What is it used for?

Various devices are used to remove rust or old paint from a metal surface. You can get the job done quickly and efficiently using a grinder and a special brush attachment.

The design is a round base with wire or nylon bristles. The working elements are located evenly around the entire circumference of the cup. The length of the bristles is uniform.

Disc brush for angle grinders, nylon wire with abrasive coating BISON “PROFESSIONAL”

If the wheel is unevenly covered with wire bristles, involuntary vibration of the attachment is observed during grinding. Because of this, the quality of cleaning decreases.

Equipment is selected for an angle grinder taking into account technical indicators. One of the main ones is the number of revolutions per minute. It is unacceptable to use a metal brush with a low speed on an angle grinder with a high rotation speed. The effect of such processing will be minimal. The equipment will quickly fail.

For what purposes are cord brushes used:

- stripping the old protective coating (LCM);

- grinding of metal blanks;

- deburring;

- brushing, roughening of wood blanks;

- cleaning parts before welding;

- removing unnecessary part of the deposited metal from the seams;

- grinding off sharp corners, etc.

Sometimes metal brushes are used as substitutes for abrasive wheels.

When should you remove old paint and why?

It's no secret that 15-20 years ago, the favorite finishing materials of all builders were paint and paper wallpaper. You can especially often find painted walls in the bathroom and toilet, in the kitchen or in the hallway. Builders with a creative approach to their work often decorated the walls with flowers and boats. Unfortunately, such a print stops touching when it becomes necessary to get rid of it. It’s one thing when the old paint has already peeled off and can be easily removed with the help of a spatula. And it’s quite another thing when there are several layers, they are applied conscientiously and adhere with enviable strength. Assuming the full burden of future work, many give up and the thought creeps in: “ what about him?” "

We hasten to please you - in some cases,

old paint really not an obstacle to further finishing work. It all depends on their type:

- For example, if we are talking about a bathroom, where there is a need to level the plane of the walls for further laying of facing tiles, you can simplify the task with the help of plasterboard. Some walls are so curved and have such obvious differences that sometimes it is actually faster and even more economical to level them with plasterboard fixed to profiles than with plaster. Plus you will get a surface with excellent adhesive properties;

- For fastening plastic or other wall panels, lining, old paint will also not be an obstacle;

- If you plan to repaint and the surface of the walls allows you to do without leveling them, you can apply a layer of new coating on top of the old one. Provided that it does not swell, does not peel, holds tightly and does not have cracks. In some cases, individual areas of peeling paint can be removed, and the resulting unevenness can be filled with finishing plaster. But please note, this point only applies to situations where acrylic paint is applied to old acrylic paint, or enamel paint to old oil paint. If acrylic or water-based paint is applied to old enamel paint, these compounds simply will not “stick” to the glossy surface. Perhaps, when applied, it will seem to you that the paint is still evenly distributed on the surface and everything worked out, but after drying you will find separate islands of a new color, which are interconnected by thin cobwebs;

- Modern means will allow you to avoid the need for old coating before tiling the walls. For example, a primer composition called “concrete contact” and other interpretations of the name with a similar meaning promise good adhesion after drying, even with a completely smooth surface. Even glass appears on the list, and on the Internet you can find a lot of video evidence.

- If you plan to apply wet plaster and other compounds, such as wallpaper glue, for example, to the walls, the paint must be removed without fail . Plaster simply will not “stick” to a smooth surface. The paint has minimal ability to absorb liquid, so the usual primer simply will not be able to penetrate its structure and ensure adhesion. And under the weight of heavy wallpaper soaked in glue, the paint can simply come off along with the freshly pasted wallpaper. Even if at first glance, it seems that she is holding on tightly.

Main characteristics of brushes

The base of the brush is a circle with a hole in the center (diameter 22.2 mm). Outwardly, it resembles a cutting disc. The equipment is installed on the angle grinder in the same way. To do this, the attachment is put on the spindle of the angle grinder, and then tightened with a lock nut.

Brushes are produced in different diameters (from 115 to 200 mm). The degree of stiffness of the bristles depends on the thickness of the wire. The nozzle option is selected taking into account these parameters so as not to damage the appearance of the working surface.

Tooling with fine wire is suitable for processing workpieces of complex shapes or soft structures. It is advisable to use thick bristles for cleaning weld seams or burrs.

The stiffness of the brush head also depends on the type of material used to make the brush and the shape of the bristles. Each variety is designed to perform specific jobs.

When choosing a nozzle you need to consider:

- cup diameter;

- spindle rotation speed;

- number of rows of bristles on the base;

- pile material.

Do-it-yourself removal of different types of paint

There are recommendations for removing different types of paint. The choice of cleaning composition depends on this.

| Paint type | Preferred cleaning method |

| Oily | Mechanical or chemical cleaning method. |

| Acrylic | Solvents containing acetone or alcohols, mechanical cleaning. |

| Water-based | Mechanical method: with a grater or sandpaper. With a professional remover, or glue and newspaper. |

| Obsolete | It is best to combine several methods: large areas are treated with power tools, and hard-to-reach areas are treated with a remover or solvent. |

Criterias of choice

You can choose the most suitable brush based on the following criteria.

Manufacturer

The quality of the nozzle is identified with the manufacturer. Products made by well-known brands inspire confidence. These include brands:

- STAYER;

- Bosch;

- GROSSSMEISTER;

- Lessmann;

- SKRAB;

- Matrix;

- Anchor;

- Bison

What are there

Metal brushes for angle grinders come in different types.

Cord brush

The equipment is characterized by high rigidity and hardness. Therefore, it is not used for processing wood and soft metal alloys. The main purpose is brushing. This is where the tool got its name – a cord brush.

For wood and soft metals, a hard attachment is not suitable due to damage to the structure of the processed materials and loss of aesthetic qualities of the surface.

Petal disc

The nozzle is available in different diameters. The range is 15-500 mm. Grit values are also available to choose from - 40-2500. For the manufacture of equipment, zirconium and electrocorundum are used.

This type is used for processing flat and curved surfaces with a complex structure.

Abrasive cup

The nozzle got its name because of its similarity to a tableware. Its shape is cylindrical. The abrasive is produced in diameters of 100-180 mm. One of the popular models is the 125 mm cup.

Grinding abrasive disc

The design consists of a metal base onto which circles of different grain sizes are fixed. They can be replaced quickly. Circles are consumables. The base of the nozzle does not wear out.

To treat the surface, a type of grinding agent is also used - a grinding brush wheel. It comes in different diameters, grits and heights. Selected taking into account the type of work and type of material.

Type

When choosing a brush for processing a part, you need to consider the type of surface. Is it smooth, or has grooves, corners, internal edges, or hard-to-reach recesses? Based on the characteristics of the workpiece, a suitable nozzle shape is selected.

| Nozzle type | Peculiarity | Purpose |

| Disk | The basis of the design is the disk. Wire flagella are fixed along its edges. | Processing surfaces with corners, grooves, parts with joints. |

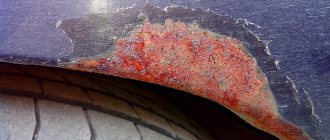

| Cup | The base is made in the form of a cup. Its edges are equipped with bristles made of straight/twisted wire. | Removing scale, removing old paint from a large surface area. |

| Conical | The base design resembles a slightly concave disk. The edges are framed with twisted wire. | Processing of parts with plane differences, radius changes, and notches. |

| Radial | The base is almost the same as the disk attachment. Features wire bristles. It is made of a thin flat/twisted shape with dense padding around the circumference. | Cleaning steel parts from scale, rust and other sludge. |

Brush material

The wire acts as an abrasive. To give the nozzle different rigidity, different materials are used:

- brass;

- nylon;

- stainless steel.

The first and third options are suitable for processing metal, concrete, brick, etc. Nylon is chosen for sanding wooden and plastic blanks and applying patterns to wood.

Using wire

The bristles differ not only in the type of material, but also in the shape.

- Harness - is a twisted bundle of metal fibers. This attachment is used primarily for rough work.

- Corrugated - reduces vibration of the angle grinder due to its springy properties.

- Twisted is another type of twist that provides high rigidity.

- Smooth is a standard product for processing wood, metal, and steel.

Using equipment as intended extends the service life of consumables.

Purpose

Angle grinder attachments can be used for processing workpieces and products made from the following materials:

- metal;

- tree;

- concrete;

- tile;

- brick.

Diameter

The indicator is measured in millimeters. In stores there are models with a diameter of 115-200 mm. To perform non-standard work, equipment from 5 to 900 mm is used.

The smaller the diameter, the lower the load on the power tool motor.

Landing diameter

This parameter determines the size of the hole in the nozzle. It corresponds to the diameter of the grinder spindle on which the equipment is installed. Options for metal brush diameters:

- 22 mm;

- 22.2 mm;

- M

Disc thickness

The unit of measurement for the indicator is millimeters. Discs are available in thicknesses of 1.7-55 mm.

Diamond layer thickness

The diamond layer is applied to a nozzle with a thickness of 2.4-6 mm.

Grain

Abrasive consumables have varying degrees of hardness. On the nozzle, the grain size indicator is indicated by the symbol P. For metal brushes, the following values are used: 40; 60;80. These are coarse grain options. The lower the number, the smaller the grain.

Amount in a package

The nozzles are sold in packaging. The quantity varies from 1 to 230 pcs.

Preparation for wallpaper

In order for the wallpaper to stick well, the layer on which it is attached must be stronger and heavier than it . If they weigh more, they will very soon simply move away from the wall. Therefore, all cracked paint must be cleaned off. Defects must be puttied.

You can check whether the wallpaper will be securely fixed in a simple way: apply glue to the wall and leave until completely dry. If it is securely fixed and does not come off in the form of a film, then you can start gluing.

Oil and alkyd paints are sanded with sandpaper. The formed depressions will improve the adhesion of the glue to the surface.

Before covering a wall with wallpaper, you need to remove dust and other contaminants from it, and then prime it . They will adhere firmly to such a surface, even if all the coloring composition is not cleaned off.

You should not glue light wallpaper to walls painted with dark paint. It will show through them in ugly spots.

How to use it correctly

The attachment is not difficult to use. It installs quickly. The main thing is to check the degree of fixation of the locknut and the integrity of the equipment. If there is a concave pile, it is leveled. After work, it is necessary to clean the bristles from dirt and rust.

Test of grinding attachments for angle grinders (stripping/flap/end twisted wire). PART 1

The quality of work performed by a metal brush depends on how correctly the number of revolutions is set.

It is easier to cope with the processing of metal and other surfaces if you take into account the recommendations for choosing a brush.

| Peculiarities | Speed, m/s | Number of revolutions, rpm |

| Cleaning and final sanding | ||

| Polymer abrasive is suitable. Used for wood and plastic. | 5-20 | 1000-4500 |

| Processing of weld seams | ||

| The wire on the brush should be cold-drawn and self-sharpening. | 35-45 | 6000-12000 |

| Cleaning the surface from paint/rust | ||

| A cup brush should be used. | 20-35 | 6000-12000 |

| Sanding hard-to-reach areas | ||

| A conical tool will do the job. | 35-45 | 6000-12000 |

| Deburring | ||

| Processing is carried out with a nozzle with corrugated wire. | 35 | 1000-6000 |

| Sanding in cavities | ||

| End wire brushes are used. | 5-35 | 3000-15000 |

How to choose a working mode

When setting up the tool, you need to choose the right operating mode. After a test run of the equipment on the working surface, the following actions are performed.

If the hangnails fall off, it is recommended:

- set high speed;

- replace the brush with another model with shorter or wider bristles;

- use a nozzle with a larger diameter bristle.

The pressure force is adjusted as follows:

- increase in speed;

- installation of equipment with a pile of larger diameter.

If the effect is insufficient, you should adjust the speed higher and/or use a nozzle with a short wire. You can also try a brush with larger bristles. If the effect is excessive, the speed is reduced, and nozzles are used with thin long wire.

Grinder Attachment for Paint Cleaning

How to clean old paint

Probably home craftsmen, when renovating an apartment, are faced with the problem of cleaning the walls from old paint. I would like to share my experience with you. I tried different available methods, and I’ll tell you about others.

Technical hair dryer as a paint cleaning tool

What is needed, the first thing that was tried here was a technical hair dryer. I have a cheap hair dryer from MAKITA, model HG5012K 230V. Industrial hair dryers differ mainly in their heating level.

Technical hair dryer MAKITA

This is what a technical hair dryer looks like. very similar to the regular one you use to dry your hair, but don't do it

Source: https://ctln.ru/nasadka-na-bolgarku-dlja-ochistki-kraski/

Safety precautions when working

Using accessories for an angle grinder requires compliance with safety measures.

- It is prohibited to use accessories for angle grinders with inappropriate technical parameters.

- When processing any surface, small solid particles fly off. They can damage the eyes, skin, and respiratory system. At high speeds, the brush itself may fly apart. To avoid a traumatic situation, it is recommended to wear personal protective equipment before connecting the power tool. These are: glasses, a respirator, gloves, workwear made of thick fabric.

- Contact of the brush with metal at high speed is accompanied by a loud sound. Construction headphones or earplugs will help to avoid irritability and strain on the hearing organs.

- Before installing the attachment on the grinder, you need to inspect it for damage and defects. If they are present, they must be replaced.

The importance of safety lies in taking care not only of your health, but also of those around you.

Thermal methods

Methods of removing old paint layers using elevated temperatures are also considered extremely dangerous. When carrying out such work, you need reliable protection and concentration and, of course, experience with the tools below. There are three commonly used methods.

No. 6. We use a regular iron

For a coating that is no longer held in the most reliable way, the method of applying temperature using a regular iron is suitable. Through a sheet of thick foil, food grade, the desired area is heated well, and then the softened coating is removed using a spatula.

No. 7. We use a hair dryer

In a similar way, only much faster, you can “melt” the paint using hair dryer, and then remove it with the same spatula or other convenient scraper.

No. 8. Blowtorch method

Sometimes a blowtorch is used. Or in other words, a burner running on kerosene or gasoline vapors. On average, one liter of fuel is enough for continuous operation for 20-50 minutes. The flame must be brought as close to the paint as possible and watched carefully. When the paint begins to melt but not burn, you can scrape it off the wall.

All thermal methods are necessarily accompanied by a sharp and unpleasant odor that appears when the paint is heated. Therefore, it is strictly not recommended to work in unventilated areas. Also, under no circumstances should you heat places where electrical wires pass or where there are wooden embedded parts in the wall.

Corrugated cup brush 60xM14 (st. 0.3)

In general, the brush coped with the task, although not too clean. The main disadvantage is that it is very aggressive towards soft pine wood. The surface structure turned out to be cut by hard wire.

But CD wheels from different manufacturers coped with the task as it should.

Finishing wheel Cibo FAG 5, d115

This is a circle with the softest structure and fine abrasive grain.

He cleaned up the paint superbly, but still left the smoothest surface of all the competitors. The photo doesn't really convey it, but you can feel it with your hands.

These circles come in several options - from small heads and velcro circles, to large wheels with a diameter of 200 mm. There is an instrument for everyone.

Thus, CD paint and rust wheels for metal turned out to be an excellent solution for working with wood.

Of course, sanding wood with a grinder is a dustier task than with other tools. But the performance is worth it.

You can find some of these circles in the form that is most convenient for you. For example, for use on a drill.

Or just small rollers with a diameter of 25, 50 and 75 mm for making your own grinding tools.

Video of our test:

The latest news on our social networks and on our channel:

Source

3M™ Scotch-Brite™ Clean and Strip Pro Extra Cut XC-RD Circle, A XCRS, 125xM14

Premium circle from 3M. He also did an excellent job - he cleaned the paint without damaging the surface.

This is the most expensive circle of all used in the test. But it has its own characteristics. A combination of soft thread with aggressive grain, and a plastic support plate. What can I say - 3M.

And the last option.