The main condition for a high-quality floor covering is a flat base. Laminate is a material that especially requires this. Changes in height can reduce its durability by more than half. How to level the floor in an apartment under laminate - today we are talking about this in this article

The main condition for a high-quality floor covering is a flat base. Laminate is a material that especially requires this. Changes in height can reduce its durability by more than half. How to level the floor in an apartment under laminate - today we are talking about this.

About using plywood flooring

Natural wood is widely used in construction for the manufacture of floors. It has good thermal insulation, a pleasant-to-touch surface, and creates a cozy, warm environment in the house. However, over the years, such a coating loses its attractiveness - the boards dry out, begin to sag and creak. There are ways to renew wood flooring, but often it fails and the wood floor needs to be completely replaced.

If you need to lay laminate or parquet instead of an old floor, it becomes necessary to prepare a high-quality substrate. Modern floor coverings are extremely demanding on the surface, and an uneven wooden covering is not suitable, even if it is well preserved. But if the wood floor is still in good condition, you can lay a subfloor made of plywood sheets over it. This substrate is distinguished by the quality of the resulting surface, speed of installation and low cost.

A wooden floor can retain sufficient strength, but be visually unattractive Source bricoleurdudimanche.com

Plywood is a material made by pressing together an odd number of sheets of rotary-cut veneer. The veneer is made on a special peeling machine. Adjacent sheets are laid in a mutually perpendicular direction, which ensures high physical and mechanical properties of plywood. The material is used in construction, furniture production, carpentry and carpentry. Plywood is often chosen as a substrate for parquet, linoleum or laminate due to a number of advantages:

- The plywood backing provides a smooth surface.

- Large sheet area ensures quick installation.

- Plywood sheets have high strength, wear resistance, and load resistance.

- The subfloor extends the life of the underlying floor covering.

- Creating a plywood backing does not require large financial costs.

You can lay flooring on multilayer plywood Source fanerasnab.ru

Why choose plywood

Plywood - flooring material

Plywood is a durable, multi-layer wood material. Due to its affordable price and excellent technical characteristics, it is often used in construction.

This material is chosen as a subfloor due to many factors. Plywood has an affordable price per m2, it fits well without additional time and money spent on leveling the floor. Due to the arrangement of fibers in different directions, it is a fairly durable material. It can be used not only to obtain a flat floor, but also to make minor repairs to eliminate flaws and defects.

Which variety to choose

To determine which plywood to choose for your floor, you should consider the existing varieties. Plywood is classified according to the following criteria:

- According to wood material

Plywood can be made from softwood and hardwood. Hardwood material has higher mechanical properties, but is also more expensive

- By moisture resistance

Moisture resistance directly depends on the adhesive composition used in plywood. For example, FBA plywood uses natural albumin-casein glue, so it is resistant to moisture. FSF plywood contains formaldehyde glue, which ensures high moisture resistance

- By defects

Based on the presence of knots, wormholes, curls, etc. in the veneer, 4 grades of plywood are distinguished. Grade I is the highest quality and most expensive, grade IV has a large number of defects

- For surface grinding

Plywood can be sanded on both sides (Sh2), sanded on one side (Sh1) or unsanded (NS)

- By number of layers

There are three-, four-, five-layer and multi-layer plywood

There are many varieties of material Source amazonaws.com

To determine which plywood is best to lay on the floor, you need to know the conditions of its use. The room where the subfloor will be laid must be heated. Temperature changes are allowed within 16-28 °C. The relative humidity in the room should be within 60%.

If you plan to make a substrate in rooms with low humidity levels (bedroom, living room, hall), you should use FBA plywood, as this is the most environmentally friendly material. In rooms with humid air, it is better to use moisture-resistant varieties - FK or FSF.

A typical solution to the question of which plywood is best for the floor is to use birch plywood Ш1 or Ш2 grade II or III with a thickness of 10-22 mm. This solution combines a fairly high quality surface combined with an acceptable cost.

It must be said that the thickness of the plywood should be 2-3 times thicker than the final floor covering. Using thick plywood will provide greater rigidity to the subfloor, but working with such material will be inconvenient. In addition, the price of plywood will be higher.

Mid-price plywood is suitable for the substrate Source remontnik.ru

How to buy plywood correctly?

Plywood of different thicknesses

When purchasing plywood used for leveling, you should take into account the following parameters:

- Brand;

- Class;

- Variety;

- Thickness;

- Manufacturer of the material.

Depending on the type of premises, preference should be given to different brands. For residential premises, preference should be given to the FC or FSF brands. This plywood is safe because it contains no phenolic compounds. For wet rooms, it is preferable to choose FSF brands. This plywood is moisture-resistant and resistant to mechanical stress.

Differences in plywood grades

The grade of plywood indicates the level of release of free formaldehyde particles into the air. There are two classes:

- E1 contains 10 mg of formaldehyde per 100 g of wood material;

- E2 contains 30 mg of formaldehyde per 100 g of wood material.

For living rooms it is preferable to buy E1.

Plywood is produced in 4 grades. Grade 1 material is high-quality plywood. The fourth grade is a material with a large number of flaws, chips and knots. Professional craftsmen recommend using grade 3 and 4 plywood for rough flooring. For the main floor, grades 1 and 2 are preferable.

Varieties and classification

The thickness of the material is selected depending on the leveling method, the curvature of the floor and the coating laid on top. Creating a subfloor for laying linoleum and carpet allows you to choose a material up to 10 mm thick. Under laminate or parquet, a plywood thickness of at least 12 mm is required to level the floor.

When choosing the thickness of plywood for the floor under linoleum, be guided by these indicators. If you choose the wrong thickness, the sound insulation will decrease and the floor will quickly become unusable.

The manufacturer determines the quality of the plywood. European manufacturers guarantee excellent quality of the produced material. But Chinese-made sheets do not always meet consumer requirements.

Floor leveling scheme

Also, plywood can have a sanded or unsanded side. If it is used as a subfloor, then it is laid so that there is a surface at the top without sanding. This will ensure good contact with the finishing material.

When using plywood as a finished floor, the top layer must be sanded for subsequent opening with varnish.

Before installation

It must be remembered that plywood sheets can be laid in a relatively dry room. Before laying plywood on the floor, you should check that the humidity conditions are suitable for installation. To do this, a sheet of polyethylene with dimensions of 100x100 cm is laid on the floor, its edges are pressed tightly, and the polyethylene is left for 2-3 days. If after 2-3 days no drops of vapor appear on the polyethylene, the room is dry and you can lay a rough covering of plywood.

The next stage of preparation is to determine the condition of the old wooden covering. It is necessary to check whether there are any deflections, creaks, or whether the floorboards are rotten. Loose areas need to be strengthened, damaged areas need to be replaced. This stage should not be neglected, since the quality of the future coating will depend on the strength of the wooden base.

After restoring the old floor, you need to check the height difference using a building level. The smoother the old covering is, the denser the plywood sheets will lie on it and the more reliable and durable the final floor covering will be. Therefore, you need to use the rule to determine the protruding areas of wooden boards and level them with a plane.

Leveling the floor before laying Source ironflex.ru

Before installation, you need to remove the baseboards, adjust the length of the door leaf and door jamb taking into account the calculated floor level. The prepared old floor must be cleared of debris. If desired, you can coat the surface with antiseptic primer or fire protection. In this case, it is necessary to dry the base for 2-3 days.

Before laying plywood on the floor, you need to prepare it. The plywood sheets should be brought into the room where they will be laid and left in an upright position. If there is enough time, it is better to let it sit for 5-7 days. During this time, the material will “get used” to the conditions and will not expand much in the future due to temperature changes. After drying, it is recommended to soak the plywood with antiseptics and water-repellent agents and ventilate it.

Impregnations increase moisture resistance Source neoplus.spb.ru

After all the manipulations, you need to bring the plywood sheets into the room where the installation will take place, lay them out horizontally and leave them for another 3-4 days. A long preliminary stage is necessary, since the place where the plywood was stored before purchase may differ greatly in conditions from the room where the plywood will be laid. Due to a sharp change in temperature and humidity, the sheets will begin to evaporate or absorb moisture and change their size. Laying such plywood is highly not recommended, because the quality of work can be greatly affected as a result of thermal expansion of the sheets.

Preparing for leveling

Let's find out the condition of the floor Before starting restoration work, you should analyze the condition of the old floor.

This analysis is not difficult to do: several floorboards are lifted and the foundation joists are checked. If their surface is dry and strong, without visible signs of damage, then you can start working.

But often defects, rotting and cracks are found on the logs themselves and on the inside of the boards covering them. Such problem areas need to be replaced.

Sometimes the base is damaged by insects to such an extent that the wood looks more like dust. In this case, the entire ceiling will have to be replaced. Fortunately, such situations are quite rare.

We identify deviations

The next stage is to determine the deviation of the wooden covering from the horizontal plane. To do this, you will need the most accurate level (preferably a laser), which is placed at the highest corner of the room. Marks are applied to all walls to help you choose the most suitable alignment method.

Defining the alignment method

There are several of them. These include alignment:

- scraping;

- plywood;

- putty with filler containing PVA glue;

- specially prepared mixtures for this purpose.

Choosing a installation method

There are 2 main ways to properly lay plywood on a wooden floor:

- Laying on an old wooden base

The method is used if the horizontal difference of the old base is less than 1 cm, and also if it has sufficient strength. This method is simple, but can be used only in limited cases, since the difference in the old floor is often more than 1 cm

Laying over old coating Source chudopol.ru

See also: Catalog of companies that specialize in home renovation

- Laying on joists

If the difference in height of the old base is significant, plywood is laid on logs made of timber. This method is longer and more labor-intensive, but it allows you to deal with significant horizontal differences and damage to the base. Can also be used if the old floor has failed and cannot serve as a solid base for a plywood underlay

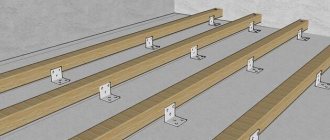

Laying on pre-prepared joists Source slavasozidatelyam.ru

Next, we’ll take a closer look at which method to choose in a particular case and how to properly lay plywood on the floor.

Installing plywood on concrete

Installation of plywood on a concrete floor is done using glue and dowels, which is what professionals recommend, but some use only dowels.

Fastening plywood to concrete using glue and dowels:

- To attach the plywood, you will need a partner, because this work certainly cannot be done alone. Apply glue to the floor surface and remove excess with a comb.

- After the glue has cooled to a consistency similar to a putty solution, place a sheet of plywood on top.

- Using a pobedit-tipped drill bit, drill holes through the plywood into the concrete at a distance of 30-40 cm.

- Insert the dowels to a depth of 3-4 cm. If the screed is made of high quality from reliable materials, then you can save money at this stage, but if you are fixing plywood on a low-quality screed, then you should use more expensive dowels with spacers. Carefully recess the heads of the dowel nails so that they do not stick out. Fasten the corners first, and then the entire surface of the slab.

- The next slab should be laid leaving a small gap. To do this, you can use thin (2-3 mm) cardboard. Level the bottom edges of the slabs with a level, straight edge or straight stick so that later when laying the remaining slabs there will be no problems.

- Sew up the cracks in the walls, leaving a gap.

At this point, the installation of plywood on concrete is completed, and you can see an example of the work performed in the photo.

The first method is laying on the old coating

If the wooden floor in the house remains in good condition and does not have major defects or flaws, but you need to lay a new floor covering, then laying a subfloor made of plywood on the existing wooden floor is the best solution. It is important that the old coating is fairly even: the height difference should not exceed 1 cm. This installation method is demanding on the surface, so it is necessary to prepare the wooden floor by renewing defective old boards and leveling the surface.

For ease of work, pre-dried plywood sheets can be sawed into squares measuring 60x60 cm. If plywood is laid in a room with a large area, you don’t have to cut the sheets into squares, but sawing allows you to identify possible delaminations in the middle of the sheet that are not noticeable from the outside. It is better not to use plywood with delaminations for subflooring.

For large premises, it is permissible not to cut sheets Source couo.ru

After preparing the old wooden floor and plywood sheets for the new one, the installation process begins, consisting of several successive steps:

- Marking

The sheets are laid out on the base so that adjacent rows are offset from one another by approximately one-third of the width of the sheet. Protrusions, niches, etc. are marked on the sheets.

Lay out sheets prepared for marking Source parket-sales.ru

- Sawing

According to the markings made, recesses are cut out in the plywood. Sheets are cut so that the number of seams is minimal

Cutting plywood with a circular saw Source pinimg.com

- Laying the substrate

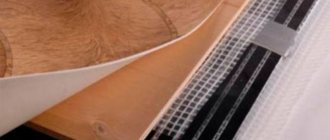

To smooth out minor unevenness in the floor, you can lay a polyisol backing between the plywood and the boards. It consists of polystyrene granules enclosed between two layers of film. In addition to smoothing out unevenness, the underlay provides sound insulation and also removes moisture from the plywood flooring. Polyizol is spread on a wooden base, the seams are taped

Polyizol can be laid not only under laminate, but also under plywood sheets Source stroyday.ru

Evaluation of the base for laminate

An apartment floor always requires the presence of a concrete slab and screed. Often the subfloor is also logs with boards. Under the laminate, any base needs to be leveled. Let's look at the problems with each:

Wooden floor

Old logs under constant pressure and interaction with a humid and aggressive environment become deformed. Temperature changes and passage activity cause cracks, shifts, and fractures.

Often the wood rots. Before leveling the floors for laminate, a radical replacement of the beams with new ones is required.

The boards similarly deteriorate and become humpbacked, which affects the floor level. Gaps form at the joints between them. It is prohibited to lay laminate flooring on a defective floor. Pressure on the lamellas in void areas is fraught with loss of the sealed connection and, as a result, fracture of the expensive material.

Concrete screed

Over time, rough cement floors will stain. Potholes appear and the surface becomes damp. If the damage to the screed is more than 10% of the total floor area, a new one with a finishing leveling layer must be installed.

It is not recommended to lay parquet on bare concrete - plywood will act as a layer. It will provide additional thermal insulation.

A variation of the first method - laying on adhesive compounds

Sometimes the surface of the old coating is almost perfectly smooth. It will still not be possible to lay laminate on such a floor, but it is possible to replace the hardware with adhesive compounds. For gluing plywood sheets, water-based glue, mastic, assembly adhesive, bustilate, and liquid nails can be used.

Example of glue used Source eco-stroycity.ru

The second method is laying on logs

If the height difference on an old wooden floor is more than 1 cm, you need to lay the plywood in a second, more labor-intensive way. This method is also suitable if the old coating has become unusable and needs to be removed. The essence of the method is to lay plywood sheets on wooden supports, the so-called logs, which serve as the basis for the subfloor instead of the old coating that has become unusable. The logs are wooden blocks with a cross section of 40x40 or 50x50 mm and a length of 1.5-2 m.

Before installation, be sure to check the relative humidity in the room to decide which plywood to use for the joist floor. It is optimal to use environmentally friendly types of plywood - FC and FBA, but they can only be used in rooms with a relative humidity of no more than 60%.

Installing joists instead of a removed wooden floor Source pol-spec.ru

Before installation, it is necessary to inspect the old floor and replace damaged boards. After preparing the base, the process of installing the logs and laying the rough coating begins:

- Marking

The process begins almost the same as in the first method. In addition to the protrusions and niches, the joints of the sheets are marked. This is necessary in order to subsequently install the lag exactly in the place of the future seam. Otherwise, the edge of the sheet may “hang in the air”

- Sawing

This stage is no different from the previous method. Sawing is carried out according to the applied markings

- Installation of logs

Installing joists is the most critical stage, since the quality of the entire floor depends on their correct installation. Beams begin to be laid from the highest point of the floor, which is located using a building level. The logs are attached one by one to the base with self-tapping screws. In sagging areas, place bosses of the required height from fiberboard or timber. After installing all the beams, for greater structural rigidity, it is permissible to lay the second row perpendicular to the first.

You can install 1 row of logs Source pol-spec.ru

Or 2 rows of joists Source blog-potolok.ru

The frequency of installation of the bars determines what thickness of plywood to use for the floor along the joists. The more often the bars are installed, the thinner the sheets can be. It is recommended to install logs at intervals of 40-50 cm.

The main task when installing joists is to ensure that the upper ribs of all beams lie in the same horizontal plane. This is achieved by constantly checking the installed bars with a level and using a laser level

- Laying insulating materials

If necessary, sound and heat insulation is placed in the space between the joists. Communications can also be laid in this layer. It makes no sense to install heated floors under plywood, since it has poor thermal conductivity and retains temperature well without additional materials.

Communications can be installed under the subfloor Source archiq.ru

The third way to level a wooden floor

The third method is puttying with PVA glue and sawdust. It is very easy to use, but takes quite a lot of time. To do this, you need to take sawdust from wood, PVA glue, wooden guides, a spatula with a width of 300 millimeters, and an installation level. Next, we recommend following the step-by-step instructions.

Putty with PVA glue and sawdust

- Installation of guides. After determining the level of the future floor, we set the guides with a distance between them of 30 centimeters over the entire floor area. You need to start from the side where the floor has less deviation from the level. At the same time, we install guides around the entire perimeter of the room.

- Surface treatment with primer. Initially, the surface should be treated with a primer. The composition is applied using a brush.

- Making putty mixture. You need to add sawdust to the PVA glue. You need to add until you get a substance with a creamy consistency. You can mix it using a construction mixer.

- Applying the composition to the surface. The mixture should be applied no more than a centimeter thick, as it will shrink. After applying the first layer, you must wait for it to dry completely. Then we apply the next layer and so on until the required height of the applied putty is achieved;

- Laying plywood or fiberboard. When the putty is completely dry, you need to put thin plywood or fiberboard on top of it. These sheets are attached to the guides with screws or nails. It is also worth initially deciding what you will use to cover the putty floor. This is necessary so that the joints between the sheets fall exactly on the guides.

Video description

This video clearly shows the process of installing joists instead of the old floor that was removed:

The main thing to remember is that the seams between the sheets should run exactly in the middle above the joists so that their edges do not sag. We also must not forget that the thickness of the plywood for the floor along the joists depends on the frequency of laying the joists. Typically, plywood sheets with a thickness of 16-20 mm are used.

The only drawback of the method is that the floor on the joists “eats” about 10 centimeters from the height of the room, depending on the thickness of the joists and plywood. However, if it is installed in a large country house, such a loss will not be decisive. Therefore, to the question of what kind of plywood is best to lay on the floor in a house made of timber, the answer is unequivocal - as thick as possible.

Tips for selecting materials

In order to determine what materials will be needed to level a wooden floor, you must first determine the level of unevenness and defects that need to be eliminated.

Using a two-meter building level, you need to mark markers in the middle of the room and each wall. And based on this data, determine what materials will be used to level the floor.

There are several useful recommendations for choosing materials for leveling the floor:

- If the wooden floor is in unsatisfactory condition and has significant curvature, then it is advisable to take a plywood sheet with a thickness of more than 10 mm. This will give the base the necessary rigidity.

- In no case should you use fiberboard panels as the base of the floor; their insufficient thickness can subsequently lead to deformation of the finishing coating.

- If leveling the floor is done in the kitchen, then it is better to use moisture-resistant plywood sheets.

- To eliminate cracks, dents, and potholes, it is better to use thick-layer self-leveling mixtures. The thickness of the layer of such mixtures is usually at least 5 mm and they are ideal for finishing laminate floors.

An alternative method is laying with self-tapping screws and polyurethane foam.

There is an alternative version of how to lay plywood on a wooden floor. This method is applicable if the old coating has sufficient strength, but the horizontal difference is too large.

The essence of the method is as follows: self-tapping screws are screwed into the old coating so that the ends of their heads are located exactly on the same plane. The distance between adjacent screws should not exceed 10-15 cm. The free space is filled with polyurethane foam. The result is a cushion on which plywood sheets are attached.

Useful tips

To understand how and what kind of plywood to lay on the floor , you can read brief tips on laying a subfloor:

- Plywood sheets should be laid offset, as in brickwork.

- When marking recesses and niches, the sheets need to be numbered and a diagram of their installation drawn up.

- More than 3 sheets of plywood should not be joined in one place.

- There should be a gap of 3-5 mm between the sheets, and 8-10 mm between the sheets and the wall.

- The thickness of the plywood sheets should be 2-3 times greater than the thickness of the final coating. Typically 16-20 mm is used.

- Self-tapping screws are selected at least 3 times the thickness of the plywood.

- The pitch between the screws should be approximately 15-20 cm.

- If thin plywood is available, you can lay the floor in 2 layers. In this case, the seams in the layers should be in different places.

- If logs are installed, the gap between them should be no more than 50-60 cm.

- The edges of the sheets must rest on the joist.

The result of high-quality work in compliance with technology Source pinimg.com

Briefly about the main thing

Laying plywood over an old wood floor is a great way to quickly and inexpensively prepare the flooring for laying linoleum, laminate or parquet. The plywood floor creates a flat surface for laying the final floor covering. There are 2 main ways of how and what kind of plywood to lay on the floor: laying directly on the old covering and laying on joists. The choice of method primarily depends on the condition of the old floor covering. Regardless of the chosen method, when laying it is necessary to comply with technological requirements: leave damping gaps, arrange the sheets in a checkerboard pattern, use high-quality materials. If all requirements are met, flooring laid on a plywood subfloor will last for many years.

Ratings 0

Content:

Evaluation of the base for laminate

Wooden floor

Concrete screed

Raw materials for floor leveling

Dry cement-containing mixtures

Plywood

Leveling the concrete base

Required materials and tools

Installation of a new screed

Installation of plywood