Frame construction is gaining popularity among those who want to build a country house. The construction of a frame house is carried out in the shortest possible time and is quite cheap. This is due to the use of inexpensive, comfortable and lightweight construction materials.

OSB boards are often used for wall cladding. These large-format wood boards can be used quickly and conveniently to cover large surfaces of the exterior walls of a house. But many owners decide to use them, including when installing internal interior partitions. However, after the construction stage of the entire house, finishing work begins. And here the question arises: was the use of OSB indoors justified? In order to understand the rationality of such a decision, it is necessary to study all the properties of this material and the technology for its installation and finishing.

Characteristics of OSB board finishing

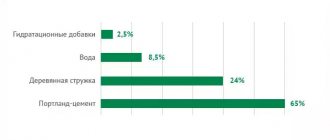

OSB boards are multi-directional layers of wood chips that have been sandwiched and glued together. In this case, pressing and gluing occurs at a temperature of 1700C. They are made from coniferous wood, and the size of the shavings used is: thickness from 0.5 to 1.5 mm, length 1-20 cm, and width 1-50 mm. Wax and adhesives based on phenol-formaldehyde resin or boric acid are used as binding materials.

The abbreviation OSB stands for Oriented Strand Board, which translates as oriented strand board (OSB). The layers in which the shavings and chips are located in perpendicular directions, as well as the properties of the binder material, give OSB the following characteristics:

- moisture resistance;

- sufficient strength;

- elasticity;

- easy workability.

OSB boards have a pronounced surface structure, consisting of a mixture of large and small chips. For cladding work, the most popular are slabs with dimensions: 1250x2500 and 1200x2400, the thickness of which ranges from 12 to 18 mm.

Also, when choosing slabs for interior decoration, you need to pay attention to the class of products. At high humidity levels, the use of a third or fourth class is required. Also, the lower the class of OSB, the lower its mechanical strength, and therefore its ability to withstand loads.

How dangerous is formaldehyde and what are the standards for its concentration in the air?

What is formaldehyde, and is it really so harmful to human health or is it just another horror story from competing marketers?

Formaldehyde (also known as formic aldehyde) is a colorless gas with a pungent odor, relatively stable at 80-100°C and slowly polymerizing at temperatures below 80°C. It has found wide application in various areas of the national economy: in the chemical industry - for the production of plastics and artificial fibers, in the construction industry - for the production of varnishes, paint, polyurethane foam, linoleum, various particle boards (chipboard, OSB, MDF, plywood) and as an antiseptic for wood processing, in leather production - as a tanning agent, in agriculture - as a fumigator when storing grain, etc.

With short-term exposure to high concentrations of formaldehyde vapor (1.2 mg per cubic meter of air), irritation of the upper respiratory tract, skin, and mucous membranes of the eyes is observed, and the first signs of damage to the central nervous system appear (headaches, dizziness, weakness). Everyday exposure to small concentrations of formaldehyde on the human body over a long period of time is the cause of chronic rhinitis, chronic bronchitis, obstructive pulmonary disease, and bronchial asthma. In addition, formaldehyde is a carcinogen: with prolonged contact with its vapors, the risk of developing nasopharyngeal cancer increases significantly.

In accordance with sanitary and hygienic standards SanPiN 2.1.2.1002–00 and GN 2.1.6.1338–03, approved by Russian legislation, the maximum permissible concentrations of formaldehyde in the air of enclosed spaces are:

- maximum single (MPCmr) – 0.05 mg/m³ (exposure 30 minutes),

- average daily (MPCss) – 0.01 mg/m³.

The value of a single maximum permissible concentration (MPCmr) corresponds to the maximum concentration of a substance in the air, at which there are still no reflex reactions of the human body to contact with this substance. The value of the average daily maximum concentration limit (MPCcc) indicates the concentration limits within which a substance does not cause direct or indirect harm to human health under conditions of constant inhalation for an indefinitely long period of time. At concentrations of formaldehyde vapor below the maximum permissible concentration, there is no need to fear the appearance of any pathological changes in the body. The substance does not have a general toxic, carcinogenic or mutagenic effect at such concentrations.

It should be noted that the requirements of the World Health Organization (WHO) are less stringent: the limit of safe concentration of formaldehyde is defined by its regulatory documents as 0.1 mg/m³ for a single exposure of no more than 30 minutes.

Wall cladding with OSB boards

Before starting interior work, it is necessary to insulate the external walls, completely cover the frame from the outside and the insulation with a vapor barrier material. Installation of OSB boards for internal partitions should be carried out on a supporting wooden frame or on a metal profile.

It would be preferable to use a metal profile, since it is cheaper, easier to install, and is not subject to moisture and deformation. If the choice was made in favor of wooden blocks, then you should ensure that the wood is well dried - otherwise, after installation and complete drying, swelling or depression may form on the surface of the walls.

The technology for installing lathing made of metal profiles or wood is not fundamentally different from each other and is carried out in the following sequence:

- Guide bars or profiles, called starting profiles, are placed on the ceiling and floor. The plane formed by these guides must be strictly vertical. This needs to be checked by level.

- Next, the location of the vertical guides is marked. This is done based on the width of the planned OSB board. The joints of two adjacent slabs must fall on one vertical guide. In addition, you need to add at least one guide in the middle of the slab. If you plan to place heavy objects on the wall in the future (kitchen set or water heater), then a vertical profile is also marked at their locations.

- A vertical profile is installed with fastening to the guides using self-tapping screws. It is important to monitor the level and adjust it if necessary.

After installing the entire sheathing, we begin to attach OSB to it. This procedure is carried out using self-tapping screws, which are screwed at a distance of at least 5 mm from the edge of the slab. The slabs must be installed with a gap of about 3 mm between them, which compensates for the deformation of the slabs due to their expansion when humidity and temperature change.

When the cladding work is completely completed, you can begin finishing.

Simple rules

When installing slabs, it is almost impossible to avoid the accumulation of formaldehyde and similar substances in the air. But this problem is easily solved with careful ventilation of the room.

Daily ventilation and wet cleaning will also help neutralize the potential harm of fumes. For reliability, you can also install a supply and exhaust system.

The rate of toxin elimination is affected by high air temperature, so the thermal regime in the room where there is OSB should not exceed 30 degrees. An increase in this indicator for every 5 points automatically doubles the content of harmful fumes in the air.

Formaldehyde is highly soluble in water, so when the humidity level increases to 70 percent, potentially hazardous substances are released 40 percent more intensely.

You can also clear the air of accumulated fumes using indoor flowers. Dieffenbachia does this job perfectly.

Finishing options for OSB boards

The use of fairly large shavings and chips in the production of OSB, despite their pressing at high temperatures, gives the surface a significant roughness and rough structure. There are options for sanded OSB on the market, but the cost of such material is much higher, which neutralizes all its other advantages. The process of interior finishing using traditional methods for this type of work requires an additional surface preparation operation, the complexity of which will depend on the material of the finishing coating.

Varnishing

OSB has a characteristic appearance, and in some cases this property is used in the design of the room. The slabs are used as a finishing material and the walls retain their structure. However, it is not enough to leave the material without any processing. Varnishing is used - a method that allows you to preserve the appearance of the slab and increase its moisture resistance. Immediately before applying the varnish, it is recommended to thoroughly sand the surface to remove burrs using sandpaper and prime it.

Coloring

Painting is the simplest and most affordable option. However, before applying paint, the surface should be leveled to hide the relief of the slab.

First of all, cover the joints of the plates and the places where the screws are attached with elastic putty and clean them after drying with sandpaper. Next, the surface is primed in two layers, and then wood putty is applied and leveled. Only after the putty has completely dried can you begin painting.

Water-based paints (water-based, acrylic or latex paints) are used as the finishing material. They allow steam to pass through perfectly and thus provide a good microclimate in the room.

Wallpapering

To obtain maximum quality when wallpapering on OSB, it is necessary to completely putty the entire surface of the slabs. Large surface roughness will be visible under the wallpaper, so maximum leveling is required. In addition, PVA glue is added to the wallpaper glue, which will give the composition greater strength.

Decorative putty

One of the exotic types of interior decoration. In this case, it is necessary to finish the joints of the slabs with serpyanka mesh or fiberglass fabric, then the surface of the wall is carefully primed in several layers with a special primer with the addition of PVA glue and non-woven fabric. After this, puttying begins.

Laying ceramic tiles

For the kitchen area or bathroom, ceramic tiles are often used as finishing. Finishing OSB boards with tiles can only be used in exceptional cases, when there is a guarantee that the wall surface will remain dry and there will be minimal changes in temperature and humidity in the room.

The fact is that ceramics and wood have different linear expansion coefficients, and the slightest changes in the state of the OSB will lead to the tiles falling off. The situation is also aggravated by the low adhesion of adhesives to the OSB surface. If you still decide to glue the tiles, you need the highest quality primer and the use of glue with the possibility of using it on wooden surfaces.

What harm does formaldehyde cause?

Formaldehyde is a colorless and odorless gas. Gas is widely used in the chemical and construction industries for the production of finishing paints and wood building materials.

Formaldehyde vapor causes irritation of the skin, mucous membranes, throat, dilated pupils, headache, loss of consciousness and weakness. Long-term exposure to gas provokes chronic bronchial asthma and other lung diseases. Formaldehyde also provokes the development of cancer of the respiratory tract.

Disadvantages of OSB for interior decoration

Despite the popularity of OSB in frame construction, you should not make hasty decisions about their use for interior decoration. The material has a number of disadvantages, due to which, even with full compliance with all finishing technology, you can get an unsatisfactory result:

- low surface adhesion - there is no guarantee that paint or wallpaper will not come off in 1-2 years, and maybe even earlier;

- the need to leave a temperature gap between the plates - additional elastic putties are required;

- low moisture resistance - the slabs may swell, rot and destroy, and the purchase of high-quality materials significantly increases costs;

- increased roughness - a labor-intensive operation to level the surface is required.

Also, this material has increased toxicity, which can adversely affect the condition of people living in a room decorated with OSB sheets.

Material selection

To sheathe a house, you need to choose the right products. For every indoor and outdoor process, there is a product type that is most suitable.

OSB is divided into categories according to technical characteristics and size, so when choosing, you need to know the properties of the material, which must correspond to a specific situation.

Due to the interweaving of the chip elements with each other, OSB is also called bonded plywood

Types of OSB

There are four main types of products:

- OSP-1. The lowest class used for interior work. Such slabs are laid only in areas not subject to loads.

- OSP-2. This variation is more resistant to impacts, but is only suitable for dry rooms.

- OSP-3. The most popular type, which is used for work inside and outside. The products are able to withstand constant load and variable humidity.

- OSP-4. This option is characterized by increased moisture resistance and resistance to serious mechanical stress.

It is the products of the third class that are universal and suitable for all stages of work, which allows minimizing costs.

With a reasonable distribution of material, you can save up to a third of the budget, so spending money on moisture-resistant OSB-3 or OSB-4 for interior work only makes sense for cladding rooms with high humidity

Optimal size

Products are selected by thickness, depending on the design characteristics:

- For cladding a frame house, slabs of 9.5 and 11 (for one-story buildings) and 12 and 12.5 mm (2–3 floors) are used.

- Finishing vertical surfaces inside rarely requires the use of parts thicker than 9–9.5 mm, except in situations where the structure will experience loads or act as partitions.

- Products with a thickness of more than 15 mm are used for the construction of main and interfloor ceilings.

To sheathe a dacha for seasonal living, you can choose OSB-6 (the number indicates the thickness in millimeters).

When purchasing a material, in addition to the thickness and level of moisture resistance, you need to take into account the size and weight of OSB boards

Using Quick Deck instead of OSB

For finishing interior walls, it is recommended to use Quick Deck Professional building boards. These boards are made on the basis of moisture-resistant high-density wood chipboard and are equipped with a tongue-and-groove joint around the perimeter. Compared to OSB, Quick Deck Professional boards have the following advantages:

- Smooth and even surface.

This property allows you to significantly save time and money on preparatory operations for finishing. The cost of primer and putty for leveling the surface of an OSB board can reach from 50 to 100% of the price of the board itself, and labor costs are commensurate with installation work. While the Quick Deck Professional surface is completely ready for any type of finishing immediately after mounting on the wall. - No gaps in joints.

Sealing joints and seats of self-tapping screws also causes considerable difficulty when working with OSB. After installation of Quick Deck Professional, the tongue-and-groove connection creates a perfectly flat, continuous surface without gaps. - Increased rigidity.

The strength of the slabs and the connection of all elements into one whole gives additional rigidity to the wall structure and the entire building frame. - No warping or deformation.

Quick Deck Professional slabs are not subject to temperature and humidity changes, which allows them to maintain their shape throughout their entire service life - Convenient format.

The dimensions of Quick Deck Professional slabs make them quick and easy to assemble and install on the wall.

Quick Deck Professional slabs with a thickness of only 12 or 16 mm are used for wall cladding, which does not create additional loads on the structure of the building.

Siding

The use of siding for exterior work is very justified, since this material was created precisely for such purposes. The cladding reliably protects the walls. At the same time, the cost of materials is affordable, and the appearance is decent.

There is vinyl siding, metal, wood and cement. Most often the first option is used. Its surface can imitate other materials, such as brick or wood. Siding is convenient to use for OSB, since to fix it it is not necessary to form a frame, as with conventional wall cladding. But, everyone chooses for themselves which option is better: with or without lathing.

But what you don’t have to choose is the presence of a hydro- and windproof membrane. Without it, condensation will form between the OSB boards and the siding, which will be transferred to the surface of the boards. This will cause them to swell.

Siding is produced with a thickness of 0.8–1.3 mm and can withstand temperature fluctuations, moisture, UV rays and mechanical damage. After covering the walls, the cladding will last for decades.

Video description

This video explains which typical house designs can be built using SIP panels:

- Reusable formwork.

OSB can be used as a material for removable formwork for foundation work. For such applications, either laminated or sanded boards are used.

Reusable formwork Source onlyprofi.rf

- Packaging.

Low price and safety factor made this sheet material an excellent solution for packaging large cargo.

The walls of the drawers are made of OSB Source tcrllc.com

- Furniture.

Using OSB for furniture production is a non-standard solution. However, such furniture looks original and can become a decoration for a designer interior.

An example of organic use in the interior Source helblingfotografie.ch