“Bark beetle” is one of the types of finishing plaster. To apply it, a special heterogeneous mixture is used - viscous, with an admixture of solid components. "Bark beetle" is used to decorate external and internal walls. The advantages of this material are:

- simplicity and speed of application,

- practicality,

- durability,

- aesthetic appeal.

Bark beetle plaster is resistant to high humidity. It does not allow water to pass through, protecting building structures from getting wet. Another obvious advantage is the appearance.

When applied correctly, the result is a stunning finish that has excellent durability.

If you are thinking of using some other material instead of bark beetle, then you can see a list of modern materials, their advantages and disadvantages in our article: modern materials for finishing walls inside the house.

Material composition

Mixtures for bark beetle plaster consist of a base and solid fractions. The basis is a dry composition of cement, gypsum and industrial additives. After adding liquid, it becomes plastic and homogeneous. Fine sand, marble or granite chips are used as solid particles.

To prepare the solution, add water at a temperature of 15-20°C to the mixture. Liquid is taken at the rate of 200 ml per 1 kg of product. Knead with a construction mixer at low speed until the mixture can be held on the spatula without dripping. Then the composition is infused for 15 minutes, stirred again and immediately put to work.

Preparation of plaster mortar

How to prepare the mixture at home

You can prepare the bark beetle mixture yourself. To do this, classic plaster made of cement and sand is diluted with water. Once homogeneity is achieved, marble chips are added to it in an amount of 10% of the total volume. The result should be a viscous mass that, when applied to a vertical surface, will hold its shape.

The marble chips must be of the same caliber - in this case, the plaster will lie in an even layer with a characteristic “bark beetle” pattern.

Coloring the mixture

If the plaster needs to be painted, you can use a liquid dye for water-based paints. You should not tint the entire mass at once - the shade may change when applied to the surface. It is optimal to prepare a test portion and add dye.

Then apply the sample onto a stable base, for example, onto unwanted building materials. After complete drying, you can see what color it will turn out to be. This will allow you to understand how to adjust the amount of color for the desired result. This way you can avoid a situation where one shade is expected, but the result is completely different - brighter, darker, or, on the contrary, more faded.

Liquid dye for water-based paints

Colors

Manufacturers of bark beetle plaster mixtures present a certain range of basic colors . If a different color scheme is needed, you can use color scheme . When preparing a mixture, color is added to the water before mixing. You need to tint extremely carefully and remember that the shade in the bucket is different from the applied and frozen color. Therefore, before completely covering the wall with material, it is recommended to apply the mixture to a small area and evaluate the result.

A variety of colors allows you to choose the best coating option for your interior

Surface preparation

Application of bark beetle requires the most even base possible. A height difference of more than 2 mm will increase the consumption of plaster. The quality of the final result will be correspondingly lower.

To assess the evenness of a wall, you will need a rule or level more than 1 m long. If, when you apply the tool to the wall (it can be vertical, horizontal, diagonal - absolutely any line), gaps are visible, then the surface is not level. This does not mean that there is a problem.

For gaps, use a match - its thickness is exactly 2 mm. If it does not fit into the slot, it means that the relief has acceptable deviations. But if the match passes, and even more so if there is still a gap, the surface must be leveled. To do this, zones of relief differences are marked with chalk - this makes it easier to navigate.

Alignment of walls

Places of greatest difference are leveled out locally. Then the entire surface is covered with finishing plaster. This will ensure the integrity of the coating and level out the microrelief. Upon completion, the rule check must be repeated. If the wall meets the requirements, bark beetle can be applied. The finishing layer is pre-dried and then coated with a primer.

Question to the expert

What is a primer used for?

The primer increases adhesion - it determines how well the plaster will adhere.

Secrets of mastery

People often ask the question: what kind of trowel is needed to renovate an apartment with their own hands? The answer is – this is a tiler’s trowel. This trowel is very convenient for laying building mixtures on the work surface. It can also be used to “polish” the frozen solution, but you must not forget to moisten the trowel with water.

When working with a grater, one of its ends is supported, for example, on a box and a bed of mortar is placed on it with a spatula. Then take the grater with both hands and bring it to the work surface, pressing one longitudinal side to it and lifting the other. Then the trowel is moved from bottom to top along the wall, thus applying strips of mortar of equal thickness.

To obtain an even layer, pressing on the grater is of great importance . While working with the grater, its handle is held firmly with both hands.

After applying the primer, you should prepare a creamy solution without using gypsum and cover the surface with it. This solution is rubbed off much easier.

Required Tools

For comfortable work you will need the following tools for the bark beetle:

- trowel - use it to scoop up the mixture and transfer it to a spatula, adjusting the quantity;

- spatula - with its help the composition is transferred to the wall and initially leveled;

- grater - forms a pattern, helps complete the work;

- A smooth disc sander is a mechanical alternative to a grater.

It is preferable to choose the first two tools from stainless steel - they have the longest service life.

A grater is an inexpensive tool. But even when choosing it there are certain requirements. The tool should be light in weight and have a comfortable handle. This is necessary to move the granules smoothly and save the technician’s effort. The base must be strong and not bend, preferably made of polyurethane.

A properly selected bark beetle grater ensures smooth movement of granules, does not scratch, and is comfortable to use.

The best manufacturers

The popularity of models depends not only on ease of use, but also on the reputation of the manufacturer. In 2022, construction tools produced by the following companies remain popular: FIT, Kapriol, TOPEX, Stayer and others. Domestic ones, RemoColor, Zubr, are not inferior to foreign ones in terms of the quality of products and their popularity.

Our rating for 2022 and a review of popular models, according to buyers and professionals, will tell you how to choose a suitable grater for plaster, which company has better and more reliable products.

Application of "bark beetle"

The best time to perform finishing work with bark beetle is autumn and spring. During this period there is no intense heat, so the plaster will dry evenly and the moisture will leave it gradually. Rapid drying may cause cracks to appear. They immediately catch your eye and significantly reduce the quality of work.

If finishing is needed for the interior, you can work at any time of the year. But you will have to create a suitable microclimate: cool the room in the summer, warm it up well in the winter.

Question to the expert

At what temperature can bark beetle be made?

Experts have different opinions about the temperature at which bark beetle can be made. I adhere to the most common position that the range should be +5 - +30°C

Mixing plaster

You will need a clean bucket and a construction mixer. Instead of the latter, you can use a screwdriver with a mixer attachment. The mixture is mixed immediately before use, when the walls are already primed.

The likelihood of lumps will be reduced if you pour in the liquid first, then the dry component. Liquids should be taken less than prescribed. Do not blindly follow the instructions: adding the rest of the water may make the mixture too sticky.

It is technologically correct to add the bulk mixture to the liquid - this sequence makes the composition homogeneous.

Since the plaster mixture dries already in the bucket, it is not recommended to mix the entire volume of material at once. It is enough to calculate the amount for one wall, then make a new batch. Each manufacturer indicates how many grams of a particular mixture are consumed per 1 m2 of surface. Having measured the area of the wall, all that remains is to multiply both indicators.

When calculating consumption, you should rely on the manufacturer’s information: depending on the size of the solid elements, 1 m2 of area can require from 2 to 3.5 kg of mixture.

Wall decoration

The composition is collected from a bucket with a trowel, then transferred to a bark beetle spatula. Using the back of the trowel, lightly level it over the surface. The mass is transferred from the spatula to the wall; movements must be strictly horizontal or vertical.

It is advisable to visually zone the wall into strips in order to cover it from top to bottom in one application. Or make the stripes wider, and apply each portion of the mixture only halfway - from the middle up or down. This technology will allow you to create an approximately equal layer of “bark beetle” over the entire wall.

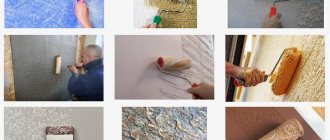

Applying bark beetle plaster

The solution is applied in a top-down direction. The ideal angle of inclination of the spatula relative to the wall is 40-50o. The layer thickness should be only 1-2 mm. But it is more important that it does not exceed the thickness of the solid fractions. Otherwise, when grouting, the granules will not be able to be pressed to the base. Consequently, the desired pattern will not work.

When learning how to plaster with bark beetle, it is important not to forget one of the key points. After applying the mixture to the area, you must wait 20 minutes, then apply a grater. If the mixture does not stick to the tool, you can begin finishing. If it gets sticky, give it more time, but don’t wait too long, otherwise it will dry out.

Sometimes all that remains is to cover a small part of the wall with plaster, but at the point where the process begins, it’s time to grout. Then the dried mixture is sprayed with water from a spray bottle - this allows you to gain time to complete the work. The composition in the bucket also needs to be stirred periodically. This is important to protect against drying out.

If you watch a video about applying bark beetle, it becomes obvious that everything is completely simple.

Creating a pattern with a grater

Application of “Bark Beetle” is possible using the following methods (the final design depends on this):

- vertical;

- horizontal;

- cross;

- chaotic.

Drawing of decorative bark beetle plaster

There are two methods of bark beetle plastering - manual and mechanical. The second option is more convenient, but with its help you can only make a chaotic pattern.

For vertical, horizontal or cross, you will have to resort to manual labor. In this case, the applied material is grouted using a trowel. It is moved along a given line without swinging to the sides. The lines should be straight. If a cross pattern is needed, first make all the vertical lines, then all the horizontal ones.

The mechanical method of plastering uses a grinding machine with a smooth attachment. They rub the wall with it until a smooth surface is obtained with the desired effect.

Using a trowel

When working with those building materials that require high-quality installation, it is impossible to do without special tools. Trowel is one of them. It is a blade made of high quality steel, polished on both sides . In addition, the trowel has a comfortable handle, which can be made of wood or plastic. The main purpose of this tool is to form seams between individual building elements during the construction of walls, as well as to apply and level mortars.

Good trowels are made from manganese or stainless steels, which have springiness

Construction operations that can be performed using a trowel:

- laying tiles;

- bricklaying;

- jointing;

- interior decoration;

- external decoration of buildings.

The convenient shape of the trowel's base and handle allows you to take exactly as much solution as you need for quality work. The trowel will also come to the rescue when you need to mix the solution or get rid of lumps. This tool is very actively used when working with concrete blocks, bricks, and plasterboards.

A sharp-nosed trowel is useful for sealing seams and eliminating any depressions in the joints. With the help of a trowel, such operations can be performed very quickly, and this ensures that the structure is reliably protected from moisture.

Features of facade coating

For finishing external walls, special requirements are imposed on materials. These objects are subject to increased exposure to natural factors, such as:

- temperature changes;

- precipitation;

- solar ultraviolet.

Bark beetle plaster is a moisture-resistant material. But in the cold season, precipitation is not only a frequent occurrence, it also takes longer to dry. Temperature changes can affect the density of the material, and bright sunlight causes color fading. That is why for facade work it is important to strictly follow the finishing application technology. You should also only use mixtures intended for outdoor use.

For facade work, mixtures with large fractions are produced - 1.5 mm or more. The packaging should indicate that this product is suitable for outdoor use.

When decorating external walls with “bark beetle”, technologists recommend making a layer of external insulation. This will not only help keep the house warm, but will also shift the dew point. This move will reduce the likelihood of moisture accumulation and subsequent mold formation inside the structure.

Before you begin applying finishing plaster, you need to study the scope of work to find out whether additional processes are needed. This could be dismantling drainpipes, an outdoor air conditioner unit, and similar tasks. This will allow you to calculate the working time and determine in what portions to knead the mixture.

If it rained the day before, you should wait until the walls are completely dry. In this case, it is better to delay the deadline than to get a poor-quality result.

All preparatory work is carried out before the start of mixing in order to make the application of the “Bark Beetle” as effective as possible. Perforated corners are installed at the corners of the building - they are pressed against the wall and covered with a layer of plaster. This helps maintain even corners when decorating the building.

Types of trowels

Both a professional builder and a hardworking owner should have trowels in their arsenal. You can’t do without this tool either when performing cosmetic renovations of an apartment or when building a country house. Today there are many types of trowels. The form of each of them is determined by the particular type of work for which it is intended.

Types of modern trowels:

- mason's trowel . Such a trowel will be needed when large-scale work is planned, for example, building a house from concrete blocks. Its base has the shape of a trapezoid. Using this tool, you can easily mix the ready-made cement mortar and then place it in the spaces between blocks or bricks. They can also remove excess mortar from seams and even in hard-to-reach places. A professional can work with a mason’s trowel, the blade length of which is 300 mm, but amateurs should not purchase such a bulky tool, as it quickly tires the hand. In this case, it is best to use a tool up to 200 mm long;

- concrete worker's trowel . When building a house from concrete blocks or bricks, you cannot do without such a trowel. Its base has a triangular shape. The tool is used for stirring and applying building mixtures to bricks and blocks. They can also trim excess mortar from vertical seams;

- finisher's trowel . This trowel is very convenient for measuring and applying the required amount of solution to work surfaces. The optimal length of its working surface is 120-180 mm;

- pointed trowel . Used to fill joints between concrete blocks or bricks. It has a short blade length - 75-100 mm;

- plasterer's trowel . Can perform several functions. The main thing is the application of finishing solutions and their subsequent leveling. The second is smoothing or “polishing” the already hardened solution;

- tiler's trowel . The working blade of such a trowel has a drop-shaped shape, which allows you to very quickly and conveniently take up the required amount of solution and apply it to the work surface;

- corner trowel . You cannot do without such a trowel when applying and leveling the mortar in the corners. Its working surface is not flat, but curved in the shape of an angle;

- jointing trowel . The working blade of this trowel is very narrow. One of its edges is used to remove excess mortar from the seam, and the curved end is intended for undoing seams.

The tiler's trowel is the most versatile tool for all types of work.

Features of interior decoration

"Bark beetle" is perfect for interior decoration. This coating has good wear resistance. It is subject to wet cleaning and does not collapse when in contact with household chemicals.

It is applied both in rooms with high loads (corridor, kitchen, bathrooms) and in living rooms.

For interior work, mixtures with small granules are used. There are also options with larger fractions (and as a result, grooves). When applying the material to the prepared surface, bright lighting is necessary. This will allow you to see all the irregularities and eliminate them in a timely manner.

It is also important to exclude drafts and sudden temperature changes.

Modern industry offers various types of mixtures for interior decoration. Depending on the composition, the properties of the products vary. Knowing their differences, you can choose a mixture that is optimal for specific purposes:

- Mineral - fireproof, resistant to mechanical stress, and low cost. Among the disadvantages is poor plasticity, requires certain physical effort, and is not resistant to sudden changes in temperature conditions.

- Acrylic - has high adhesion, moisture resistant and elastic, can be painted at the mixing stage. But she also doesn't like rapid temperature changes.

- Silicate is an ideal option for places with high humidity, can allow steam to pass through, and has the highest wear resistance. The disadvantages include rapid hardening, therefore it is necessary to work with it quickly and without errors; walls require pre-treatment with a special primer. The cost of such plaster is the highest.

Plaster bark beetle

Why are plaster floats needed?

Plaster is used to level walls made of brick, stone or blocks. Additionally, it is used as a heat insulator against cold and heat. A relatively thick layer of heavy wet composition cannot be leveled and made immediately smooth. As it dries, the surface roughness increases.

The putty is applied in a thin layer and is not able to hide unevenness. Wallpaper and painting will only emphasize the roughness and bumps. The graters remove protrusions, gradually smoothing out all the unevenness and bringing the walls to a state of perfect smoothness. They are classified according to the materials of the sole body and the operations performed: grinding, applying mortar, leveling, grouting.

Before purchasing, when analyzing the parameters of the product, you should take into account the type of plaster, its composition and the required degree of smoothness.

How to paint the “Bark Beetle” after application

Monochromatic painting of the “bark beetle” is not much different from ordinary painting of walls. But the peculiarity of this type of plaster is its relief. Therefore, contrasting coloring looks more interesting, emphasizing the uniqueness of the texture.

Contrasting painting is done with paint for interior or exterior (depending on location) work. It consists of the following steps:

- First, use a roller to paint the surface in the color that will be in depth. Usually light colors are chosen for this. You can move the roller in any direction, the main thing is to paint over everything. A long-haired tool will do the job better.

- The final coating with a second, darker color is applied only after the previous paint has completely dried. Here you will need a roller with short pile - the short length of the pile will not allow you to paint over the grooves. You need to move in one direction.

- The last stage is varnishing. Most often used in public buildings. Or if you want to add shine to the texture and give additional protection to the decorative finish. In this case, use a special acrylic-based plaster varnish. It should be applied strictly according to the instructions. It is advisable to first test on an inconspicuous area or a sample, since after drying the color of the surface may change.

Painting the bark beetle in contrasting colors gives depth to the interior.

This looks especially advantageous in small rooms, visually expanding the space. “Bark beetle” is a decorative finish that is easy to apply, but looks impressive and lasts a long time.

Even an inexperienced master can work with this material. The main thing is to choose the right raw materials taking into account the characteristics of the room, purchase a high-quality tool for applying bark beetle and take into account all the details of the process, even if some seem completely insignificant.

Did our article help you figure out how to apply bark beetle?

What is grout?

Grouting is the final stage of plastering work, which consists of eliminating the smallest errors, leveling and smoothing the surface by rubbing the dried mortar with a special tool. When using decorative plaster, the main purpose of the grout is to form a certain relief of the working plane.

Applying a finishing layer of fine leveling plaster

Before grouting, a “covering” is applied to the base - the finishing layer of plaster mortar. The base layer, or primer, is very durable and therefore difficult to process, while the covering ensures uniform filling of uneven surfaces and maximum smoothness when grouting. Rub the plaster after the mortar has set, but before it dries completely.

Rub the cover

Preparatory work

The best base for decorative plaster is walls lined with regular plaster along the beacons. Make sure that there are no sinkholes or depressions on the surface, and also check the walls with the rule - if you find more than 2 depressions per 2 meters, the surface will have to be plastered with a mixture to level it. If the walls are smooth, before applying plaster you need to do the following:

- Remains of old finishing, dirt and dust are removed from the walls.

- If there are cracks, they must be widened and sealed with cement mortar.

- Nails, screws and dowels are removed, and holes are also sealed with cement.

- The surface is primed with two types of compounds: the first layer is made with a deep penetration primer, which strengthens the surface and reduces the absorbency of the base material. For the second layer, a primer with quartz sand is required.

Tip: we recommend using primer and decorative plaster from the same manufacturer. If you choose bark beetle plaster from Ceresit, then compositions CT-17 and CT-16 will suit you for two layers of primer.