capable of withstanding direct exposure to fire for at least 20 minutes.

Types of drywall

Separately, it should be noted the universal variety - GKLVO. The sheets simultaneously resist moisture and high temperatures. More recently, the popularity of another product has increased - GKLZ. This is a soundproofing material, recommended for use in facilities where it is important to reduce the noise level from the outside.

The main differences between products of this type:

- fiberglass reinforcement;

- high density gypsum core.

A common version of GKLZ is KNAUF sheet (GSP-DFH3IR). Other material properties:

- moisture resistance;

- strength;

- resistance to point mechanical loads - impacts.

GKLZ (soundproof plasterboard)

There are quite a lot of advantages of plasterboard. Having studied the properties given above, you can decide whether it is suitable for finishing under given conditions at a facility under construction or in a room where renovations are being carried out. The main disadvantage of sheets of this type is the small risk of releasing gypsum dust into the air.

Technical and operational characteristics

Based on gypsum, but produced using different technologies, gypsum boards and gypsum boards also have different characteristics. For convenience, all important indicators are summarized in Table 1.

Table 1. Main technical and operational characteristics of materials.

| Indicators / Materials | Drywall | Gypsum fiber sheets |

| Density, kg/m3 | 735-900 | no more than 1250 |

| Thermal conductivity coefficient, W/m*C | 0,30-0,36 | up to 0.36 |

| Swelling in thickness over 24 hours, % | 3 | 1.8 |

| Hardness, MPa | 5 | at least 20 |

| Impact strength, kJ/cm2 | 0,5-0,8 | 5 |

| Ability of 12.5 mm thick material to hold a load on one screw (vertical surface), kg | 7 | 40.8 |

| Dry bending strength, MPA | 2 | 5 |

| Flexural strength in wet condition, MPa | 0.01 | 0.3 |

| Compressive strength, MPa | to 10 | at least 10 |

| Flammability class | G1 (low-flammability) | NG (non-flammable) |

Note that during the work it was not possible to find data on the molly dowels screwed into the gypsum plasterboard. In drywall they hold weight up to 25 kg. Naturally, in a gypsum fiber sheet this figure is several times higher (where a simple self-tapping screw can withstand up to 40.8 kg).

How much does GVL cost: overview of the main sizes and types

The price of gypsum fiber boards for flooring primarily depends on the type and size of products, which can be different. The German company, founded in the middle of the last century, has been considered the leader on the market for many years. It was she who first began producing gypsum-based building materials.

The most popular when designing floor coverings are moisture-resistant gypsum fiber boards for Knauf-superfloor floors, which are characterized by increased thickness and improved strength characteristics. The average cost of gypsum plasterboard for flooring is 250-350 rubles.

On average, one sheet of gypsum fiber board for the floor can be purchased for 250-350 rubles.

The most common and most popular slabs are the following sizes:

- GVL for floors, moisture-resistant 1200x600x10mm - price 180 rubles;

- GVLV PC 2500x1200x12.5 mm – 590 rub.;

- GVLV FC 2500x1200x12.5 mm – 610 rub.;

- GVLV FC 2500x1200x10 mm – 520 rub.;

- GVL for floors, moisture-resistant 1200x600x20mm Knauf-superfloor - 275-325 rubles;

- fireproof gypsum board Fireboard Knauf 2500x1200x12.5 mm – 2290 rub.

Of course, besides, there are other manufacturers. For example, it is considered one of the most popular in the world and also produces gypsum-based products, but its product range includes only plasterboard. Thus, a slab from this manufacturer with a size of 2500x1200x12.5 costs exactly 2 times cheaper than moisture-resistant gypsum fiber boards for floors 1200x600x20mm from Knauf, because the price, depending on the type of material, is 210-310 rubles. It should be remembered that using gypsum plaster boards for the base is strictly not recommended.

What is the main difference

Despite the gypsum base, the materials have many differences:

- drywall is a three-layer sandwich made of paper and gypsum, GVL is a single piece of hardened gypsum mortar;

- The strength of gypsum fiber is many times higher. You can hang kitchen cabinets on it, which is excluded with gypsum board;

- GVL is less natural - it contains magnesium oxide and magnesium chloride. But these components of the composition are harmless;

- drywall has a much smaller scope of application;

- When cut with a knife, gypsum plasterboard crumbles and becomes dusty when working with a grinder; gypsum board is cut without residue;

- breaks differently when cut: drywall down, gypsum fiber upward. A small thing, but important. If you don’t follow the technology, you won’t get smooth edges;

- It is difficult to work alone with GVL due to its heavy weight. Need an assistant;

- The drywall is puttied before wallpapering. For GVL, such an operation is unnecessary. Here only the joints and heads of hardware are sealed;

- gypsum fiber sheets are more difficult to bend. Therefore, they are difficult to use for curved surfaces;

- Heavy gypsum fiber boards must be mounted on a more durable sheathing. Therefore, it is necessary to use a metal profile with a thickness of at least 0.5 mm.

Areas of application of the material and installation features

Due to its versatility, the material is used to create walls and partitions. To do this, build a frame of wooden blocks or an aluminum profile, on top of which the material is attached. Inside such partitions, you can additionally install sound and heat insulation if the standard characteristics of gypsum fiber are not enough for you. In addition, wiring and communications can be laid in the cavities.

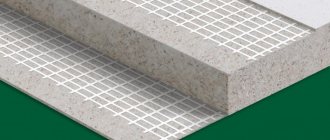

Gypsum fiber sheets are often used as subflooring

Due to their fire-resistant properties, gypsum fiber board sheets are used in premises that have special fire safety requirements. These can be boiler rooms, electrical panels, elevator shafts and corridors. The material is used for arranging emergency exits and fire escapes. GVL sheets are suitable for covering wooden surfaces to protect them from fire.

All these qualities also make it possible to use GVL as a rough covering for floors, and to use the material as an element of a dry screed. This method is especially relevant when it is necessary to arrange floors in the shortest possible time, since there is no need to wait for drying, as happens with the concrete version of leveling the floor. In addition, such coatings have less weight compared to wet screeds, and this can be extremely important when installing floors on weak floors or wooden joists on the second floors of a private household. The only thing that is recommended is to use a moisture-resistant version of gypsum fiber boards.

As you can see, the areas of application of gypsum fiber are extremely diverse, but in order for the material to last as long as possible, it is necessary to take into account some of the nuances of its installation. Gypsum fiber boards can be attached in two ways: framed and frameless. In the first case, special self-tapping screws are used that are able to pass through the thickness of the material, since those intended for drywall will not work. When attaching gypsum fiber board to glue, a special reinforced composition is used, which is able to withstand significant weight of the material.

When laying gypsum fiber board on the floor, it is necessary to lay the flooring in two layers, with the second being laid across the direction of the first so that the seams of the two slabs do not coincide, i.e. with offset. When laying the material, it is important to leave gaps between the plates, the thickness of which is equal to half the thickness of the sheet. It is important to know that, unlike plasterboard, the chamfer is not removed from the slab, and the seams are reinforced and sealed with putty specially designed for gypsum fiber. You can also lay gypsum fiber board on a wooden floor to level the base for laying a new floor covering, such as linoleum, laminate, parquet boards.

Comparison of characteristics

Having only the strengths and weaknesses of materials at hand, it is impossible to make a clear choice. We need a comparative analysis of the main indicators. Experts include the following selection criteria:

- price;

- density;

- strength;

- ease of installation;

- thermal insulation properties;

- sound insulation level;

- flexibility;

- environmental friendliness;

- sheet weight.

Price. The most important factor when choosing any building material is its cost. Here, drywall has an undoubted advantage. Its sheets are approximately 2-5 times cheaper than its competitor. So, 1 m2 of gypsum board (standard options are compared) can be bought from 70 rubles. and higher. And for a sheet of gypsum fiber of the same area you will have to pay from 180 to 360 rubles. per m2 (depending on the type of edge and surface of the material: polished or not).

The truth needs to be clarified: moisture- and fire-resistant options are close in cost to the standard gypsum plasterboard version, and in some cases gypsum plasterboard is even more expensive. But we emphasize this again when compared with simple, without additives, gypsum fiber boards. For improved gypsum fiber board options you will have to pay around 750-910 rubles/m2.

Conclusion: GVL is purchased either with unlimited funds for repair work, or if necessary, for example, for lifting or leveling the base of the floor, where gypsum board is not used.

Density. The density indicator affects the weight of the sheet and the ability to hold fasteners: nails, screws, self-tapping dowels. It is difficult to give unambiguous assessments based on this criterion. After all, the greater specific gravity of gypsum plasterboard (see Table 1) is an undeniable plus when leveling walls in the kitchen: you can hang kitchen cabinet drawers on self-tapping screws without any problems. In other rooms there is a minus: it is difficult to work. It is difficult to cut and lift - you need a helper.

Conclusion: using the given criterion, it is impossible to unambiguously determine what is better for walls - gypsum plasterboard or gypsum fiber board. It is necessary to evaluate the material in specific relation to the place where the work is performed. The same situation occurs on the ceiling. But for the floor, the high density of gypsum fiber boards is an undeniable advantage.

Strength. A layer of gypsum of the same thickness in gypsum plasterboard is fragile, breaks easily, does not withstand dynamic (shock) loads - holes appear. It is reinforced only by a cardboard shell.

GVL penetrated with cellulose fibers can withstand high static and dynamic loads. The difference is clearly manifested in the sealing of corners: gypsum board requires plaster corners, but gypsum board does not, and when leveling the floor - gypsum board is one of the best options, and gypsum board is not considered at all for such work.

The ability of gypsum fiber to withstand heavy loads has found application in industrial construction, where the walls of workshops are finished with this material.

Conclusion: according to the criterion: which is stronger, gypsum boards reinforced with cellulose fibers have absolute superiority.

Ease of installation. Practice has shown that when choosing a type of dry plaster, the consumer first of all evaluates the cost of the material and, oddly enough, its manufacturability. According to this indicator, at first glance, drywall is beyond competition. His:

- easier to cut;

- easier to carry;

- It’s more convenient to attach to the sheathing: firstly, special screws are not needed, and secondly, the hardware is screwed in without much effort.

However, there is another side to the problem. When using gypsum fiber:

- the surface does not need to be puttied before wallpapering;

- when passing internal and external corners, painting corners are not required;

- before painting, unsanded sheets are puttied - sanded sheets are only primed;

- When sealing joints, reinforcing tape is not needed, therefore, sheets with straight edges can be used. Falset edges are needed when leveling the floor.

Conclusion: in terms of manufacturability, the materials are approximately equal.

Thermal insulation properties. Both materials consist of gypsum. Therefore, the heat conductivity indicators are approximately the same: the coefficient value is slightly higher for GVL due to its higher density, but in practice this is not noticeable.

Conclusion: both materials are good insulators. That is why experienced specialists do not recommend laying gypsum fiber boards on top of a “warm floor”.

Soundproofing. Due to different densities and compositions of components, the compared materials have different noise insulation performance. So, when installing partitions from gypsum plasterboard, it is imperative to lay mineral wool between the walls. Otherwise, almost any noise from the adjacent room will be heard. And gypsum fiber board will perfectly dampen sound waves even without a soundproofing layer.

Conclusion: GVL has an advantage in terms of noise insulation characteristics.

Flexibility. A wet plasterboard sheet becomes flexible. Using a certain technology, it can be used to form semicircular arches, curved two-tier ceilings, and other shaped structures for finishing walls and ceilings.

Gypsum fiber board has a high level of rigidity. It is impossible to bend it without breaking it, and it is impossible to get it wet - the structure of the material does not allow obtaining a plastic mass in a wet state. Therefore, GVL is used for flat surfaces.

Conclusion: gypsum board has flexibility, but gypsum board completely lacks it.

Ecological cleanliness. The materials are absolutely equal in terms of environmental friendliness: both do not contain harmful substances or allergens.

Weight. The heavier weight of GVL makes the work of home craftsmen more difficult - an assistant is needed. If it is not there, then there is a high risk of breaking the sheet during installation. Some experts find a solution by cutting the gypsum fiber board in half, which, in the opinion of the site’s editors, is not a rational solution - the technological process becomes much more complicated.

Conclusion: when finishing the premises, it is necessary to take into account the forces with which the repairs will be carried out. If alone, then many difficulties are expected with GVL.

General conclusion: if we consider the results of the comparison based on the overall assessment, then gypsum fiber boards have an advantage. However, two main criteria: price and complexity of the technology, despite the fact that drywall requires many additional operations: sealing seams, puttying, priming, gypsum board wins. Therefore, from a practical point of view, GVL can be used if there are high incomes. It makes no sense for people with average incomes to overpay where a simple gypsum board will perfectly perform its functions.

What distinguishes gypsum fiber from drywall

We examined the main advantages, disadvantages and characteristics of gypsum fiber sheets. At first glance, it may seem that the material is practically no different from its “younger brother” - drywall. Therefore, we give a comparative description of gypsum-containing products in order to understand whether it is worth overpaying for gypsum plasterboard, or you can easily get by with cheaper plasterboard.

Since GVL has excellent shock resistance and can withstand heavy loads, it is advisable to use it exactly where high wear resistance is required (gyms, industrial premises). Otherwise, you can easily get by with standard wall plasterboard. But if you need to create complex shapes, then preference should be given to gypsum fiber. The material is perfectly cut, maintaining an even cut, unlike plasterboard, which crumbles easily and is mainly used in solid sheets.

To create curved structures, it is recommended to take sheets of drywall. For this purpose, even a special version of gypsum board is produced - arched, which has a smaller thickness compared to a standard sheet. The drywall is pierced to make it easier for the plaster to absorb water, and then bent to the required radius. After this, it is fixed and left to dry. After drying, it does not lose the shape it was given and does not crack. In this regard, gypsum fiber is much inferior to plasterboard, since it has poor bending characteristics, so when trying to give it a semicircular shape, it easily breaks.

GVL sheets are excellent for arranging partitions or leveling walls in unheated rooms, which cannot be said about plasterboard products. According to manufacturers, gypsum fiber board can withstand up to 15 cycles of freezing and thawing, while gypsum board can withstand a maximum of 4. In addition, gypsum fiber is fire-resistant, although fire-resistant plasterboard is also produced. It has a pink shell and is impregnated with a special composition. Unfortunately, it can only withstand a direct flame attack for a while, since it contains a paper shell.

When constructing partitions in unheated rooms, gypsum fiber board is better than plasterboard

Gypsum fiber sheets with a straight edge are often used for dry screed construction because they have decent compressive properties. They are not even afraid of women's heels, and this says a lot. The same cannot be said about drywall, so under no circumstances should it be used for these needs. As you can see, each of the materials has its own advantages, therefore, when choosing a finish, you should focus on the above indicators, then you can not only make the right design, but also save money, because the cost of gypsum board is almost twice the price of plasterboard sheets of similar parameters.

What and in what case is it better to choose

Based on the comparative analysis, specific recommendations can be made for different building elements in each room.

Floor. GVL is used to level or raise the floor level. Usually these are sheets 10 mm thick, laid in two layers or 20 mm slabs from Knauf. Drywall has nothing to do with the floor.

Walls. There is no clear advice: GVL or plasterboard for walls. It all depends on the operating conditions. So, in the kitchen, where wall cabinets are usually attached, it is advisable to use gypsum fiber sheets - they will withstand the weight of the attachments. At the same time, you can also use gypsum boards by first securing an OSB strip to the wall for fasteners. Based on a combination of factors, GVL in the kitchen is preferable.

For a bathroom, with its high humidity, you need either moisture-resistant gypsum board or gypsum fiber. Here the owners have a choice: if they have money, they buy GVL. Budget is limited - drywall. Arches in walls can only be made from plasterboard sheets.

Ceiling. Both types of materials are also suitable for the ceiling. But for a designer ceiling with many curves, you need gypsum board. As an option, gypsum plasterboard can be attached to linear surfaces; curved inserts can be made from plasterboard. With noisy neighbors above, gypsum fiber will help reduce the noise level, but you need to take into account the high cost of work and the complexity of installing gypsum fiber boards. The sheet cannot be secured without clamps.

Bath, sauna. For rooms with sudden changes in temperature and humidity, such as are observed in baths and saunas, there is no alternative to GVL.

Country house. Many experts do not recommend using drywall in unheated rooms. In such situations, gypsum fiber sheets will help.

Balcony, loggia. On a glazed but unheated balcony (loggia), it is still better to mount GVL on the walls and ceiling, although moisture-resistant cardboard will do the job well.

Gypsum fiber sheet size

In general, the size of gypsum board is similar to drywall, but has fewer options. The most common sheet size is 1200x2500 mm. Gypsum fiber is also produced in the form of a slab measuring 1500x1000 mm. Thickness comes in 10 mm and 12 mm.

There is a thicker sheet (20 mm) created on the basis of GVLV, called a floor element (EF).

To understand the secret of the popularity of this finishing material, it is necessary to consider all the characteristics of gypsum fiber board. And one of the most important is fire-technical. According to them, a sheet of gypsum fiber does not ignite for a long time, burns poorly and, when burned, emits little smoke with a minimal content of toxic substances.

GVL or gypsum board: which is better?

Both materials have admirers and opponents. You will have to decide on your own which is better GVL or gypsum board. In this section we will try to compare them according to the most significant parameters. Let's go over the sizes right away. Drywall is produced in a wider range of both sheet sizes and thickness:

- GKL sheet thickness: 6.5 mm, 8 mm, 10 mm, 12.5 mm, 14 mm, 16 mm, 18 mm, 24 mm. The last three are very rare.

- The height of the gypsum board sheet can be from 2000 mm to 4000 mm in increments of 50 mm.

- The width of the gypsum board is 600 mm or 1200 mm.

As you can see, the range is more than wide. Another thing is that there are usually two or three types on sale. But, if you really want to, everything can be found/ordered. Although, it is usually easier (and cheaper) to buy what is available.

GVL is better for the floor

We had less luck with the size of the GVL. We have only two options for gypsum fiber boards: 2500*1200 mm (standard) and 1500*1000 mm (small format). Both options are available in 10mm and 12.5mm thicknesses. All. There are no other standard sizes. There is also GVL for the floor. Its dimensions are 1200*600 mm, thickness 20 mm. It may be chamfered or not.

| GKL | GVL | |

| Cost per square | from 70 rub/sq.m. | from 180 rub/sq. m. |

| Shock loads | crumbles | tolerates it well |

| Bending loads | tolerates well, bends | breaks down |

| Uncover | easy to cut with a utility knife | you need a serious tool with a special disk |

| Installation of fasteners | special screws are easy to tighten | difficult to twist, you need to pre-drill holes or use self-tapping screws |

| Changes in size with increasing humidity/temperature | 1 mm per meter | 0.3 mm per 1 meter |

| Fire resistance | high - G1 | non-flammable - NG |

| Installation on curved surfaces | available | No |

As a result, it is possible to say that gypsum fiber board or gypsum board is better only based specifically on the area of application and operating conditions. In short, here's how you can divide the areas of application:

- GVL for walls and ceilings is better if fire resistance is required or if it is necessary to increase the rigidity of the structure (in frames).

- It is better to put GVL on the floor, since it reacts less to humidity and does not change its properties.

- GCR is indispensable if you need smooth lines or complex multi-tiered structures. A multi-level ceiling, arches, columns, rounded walls and corners are just drywall.

- If you need to achieve good sound insulation of the second floor, it is better to hem the ceiling with gypsum fiber board.

As you understand, there is no way to definitively say which is better than GVL or gypsum board. In some conditions, one material is better for performing one task, while the characteristics of another are more suitable for another.

Application

The technical characteristics of GVL allow their use in a wide range of construction and finishing works. The most common application is cladding walls, ceilings, door and window openings, both for the purpose of leveling and hiding communications, and for fire protection.

Gypsum fiber sheets can also be used to create internal partitions, since their increased strength allows them to support the weight of doors and other hanging elements. GVL can also be used as a substrate for flooring for reinforced concrete and wooden floors, although in this case it is better to prefer moisture-resistant sheets. Any material can be laid on top: linoleum, laminate, parquet, tile. The use of GVL significantly speeds up flooring compared to “wet” methods, because there is no need to wait for complete drying for several weeks, and compared to OSB, which is often used for the same purposes, GVL does not contain harmful resins and formaldehydes.

What are gypsum fiber sheets: key characteristics

In appearance, gypsum fiber sheets are very similar to plasterboard, but their production technology is completely different. In both cases, gypsum is used for manufacturing, but if cardboard is used for gypsum board, then the key component in gypsum board is cellulose fiber, which is obtained by processing waste paper. In addition, gypsum plasterboard sheets are homogeneous, while drywall consists of several separate layers.

To produce GVL, cellulose fiber and gypsum are used. Please note! When choosing between gypsum plasterboard or plasterboard, you need to take into account that gypsum plasterboard is not used for flooring due to its fragility and insufficient strength.

The production of gypsum fiber (gypsum fiber) boards is regulated by the requirements of GOST R 51829-2001, so the use of the material is clearly regulated. According to the standards, panels can be used in private, public and industrial premises, including children's institutions. In addition to flooring, the sheets are suitable for cladding walls and ceilings. The material is perfect for pre-finishing, thus eliminating the need for plaster, putty and the use of liquid screed.

The composition of the sheets, in addition to gypsum and loose cellulose fiber, also includes latex, which not only gives the material strength, but also gives the panels moisture-resistant qualities. During production, all components are mixed together, after which the finished mixture is gradually diluted with water. The resulting dough-like mass is then fed to the press, where the finished slabs are formed. After pressing, the panels are dried. Some then go through a sanding process, while others remain as is.

Drywall: price per sheet, sizes, types of material (read more)

As a rule, treated slabs are more expensive and are used mainly for finishing floors and walls. GVL floor panels are not sanded, because a finishing coating is then laid on top of them - this can be tiles, laminate, parquet or even linoleum and carpet. The sheets can be mounted on joists or on a subfloor, on which all cracks and cracks are previously sealed. They can also be used in the case of a floating floor, as a material for dry screed, which does not require a long time to dry. Moreover, the material is considered suitable even for surfaces on which it is planned to subsequently exert significant loads.

GVL sheets are used not only for floors, but also for cladding ceilings and walls.

For the purpose of additional leveling, it is permissible to attach gypsum fiber boards to a wooden floor, concrete or cement base

It is important that the sheets not only level the surfaces, but also allow you to soundproof and insulate the floor. At the same time, the material has “breathable” properties, which allows it to let air through.

This quality helps to establish the microclimate in the room. A GVL floor is capable of absorbing excess moisture that is released from the environment.

The cost of gypsum plasterboard and its disadvantages

The big advantage over other building materials is that it is inexpensive. Minimum price for 1 sq. m is from 100 rubles. It all depends on the type of plasterboard sheet. If it contains various additives, it will cost much more. The biggest disadvantage is that it is not able to withstand heavy loads, so it should not be used in the construction of load-bearing walls. In addition, many types of gypsum plasterboard are not capable of retaining moisture, so the material is selected individually for each room

This is very important, because otherwise you can simply waste your money. The disadvantage is that drywall is not recommended for use in the construction of load-bearing surfaces, since it is not so durable

https://youtube.com/watch?v=tCsAQtdvTsg

Thus, we can conclude that. that this material is very valuable and is widely used in construction and finishing works. In addition to it, there are other materials, for example, gypsum fiber (GVL). Many will wonder what is better to use: gypsum board or gypsum board. The answer is not simple. Let's take a closer look at what a gypsum fiber sheet is.

Main characteristics of moisture-resistant gypsum fiber sheet (gvlv)

The very concept of “plasterboard” is quite broad, since it includes several types of this material. They differ significantly in operating conditions, and, accordingly, in their composition. In addition, there is such a thing as a “fiber supersheet”. Such material has a number of advantages compared to gypsum board and, according to the Knauf classification, is divided into:

- superlist (gvl),

- moisture-resistant supersheet (gvlv),

- small format supersheet.

Each of the above options is characterized by increased mechanical strength, excellent sound insulation, fire resistance and has a special fibrous structure. The latter property allows you to carefully cut drywall and process edges without much effort.

Technical characteristics of gvl (gvlv)

Gypsum plasterboard supersheet has special properties that allow it to be used not only for covering walls, ceilings, but also for floors! Thanks to a high-quality mixture of fiber and gypsum, as well as a special anti-chalking impregnation, supersheet can be used in buildings and premises for any purpose. The only fundamental difference in the use of gypsum board and moisture-resistant gypsum board is the possibility of installing the latter in places with high humidity. All main parameters of the sheets are given in Table 1.

Table 1. Characteristics of gvl supersheet (gvlv)

The moisture-resistant material differs from standard gypsum plasterboard in that its surface on both sides is treated with a special water-repellent agent. This allows it to be used in rooms with any degree of humidity.

If we talk about the properties of the materials, they are very similar. The dimensions and weight of moisture-resistant gypsum board are the same as those of a standard super sheet. The following characteristics are also identical: humidity, Brinell hardness, flexural strength and thermal conductivity gvl and gvlv. At the same time, the range of applications for moisture-resistant drywall is wider than standard, since even in the bathroom it will “stand idle” for its entire service life.

Advantages and application of moisture-resistant supersheet

Fibrous gypsum board has all the advantages of conventional drywall:

- environmental friendliness,

- high heat and sound insulation,

- non-flammability,

- mechanical strength and abrasion resistance,

- ease of installation.

It has only two drawbacks: price and significant weight of the gvl (gvlv) sheet. The first problem can be solved by minimizing waste, and the second can be solved by using a good assistant during the installation process.

Moisture-resistant plasterboard can be used in almost any type of building. Main use cases:

- in places with a high fire hazard as wall and ceiling cladding,

- for cladding attics, balconies and basements (if ventilation is available),

- for the construction of partitions in apartments with high humidity (for example, in bathrooms),

- for unheated rooms,

- for prefabricated floor subfloors.

In the bathroom, it is recommended to additionally treat the surface of the wall made of glvv from Knauf with special moisture-resistant decorative coatings (paint) or cover it with ceramic tiles.

Installation of gvlv on the floor

The slabs can be laid on almost any base: reinforced concrete or wood. For these purposes, the best option would be to use a 12 mm thick gypsum board sheet. The order of work will be as follows:

- Attaching a special edge tape.

- Filling with expanded clay or installing insulation.

- Laying a standard size gypsum board (gvlv) sheet on the floor.

- Treat the surface of the first layer with glue or mastic.

- Installation of the second layer.

- Tightening the layers with screws.

- Primer.

- Installation of covering (most often linoleum).

If you need to install bathroom floors, you should definitely treat the joints with waterproofing tape. This will help avoid moisture ingress and protect the structure from premature destruction.

Of course, gvlv is a “new word” in the development of the construction business. It is especially convenient to use this material during DIY repairs, as it is very easy to process. Moreover, the market offers gypsum board sheets of various thicknesses and sizes, which significantly optimizes marking and installation work.