Foil insulation is a specific thermal insulation material that not all professional builders know how to use correctly. The reason is trivial: they do not know at all or do not fully understand the principles of operation of foil insulation. What can we say in this case about home craftsmen who understand the essence of the issue even worse. As a result, you can see that the foil thermal insulation of the walls is carried out in accordance with all the rules and regulations of building science, but in the end it turns out to be meaningless from the standpoint of saving heat in the house. This is especially true for facade insulation.

The editors of the StroyGuru portal decided to take a closer look at the problems that arise when insulating walls with foil-coated thermal insulation materials and give specific recommendations to everyone when purchasing them.

Foil materials: structure and principle of operation

Even people far from construction have at least once encountered insulation that is shiny on one side; the name of one or another of its varieties is known to owners involved in construction or repair. Such materials are often called two-layer, because of the conspicuous metal (reflective) layer; There are options coated with a reflective layer on both sides.

The bottom (or inner) layer is made of a porous or fibrous material. It serves as thermal insulation and serves as a strong base for the foil. The foil component, glued on top of the insulation, is needed to reflect infrared (thermal) radiation. It is made of aluminum foil or metallized film, different in properties:

- Aluminium foil . It is applied by heat welding and polished to the desired reflectance (95%). The foil is destroyed by the salt contained in the cement mortar.

Foil retains heat in the room Source otoplenie-gid.ru

- Metallized film . Apply to one or two sides of the material. It reflects less heat, but is resistant to alkaline influences.

Each layer has its own “responsibilities”. The foil reflects thermal energy, and does it effectively: according to manufacturers, up to 90-95% of thermal radiation is returned. The remaining percentage is partially absorbed by the insulation, and partially the heat is dissipated in space.

Attention! Practical measurements have shown that the efficiency of foil thermal insulation is 30-60% higher than that of a similar single-layer thermal insulation material. It is important that the price difference is not so significant; In the long term, this means savings on heating.

Foil underfloor heating reduces heat loss Source veralline.com

Technical characteristics and types of base layer

Foil insulation is considered a relatively new material, but has already won the respect of consumers. It is designed for installation on building facades, interior walls, ceilings and roofs. The material is a combination of polyethylene foam and polished foil. Thanks to the presence of the latter component, the insulation reflects heat and retains it in the room. Research was conducted on its effectiveness, which showed that the reflectivity is at a level of more than 95%.

In addition to thermal insulation, protection from noise and moisture, the material is quite elastic, which makes it convenient for transportation and further installation. The insulation is thin and will not hide the usable area of the room. Resistance to moisture means that the material does not become damp over time. It will be able to protect the building from wind and severe frost. An important point is the environmental friendliness of foil insulation.

The scope of application of the material is extensive. Depending on the purpose of the object, it is necessary to select the appropriate type. It is used to insulate wooden houses, the interiors of apartments, bathhouses, outbuildings, various partitions and even pipelines.

What does foil wall insulation look like?

By insulating the facade of a building, you can be sure that your home will become much more comfortable and will not be afraid of even the most severe frosts, winds, high humidity and temperature changes. Foil thermal insulation is resistant to ultraviolet and radon radiation. The insulation also interacts well with any facing materials.

Pros and cons of reflective insulation

A wide range of applications makes shiny insulation in demand; what this or that variety is called and where it is used depends on the composition of the layers. Foil-based materials are designed to protect ceilings, floors and walls; They are used to insulate pipes and roof vaults. Widespread use is possible thanks to properties, some of which are unique to them:

- High efficiency . A shiny coating allows only 5-10% of heat waves to pass through, the rest are reflected back.

- Hydro- and vapor barrier . The metallized layer is irresistible to atmospheric moisture and steam. This property is actively used in the construction of baths and saunas.

- Easy installation . The material is secured with a stapler or nails; some varieties are made on a self-adhesive basis. Insulation with foil is flexible and easy to install on complex shaped surfaces.

Forming a gap for ventilation Source world-comfort55.rf

See also: Catalog of companies that specialize in insulating houses

- Long-term operation . Achieved with proper installation. The insulation will not become moldy, and the metallized layer will not collapse.

- Safety . Reflective thermal insulation materials are non-toxic to humans.

The disadvantages include the following features:

- Thermos effect . It occurs as a result of the circular use of foil material in violation of installation rules, and provokes the appearance of mold. The problem is not always solved with ventilation.

- Terms of Use . Concrete is a bad neighbor for aluminum foil; the salts it contains corrode the metal layer within a year.

- Thermal conductivity . The heat-reflecting layer, like any metal, heats up, due to which some of the energy is lost.

Wall mounting Source pechiexpert.ru

Video description

About the comparison of samples of foil polyethylene foam in the following video:

Based on mineral wool

The market offers mineral wool with foil in the form of rolls or packs of slabs (10-12 pieces each). The lightweight material is made from basalt rock wool or fiberglass, which provides the following properties:

- Fire safety. The fibers of the material can withstand temperatures up to 1000 °C.

- Durability. The insulation covered with foil does not compact over time, the thickness of the thermal insulation layer remains unchanged.

- High water-repellent and heat-saving properties make it possible to use mineral foil insulation for baths and saunas, for private housing construction (interior decoration), and for chimney pipes.

- Thermal conductivity coefficient: 0.036 W/(m*C).

- Vapor permeability coefficient: 0.3 mg/m*h*Pa. The mineral base ensures steam circulation and better insulation.

- A package of 12 slabs with a width of 60 cm and a volume of 0.288 m³ weighs 10.7-10.8 kg.

- Bathroom insulation with fiberglass foil is a source of glass dust, which poses a health hazard. Laying of the material is carried out in protective clothing, gloves and a respirator.

Basalt cylinders for pipes Source tstan.ru

Types of reflective insulation

For owners who have started construction or renovation, it is not indifferent to the name of the insulation, on one side of which foil is glued, since not all varieties are interchangeable. It is equally important to understand how to properly install insulation with foil in order to minimize heat loss. There are several types of thermal insulators with foil on the market, with different thermal insulating material as a base.

Foamed polyethylene (polyethylene foam)

The material looks like an elastic fabric 2-10 mm thick, structurally consisting of closed-porous cells. Insulation is sold in rolls; some manufacturers supply it with a self-adhesive base; The reflective layer is aluminum foil.

Polyethylene foam with foil is suitable for thermal insulation of the floor, where it is placed under the final finish (for example, laminate). For heating radiators, thin varieties of fabric are chosen as a reflective screen. Elastic material is suitable for insulating water and sewerage pipes; it will keep the pipes from freezing and at the same time protect the owners from annoying noise.

Insulation made of foamed polyethylene Source of peace-comfort55.rf

Application area

Thermal insulation with foil is used in the following cases:

- if necessary, insulate water risers;

- to protect ventilation systems, wells and boreholes from cold outside air;

- to increase the reflectivity of the “warm floor”;

- to create a screen that is designed to reflect heat waves from a heating radiator or air heater;

- as a classic protection against cold outside air in country houses, bathhouses and other outbuildings.

Features of installation of foil insulation

Before purchasing, measurements are taken and the required quantity is calculated based on the fact that the insulation will be fixed not overlapping, but end-to-end. The question of how to properly lay insulation is solved in the same way for both types of metallized coating. When insulating walls, adhere to the following rules:

- Foil thermal insulation is laid with the reflective (shiny) side inside the room.

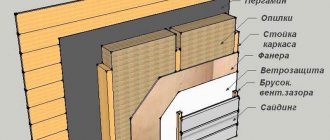

- Double-sided material is intended for thermal insulation of frame buildings.

- Installation on walls includes the organization of sheathing, the slab insulator is fixed in it between the guides and is additionally strengthened with dowels.

- Installation on the ceiling is carried out using a stapler. The joints are sealed with metallized tape or aluminum adhesive tape. Between the insulation and the final finish, a gap of 2-2.5 cm is created for ventilation.

Fixing joints Source krovlyaikrysha.ru

Briefly about the main thing

Reflective insulation works according to a special principle based on a layer structure. The main layer consists of a porous or fibrous material; on top (sometimes on both sides) it is complemented by a layer of aluminum foil or metallized film.

It is the shiny surface that does the main job of retaining heat in the room. Additionally, it serves as a steam, hydro and sound insulator, and if the installation technology is violated, it causes the appearance of a thermos effect.

Common foil materials include polyethylene foam, basalt and glass wool, and foil polystyrene foam. To fix the material on the surface, you need a stapler or dowels; the joints are fixed with aluminum adhesive tape.

Ratings 0