The AKRUS® trademark offers services for applying anti-corrosion coating. We produce protective paints and varnishes that protect against corrosion, fires, high and low temperatures, moisture, and aggressive chemical compounds. We are ready to carry out projects for industrial, civil, infrastructure and road construction, bridge construction, shipbuilding, various industrial buildings and structures.

Causes of corrosion

The development of pipeline corrosion occurs as a result of the oxidation reaction of the metal from constant exposure to a humid environment. The composition of the metal changes at the ionic level. This process can be influenced by the composition of the liquid flowing inside the pipeline. The causes of rust may be the following:

- The alloys from which pipelines are made have different electrochemical potentials. This causes currents to flow through the pipe. Different potentials can arise due to changes in soil components, as well as different parameters of environmental indicators.

- Groundwater or moisture found in the soil.

- The chemical composition of the soil, including the presence of acidic impurities in the external environment.

- Composition of the liquid transported by the pipeline.

- The presence of stray currents in the soil.

To perform anti-corrosion protection, it is necessary to evaluate the characteristics affecting the metal surface.

Completion

I hope that my short review seemed quite informative to the reader. Some additional information can be learned by watching the video in this article. I look forward to your comments and additions.

We present a catalog of paints for special purpose metal: primer-enamels, enamels, “3 in 1” paints. The main advantage of our product range is the ability to choose paint for specific operating conditions, application and for a specific type of metal. Optimally selected protective material is the key to effective operation of metal structures.

| 260 | |||||||||

| POLISTIL paint | Application in 4-5 layers. | ||||||||

| 320 | |||||||||

| Metal paint | Price per kg, rub | Set/bucket weight, kg | Price per set/bucket, rub. | Ferrous/non-ferrous metal | The basis | Gloss | Drying to degree 3, h | Application, t, from | Coating service life, from * |

| PROMOMET | 135 | 20 | 2700 | +/- | alkyd | – | 14 | -5 | 5 |

| ANTIKORRO-ENAMEL | 180 | 20 | 3600 | +/- | alkyd | + – | 3 | -10 | 5 |

| ANTI-CORRO-C | 190 | 25 | 4750 | -/+ | acrylic | – | 3 | -15 | 5 |

| ANTIKORRO-Plus | 190 | 25 | 4750 | +/+ | acrylic | – | 3 | -15 | 5 |

| METELAST-AQUA | 170 | 25 | 4250 | +/- | water | – | 1 | +5 | 5 |

| METELAST | 200 | 20 | 4000 | +/- | alkyd-urethane | semi-gloss | 0,5 | -10 | 7 |

| PROMELAST | 195 | 25 | 4875 | +/+ | vinyl | – | 0,5 | -15 | 7 |

| LAROMET | 215 | 25 | 5375 | +/+ | vinyl | – | 0,5 | -20 | 7 |

| AURITHON | 245 | 20 | 4900 | +/- | urethane | + | 4 | +5 | 7 |

| PROMOZINC | 250 | 20 | 5000 | +/+ | zinc orthophosphate | – | 0,5 | -10 | 10 |

| EPOXMET-M | 270 | 20 | 5400 | +/+ | epoxy | semi-matt | 2 | -10 | 15 |

| ANTIKORRO-Polymer | 320 | 25 | 8000 | +/+ | polyurethane | + | 4 | +5 | 10 |

| EPOXMET | 375 | 23 | 8625 | +/- | epoxy | + | 4 | +5 | 15 |

| ANTIKORRO-2K | 365 | 25 | 9125 | +/+ | polyurethane | + | 2 | +5 | 15 |

| METELAST-2K | 405 | 25 | 10125 | +/+ | polyurethane | +/- | 3 | -5 | 15 |

| *subject to application requirements | |||||||||

About types of corrosion

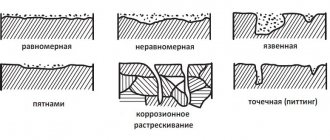

There are several types of corrosion of metal pipes:

- superficial, spreading over the entire area of the pipe;

- local, located in separate areas;

- crevice formed in a small crack.

Local corrosion is the most alarming, since the bulk of damage occurs as a result of its occurrence. The development of crevice is also common, but it does not lead to significant damage to the material.

The probability of corrosion is higher for sections of pipes extended under railway crossings or under overhead power line supports. The rate of development of the corrosion process ranges from 3 to 30 mm per year.

What is chemical corrosion

This process occurs in non-electrically conductive media. They may be gases, petroleum products and alcohol compounds. As temperatures increase, the rate of corrosion development increases. Rust can form on non-ferrous or ferrous metals. Aluminum products under the influence of corrosive factors are covered with a thin film, which then provides a protection system and creates an obstacle to the development of the oxidation process.

Under the influence of this type of corrosion, copper begins to turn green, while the formed oxide film in a humid environment does not always contribute to the creation of a protective barrier against rust, but only as an exception, when the structure of the metal is the same as the structure of the film.

Alloys may be susceptible to another type of rust, that is, there are elements that are not subject to oxidation, but on the contrary, they are reduced. For example, with increased temperature characteristics and increased pressure, carbides are restored, but, again, the necessary qualities are lost.

About electrochemical corrosion

The statement that electrochemical corrosion is achieved only when a metal surface comes into contact with an electrolyte is erroneous. A thin film on the base of the material is enough for corrosion to form. The cause of this type of rust is the use of table or industrial salts. For example, if snow is spread on the roads, then cars and pipelines laid underground suffer.

The process of this origin is as follows:

- In the connections of metal structures, atoms are partially lost, they are transferred into an electrolytic solution, that is, ions are formed. Atoms replace electrons, they charge the material with negative charges, while positive charges accumulate in the electrolyte.

- Electrochemical corrosion is also caused by stray currents, which, when leaking from an electrical circuit, go into water solutions or into the soil, and then into the metal structure itself. Specific places where rust appears are those areas from which stray currents enter the water.

On video: electrochemical corrosion of metals and methods of protection.

What should the paint be like?

Do you know which open communications have the greatest length in our apartments? Of course, heating systems, and since heating pipes are a special type of surface, the painting composition must therefore meet certain requirements.

Captain Obvious informs: it is not recommended to use ordinary paint on batteries and supply pipes, since, most likely, it will not live up to expectations and will quickly become unusable.

So, what paint should you use to paint heating pipes? Among the requirements, the most important are the following:

- Lack of water permeability . It is important that the paint functions as an anti-corrosion coating. Even if heating pipes are located in a dry room, there is a risk of rust on black steel. Properly selected paint will avoid this;

- The aesthetic point is no less important , since the color of the paint should not only not disturb the external aesthetics of the room, but also complement it. In principle, if the pipes are located in niches that will be closed in the future, then only protective properties will be required from the paint.

However, you should not hide any communication pipes with any insulating materials, as this will make it difficult to access them in the event of a breakdown;

Pipeline paint can be any color.

- Since the surface of the battery is often subject to heat, one of the most important points among the paint requirements is its resistance to high temperatures . Otherwise, the coating may become yellow in the future, and cracks and delaminations may appear on the painted surface.

- It is preferable to choose paints with good adhesion to metal , otherwise you will have to treat the surface to be painted with a primer.

How to provide protective protection

Coating pipes with special compounds is not only a task for the manufacturer; during the operation of the structure, ensuring protective properties must also be carried out. There are several ways to protect metal from aggressive environments:

- chemical treatment;

- coating the walls with special compounds;

- protection against stray currents;

- connecting the cathode or anode.

The method of tread protection of pipelines from corrosion is popular in organizations that install and operate pipeline transport.

About passive and active methods

Anti-corrosion protection is a whole range of measures carried out by enterprises. Passive protection methods involve performing the following work:

- At the installation stage, an air gap is left between the pipeline and the ground to prevent the ingress of groundwater, including those containing acidic and alkaline impurities.

- Coating with specialized compounds, the purpose of which extends from the negative effects of the soil.

- Treatment of metal with chemical compounds to form a thin film.

Active methods of protection involve the use of current and ion exchange based on chemical reactions, which ensures:

- Protection of underground pipelines from corrosion by creating an electrical drainage system to isolate pipeline transport from stray currents.

- Anode protection against destruction of metal surfaces.

- Cathodic protection to increase the resistance of metal substrates.

Only by taking into account all the methods that prevent the formation of rust on metal will the service life of structures be increased. Anti-corrosion protection of pipelines must be carried out comprehensively.

On video: protecting pipelines and cable lines from electrical corrosion.

About the advantages of using protectors

Pipe protection in this way is carried out with the addition of a component - an inhibitor. It is a material with a negative electrical charge. Under the influence of air masses it dissolves, but the structure remains intact and does not rust. Tread protection against corrosion is used to extend the service life of building structures, heating and water supply systems, as well as main and field pipeline transport.

The use of electrochemical protection makes it possible to eliminate the causes of many types of corrosion. Such anti-corrosion protection of pipelines is a good solution even for enterprises that do not have the financial capacity to provide full protection against an uncontrolled process.

To ensure a competent approach you should:

- Protectors made of aluminum are used in marine environments and coastal shelves.

- In environments with low electrical conductivity, use magnesium protectors. But, again, they are not suitable for treating the internal coating of tanks and oil settling tanks due to the fact that they have a fairly low fire and explosion hazard.

- Use protectors to protect against fresh water environments.

- Projectors made on the basis of zinc are completely safe and can be used in fire and explosion hazardous industries.

Protective anti-corrosion protection includes the following number of advantages:

- the lack of funds and production capacity of the enterprise will not be an obstacle to its implementation;

- the ability to protect small structures;

- if the pipes are covered with thermal insulation materials, then such protection is acceptable.

Materials used and purposes of application

Anti-corrosion protection is required for all metal substrates. This type of anti-rust treatment is widely used for treating tankers, since these vessels are most susceptible to exposure to water containing aggressive components. Even special painting cannot solve this problem.

The most rational choice for coating steel structures would be to use protectors with negative potential. In the manufacture of such devices, magnesium, zinc or aluminum is used. The large difference in potential between metal and steel surfaces helps to increase the spectrum of protective action, as a result, various types of corrosion are eliminated.

The protection system is carried out based on the specifics of the protectors themselves, as well as the environments in which they will be used.

Passive protection is required for steel coatings and metal products. The essence of the method is the use of galvanic anodes, which ensure that underground pipelines resist corrosion. When making calculations for this installation, the following indicators must be taken into account:

- current parameters;

- resistance against voltage surges;

- characteristics of the degree of protection used for 1 km of pipeline;

- indicator of the distance between protection elements.

What do we offer

The AKRUS® trademark develops and selects protective compounds for individual orders with the required properties. We also have ready-made formulations suitable for even the most extreme operating conditions. We offer professional application of anti-corrosion coatings using specialized equipment, in full compliance with GOST paint and varnish standards and customer wishes.

Our specialists accompany all the necessary stages of work - from inspecting the objects being processed and their preparation to applying primers, finishing coatings and quality control of work.

Methods for protecting pipelines

Corrosion of pipelines occurs during their operation. Rust formation occurs on pipes inside and outside. Deposits appear on the inside, and the reason for this is chemical reactions between the composition of the transported liquid and the metal. The condition of the surface is also influenced by high soil moisture.

If protection is not provided in a timely manner, a number of consequences may occur. What is important:

- It is recommended to carry out routine inspections at short intervals.

- Carry out repair work periodically, regardless of the presence of corrosion.

- suspension of the functioning of pipeline transport is inevitable, since it is necessary to carry out inspections and carry out scheduled preventative and other routine repairs.

Important! To ensure complete protection, it is necessary to take into account the installation method, contact with aggressive media, and the type of pipeline.

Options for coloring compositions

The modern construction market offers a wide variety of paint options that can be used on heating pipes. Let's look at the most popular among them.

The most common type of paint.

Alkyd enamels

Such coloring compositions are the so-called time-tested classics. This paint is attractive due to its low cost, the price per package is one of the lowest on the market, but you should be prepared for a not very pleasant smell during its use, which subsequently disappears for a very long time.

Other advantages of alkyd enamel include resistance to wear and temperature fluctuations from 0 to 90 degrees. However, unfortunately, it will not be possible to avoid yellowing of the white color after a couple of years. Actually, it’s like painting a heating system without smelling too.

| Name | Features of application | Price per kg, rub |

| Alpina Heizkorperlack | Consumption 90–120 ml/m2. |

Drying time – 5-12 hours

Consumption - 100 ml/m2

Drying time -2 hours

Acrylic paints

Often, acrylic paints, which may contain a silicone or latex base, are used to tidy up radiators and other heating pipes. Often such paints are called facade paints due to the most common scope of their application.

Each of these paint options has its own characteristics. For example, acrylic-silicone paint is resistant to moisture, so you can wash batteries and pipes as often as you want without fear of damaging the surface.

However, if the surface to be painted is classified as problematic, you should pay attention to acrylic paints with latex, since they have high adhesion rates.

They can be used on glass, ceramics or polished metal. In search of an answer to the question of how to paint copper heating pipes, you should turn your attention to paints with a latex composition.

Acrylic paint for heating pipes.

The most common acrylic-based paints are water-dispersion coatings. However, their use is accompanied by a number of certain subtleties that should be taken into account.

The most significant among them:

- Such a composition, provided it does not contain silicone or latex, is very sensitive to washing with special detergents; accordingly, over time, the paint will simply be washed off the surface of the radiators;

- An important point is whether it is possible to paint pipes with these compounds during the heating season. Acrylic-based water-dispersion paints have a certain threshold of heat resistance. When the temperature reaches more than 90 degrees, the paint coating will soften. If the temperature reaches 120 degrees, the coating will begin to decompose;

Captain Obvious informs: since according to standards the temperature of heating radiators cannot exceed 95 degrees, decomposition of the coating will not occur at home.

- If you are going to pay attention to this type of paint, it is advisable to give preference to those that the manufacturer positions exclusively as radiator paints. Only in this case do they contain a special component that imparts resistance to heat.

| 770 | ||

| Enamel Sniezka 0.4 l | Does not turn yellow. | |

| 400 | ||

| Aura Luxpro Thermo enamel | Consumption 90–120 ml/m2 | 300 |

| Dufa enamel | Consumption - 100 ml/m2. | |

| 370 | ||

| Name | Features of application | Price per kg, rub |

| Eskaro Element radiator | Contains a corrosion inhibitor. Consumption 100-170 ml/m2. Withstands heating up to +120C | 900 |

| Maxima Akril | Consumption 70-100 ml/m2 Does not turn yellow. | 450 |

Enamels KO

Another coating option for radiators and heating pipes is silicone-based paints (OS). Among the undoubted advantages of such paints are excellent adhesion to almost all metal surfaces and high resistance to a wide range of temperatures.

If your home's plumbing is made of copper, you shouldn't look for a better option than KO enamels. There are several options for enamels of this type, each of which does not lose its properties even after a considerable time after application.

An example of domestically produced KO enamel is the composition “Celsit-500”, which is actively used for painting metal pipes. The manufacturer of the composition is the Moscow company KrasKo.

Enamel KO Celsit-500. The paint calculation for the pipe is indicated by the manufacturer on the label.

Preparing the work surface

- Surface treatment for aerosol painting is carried out in the same way as for rust enamel in the form of a suspension.

- The surface is cleaned with a stiff brush to remove dirt deposits, loose rust and old paint residues.

- Then it is degreased using gasoline or acetone.

- After this, the surface is washed with soapy water and dried.

Cleaning pipes from rust

Mode of application

When using an aerosol, you must shake the can periodically. An indicator of its readiness for use is the free movement of balls inside it, which serve to mix the composition.

When spraying, the can should be held in a vertical position, evenly making back-and-forth movements. The work is carried out from a distance of 20 cm.

The use of aerosols is possible in a temperature range from +5 to +32 degrees Celsius.

If necessary, remove paint; fresh paint can be removed with acetone, and dried paint can be removed with a special remover.

Aerosol paint for metal

Aerosol paint for metal against rust comes in three types:

- Standard, used for simple one-layer painting.

- Double, which acts as primer and enamel. Its advantage is that before painting the surface there is no need to apply a separate primer to it.

- A universal aerosol paint that simultaneously acts as a primer, regular enamel and a rust converter.

Aerosol paint for metal

To work on rust, type 3 aerosol paint is used. One can of it is enough to apply to a surface of approximately 3.5 m2, with a layer 0.05 mm thick. Therefore, spray paint on metal is not used over large areas. It is advisable to use it for small surface areas.

Aerosol paint for metal and rust is especially convenient for touching up damaged paint layers and for painting hard-to-reach places.

As a rule, aerosol paint for metal against rust is multifunctional; in addition to working on steel surfaces, it is suitable for painting non-ferrous metals, as well as wood, plaster and stone.