You can give a beautiful appearance to the facade of your house using various finishing materials. This can be brick, wood, siding and plaster. It is noteworthy that it is the latter option that is considered the cheapest and is used more often than others. But at the same time it requires certain labor costs. But this coating looks quite beautiful. Mineral plaster for facades, which has a rich history, can radically change the appearance of a house, while being considered the most durable type of facade coating.

Facade plaster

Mineral plaster for facades

Mineral plaster - what is it?

Mineral plaster mixtures have been used by humans since the times of Ancient Rome. Initially, their composition included volcanic ash and clay, and after several centuries the plasters acquired a strengthening component - cement. In the 80s of the last century, the composition of the mineral mixture expanded even more when modern modifiers, quartz sand, Portland cement and other components began to be introduced into it.

Ancient plaster made of ash and clay

These substances in combination promote the occurrence of a chemical reaction with the formation of a hard stone (plaster layer), which reliably adheres to the base and protects it from cold, damage and water. Mineral plaster got its name due to the fact that its base is a natural mineral raw material, which is made from natural, environmentally friendly ingredients.

Due to the nature of polymerization, all building mixtures of this type are produced in dry form, since they quickly harden after contact with moisture. As they are diluted, they are applied using standard construction tools or by mechanized means. After drying, a durable, vapor-permeable, non-flammable layer with high heat-insulating and sound-proofing properties is formed.

Use of mineral based plasters

Composition and characteristics

There are both simple mineral plasters on sale with 2-3 components, as well as more complex multi-component mixtures. The basic components are cement, sand, clay, lime, gypsum, asbestos, talc, kaolin, and in most mixtures cement is considered the main one, and the remaining substances are auxiliary. Also, many plasters contain a mineral filler - anthracite, quartz, marble, granite, etc. The filler is responsible for making it heavier or lighter, or for structuring the mixture.

Other additives to mineral plaster are:

- plasticizers that facilitate the laying of the mixture;

- modifiers - biocides, fire retardants, frost-resistant additives;

- additives - substances to increase moisture resistance;

- pigments for coloring the mass.

Fillers for decorative plasters

Mineral plaster for interior and exterior use may have different characteristics, but in general the differences between them are insignificant. This material is characterized by high strength, does not crumble or crumble. After drying, the coating becomes breathable, so it does not disturb the microclimate in the room - it allows air to pass through, but repels moisture.

Mineral plaster only does not tolerate stress and vibration well, because its elasticity is not very high. In this regard, you should not use products with this composition until the buildings have completely settled, as well as when finishing buildings in seismic zones located near the railway.

The average technical characteristics of mineral compositions are as follows:

- dry density - 1.4-1.5 t/cub. m;

- possible layer thickness without the use of reinforcement is 3 cm;

- maintaining plasticity after diluting the solution - 1-2 hours (depending on additional substances in the composition);

- water consumption per pack of mixture weighing 25 kg is 4.8-5.5 l;

- high vapor permeability (equivalent thickness of water vapor diffusion resistance Sd - less than 0.1 m);

- the optimal temperature for setting is within +5...+25 degrees;

- drying time of the layer - 16-24 hours;

- thixotropy, absence of drips on the treated surface.

Use for interior work

Very often, mineral decorative plaster (including bark beetle) is used for interior work with drywall. It does not require additional processing, and plaster can change its texture. It is often used to highlight certain objects. These are niches, cornices, and sometimes separate walls. Thanks to mineral plaster, you can give the coating a rougher look. If this is interior work, the surface can be additionally varnished. This makes the color of the wall more saturated and gives the coating more gloss. In addition, the strength characteristics increase.

Types of mineral plaster

Plaster mixtures are divided according to the grain size of the filler, as well as the appearance and type of filling components. In addition, all of them can be classified into ordinary, special and decorative. Mineral plasters are also divided into those intended for external and internal use and into universal compositions.

Filler size

Based on the grain size of the plaster filler, they are:

- Fine-grained. The particle size does not exceed 0.5 mm, so the filler is more like flour.

- Fine-textured. The fraction size is 0.5-1 mm, the materials are widely used for finishing premises. The surface will have a barely noticeable relief, which is ideal for residential and public buildings.

- Medium textured. The filler fraction is 1.1-3 mm. Such mixtures are considered universal; they are suitable for exterior and interior use. Indoors, medium-texture plasters are most often applied to walls in hallways, corridors, and rooms with high humidity.

- Coarse-grained. They are considered façade, as they are usually used for exterior decoration of houses and buildings.

- Rough textured. Also used in facade repairs. They give a pronounced relief surface. They are even suitable for cladding multi-storey buildings.

Coarse lime-gypsum mixture

The size of the fraction has a significant impact on the technological process. The larger the filler granules, the thicker the coating layer will be. The exact size of the fraction is always indicated on the packaging of the plaster.

Type of filler

Filling additives are introduced into the plaster to give it various properties, increase decorativeness and improve technical characteristics. Here are the most popular fillers for mineral plasters:

- colored glass in the shape of balls - provides the walls with an unusual and very impressive appearance;

- colored clay - used for interior work, gives the surface a smooth, “silk” appearance;

- crushed quartz - is a larger-than-usual quartz sand, which gives an interesting roughness and strengthens the composition;

- anthracite (coal production waste) - used infrequently, allows you to make the plaster dark, rich in color;

- mica - suitable for external and internal work, the surface after its introduction will shine under the sun, resembling pieces of glass;

- marble chips - used in expensive plasters such as Venetian, it increases the aesthetic properties of the material;

- ceramic granules - increase the strength of the plaster and give a beautiful texture.

Plaster with marble chips

Texture and appearance

Textured (decorative) plaster is often made on a mineral basis and sold in dry form. After dilution, it is applied to walls and other surfaces using a special technique, thereby creating a certain decorative effect. Most often, plasters with the following effects are found on sale:

- "Bark beetle." This is a pebble mixture with medium or large granules, which are contained in large quantities. After application and rubbing with a construction float in one direction, grooves are formed on the surface, reminiscent of traces of the activity of bark beetles.

- “Lamb” or “fleece”. Small stone particles allow you to give a layer of plaster waves similar to sheep's wool. This effect is achieved by circular movements of a grater or grater.

- "Fur coat". To obtain this type of finish, plaster with fine-grained marble or quartz is used. After leveling the mass on the wall, apply a grater to it and sharply pull it away, leaving behind sharp tubercles reminiscent of the wet fur of fur-bearing animals. Most often, this type of application is used in facade work.

- "Venetian". This plaster imitates natural marble coating. The Venetian mixture contains fine marble chips or flour, as well as colored clays. It is applied using a special technique in 5-8 or more layers, making short strokes in different directions with a special rounded trowel. After grinding the last layer, it is ironed - treated with a metal float. Finally, the finish is coated with wax.

- "Travertino". Mineral plaster can be similar to natural travertine stone, which has a unique ribbed surface. Apply the composition in 2 layers, with the second applied in the form of chaotic strokes. After the formation of irregularities, the surface is smoothed slightly to make some areas smoother.

- "Wet silk" To obtain this effect, you will need plaster containing cellulose, cotton, polyester or silk fibers. Two layers of material are made by randomly applying strokes, which can be long or short. They also use the technique of making patterns using special figured rollers, as a result of which the coating will resemble textile.

Exterior works

Since this plaster perfectly withstands moisture and other atmospheric influences, it is often used for facade work. As practice shows, such coatings last quite a long time. The composition can withstand both severe frosts and frequent temperature changes. You can care for this coating with any detergent composition. Decorative mineral plaster is used for finishing:

- External stairs.

- Entrances.

- Socles.

It can cover either a separate element of the house or the entire facade. The material is non-flammable, so it can be used as protection for wood, chipboard or MDF panels.

Advantages and disadvantages of plaster

Mineral plaster mixtures are valued by professionals and users because their advantages are obvious:

- high degree of adhesion with all building materials (concrete, brick, plasterboard, gas blocks, etc.);

- resistance to ultraviolet radiation, temperature changes, frost, heat, precipitation;

- low thermal conductivity, excellent thermal insulation properties;

- high mechanical strength, wear resistance, long-term preservation of coating integrity;

- vapor permeability - the ability to get rid of accumulated moisture, no fogging of walls, reducing the risk of fungus and mold growth;

- fire safety, non-flammability, possibility of use as a fire retardant layer;

- ease of care - plaster can be washed with water, detergents, vacuumed, wiped, cleaned with brushes;

- increased level of acidity, which prevents the proliferation of microbes and fungi;

- environmental friendliness, absence of unpleasant odor and released toxins;

- affordability (except for marble plasters);

- a wide variety of options, the presence of many types of plaster with a decorative effect.

Mineral mixtures also have disadvantages. If you violate the ratio of the proportions of cement and other mineral additives, and also incorrectly dilute the plaster with water, the solution may lose its strength and some of its other useful properties. Such cladding can crack and crumble over time. Finishing work with decorative plaster is carried out only by hand, therefore it is considered quite labor-intensive and time-consuming, especially if the surface has a large area.

When buildings shrink and vibrate, the plaster layer can crack, because the elasticity of mineral mixtures is at a low level. Compared to silicone, silicate, and acrylic plasters, the service life of mineral compositions is short, so repeated repairs will have to be done faster. In addition, mineral mixtures are rarely colored, and you will have to tint them yourself.

If the components in the composition are gray, the final shade may not be attractive. And the last disadvantage: before plastering a house or apartment, it is better to practice on a rough surface. The finished solution has a limited service life, hardens quite quickly, and it will be difficult for a beginner to handle it.

Comparison with other plaster mixtures

Mineral facade plaster for exterior use is usually made with cement. Such mixtures adhere well to the base, cost the home owner less than other types, and are often used both for leveling walls (rough finishing) and for finishing. However, where there are railway tracks nearby, it is not recommended to use it in areas with seismic hazard due to increased fracturing. In this case, silicone and acrylic compounds work better due to their elasticity. These two species have a richer palette.

Without taking into account special mixtures, comparison with silicone, acrylic and silicate leads to the following conclusions:

- Due to the lack of elasticity, mineral plaster is not suitable for areas with high seismicity, near railway lines, where it becomes covered with cracks, and is inferior to elastic silicone or acrylic plaster.

- Due to the availability, as well as the low price of the components of the composition, mineral is cheaper to purchase than other types.

- In terms of safety and comfort, mineral is preferable in residential areas, especially lime, gypsum or clay.

- In terms of strength, MS is not inferior to others.

- Acrylic is inferior to the others when applied to façades, as it is not very resistant to ultraviolet radiation and fades quickly. It is also not applicable near flame sources or in places with high temperatures. It is not recommended for use in bedrooms or living rooms due to low vapor permeability.

- Silicate is suitable for facades, but is not suitable for indoors because it releases harmful substances during application and hardening. It is more expensive, requires a silicate primer, and special coloring compounds (also expensive).

- Silicone is significantly more expensive than all other types. However, in terms of working quality it outperforms them. For facades, due to the cost savings, mineral or acrylic ones are more often used than silicone ones.

Application of mineral plaster

Mineral mixtures are suitable for a huge number of works inside and outside buildings, as well as for decorative finishing. For a specific type of activity, you can always choose the most suitable composition: where cement plasters are not suitable, gypsum or lime mortars will help out.

Primary rough work

Mineral compositions are the main type of materials with which you can level walls, facades, ceilings, and floors. No polymer plaster can replace them, for example, when pouring screed. Only when processing smooth metal and plastic do you have to use other compounds, and even then only after preliminary surface preparation.

In addition, mineral-based plasters can protect sheet insulation from damage when installing thermal insulation. Cement and asbestos solutions are also applied to pipes to prevent rusting and damage. To choose a composition that is truly suitable for rough work, you need to pay attention to the strength of its adhesion to the substrate material and the permissible thickness of the plaster layer. All these parameters are indicated on the packaging of the product.

Applying a mineral mixture to insulation

Interior work

Usually, for plastering premises, plasters with a finely dispersed base - lime, gypsum - are used. They provide an optimal microclimate in the room, as they do not block the release of moisture and regulate humidity. Only where the natural air humidity is constantly high can they quickly deteriorate by absorbing excess liquid. This problem can be solved by installing moisture insulation in areas of direct contact with water and installing a high-quality and powerful hood.

Yakhont gypsum plaster for interior work

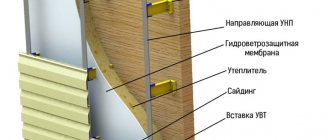

Exterior works

Outdoors, plaster is regularly exposed to adverse factors - rain, snow, wind, ultraviolet radiation, and temperature changes. Therefore, for facade and other exterior work, reliable mixtures based on cement and special modifiers are chosen. They can be applied to the external walls of houses, retaining walls, gazebos, verandas, balconies, fences.

There are special lightweight mineral plasters that help insulate walls and are used independently or in combination with sheet insulation. To finish and protect the foundation and base of the house, special waterproofing mineral compounds are used. In regions with extreme climates, mixtures are chosen that have enhanced frost resistance and the ability to withstand many cycles of freezing and thawing.

Decorative finishing works

For wall cladding, for the purpose of protecting and decorating them, special finishing mineral plasters are used based on lime, cement, sand, gypsum, but containing special fillers. These are so-called decorative structural or textured mixtures, which are applied using a certain technique, which is determined by the desired effect. For example, to obtain a “bark beetle” texture, the mixture is grated with a grater in one direction. To make the surface aged, mineral plaster is treated in a special way during the drying process, causing it to crack (the “craquelure” effect).

Decorative finishing mixture

Tools used

Mineral plaster has a high alkali content, so finishers must wear protective suits. Masters also need:

- containers for making mortars or a construction mixer;

- spatulas of different sizes and hardness;

- plastic and metal graters;

- trowel.

Metal floats are used for the initial application of mortars to the surface, plastic floats are used for finishing grouting. When plastering walls with large unevenness, the following are required: beacons, corner profiles, masking tape and plaster mesh.

Material consumption

Typically, the approximate material consumption is indicated on the packaging. The exact consumption will depend on the thickness of the layer, the equipment and tools used, the level of skill of the plasterer, the specific type of plaster and its grain size, and the degree of evenness of the base. Even the same mixture, but from different manufacturers, may have slightly different consumption. Typically, up to 1-2.5 kg of plaster mass is spent per 1 square meter of wall area with a layer thickness of about 3 mm.

Consumption of plaster mixtures of various grain sizes

Plaster application technique

The material can be applied in different ways. The specifics of the work will also be determined by the required effect and purpose of the plaster layer. It is advisable to start plastering when the building has settled, otherwise there is a risk of cracking of the coating.

Preparing the walls

Some types of mineral compositions are capable of partially leveling the base, so there is practically no need to smooth out unevenness before applying them. Rough compounds themselves are used to level walls and ceilings. Venetian plaster is applied in thin layers, and before cladding the walls will have to be given a perfect smoothness.

The procedure for preparing the foundation will be as follows:

- remove old, poorly retained finish using a wire brush;

- deep cracks are opened, sealed, holes are also covered with cement mixture;

- remove metal elements or cover them with protective compounds so that rust does not show through the plaster in the future;

- Use a solvent to remove greasy stains, fuel oil, traces of oils and petroleum products;

- the soot is washed off with a 3% solution of hydrochloric acid and washed with water;

- treat the walls with a mold repellent and prime them;

- if a thick layer of plaster is to be applied, a reinforcing mesh is secured;

- To level the walls, beacons are placed, and for decorative finishing, the boundaries of the picture are marked with masking tape;

- On too smooth substrates, notches are applied and then primed.

Cleaning a brick wall from old plaster

Tools

To work with mineral mixtures, different tools may be required - the exact list depends on the technique and purpose of surface treatment. Usually the plaster mass is scooped up with a small spatula, applied to a wide spatula or trowel, and then leveled using a trowel. During their work, craftsmen also use:

- level;

- trowel;

- rollers;

- buckets;

- with brushes.

Tools for plastering facades

Masking tape, rags, sponges, guides (beacons) and corner profiles are used as consumables. To dilute the plaster with water, prepare a container and a construction mixer in advance. To apply decorative plaster, it is necessary to have a trowel made of metal, plastic, polyurethane or foam.

Solution application process

Finishing can be carried out in one or several layers, depending on the specific technique. When carrying out interior work, decorative mineral plaster is applied in a thin layer not exceeding the size of the fraction. The trowel, spatula or trowel is held at an angle of 15 degrees to the wall. The tool is moved in a straight line or in an arc. Examples of techniques used are the following:

- applying a layer of plaster, leveling from corner to corner;

- applying a new layer of plaster on the previous layer that has not yet dried;

- applying strokes of plaster in different directions using a spatula;

- transferring the mixture with a roller or smoothing out pre-applied “islands”, etc.

Usually they fill one small area of the surface (up to 1.5 square meters), and then start working with the next one. They try to work quickly, because mineral plasters harden quite quickly. If a break is required, cover the border of the plastered area with masking tape, and then remove it and continue working.

When finishing walls with rough plasters, beacons are first placed, then the area between them is filled with 2-3 layers of mortar. Each subsequent layer is applied after the previous one has dried. The first, coarsest layer is leveled with a spatula, which is held at an angle of 15 degrees, the remaining layers are rubbed with a grater. Corners are formed by placing perforated corners directly on fresh mortar, pressing tightly and leveling them.

Plastering facades with mineral mixtures is carried out according to the following method:

- the first layer up to 5 mm thick (spray) is thrown onto the wall with a ladle, spatula, and leveled using the rule;

- a day later, a second layer up to 8 mm thick (primer) is applied, rubbed, and left for another day;

- make a third layer 2-5 mm thick (covering), which can be made using decorative plaster.

Simple

Simple plaster (PS) is applied in one layer with or without rubbing. Grinding is carried out without applying an additional layer of fresh mortar using polyurethane or foam floats. No splashing or covering.

At construction sites, the material used is a lime-cement mixture; when renovating apartments, it is replaced with any mortar suitable for the premises, taking into account its characteristics. Do not think that PS is a rough smearing of mortar on the wall “just so that the bricks are not visible.” Deviations when checking the accuracy of work with a two-meter level are a maximum of 4 mm, and along the height of the wall, clearances do not exceed 7 mm.

This type of plaster is used for:

- Preparing walls for laying tiles,

- Leveling surfaces in utility rooms and basements,

- Protection of the foundation and facade from external influences.

Beacons are not used in the work; the solution is applied with a trowel, a trowel or from a station hose, and the base is leveled using a plaster rule. Layer thickness up to 2 cm.

When leveling walls in damp rooms, cement is added to the plaster, regardless of the type.

Popular manufacturers

You can find various plasters from domestic and foreign manufacturers on sale. The following companies make high-quality mineral mixtures:

- "Volma";

- "Baumit";

- "TechnoNIKOL";

- "Ceresit";

- "Eunice";

- "Caparol."

The assortment of any brand includes different materials that differ from each other in the basic composition, the presence of modifiers and polymer additives, color, fraction size and other indicators. The price greatly depends on the manufacturer, as well as on the specific characteristics and quality of the plaster. Typically, rough mixtures are sold at a price of 200-500 rubles/25 kg, decorative ones are more expensive - from 300-600 rubles and more.

Making your own mineral plaster

At home, it’s easy to make a simple mineral mixture with your own hands. To do this, you need to buy high-quality cement, sand, prepare water, a container, a construction mixer, and detergent. The process for preparing plaster will be as follows:

- pour 1 cap of detergent into a bucket of water - it will reduce the risk of shrinkage of the plaster layer after drying and will serve as a kind of additive;

- pour sand into a large container, pour it with soapy water, mix well with a mixer until the mass becomes mushy (do not pour all the water at once, otherwise the plaster will be liquid);

- dry cement is scattered over the surface of the mass (3 parts sand - 1 part cement), knead the solution again with a mixer;

- gradually add water, making the plaster look like thick sour cream;

- the dried pieces of solution along the edges of the container are knocked into a total mass and mixed;

- use plaster for its intended purpose.

Mineral plaster is an inexpensive and reliable composition that can be used to decorate, protect and decorate the interior and exterior of a home. It is universal, easy to apply, has excellent technical characteristics, and is therefore considered indispensable in finishing work.

General classification

I previously introduced you to Shuba plasters, as well as bark beetle. The issue of terrasite plaster was considered separately.

There is a wide variety of such building materials. By color and more. The main feature of the classification is composition. Namely, the main component from which the mixture is made.

So plaster compositions are divided into:

- silicate;

- silicone;

- acrylic;

- mineral.

Each type has its own characteristics, characteristics, and application technology.