According to the technology, linoleum should be laid on an adhesive layer, which ensures reliable fixation of the coating to the floor. Since linoleum can be different, the appropriate glue must be used in each specific case, otherwise a high-quality result will not work.

Adhesive for linoleum

What types of glue exist, how to choose the right composition, and is it possible to do without gluing the canvas to the surface?

Is it worth gluing

There are three ways to lay flooring:

- gluing to compounds offered in stores;

- flooring with the canvas secured with skirting boards;

- fastening with construction double-sided tape.

It is recommended to fix linoleum with glue if the room size is more than 20 square meters. Long-term guarantees are issued for glued materials. Felt material is also offered in a wide range.

It is necessary to glue the canvas if the room has large furniture that moves frequently. This will eliminate the risk of deformation of the floor covering. Thanks to gluing, the wear of the material can be minimized, so it will last longer. Even non-professionals can do this.

During the off-season, linoleum can stretch or shrink as it is affected by sudden changes in temperature and high levels of humidity. You can avoid such troubles if you attach the linoleum with glue.

It is necessary to apply glue at the joints of the panels, covering every centimeter. These areas need a strong connection, otherwise they will begin to lag.

Common mistakes when gluing

Incorrect gluing leads to poor-quality repairs. If the master does not follow the work algorithm, he has to figure out why the linoleum moves in waves and does not stay in place.

There are several reasons. This may be a poor-quality composition that no longer provides strong adhesion. Other problems may arise due to the fact that the surface was not properly cleaned before gluing. Any dirt or dust impairs adhesion and prevents the materials from bonding tightly.

Masters advise following these working rules:

- you need to work in rubber or latex gloves;

- it is advisable to use a mask or respirator;

- the adhesive seam must be uniform;

- there is no need to quickly remove excess - it is better to wait for the seam to dry completely so that it does not peel off;

- Having chosen the cold welding method, you need to make sure that the composition is driven deep into the seam.

Installation methods

This material is soft and flexible. To properly glue linoleum, you need to focus on what kind of floor in the room. If you don’t know what to glue linoleum to, then read the important information.

To achieve effective results, the basis must be:

- Durable: individual pieces of concrete or peeling wood floorboards must be excluded;

- Dry: if the base is wet, it is impossible to carry out the work efficiently;

- Smooth: differences and unevenness will be visible on the finished floor surface;

- Clean: if there is debris under the linoleum, the appearance of the floor will suffer.

PVC products can be laid on various substrates if they meet the basic requirements. To glue linoleum efficiently, the room temperature must exceed 18 degrees, and the air humidity level must be up to 70%, but no more.

If you are carrying out renovation work in winter, then let the rolls lie in the room for several days so that they adapt to the conditions.

Recommendations for choosing and using glue

So, the main criterion when choosing an adhesive is the type of subfloor. Absorbent and non-absorbent substrates use different formulations, and if you use the wrong adhesive, a strong bond will not work. Absorbent surfaces include cement and concrete screed, solid wood, plywood flooring, chipboard, fiberboard, OSB.

Wood is a highly absorbent surface

Linoleum is glued to them with water-soluble compounds, but this also has its own nuances. Board materials such as plywood, fiberboard and others can become deformed from excess moisture, so for them you need to choose thick adhesive mixtures with a minimum water content. For a concrete floor, the consistency of the glue is not particularly important.

If the floor is concrete, the consistency of the glue can be any

Floors lined with natural stone, porcelain stoneware, and tiles are considered non-absorbent. Here, water-soluble compounds will be ineffective, since there is nowhere for moisture to escape, and high-quality adhesion between surfaces will not work. For such bases, reaction adhesives are used, when applying which it is necessary to take precautions - use protective gloves and masks, ventilate the room.

If the floor has tiles, it is better to use reaction adhesive

You need to buy glue along with or after linoleum to make sure that the composition is suitable for this particular coating. The glue packaging always indicates what types of linoleum it is suitable for and what the coating base should be. Be sure to check the expiration date, because expired glue will not hold the canvas. It is best to buy adhesive compositions in construction supermarkets or large stores where there are conditions for proper storage of such materials. This is especially true for water-soluble adhesives, which completely lose their adhesive properties after freezing. The exception is special dispersions with frost-resistant additives: they can withstand 3 to 5 cycles of freezing and thawing without losing their basic characteristics.

Universal adhesive fixer for linoleum and carpet Axton

Information about the glue is always on the packaging

This is what linoleum glue looks like

In order not to overpay, before purchasing you should calculate the required amount of glue. To do this, you first need to take measurements of the room and calculate the total coverage area. As a rule, consumption varies between 200-500 g per m2 (this is influenced by the type of working surface and coating base). For example, a fabric or felt base requires more glue than foam and rubber, and a plank floor requires more than a concrete screed.

To reduce glue consumption, it is recommended to prime the floor. Glue should be purchased with a small supply so that you do not have to interrupt installation and go back to the store.

Primer concrete-contact

Acrylic primer for wood floors

The photo shows the process of priming a wooden floor under linoleum

Advice. You cannot mix glue of different brands, even if the name of the composition is the same. Each manufacturer has its own manufacturing technology, so the compositions may differ in the number of components, drying time, peel strength and other characteristics.

Linoleum and glue must be kept in the room where the covering will be laid for at least 24 hours. Work should be carried out at a temperature not lower than 15°C and air humidity not higher than 75%. In this case, the humidity of the floor base should not exceed 8% for wood and 2% for screed.

Let the linoleum sit at room temperature for 24 hours

Immediately after applying the glue, you cannot lay linoleum; you need to let the composition dry a little for 5-10 minutes (the exact drying time is indicated on the packaging). Also, you should not apply glue in a thick layer: this will not make the fabric stick better, and excess glue will appear as thickenings and bumps on the surface of the linoleum.

How to glue correctly: step-by-step instructions

So, when you're ready to start laying linoleum, follow these simple tips.

Preparing the base floor

If you are gluing the material to concrete, then preparing the base involves checking for unevenness. If they are, then you need to eliminate them using a cement mixture or putty. In the case of wooden flooring, it is necessary to strengthen creaking boards and eliminate differences in the plane. You need to get rid of traces of old paint and varnish coatings, because they will not allow the canvas to adhere well to the surface. This way you can install the material correctly.

Linoleum fitting

To adjust the material to the size of the room, special knives are used. You can also use a stationery knife, but the work process is slightly more complicated. Bend the linoleum slightly along the wall and leave a mark on its reverse side. The calculation must be carried out so that there is a gap of 3 mm between the wall surface and the material. Leave the same marks every 20 cm. Using a ruler, connect these marks and cut a neat, even strip.

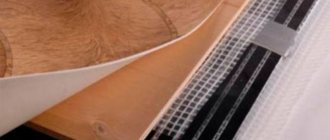

Gluing

You can glue the coating with glue or double-sided tape if we are talking about an area of more than 20 square meters. Most often, a variety of adhesive compositions are used. It is necessary to carefully lubricate the floor surface with the selected glue using a spatula. After this, the canvas is pressed against it and carefully smoothed. You need to go over every square centimeter to get rid of the air under the coating, because otherwise it will not be securely fixed.

How to glue the edge

The appearance of the surface will deteriorate if the edges and seams are poorly glued. To glue the edges, you should use bustylate. Such a composition that gets on the material cannot spoil the coating, because it is transparent.

Apply bustilate to the floor, bending the edge of the linoleum. Press the edge butt together and smooth it out to get rid of any air. Place a weight on top to secure the material. After the bustilate has dried, attach the threshold strip or install the baseboard.

You can fix the joints if you use adhesive compounds that cause chemical reactions. Cold welding can be used to seal seams. One tube allows you to treat a considerable amount of territory. This sealant is very beneficial. If there is a substrate, it will be additionally insulated.

This technology is simple and understandable. Painting tape is attached to the joint and cut along the seam. After this, the glue is squeezed out along the joint and wait until it hardens. Then the strip is removed along with the remaining product.

Types and characteristics of glue

The choice of adhesive depends on the surface on which the installation is being made and the type of coating itself. At the moment, linoleum adhesives are presented in dispersion and reaction compositions.

Dispersive

This type includes water-soluble compounds containing cellulose acid, acrylic, latex, rubber, chalk. They are the safest for health, do not emit a smell, and have good elasticity. They are used for natural and PVC linoleum on different types of bases - felt, fabric and foam.

Adhesive for commercial and semi-commercial linoleum, water-dispersion

The presence of water in the composition causes some restrictions: dispersion adhesive can only be applied to an absorbent base, in dry rooms where the temperature does not fall below 15°C and the humidity does not exceed 60%. The adhesive layer must not be allowed to freeze, as this will cause the material to lose its elasticity and begin to crumble.

Special water-dispersion adhesive for PVC coatings

The group of dispersion adhesives includes:

- acrylate glue - a mixture based on acrylic resin. It is characterized by high adhesion and viscosity, which ensures excellent adhesion of the coating to the floor. Can be used for homogeneous and heterogeneous linoleum with jute and synthetic base;

- Bustilate is a synthetic water-soluble composition with latex, chalk and cellulose thickener. It has high tear strength and elasticity, best suited for thick linoleum on a dense felt base;

- humilax – the composition is based on a mixture of rubber and latex, thanks to which the adhesive is easy to apply, has high elasticity and adhesion to various types of surfaces. Suitable for natural and synthetic linoleum with felt and fabric backing.

Dispersion adhesive for natural linoleum

Reactionary

This type combines two-component compositions containing polymers and epoxy resin. Bonding of surfaces occurs as a result of a chemical reaction, which is caused by mixing the components. This type of glue contains a solvent, therefore it has a pungent odor and is a flammable substance. The advantage of such compositions is the absence of shrinkage, plasticity and resistance to moisture, and they are used mainly for sealing joints between sheets and repairing damage.

Two-component epoxy-polyurethane adhesive for linoleum

Three types of two-component glue are available, differing in their consistency:

- type A is the most liquid, used for all types of linoleum on a rigid basis. It is used to seal joints when laying a new coating, as it forms an almost invisible, but very strong seam. It takes about an hour to fully cure;

- type C - a viscous transparent composition, used for sealing open seams on used flooring. Capable of closing gaps up to 4 mm;

- type T - paste-like composition for fastening seams on PVC linoleum with a polyester base. Intended for professional use, so it is rarely used by home craftsmen.

Advice. When applying these compounds, you must do everything very carefully, because glue that accidentally gets on the canvas will melt the top layer of the coating and leave a noticeable mark.

Popular brands of adhesives for linoleum

| Name | Main characteristics |

EXPERT Glue Bustilat | Suitable for gluing artificial surfaces to concrete, wooden floors, chipboard, OSB. Used for PVC linoleum on a jute base and felt. Consumption per meter of area is 500-600 g with continuous application, dries within 24 hours at a temperature of 20 ° C |

PVA glue “Universal” | Thick composition with the addition of latex. It has a wide range of applications, suitable for felt-based linoleum when laid on chipboard, OSB, wood, and concrete screed. Consumption per square meter is 200-500 g. Drying takes 24 hours at a temperature of 18-20°C |

Clay Polynom 105 | Acrylic composition for all types of linoleum, regardless of the base. Can be used on any surface. Consumption for continuous application is about 300-400 g/m2, drying time is at least 12 hours |

Homakoll 208 glue | Viscous polymer composition for roll coverings on fabric, pile and foam bases. Used only on moisture-absorbing surfaces - concrete and cement screed, plank floors, chipboard, OSB. Consumption for continuous application is 300-500 g/m2 |

Thomsit L 240 D glue | Acrylic paste composition intended for gluing natural linoleum to absorbent substrates. Can be used on heated floors. When applied continuously, the consumption is 450 g/m2, complete drying time is 72 hours |

Frost-resistant adhesive for natural linoleum

Features of gluing to a wooden floor

It is recommended to purchase flooring according to the size of the room. This will avoid making unnecessary seams. Immediately before gluing, it is necessary to trim the linoleum around the perimeter of the room, taking into account all the architectural features.

- The floor must be clean, dry and perfectly level.

- Spread the glue evenly with a spatula, first on the floor and then on the linoleum base.

- If gluing is to be done end-to-end, add additional adhesive tape to the seam.

The procedure for gluing linoleum is similar to the same process for concrete. No matter how carefully you try, glue may accidentally end up on the surface.

If it has time, it will dry out and be difficult to remove. A fresh stain can be easily removed with a soap solution.

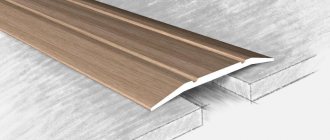

Overhead connection

Joining linoleum at home can be done using overhead thresholds. They have an affordable price, they are easy to choose by color and composition (plastic and metal products are found). The thresholds have ready-made holes for self-tapping screws. The connection is reliable and durable.

The process consists of several stages:

- Using a jigsaw or a metal file, cut the strip to the required length and apply it to the joint of the linoleum. Holding the threshold, mark the exit points of the screws.

- A 6mm drill is inserted into the drill and holes are made according to the markings. Dowels must be inserted into them immediately.

- The threshold is applied to the surface and secured with self-tapping screws.

USEFUL INFORMATION: 3D floors in the bathroom and toilet: 9 photos, price, technology

This method of joining the edges of linoleum is simple, but has its own peculiarity. The strip screwed to the floor stands out noticeably above the surface, so such a threshold looks good only in interior openings.

Summarize

Based on the results of the article, we can conclude that it is possible to glue new linoleum over the old one, and you can do this on your own without the involvement of specialists. Now you know how to glue one canvas to another, and that there are adhesive compounds that can harm a person.

But in order to get a high-quality result of your installation work, it is important to choose the right adhesive composition, which is primarily responsible for the long-lasting service of the coating. If you don’t know which glue to choose, you can always turn this question to a specialist who will definitely advise the right option, because not every composition is capable of providing high adhesion to a particular base.

We hope that our article and detailed instructions about the process of installing a new coating over the old one will be useful to you, and you will get a high-quality result and new linoleum for a long time.

Required Tools

Whether it is necessary to glue linoleum - each owner decides based on personal considerations and the technical characteristics of the room. Based on this decision, the foundation will be prepared. To conveniently lay and properly glue linoleum, the master will need a number of the following tools:

- roulette;

- masking tape (and double-sided);

Styling tools - marker;

- knife;

- notched spatula;

- long screws;

- belt grinder;

- dense rubber roller;

- scissors large and small;

- metal ruler;

- glue and rubber gloves (respiratory mask).

Particular attention should be paid to the glue: the entire result of the repair will depend on it. To decide what is better for gluing linoleum, you need to pay attention to the type of material and type of floor.

Watch the video to know about the tools: