The frequency of inspection and the rules for fire retardant treatment at any facility are regulated by the requirements of the fire safety regime, and the head of a particular organization is personally responsible for observing the mentioned deadlines and checking the state of fire protection.

Current domestic laws require a certain frequency of checking the quality of fire retardant treatment of building structures, both wooden and metal. If deficiencies are identified in the protection in question, the coating providing fire protection is subject to restoration in accordance with Resolution No. 390 or No. 113, respectively, dated 04/25/12 or 02/17/14.

The regulatory documents of the fire safety regime clearly state that the responsibility for control and frequency of checking the quality and condition of fire retardant treatment or impregnation lies directly with the head of each specific organization. The same person is responsible for eliminating all deficiencies discovered during the inspection, be it defects in fire-retardant plasters, coatings and compounds, or damage to protective sheet materials, slabs, cladding, etc.

Timing of impregnation of wooden structures

The frequency of treatment with fire retardants is determined by the technical description of the selected product provided by the manufacturer. The period can be from one year to 10 years. If there are no special instructions there, then the warranty conditions of the composition are taken into account. In a situation where the manufacturer does not give recommendations, they are guided by the standard once a year. This is indicated in the rules of the fire safety regime PPR No. 390 of 04/25/2012 and in the Decree of the Government of the Russian Federation No. 113 of 02/17/2014. GOST R 53292.200 “Fire retardant compositions and substances for wood and wood-based materials” has been developed separately.

Before these rules were put into effect, the frequency of treating wooden structures with a fire retardant was once every two years. Outside the standard period, impregnation is carried out in case of damage to the primary coating or violation of the rules of its operation. That is why the condition of the treated structures is monitored once a year. Inspection and treatment schedules for high-traffic facilities are separately approved. These include schools, hospitals, and social welfare facilities. Here, together with the application of impregnation to the wooden parts, all metal elements of the structure are processed.

Requirements in GOSTs

If, according to GOST 30244, a building material is non-combustible, then it is not regulated by all other fire safety parameters.

Fire protection of buildings is regulated by GOST 30247. Fundamental requirements for fire protection under typical conditions of thermal exposure are determined according to GOST 30247.0-94. According to it, the fire resistance limit of a building is standardized. The document provides three key types of fire resistance limits for the constructed structure. These are: loss of the load-bearing property of the structure, loss of integrity and loss of the heat-carrying property of the structure.

The essence of the method is to set the time from the moment the thermal impact on the structure begins, according to the current standard, until the fire resistance limit is reached. The method used takes into account the functional features of the structure. GOST 30247.1-94 systematizes the fire resistance limits of load-bearing and enclosing structures.

Carrying out an examination

Without compliance with regulatory requirements, the building cannot be put into operation. The frequency of fire-retardant impregnation of wooden structures largely depends on the results of the examination, which is carried out according to plan:

- external inspection, during which mechanical defects of the previous protective layer are assessed. The data is recorded in a report indicating the features of the operation of the facility;

- test tests with the selection of at least 5 samples from a surface of 1000 sq.m. Their analysis is carried out at temperature conditions of +10…+40°C. Each sample is exposed to open flame. Control time – 5 seconds after cessation of exposure. If more than 2 samples show a negative result, the samples are taken again.

Stages of work execution

The process of treating wood with a fire-fighting composition consists of the following steps:

- Selecting favorable weather conditions if work is performed outdoors.

- Cleaning surfaces. You need to wipe them, removing unnecessary objects, dirt and accumulated dust.

- Measuring material moisture. Then, according to the data obtained, the total absorbency of the surface will be calculated, as well as the time required for its complete drying.

- Applying a layer of protective agent. If necessary, wait until the first layer dries and apply the second.

Important! Over time, any protected object will lose its useful properties. Testing is required to track this.

Nuances of the procedure

Who can do the work

A representative of a licensed company that carries out such orders. Permission to such companies should be issued by the Ministry of Emergency Situations, which will confirm the professionalism of the organization and its employees. In their work they are guided by regulations relating to fire safety.

You should not carry out the processing yourself, especially on a complex large object where there are metal and wooden parts. You may have to use different materials for them.

Who carries out fire retardant treatment of wooden structures?

In private housing construction, you can apply the composition yourself. At high-traffic sites or production facilities, specialists from an enterprise that has received the appropriate license from the Ministry of Emergency Situations and/or fire inspection authorities are authorized to carry out examinations and treat surfaces, in accordance with Decree of the Government of the Russian Federation No. 625 of October 25, 2006. Based on the results, a certificate of work performed is issued, and this document is considered to justify the responsibility of the contractor organization for the quality of processing.

The final stage is the prerogative of the Ministry of Emergency Situations specialists. They evaluate:

- thickness of the applied layer;

- uniformity of coverage;

- presence of mechanical defects.

Based on the results, a report is drawn up, on the basis of which a permit for further operation of the structure is issued. The act states:

- contractor;

- physical and chemical characteristics of the composition used;

- assessment of the quality of the coating.

If, according to the results of the examination of the Ministry of Emergency Situations, violations are identified, then the fireproof layer is updated regardless of the warranty period for the old one.

Operating principle and overview of types of OS for wood

A representative of an organization providing such services examines the object. It identifies surfaces that need fire protection. Owners building private houses usually invite such specialists separately. You should choose licensed companies operating in accordance with GOST standards.

External fire escape: requirements of SNiP PPB for buildings

The product with which the structure will be coated is selected based on the material from which the structure is assembled. Substances must:

- be effective;

- ensure a high and long-term level of fire resistance in accordance with all fire safety standards;

- have certifications confirming their quality;

- be low consumption, technologically advanced;

- match the type of working surface;

- have some decorative properties;

- provide for further application of paint and varnish on top.

Note! The finished protective layer retains all useful qualities for 10 years, this is the usual warranty period. You should call a technician later to repeat the procedure.

There are many protective agents, all of them are divided into two functional groups: coatings and impregnations.

Fire protection methods for wood: from classic, time-tested to modern.

| Name | Operating principle |

| Wet plaster | It generously covers the wooden parts of buildings. After waiting for drying, the load-bearing parts (pillars, columns, curtains/partitions) find themselves in a fire-resistant shell. It prevents fire and heat, not just once, but constantly. Therefore, stoves were covered with plaster. |

| A proven, simple and reliable method, although archaic and labor-intensive. Plus it requires periodic updating, because the plaster breaks off in pieces. | |

| Fire retardant coatings, mastics, pastes | A modern interpretation of classic wet plaster. Lime was replaced with a non-flammable binder - water with fillers (clay, salt, vermiculite, superphosphate). |

| The material is applied to the surface with a trowel/trowel. The finished result looks rather rough, so it is suitable for non-residential warehouses, garages and sheds. GOST 25130-82, adopted in the USSR, is in force. | |

| Facing | An effective method of protection. Natural stone, ceramic tiles or decorative brick are used. They are carefully attached to the protected surface. It looks beautiful from the outside. |

| Pros - the fire resistance limit is significantly increased, it looks beautiful, is universal, and will complement any design. Disadvantages: expensive, heavy weight of the structure, difficult to protect small geometric elements. As a result, the volume of premises decreases. | |

| Enamel, paint, varnish | Modern technique. A thin layer of protective agent is enough, and the wood will be protected from smoldering, exposure to elevated temperatures, and open flames. The external structure is completely preserved. Such materials can be used for any item, even small ones. |

| Pros: ease of use, large selection, availability of additional properties. Cons: high cost. | |

| Impregnation with special protective compounds | The most popular method now, it is used by construction companies and manufacturers of various wood products. The principle of fire-prevention wood treatment is coating the structure with an aqueous solution of salts (fire retardants). There is a distinction between superficial and more complex deep impregnation. The first one is used more often. Apply the product to the wood using rollers, brushes or a sprayer. Then the master waits a certain time until the composition is absorbed. The second is more difficult - you need impregnation baths or autoclaves. They are filled with the composition and the objects being processed are immersed there. |

| Pros: deep impact, allowing you to cover the internal structural part. This increases fire resistance. Disadvantages - the procedure is long, expensive and requires equipment (deep impregnation). |

Types of fire fighting equipment

Fire treatment technology

The frequency of impregnation of wooden structures depends on the type of fire retardant:

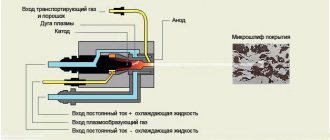

- fire retardant with deep, medium or surface penetration. The first two techniques involve complete immersion of structural parts in a solution; the surface method consists of spraying the composition with a vacuum console;

- fire-resistant paint and varnish material with swelling at high temperatures. Apply manually or by air spraying;

- paste that is used in industrial premises. In appearance, this is a simple coating of structural elements that require protection.

Fireproof protection is divided into groups. It is based on the calculation of mass loss by wood during combustion:

- Group I – less than 9%;

- Group II – less than 25%;

- Group III – more than 25%.

Fire protection test

This should be done properly by the Ministry of Emergency Situations employees. When the test period approaches, the owner calls them. In practice, specialists from the Ministry of Emergency Situations rarely come because they are busy, so people resort to the help of representatives of third-party organizations.

You can do it yourself using fire inspectors' methods, for example, making a small cut (1 mm thick) in wood impregnated with a fire-resistant agent and carefully setting it on fire. If the material is processed efficiently and has retained all its qualities, the cut will not catch fire. Private or professional inspections must be carried out every 2 years.

Verification Process

What buildings and structures require fire retardant treatment?

According to fire safety rules, the treatment of wooden structures is provided for all buildings and structures without exception. In the first place are the air ducts of ventilation and air conditioning systems. In the second - roofing elements, while metal structures and fabric upholstery are processed together with wooden elements.

In the area of increased attention are social buildings with a large number of people. These include educational and medical institutions, as well as cultural institutions. In this case, the first group of wood does not require mandatory treatment, while the second and third groups are subject to coating.