In modern construction, concrete is one of the main structural materials. It is inexpensive, strong, durable, and can withstand high loads. Therefore, floors in industrial and commercial buildings, as well as in home workshops, garages, cellars, outbuildings and storage rooms are made of concrete. Despite the large number of positive qualities, concrete also has disadvantages. Concrete is a porous material, characterized by a low level of strength and relatively low surface hardness. Therefore, when exposed to external factors and physical activity, its unprotected surface is subject to erosion. Concrete has poor resistance to chemically active liquids. As a result of these impacts, the surface wears out and characteristic concrete dust appears.

The most common way to protect a concrete floor is to coat it with paints or enamels. However, floors, especially in industrial buildings, are subject to very serious operational loads. Therefore, not all paints and enamels are suitable for protecting the concrete surface.

Requirements for protective coatings for concrete floors:

- resistance to mechanical stress;

- durability of operation;

- resistance to temperature changes;

- water resistance;

- good adhesion to porous concrete surfaces;

- UV resistance;

- decorative qualities.

Correctly selected protective coating and adherence to the application technology for concrete screed solves almost all of the problems listed above. This processing gives the following results:

- increasing the strength and wear resistance of the concrete surface;

- increasing resistance to the destructive effects of chemical compounds;

- stopping wear and dust on the surface;

- increasing moisture resistance and reducing absorbency, since the pores of the surface of the material are filled with a painting composition;

- increasing the service life of the floor;

- simplifying floor cleaning, as well as reducing the time it takes.

It is best to choose a specific protective coating for a concrete floor based on its operating conditions. Try to choose the paint so that its advantages are fully used, and the disadvantages are leveled out or do not interfere with operation.

Oil paints

Oil paints are produced on the basis of drying oil - heat-treated vegetable (linseed) oil. Therefore, they are considered an environmentally friendly material. In general, modern paints are noticeably superior to oil paints in terms of the sum of their characteristics. Therefore, they are practically not used in modern construction. As a thinner for oil paints, substances similar to the paint base are used: drying oil, turpentine, white spirit, special thinners for oil paints.

The “advantages” of oil paint include the following:

- Low price,

- High hiding power,

- UV resistance,

- Good waterproofing properties.

Disadvantages of oil paint:

- Long drying process

- Unpleasant smell

- Low vapor permeability,

- A small number of flowers

- Incompatibility with other protective coatings.

Homemade recipe

You can also make a product for treating a concrete floor for dust removal with your own hands. The performance of floors coated with such substances is often not very high, but in certain cases and rooms without serious loads, this option may be acceptable.

Recipes for preparing compositions for concrete dust removal:

- PVA glue (it is better to take PVA-m or PVA-k) with water in a ratio of 1:8 - mix until a homogeneous solution is obtained, apply to concrete.

- Dilute latex with water (the proportion is chosen according to the type of substance).

- Dissolve pieces of polystyrene foam in acetone or gasoline, add a little xylene. Apply the mixture to concrete - within a few hours the gasoline will evaporate and the polymer will protect the floor from water.

Acrylic paints

The basis of acrylic paint is acrylic resins, polymers, organic and inorganic pigments. Acrylates and polyacrylates, modified with additional components, form a protective film. Complex ester components ensure quick drying and resistance to external factors. The solvent for most acrylic paints for concrete is water. Therefore, the paint is recommended for use in both work and residential areas. Acrylic paints will perfectly protect concrete floors of offices, sports facilities, houses, apartments, underground parking lots and other premises.

Advantages of acrylic paint:

- Environmental friendliness,

- Abrasion resistance

- Vapor permeability

- Bioprotective properties,

- Elasticity,

- Large selection of colors and shades,

- Preservation of color throughout the entire service life.

Disadvantages of acrylic paints:

- Cannot withstand prolonged exposure to moisture

- Low strength (compared to epoxy compounds),

- High price.

How to paint concrete floors: preparation of the base and application technology

Using a two-component composition, you can paint old floors that have already been in use, as well as freshly poured screeds. Depending on the condition of the base, the preparation algorithm may be different.

If you plan to paint a freshly poured screed, you must wait five days for the concrete to gain strength. During this time, excess moisture will evaporate from the material, so it will be easier to process. Five days after pouring, the surface of the screed is ground using a tool called a “helicopter”. Sanding is necessary in order to get rid of the unstable top layer. It is a hardened cement “milk”. In addition, grinding removes minor surface defects and opens pores.

After this, all debris and dust are removed from the floor. To do this, you can use a construction vacuum cleaner. Since a freshly poured screed has an almost flat surface, there is no need to repair the base before painting.

Before painting, it is necessary to repair the floor, sealing all cracks and cracks.

If an old concrete floor is to be treated, you need to make sure that the surface humidity does not exceed 4%. Otherwise, the adhesive properties of the dye will deteriorate and after it dries, the coating will begin to peel off.

Algorithm for preparing an old floor for painting:

- Checking humidity using a special device.

- Removal of unstable areas, various defects and loose areas.

- Removing dirt (paint residues, oil stains, traces of bitumen).

- Preparation of cracks and crevices for sealing (the defect is worked out to a depth and width of 8-10 mm).

- Garbage collection.

- Surface primer.

- Seal cracks and crevices using repair compound or epoxy paint mixed with quartz sand.

Priming a concrete floor is an important step before painting the surface.

After repairing the surface, the patches must dry. They do not need to be additionally primed before painting.

Alkyd paints

Paints are made on the basis of alkyd resins, which serve as film formers. The most commonly used resins are glypthal (designated GF) and pentaphthalic (designated PF). Due to the excellent price-quality balance, alkyd paints are considered universal and truly “folk”. Floors can be painted with such paints both in a huge factory and in a private garage. In both cases, the owners will be satisfied with the durability of the coating and the relatively small painting budget. White spirit, toluene, and solvent are used as solvents.

Advantages of alkyd paints:

- High resistance to abrasion (including dry and wet cleaning),

- Long service life

- Excellent adhesion to concrete,

- Fast polymerization

- Low cost,

- Moisture resistance.

Disadvantages of alkyd paints:

- Contain toxic substances with an unpleasant odor,

- Low vapor permeability,

- Fire hazard,

- Short service life.

Useful tips from professionals

Coatings suitable for painting floors differ in their characteristics. When choosing what to paint a concrete floor with, check whether the surface will be slippery or rough, and whether the color can be changed by adding pigment.

To avoid having to repaint the floor, it is important to maintain compatibility of the compositions. It’s good when the old composition is compatible with a new coating, for example, acrylic-based. It is advisable to make the top layer darker - the consumption will be reduced and coloring will be simplified.

To make the film elastic, use a “soft” hardener for Temafloor 150. After adding Temafloor Flex, the floor will become safer for children.

Mechanical floor painting is fast, convenient and effective. Water-based compositions are suitable for household spray guns. The nozzle (spray gun) can become clogged with heavy paints that cure quickly.

Manual method - painting with a roller on a long handle. In hard-to-reach places, pre-paint with a brush, having previously sealed all the cracks.

Mechanical floor painting is fast, convenient and effective.

Painting concrete is a simple and affordable way to protect the floor from many negative factors. Painting with polymer-based compositions is durable protection against increased operational load and delamination of the surface of the cement screed.

Epoxy paints

The main component of paint is epoxy resin. To improve the properties of paint, modifiers, thinner and solvent, pigment, filler, and functional additives are added. The main disadvantage of using epoxy floor paint is that it is two-component. Before use, it is necessary to mix the paint and hardener in certain proportions. But all the inconveniences are offset by the high strength of the coating. It is epoxy compounds that are most often used for painting floors in workshops, garages, hangars, traffic areas and painting concrete in the open air. The most commonly used solvents are xylene, solvents 646 and P-4.

Advantages of epoxy paint:

- Versatility,

- Resistance to abrasion and mechanical damage,

- Moisture resistance (can be used in open atmosphere conditions),

- Excellent adhesion,

- Resistant to various chemicals (alkalis, acids, oils, salt solutions);

- Preservation of color during service life,

- Long service life.

Disadvantages of epoxy paint:

- The need to mix the two components before use.

Floors

0 votes

+

Vote for!

—

Vote against!

They prefer not to paint concrete surfaces, including the floor, but to leave them in their original form. However, even such a durable material as concrete is subject to mechanical damage, chipping and chemical attack. Therefore, the procedure of painting a concrete floor is not just a job of improving the room, but a way to protect the coating. But we still have to figure out what to paint the concrete floor with?

- Surface preparation

Concrete floor protection

Concrete floors today are most often installed in industrial or commercial buildings. But at the same time, they can be seen in home workshops, garages, cellars, outbuildings and storage rooms. Although concrete itself is capable of withstanding heavy loads under unfavorable conditions of use, it still requires protection.

Concrete is characterized by high porosity and a low level of tensile strength, therefore, when exposed to external factors, its unprotected surface wears out, peels off, and then characteristic dust appears. This happens most often in cases of using low-quality concrete, violation of laying technology, improper mixing of the mixture, or the use of poor cement.

To protect the concrete surface, it is customary to use special compounds. In addition to decorative properties, painting a concrete floor provides its protection from destruction, the influence of aggressive environments and abrasive wear, imparts such additional properties as hygiene, anti-slip, decontamination, antistatic, smoothes out unevenness, and masks various floor defects - chips, cracks, cavities and cavities.

Choosing paint for concrete

Alkyd and epoxy paints are usually used to paint concrete floors, which have unique anti-slip and antistatic properties, as well as great resistance to chemicals. The epoxy substance must be prepared, mixed and tinted before use; the alkyd does not need to be prepared for use. But before working with alkyd paint, the concrete surface should be primed; epoxy paint does not require this.

In addition to paints, soil mixtures are widely used, which are designed to transform a very neglected floor. Tinting impregnations give concrete a bright colored coating. Polymer compositions are able to hide all defects and level the surface; the use of special putties makes it possible to make any concrete coating monolithic. Glitters and flocks that do not fade over time will help provide additional decorativeness to the floor.

When choosing which paint is best for a concrete floor, it is recommended to take into account the characteristics of the room. For example, in production areas where mechanical damage or impact loads on the surface are often possible, the creation of a highly reliable coating is required. In this case, it is best to use wear-resistant paints.

For thin-layer self-leveling coatings for civil purposes, choose concrete floor varnish or polyurethane enamel. For finishing floors in garages and processing concrete elements of landscape design, products are used that are intended for coating various industrial premises, which are based on solvents and epoxy enamels.

To paint a concrete floor in a residential area, you need to use a water-based composition. For surface treatment on balconies and corridors, it is better to buy two-component polyurethane elastomers. If you need water resistance of the coating, give preference to one-component polyurethane dyes. Next, we will consider the advantages of each type of coloring composition for concrete floors.

Epoxy paint

Epoxy paint is a very strong and durable coating that extends the useful life of the floor and guarantees a presentable appearance. Such paint is quite resistant to external influences and various chemical environments - acids, alkalis, fuels and lubricants, salt solutions, has waterproofing properties, can withstand heavy loads and adheres well to concrete.

Epoxy does not wear off or turn yellow, even if it is used to cover concrete floors in hangars, production workshops, auto repair shops and parking lots. This paint can be used in open areas, as it is resistant to weather conditions, and in enclosed spaces. Another advantage of this paint is the ability to apply it directly to fresh, insufficiently dried concrete.

The main disadvantage of epoxy paint for concrete floors is that it is two-component: it must be mixed before use. Some problems may arise when re-painting. In addition, if you want to change the color of the concrete floor to another, it will be quite difficult to do.

Acrylic paint

Acrylic paint for concrete surfaces is a water-based composition based on acrylic resin with the addition of various polymers. Such paint prevents the destruction of concrete due to corrosion, creates a protective polymer film on the surface that prevents various mechanical and chemical influences.

The coating that is formed by acrylic paint is quite reliable and durable, moisture-resistant and waterproof, so it can be used to paint the floor in the garage, basement, balcony and stairs.

Applying acrylic paint is simple and convenient. This can be done with a brush, rollers or sprayer, and unlike epoxy paint, one coat is sufficient, although two coats can be applied to be sure. Complete drying time is 12-14 hours.

Polyurethane enamel

Polyurethane enamels, as a rule, are two-component, however, this does not in any way affect their high quality. They are designed for finishing concrete floors indoors and outdoors. The advantages of the paint are its high weather resistance, cost-effectiveness, environmental friendliness, high covering power, excellent chemical and mechanical strength, and the formation of a perfectly smooth glossy surface.

Polyurethane enamel is applied at a temperature of at least 5 degrees above zero and air humidity no more than 75%. Since the paint is two-component, first mix the first component thoroughly, and then add the second to it. It is advisable to paint a concrete floor in two stages: apply a thin, uniform layer without spills or smudges, reapply the paint, but no later than 24 hours after the first painting of the concrete floor.

The main disadvantage of polyurethane enamel is the long drying time - 2 - 14 days. Such a significant spread in time can be explained by the following points: the paint does not stick after two days and you can walk on it; after a week, the floor covering finally acquires mechanical resistance, and after two weeks - chemical resistance.

Polyurethane primer

If you do not have paint for a concrete floor, then you can simply prime the surface with a polyurethane compound. The primer can be used as the only protective coating, as well as for treating the coating before the actual application of the finishing paint. Primers are available in polyurethane and epoxy.

Polyurethane primer can provide reliable filling of small concrete pores, dust removal and strengthening, as well as excellent adhesion to the coating. This substance is resistant to gasoline, detergents, chemicals, fats, oils and precipitation.

As the name suggests, polyurethane primer is used before painting with polyurethane enamel, because their compositions are almost identical. However, the paint can only be used 12 hours after finishing the floor priming work. The advantages of this primer are convenience and ease of application, reduced consumption of the finishing coat, and improved adhesion of the finishing layer.

Epoxy primer

Epoxy primer is suitable for treating a concrete surface before applying epoxy paint to it. But it is also common to use this primer as an independent coating, which ensures the closure of all pores and cells in the concrete, as well as dust removal and hardening of the floor surface.

The advantages of epoxy primer are water resistance, water resistance, improved adhesion of the finishing coating, resistance to mechanical wear and chemical agents. Before applying the epoxy primer, the concrete surface must be sanded and debris and dust removed. You should know that within 20-30 minutes the material can lose its qualities, so it must be applied quickly enough.

Painting a concrete floor

You have already become familiar with the purpose of each composition and found out the price of paint for a concrete floor, and also found out which one is best to use for painting a concrete floor. It doesn’t matter what paint you choose for the surface, the technology for applying it is almost always the same. First you need to prepare the base, clearing it of dust and dirt, then prime the concrete surface and fill up all the unevenness, and only after that you can apply paint. Remember that concrete floors are usually coated with the composition in several stages - from 2 to 4 layers.

Surface preparation

The performance properties and durability of a painted concrete floor depend primarily on the quality of surface preparation. First, make sure that there is no dirt, debris, old paint, stains of paints, fuels, lubricants, or bitumen on the floor. Traces of such liquids can be removed using detergents. Water should not collect in drops on a concrete floor.

It is also necessary to remove concrete chips from the floor. After this, you need to seal and fill all existing holes, and then grind them using special grinding machines. This procedure improves the adhesion of the paint layer and the base.

To get rid of dust, you can use a vacuum cleaner or a regular mop. As practice shows, all concrete floors generate dust equally. To prevent this process, it is necessary to remove dust from the concrete coating and treat the top layer. Dust removal is carried out using various polymer compositions that protect the floor not only from the presence of dust, but also from abrasive effects and abrasion.

The concrete surface is strengthened with strengthening impregnations, which are called toppings. These substances are presented in the form of dry mixtures of quartz, cement and other fillers, as well as plasticizers and dyes. Toppings like these can also be used for decorative purposes, giving your concrete floor a glossy, smooth finish.

The composition of the toppings clogs the pores of the concrete floor, preventing the penetration of harmful components into the surface and ensuring the stability and strength of the concrete structure, facilitating operation, which significantly saves money on maintenance of the coating. This product is usually applied to the surface 7 days after its installation. The use of hardening agents will increase the strength and keep the coating free of dust for 5 years.

Concrete floor primer

To ensure high-quality adhesion between the concrete floor and paint, it is recommended to first coat the surface with a primer. There are many varieties of this product (Beolux Aqua, Grida) that can be used outdoors and indoors. These are acrylic quick-drying materials that are quite resistant to oils, gasoline, salt solutions, chemical detergents, mineral compounds and water.

To apply the primer, it is customary to use foam rollers, which allow the composition to be well distributed on the floor surface. Apply the primer like this. The composition is mixed, if necessary diluted to 3% of the mass of the primer itself. It is recommended to add quartz sand to the substance to avoid the slippery floor effect - up to 10% of the primer weight.

The primer must be applied in 1 or 2 layers to a dry, clean surface using rollers, spray or brush. It is recommended to use the composition at a temperature of 5 - 40 degrees above zero and a relative humidity of 85%.

Surface painting

You have already decided how to paint the concrete floor, now you need to decide which tool to use for the job - a roller, brushes or sprayer. The choice of coloring option will depend on what coloring composition was chosen. The paint and varnish product is applied by spray in one layer, which can replace 3 layers that are applied in the usual way. This method of applying paint is quite simple, economical and takes little time.

When using a sprayer, remember that with its help you can treat the main part of the concrete surface, and other hard-to-reach places and corners will have to be painted with an ordinary paint brush. The thickness of the paint is only up to 0.2 millimeters.

Acrylic paints and enamels are applied to the floor surface using rollers. Wide ones that have a short pile are suitable for this - simple facade and velor rollers, which allow you to apply paint evenly and quickly. To make it convenient to work, it is worth securing the rollers on long handles. To paint the corners, use narrow small brushes.

Concrete floors are painted when the surface temperature is not lower than plus 5, the air temperature in the room is not less than 10 degrees above zero and the air humidity is not more than 80%. Water-based polyurethane paint does not emit flammable or odorous substances during operation. Containers and tools are washed with water.

It is allowed to paint fresh or wet concrete, but not earlier than 5 days after pouring. When painting a concrete floor, it is customary to first apply strokes in different directions, then rub the paint over the surface. The layers of paint should not be too thick: thin layers dry faster and look better.

Creating thicker layers results in longer drying times for the coating. Make sure that the previous layer is completely dry, and only then proceed to applying the next layer of paint. Application of the second layer is allowed only after 24 hours.

Drying floors

After the procedure for painting a concrete floor, it is recommended to wait until the coloring composition dries completely. This process should occur at a humidity of 70-80% and an air temperature of plus 18-20 degrees. Only after 3 days are mechanical loads allowed, but if the conditions differ from those presented, then the process of drying the concrete floor may take a longer period, or occur faster.

The drying time of the coating also depends on the conditions under which the paint was applied. For example, if the colorant was applied to fresh concrete, the drying period will increase significantly. Under normal conditions, polymerization of the coating finally occurs approximately on the seventh day, when maximum mechanical and chemical resistance is achieved. Therefore, do not rush to use the surface as quickly as possible, let it dry completely so that it acquires proper wear resistance.

Thus, concrete paint can increase the strength of the coating, protect it from dust and increase the waterproofing of the screed. But all this is achievable only if you make the right choice of coloring composition. In addition, the consistency and competent execution of all stages of painting a concrete floor is of great importance.

Silicone paints

Silicone paint is often called “liquid glass”. This name most accurately reflects the characteristics of the composition: after curing, a smooth, durable, hard coating is obtained. The paint consists of a water emulsion, silicone (organosilicon) resins, modifiers, and coloring pigments. This paint is rarely used to cover floors in industrial premises. And in cases where water may appear on the floor. Water on a smooth and hard surface makes it slippery. And this is contrary to safety regulations.

Advantages of silicone paints:

- Coating strength

- Excellent adhesion to concrete,

- Excellent moisture resistance,

- Vapor permeability

- Durability of the coating

- Inertness to chemicals,

- Heat resistance,

- Easy to clean due to high smoothness.

Disadvantages of silicone paint

- High price,

- Poorly protects metal from corrosion,

- Long drying time.

Popular primer compositions

Among the primers that are in demand in the building materials market are primer compositions of the following brands:

- Ceresit CT 17. universal impregnating composition of deep penetration. Maintains the permeability of the surface layer. Adding a coloring pigment to the composition simplifies the application of the primer.

- Knauf Tiefengrud. A universal primer with high penetrating ability. Designed for impregnation of super-hygroscopic materials.

- Knauf Concrete contact. The primer is a polymer dispersion with pink quartz sand. The product is ready to use. Designed for coating poorly absorbent substrates.

Different dyes may have specific applications. Therefore, before painting, you must read the instructions and follow the manufacturer’s recommendations.

Polyurethane paints

Polyurethane paints come in one- and two-component types. Single-component ones are usually produced as water-dispersed ones. Two-component – based on organic solvents. The main components of paints are polymers (polyols) and modifiers. Single-component ones are recommended for indoor use. The paint will show its best qualities in rooms with high traffic volumes, in offices and light industries. Two-component coatings, as a rule, provide a more durable coating and can be used both indoors and outdoors. For painting floors in production workshops, warehouses and retail premises, car washes and car service centers, it is better to use two-component polyurethane paints. Toluene or xylene is used as a solvent for two-component paints. For one-component products - water.

Advantages of polyurethane paints:

- Strength and wear resistance,

- Moisture resistance,

- Resistance to chemicals,

- Wide operating temperature range.

Disadvantages of polyurethane paints:

- High price,

- Toxicity upon application (for paints with organic solvents),

- Long drying time.

Why paint concrete?

Most often, the concrete screed is protected with a layer of decorative material, for example, ceramic tiles or laminate. But in utility or industrial premises such protection is not effective or its installation is impractical from a cost point of view.

Therefore, to protect surfaces from physical and chemical influences in garages or sheds, concrete floors are painted.

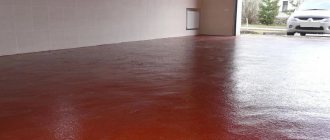

Painting a concrete floor will not only strengthen the surface, but also improve the appearance of the room.

But is it really important to protect concrete? Cement-based screed is quite durable, but has a porous structure. If you do not cover the top layer of the coating, then over time the screed will begin to deteriorate and lose its integrity.

The destruction process is due to the fact that the hardened cement mortar has:

- Porous structure in the mass. Concrete absorbs any water from the surface or from the air in the room. As a result of temperature changes, the water in the pores will change volume and destroy the screed from the inside.

- Low resistance to weight and physical impacts on surfaces. As a result of such loads, the concrete delaminates and becomes dusty.

On a note! The lower the grade of cement used when mixing the concrete mortar, the less resistant to destructive influences the screed surface will be.

Without proper protection, the concrete surface will begin to delaminate and collapse over time.

Benefits of using paint

As already mentioned, any concrete surface requires external protection. But, as a rule, durable and stable decorative materials have a fairly high cost.

Painting concrete is the most economical protection solution, because it preserves the strength characteristics of concrete and performs the following necessary functions:

- provides an increase in the strength of the screed and, as a result, extends the service life of the coating;

- minimizes the possibility of delamination or cracking;

- protects the concrete screed from abrasion;

- establishes a barrier against the effects of chemically active substances;

- increases the antistatic characteristics of concrete.

Special additives will make the concrete floor not only beautiful, but also safe.

When choosing what paint to paint a concrete floor, you can solve some other operational issues:

- make the surface non-slip, reducing the risk of possible injury;

- simplify the process of maintaining and cleaning the floor;

- To make the room more comfortable, modern paints have a very rich color palette.

On a note! Different paints and varnishes require different conditions for application. Before use, carefully study the manufacturer's recommendations. Instructions for use are always indicated on the label.

Why does dust and other defects appear?

Under the influence of mechanical loads, small particles are constantly separated from the floor surface. They form concrete dust, which poses a danger to the respiratory system and human health.

The most common causes of dust and other defects are:

- the use of low-quality materials or the wrong brand of cement;

- non-compliance with concrete pouring technology;

- violation of proportions when mixing concrete mass.

These factors lead to the fact that tiny particles of cement powder remain in the porous structure of hardened concrete, which do not have time to react with water. They penetrate into the environment and turn into dust.

Due to mechanical loads, particles are separated from the floor, which are subsequently formed into concrete dust.

The top layer of concrete can be destroyed under the influence of high humidity and low air temperature, aggressive fuels and lubricants and other auto chemicals, and intensive use of the premises (daily driving in and out of the car).

To increase the strength of the surface, prevent the appearance of dust and give the garage an attractive appearance, it is recommended to treat the concrete floor with paint or primer.

Sealing joints on concrete bases

The protection of mineral coatings consists not only of additional surface treatment with reinforcing compounds, but also of sealing the seams. Special mixtures help prevent moisture from entering vulnerable areas of the structure, which has a beneficial effect on the service life of the entire floor. What is a sealant and why is it needed?

Sealants help prevent moisture from entering vulnerable areas of the structure.

Sealant is a protective liquid composition with water-repellent properties, which is used to seal seams on mineral substrates. It may contain various components that affect the technical characteristics of the mixture. The greatest demand is for rubber and polyurethane sealants, the water absorption coefficient of which does not reach 1.5%.

For what purposes are polyurethane and rubber sealants used?

- Sealing microcracks and seams on mineral coatings;

- Installation of expansion joints in the coating;

- Sealing joints formed as a result of vibrations.

Rubber joint coating is an indispensable assistant when repairing concrete floors outdoors. The hardened sealant practically does not allow moisture to pass through and prevents the appearance of fungus at the joints.