What it is

Fireclay is a fire-resistant substance obtained from kaolin. The clay is heated to 1.3-1.5 thousand degrees, as a result of which the mass loses moisture and plasticity. During the process, the material sinteres and changes color from gray to brown. The burned pieces are crushed with special metal shafts to the state of fine sand of different fractions.

As a result of temperature changes, clay characteristics are radically transformed. The result is a very strong raw material, with parameters resembling stone. Due to the loss of liquid, the material does not expand when heated, maintaining its strength. After drying, the finished mixture does not shrink or crack.

Fireproof material Source remokna.in.ua

Fireproof fireclay is a semi-finished product for preparing mortar. By adding certain additives it is easy to adjust the parameters and adjust the mass to the needs of a person. You can find out the material in the store by the letter “Ш” on the packaging. The abbreviation “MSh” or “MP” is present in the names of the ready-to-use composition (mortar). The letter “U” is on a pack of a less strong recycled substance (after secondary processing).

Kaolin clay is classified as a material of natural origin. Raw materials are mined from the bottom of seas, lakes or rivers. The appearance and constituent substances often depend on the location of the deposits. The most common is light gray raw material, there are shades of pink, yellow and blue.

Where are raw materials mined Source teplo.guru

How long does clay mixture take to harden?

The time for complete drying of fireclay paste in air is 72 hours, inside the brickwork this time increases, it depends on the thickness of the masonry, temperature and humidity of the surrounding air. Petrification of fireclay mortar occurs at 800 degrees Celsius.

Important! Fireclay masonry does not like sudden changes in temperature. The stove is heated for the first time three days after completion of construction.

Use thin, quickly burning logs. The dampers and vents are fully opened during the first fire. Then the stove is dried for a week, burning small portions of wood daily

The furnace is heated for the first time three days after construction is completed. Use thin, quickly burning logs. The dampers and vents are fully opened during the first fire. Then the stove is dried for a week, burning small portions of wood daily.

Fireclay masonry dries faster than masonry made from ordinary clay-sand mortar and ceramic bricks, but only the firebox is usually made of fireclay. Therefore, the timing of the start of operation of a furnace with fireclay masonry will be the same as the timing of use of a furnace built on clay and lime mortar. In summer, a new stove is heated to maximum after 10-14 days, in winter - after a month.

Material characteristics

Fireclay clay is produced in powder form, with a fraction of up to 2 mm. If the substance was stored correctly (+15-25 C), then the consistency is homogeneous, without noticeable pieces or lumps. The material loses its properties after 3 years or when kept in damp conditions.

The melting point of all types of fireclay clay is from 1500 to 1850 C. As the degree increases, the performance properties do not change, which allows it to be used in the manufacture of stoves and fireplaces. After sintering, the substance loses its ability to absorb moisture without losing its fire resistance.

Properties of kaolin substance Source proraboff.rf

Kaolin and sand do not have binding capabilities, but when combined, a very strong, dense mass (raw material) is obtained. The strength level of the composition is 12-24 N/sq.mm. Fireclay clay mortar is not inferior in stability to concrete. The product has high adhesive properties, which facilitates subsequent processing.

One package of 20 kg of material is enough to lay 30 bricks. To cover the surface of the cube, use 100 kg of refractory substance. The kaolin composition allows oxygen and moisture to pass through itself, so a favorable microclimate is maintained in the room. Hardened natural fireclay is safe for human health.

Fireclay is a very expensive material with special rules for use. The treated surface takes a long time to dry (3-4 days). If you violate the technology for preparing the solution or do not comply with the exposure time, the mass will not become strong. Fireclay dust rising into the air is toxic, so a respirator with safety glasses is required when mixing ingredients.

Strengths and weaknesses Source yandex.ua

Mortar for plastering ovens

For a long time now, we have been living in a time when an ordinary stove in the house is something indescribably outdated, unusual, an element that is rare. Even private houses are now heated with gas as they should be; there is no need for any other types of fuel.

At the same time, these magical heat sources still exist in some places. Their finishing is carried out approximately the same way as before - there are no significant differences here. There is nothing unusual in this - no one developed new materials, old technologies were enough.

It cannot be said that this approach is correct: a stove is a reliable source of heat, and, moreover, completely independent. There can always be a gas supply interruption, and the electricity can be turned off. But if the supply of coal and firewood is prepared on time, there will be no problems with heating. That is why such a profession as a “stove maker” is far from obsolete - these specialists are needed everywhere.

If we talk about finishing (even if in the future you want to tile the stove), you should pay attention to how to make the correct mortar for plastering stoves.

What should this composition be like? When repairing an old structure or building a new one, many people begin to think about this question and the answer is not always found quickly. The finishing conditions are actually extreme, because the oven gets very hot and then cools down.

Furnace repair using fireclay mortar mixture

READ The logs in a wooden house have rotted, what to do?

Temperature changes are serious, not every material can cope with such changes - even if we consider modern consistencies.

Plaster is an environmentally friendly material. This also needs to be realized: when heating the room, no toxic substances should appear. In addition, plaster has better thermal conductivity and is elastic. The price of the finished solution is not high, which makes it easily accessible to any budget.

Types of raw materials

Refractory material is the basis from which solutions for various purposes are made. Lump clay is used to create heat-resistant ceramics, bricks and cardboard. The ground type has high characteristics of resistance to fire and strength, which allows it to be used in coating and molding mixtures.

Fireclay is distinguished by the presence of binding additives in its composition. Based on the amount of sand, there are 3 types of raw materials:

- Exhausted. Contains up to 21% of the substance.

- Smooth. The volume of the ingredient varies between 19-48%.

- Binder. Contains 55% loose component.

For a fire-resistant surface, traditional river sand cannot be used in the solution. The substance has a maximum limit of 800 C; at high temperatures it expands, which leads to destruction. Quartz species, kaolin and cement are often used as additives.

Varieties of fireclay clay Source rusboard.net

Stone-like varieties are not used to prepare a solution from fireclay clay. According to the degree of aluminum oxide content, the substance is divided (in percentage) into:

- semi-sour (up to 25);

- basic (26-38);

- highly basic (from 40).

Fireclay powder is divided into 4 grades. Characteristics depend on the degree of fire resistance and the amount of additional ingredients. Numbering from 0 (special) to 3 affects heat resistance and the final cost of the composition.

Main components

Fireclay fireproof kaolin clay is best suited for laying stoves

The clay composition varies depending on the components added:

- clay-sand;

- clay-cement;

- clay-lime.

Stove makers, as a rule, choose the first option. The proportions depend on what clay is used for the oven. If it is oily, the sand ratio will be 2:1, if it is medium oily it will be 1:1. Also, if the clay is of good quality, you can do without additives.

Where is it used?

Understanding what fireclay clay is, it is easy to determine the scope of use of raw materials. The powder in solutions is used to create fire-resistant building materials. The substance is used to make strong bricks or clinker tiles. The finish has a high price, so professionals recommend combining it with conventional models.

Using fireclay mortar Source techno-comf.ru

Advantages

The main advantages of chamotte include the following:

- thermal stability;

- vapor permeability: the solution absorbs, retains and returns moisture vapor well;

- durability: the material retains its original appearance for a long time without cracks or shedding;

- adhesion ability: bonds well to any type of surface;

- high environmental friendliness and safety;

- low cost compared to other building materials.

When purchasing fireclay clay, you need to make sure that it has been stored correctly. The technical characteristics of this material are negatively affected by humid air.

In addition, it is worth paying attention to the expiration date: over time, the material loses its production qualities. Purchased calcined kaolin can be stored in its original packaging for two years.

How to use it correctly

The basis of the composition is clay powder and water in the required proportion. During the production of fireclay, kaolin loses its plasticity. To restore the pliability and elasticity of the mixture, special additives are added to the composition. For each task, there are rules that allow you to obtain a strong fire-resistant material.

For laying the furnace

Plasticity indicators are often improved with kaolin sand. The white substance is sold in construction stores in bags. In one container, clay is mixed with the additive in proportions of 4 to 1, then water is slowly poured in small portions. To obtain a uniform consistency, professionals recommend using a special mixer.

In order for the ingredients to reveal their characteristics, the preparation is left for 3 days. The finished mixture resembles plasticine in thickness. The solution should not stick or flow easily, and there should be no lumps under your fingers. If you scoop it up with a trowel, the mass slowly slides off, without leaving a residual mark.

Features of technology for the stove Source stroyfora.ru

The presence of clay components is called fat content. The parameter is responsible for the plasticity of the finished material. You can increase or decrease the characteristic using sand or fireclay. Oversaturated solutions do not affect the quality of the stove, but due to “lean” options, the structure will crumble.

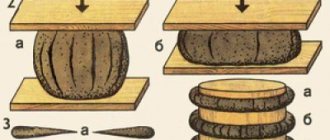

To find out the fat content of clay at home, you need to roll a ball from the finished raw materials. The samples are pressed down on top with a long board. If cracks appeared under low pressure, then the solution is “lean”. If ruptures occur at half the radius of the ball, it indicates high plasticity indicators, and at a third – average (normal). The last two types are suitable for construction work.

The surface to be treated must be prepared. The old finish is removed from the wall and the reinforcing mesh is fixed. In order for the product to hold tightly, a layer of solution must be applied on top. Knowing how long fireclay clay takes to dry, you can begin laying out the stove in 3-4 days.

The classic stove mixture consists of base material and sand. An experienced master uses at least 3 types of solution with different additives when working. Cement-lime varieties are recommended for the base and chimney. When assembling the frame, cement is added to the composition; for the combustion chamber, red clay is added.

Rules for using chamotte Source vbud.in.ua

Supplements

Salt and cement are added at your discretion. The standard composition of the mortar for laying the furnace does not provide for their addition. However, if you decide to make a complex mixture, the proportions are as follows (per 10 kg of clay): salt 150 g, cement M400 1 kg. And also: clay 2 buckets, sand 2 buckets. This quantity is enough to lay 100 bricks.

Sequence of work:

- clay is poured into a trough, poured with a small amount of water and allowed to soak for 6 hours to 2 days;

- it is stirred regularly during this time (you can put on rubber boots and trample the clay); in total you will need 1/4 of the total volume of clay;

- add sifted sand and mix with a shovel; if the mixture slowly slides off the shovel, this is its optimal consistency.

The plasticity of the finished mixture is determined in the following way: a flagellum 1.5 cm thick and 20 cm long is molded. Connect it into a ring around a wooden piece with a diameter of 5 cm. The flagellum should stretch evenly. If it breaks, the ends of the tear should be sharp. The absence of cracks on the fold means that the mixture is too oily; if multiple ruptures occur, the solution is thin. In the first case, sand is added, in the second, clay. It is necessary to achieve the formation of several small cracks on the bend.

Use Cases

Kaolin can be used for furnace masonry. It is also used as plaster and for making decorative items.

In addition to being used for decorative purposes, chamotte clay is actively used when laying stoves and fireplaces

When building stoves, they look at the markings applied to the surface of the products. Usually the letter "Ш" is indicated. The material most often used is for masonry of the firebox, since its cost is high, so it is impractical to use it for the rest of the work. They lay it on special clay. Its characteristics are the same as those of brick.

Fireclay fireclay has a unique texture and composition

That is why designers paid attention to it and began to use it to produce unique blanks. These can be ceramic dishes, original figurines

To ensure greater plasticity, various impurities are added.