Good afternoon, dear reader! To vent the mixture of gas and fuel combustion products outside, stoves, fireplaces and boilers must be equipped with smoke exhaust ducts. Their head is covered with a special visor or umbrella. At first glance, these products seem to be only decorative elements. But in fact, the cap on the chimney pipe performs a very important function in the chimney system. It can significantly increase the energy efficiency of the heating system as a whole, and also eliminate any risk of smoke in the home.

Making your own deflector

The cost of this device starts from 1000 rubles, the upper mark is noticeably higher.

The feasibility of self-manufacturing and installation is not worth explaining. A convector chimney is a good alternative to radiator heating devices. It has many advantages and has a simple design. It's not difficult to do it yourself.

It is preferable to assemble a do-it-yourself chimney deflector from galvanized steel. But recently, a replacement has been found in the form of metal, which is coated with a protective polymer layer or simple enamel. In cases where the chimney does not come into contact with hot streams of combustion products, it can be made of plastic ( Read the article about in addition to this material

).

Video: instructions for creating a chimney deflector with your own hands

Before you start creating a deflector, you need to make a drawing on which all the dimensions of the future product will be plotted. When choosing a size, you should start from the diameter of the chimney pipe. This value will determine the height of the chimney itself and the width of the diffuser. There is a table with standard ratios of chimney and deflector sizes:

To make a chimney deflector with your own hands, it is better to make the drawings in full size. Confusion with scales can significantly delay the manufacturing process.

Necessary tools that will be required for work:

- Drawing set. Measuring tape, marker, ruler.

- Metal scissors, wooden hammer, rivet tool.

- Drill and drill bits of various diameters.

Stages of work

First you need to choose the type of metal to make the deflector. After which, having completed the calculations and made sure that they are correct, you can begin to cut out the parts of the chimney from metal. The development of the diffuser body must be rolled into the shape of a plate, then, through the drilled holes, the ends must be fastened with rivets.

The upper and lower cones are riveted together, after which fasteners are installed on the lower cone to connect the device to the chimney pipe. We advise you to study in more detail on our website.

To install the chimney on the flue duct, it is better to remove its upper module. Using a workbench, the structure is assembled and then installed in place.

Why do pipes smoke?

- Wrong

pipe diameter is selected.

- Incorrect pipe length as well as height.

- If the wind increases, cold air enters the chimney. The draft becomes less as wind pressure acts on the smoke, the smoke stops leaving the chimney and, as a result, the smoke remains in the chimney.

- The chimney is clogged with soot. You cannot use any chemicals when cleaning the chimney; to clean the chimney, you must invite a specialist.

- Perhaps a brick fell from the masonry. When strong winds rise, there are cases when bricks fall from the masonry. It is necessary to remove the brick and seal the hole with clay.

- The masonry begins to crack and cold air gets into the cracks, the draft decreases, and the fireplace will smoke. All cracks must be sealed with clay mortar.

- Condensation is released, causing the oven to become damp . Reason: when the temperature of the gases released during fuel combustion decreases. Due to the soot that accumulates on the pipe walls, it reduces the thermal insulation.

- If the chimney was built incorrectly.

- If the walls of the chimney are uneven and the cross-section of the chimney is small.

- If the chimney is installed below the roof.

- When installing a chimney near tall trees and houses.

- If the chimney passes air through the brickwork.

- If the room is poorly ventilated.

- Rain, snow.

- When it's warmer outside than in the building.

- When you light it for the first time when the chimney is frozen.

Material for making fungus for ventilation pipe

To make the fixture more attractive, it can be painted to match the color of the roof covering. Since products made of black steel look unattractive, they are usually decorated with forged elements. Unfortunately, steel models have a significant drawback - their heavy weight, so this option is not suitable for all roofs.

On sale you can find mushrooms made of copper and alloy steel, which are durable, but at the same time have a high cost. Therefore, the choice of material from which this product is made largely depends on the financial capabilities of the home owner. You can purchase a ready-made device for a pipe on the market or make it yourself, which is quite within the capabilities of home craftsmen.

Recommendations from experts

It is not recommended to install a deflector on the chimney pipe of gas equipment. Since low gas temperatures in winter can lead to the horizontal part of the chimney outlet freezing, and the deflector helps to intensify this kind of tendency.

Experts do not recommend weather vanes, since their rotating elements fail quite quickly. In winter, due to the formation of condensation, they become covered with ice, which leads to loosening of the pipe masonry. Therefore, the best option for chimneys are canopies.

An example of a “smart” deflector with a rotating hood

Which design of visor to choose depends on the cross-section of the pipe. For example, for a round chimney, most often the canopy is of an identical shape, but for a rectangular structure it can have a large number of types.

How to make a fungus on a pipe with your own hands

Making a chimney cap yourself is not an easy task. If you do not have much experience in this area, you can first transfer the drawing to a sheet of cardboard, cut it out and think about ways of connecting and fastening. After the picture becomes more or less clear, you can cut out the metal parts and start assembling

It is very important to measure the chimney accurately and strictly adhere to the measured values during manufacture

Here is one of the drawings of a chimney in the form of a small pitched roof. The angle is determined by the formula indicated on the first sheet.

Drawing of a chimney cap

Drawing of a chimney cap

The procedure is as follows:

- Place the metal blank on the table face up, in the place indicated in the drawing, drill a hole with a diameter of 3.5 mm.

- Bend the part along all the dotted lines by 90 degrees. For this it is better to use a sheet bending machine. Then the lines will be clear, without dents. If there is no such device, you will have to use improvised means: fix a piece of corner on a workbench with the shelf up. To be able to bend the entire (or almost the entire) line at once, you can use a block.

- Bend the part along the lines “d”. The angle is determined experimentally: a solid cap should be obtained. The structure should be level, without distortions (put it on the table to check). If everything “comes together”, mark a point on the lower stiffening rib with a marker through the drilled hole, mark the future hole, then drill.

- Connect the cap and secure with a 3.2mm rivet.

- Fold everything along lines “a” and “b” so that the legs can be installed.

- Along the outer perimeter of the pipe, make the base of the cap from the corners. Place the corners so that one edge rests against the masonry, and the other is on the side. Prepare the “legs” for the cap. Everything is connected by welding.

- The finished base must be cleaned, coated with an anti-corrosion compound, then painted in several layers with paint for exterior use.

- Connect the cap to the base.

If making a square chimney seems difficult to you, maybe this option will be easier. Its implementation will be quite simple if you have a piece of curved sheet metal of the appropriate size. If you have a regular sheet, you can bend it using a special device (usually available from tinsmiths).

Do-it-yourself smoker

The procedure is as follows: prepare the base of the cap from the corner according to the measurements of your chimney. Place the corner so that the structure holds well: one edge rests on the edge of the chimney, the other covers it from the outside. Make legs that will support the cap and connect it to the base. Make them strong enough to withstand wind loads and withstand snow loads. Treat all parts with an anti-corrosion compound and paint. Assemble the structure into a single whole. The collection method depends on the material.

Here is an example of how to make a deflector for a metal pipe. The author of this video has it installed on a basement ventilation pipe, although a similar design can be used on a metal pipe from a solid fuel boiler.

This video shows how to make a regular umbrella for a pipe.

You're always welcome)) How to attach the cap depends on the pipe material. Judging by the fact that the development is only square or rectangular, you have a brick pipe. If so, you can attach the weather vane to dowels, and more often. And not into the seam, but only into the brick. If the winds are strong, you can make the lower part, which will be put on the pipe, wide and beat the fasteners not in one row, but in a checkerboard pattern: from top to bottom. If you didn’t get the material right, please unsubscribe.

Causes of breakdowns and their elimination

There are three types of work and troubleshooting:

- Preventive maintenance

- Major renovation.

- Partial renovation.

Prevention is carried out to remove soot. No professional help needed. It is necessary to monitor all parts of the stove, clean it from soot and ash.

The stove smokes and burns poorly. It is necessary to check the draft of the stove and whether the fuel is suitable for this particular stove.

- Poor heat output from the stove . It is necessary to check how tightly the vent and the firebox door close; you need to use a special tourniquet.

- Strong draft , all the heat will go outside and the room will not warm up.

- If there is good draft , the gases will escape through the chimney and carbon monoxide will not form.

- The oven does not warm up . There are cracks in the chimney. The cracks need to be sealed. The main channel is narrowed; the narrowed channel needs to be disassembled.

- No traction. Clean the pipe using a weight. If this method fails to clean, you will have to disassemble the chimney to clean it. If the soot is from resin, then you need to light a fire in the chimney and clean it using this method; there are also chemicals.

- The stove begins to smoke . This problem occurs when the stove is constantly fired. It is necessary to disassemble the stove and repair the internal masonry of the chimney. The riser is clogged. It is necessary to disassemble the chimney closer to the clogged riser and clean it. From strong wind. Install the deflector.

- If wet spots appear on the pipe . This is the formation of condensation. Line the pipe with glass wool, do not heat the stove with raw wood or fuel, make the firebox larger, and make the entire chimney pipe much shorter.

- If after heating the stove for a long time and it still does not heat up, it is necessary to clean the chimney of soot.

- If cracks appear , then you need to cover them with a clay solution.

- After not heating for a long time , the traction will disappear. This means that there is cold air in the pipe. You need to set fire to a piece of paper, and there will be traction again.

Types of chimney caps

The shape of the chimney must correspond to the cross-section of the pipe.

Thus, chimney caps can be:

- round;

- square;

- rectangular.

Main design options for chimneys:

- cap-house with a hipped roof;

- house with gable roof;

- chimney with a semicircular roof;

- cap with a cone-shaped umbrella;

- with a flat umbrella.

Smokers can be equipped with additional elements:

- spark arrester;

- forged ornament;

- weather vane and so on.

If the spark arrester is a purely functional element, then openwork forging is necessary to give the cap an original and attractive look. It also serves as protection from debris and birds, but a regular grill will cope with these tasks. The weather vane not only shows the direction of the wind and acts as a decoration - thanks to its presence, the draft in the pipe increases.

Manufacturing materials

For the manufacture of chimney caps the following are used:

- galvanized sheet steel;

- stainless steel;

- copper.

Galvanized steel pipe heads withstand aggressive environmental influences well, they are practical and do not lose their color for a long time under sunlight. They can be additionally coated with colored polymer material (polyester).

You can find such caps on sale in any color, this allows you to choose a shade that will harmoniously match the color of the pipe and roof. Stainless steel is a higher-class material; products made from it will be more durable.

Copper is the most durable material for a chimney cap. If installed correctly, such a chimney will last more than a hundred years. Copper caps go well with gutters and other elements made of this metal, as well as with roofing made of natural tiles.

Over time, a head made of this metal will not only not lose its appearance - on the contrary, it will become covered with a noble patina.

Make it yourself or buy it

You can make a standard weather vane, which looks like a house with a hipped roof, from galvanized steel yourself. It is easy to cut and bend using simple tools.

If you do not have any skills and tools for the manufacture of such metal structures, then you can buy a ready-made device that is in harmony in style with the overall appearance of the roof.

The approximate price of the simplest cap model starts from 1100 rubles. The cost of TsAGI, Volpert-Grigorovich or Khanzhenkov galvanized deflectors does not exceed 3,500 rubles.

A rotating model made of stainless steel will cost much more - from 8,000 rubles. Well, the most expensive ones are exclusive forged products.

Making your own fungus for a pipe

First of all, you should prepare supplies and tools, including:

- wooden or rubber mallet;

- metal sheet 10 millimeters thick;

- marker;

- scissors for metal work;

- ruler;

- metal corner 50 millimeters wide and 1 meter long;

- a pair of gloves.

Before starting work, you need to make a drawing on a sheet of cardboard and try on the workpiece.

The sequence of actions when making a fungus on a ventilation pipe will be as follows:

- A rectangle of a certain size is measured on a metal sheet and cut off.

- To make a blank for a round lid with a cut edge, you need to cut a circle from a rectangle and cut a 45-degree corner to the center.

- The edges of the plate are bent using a mallet.

- The workpiece is given a sloping bend. To do this, you can use the corner of a desktop or the surface of an iron corner.

- The workpiece is connected along the fold lines and processed with a mallet.

- To eliminate shape errors, it is necessary to walk the workpiece along a flat surface. Now the hat is ready.

- For the base you also need to cut out a rectangle. To know its length, take measurements from the pipe and add a few extra centimeters. The ends of the workpiece are processed with a mallet. Give the plate a cylindrical shape and connect the ends.

- 3-4 legs are made from the remains of the metal sheet, folding the pieces in half. Holes are drilled at their ends, then the legs are bent from below.

- Holes are drilled in the cap at regular intervals and the legs are attached with rivets.

- Try the cap on the base and use a marker to mark the places for the rivets. Having drilled holes, fasten the fungus structure with rivets.

Before proceeding with final assembly, you need to make sure that the cap is even by placing the cone on the most flat surface possible. Before painting the product, before connecting the elements, the workpiece is cleaned, primed, and coated with an anti-corrosion agent. The paint composition for exterior work is applied in 2 – 3 layers.

Making a Simple Round Umbrella

To perform such work, you need to prepare tools: a drill, metal shears, a hammer and equipment for installing rivets. Once the size of the fungus is determined , work is performed in the following order:

- Screw two self-tapping screws into a wooden plank, maintaining a distance between them equal to the radius of the product + 15 mm. It turns out to be a homemade compass, with which you can make a mark on the metal, marking the central part of the circle. Its outline is also drawn.

- The workpiece is cut with scissors, after which a sector is drawn, the arc length of which is 120 mm. The resulting figure is somewhat reminiscent of a piece of cake.

- The indicated wedge is cut out, and then the outer edges of the figure are aligned with force. Fix them with a vice.

- Drill three holes along the resulting line and connect the ends of the part with screws or rivets. The upper part of the weather vane can be considered ready.

Using steel strips, legs for the fungus and a clamp encircling the pipe are created. They take thin sheets that are bent several times. These parts are similarly secured to the umbrella with rivets.

DIY making

Before you make a fungus on a pipe with your own hands, you need to choose a model. Standard cap designs are recommended for beginning craftsmen.

The work will require:

- steel sheets;

- scissors for working with metal raw materials;

- ruler or measuring tape;

- sheet benders;

- markers;

- sheets of cardboard;

- welding device, etc.

The protective fungus is installed in several stages:

- measurements;

- drawing up a product drawing;

- transferring data to a metal sheet;

- creation of blanks;

- assembly.

Work begins with measuring the dimensions of the chimney pipe and developing drawings of structural elements on a sheet of cardboard or thick paper. It is necessary to add up to 5 mm to the standard dimensions for comfortable placement of the product on the pipe.

After checking the accuracy of the measurements, the data is transferred to the material, the lines are marked with a marker. Metal scissors are used to cut out blanks for the product.

The elements are placed on a flat surface. Using a sheet bender, the lines marked on the canvas are sequentially formed to the angle required by the design (average 90°). In places for connection, 3 openings are made at a distance of about 15 cm. The elements are fixed with rivets.

Brackets are made from metal sheets. The elements are welded to the umbrella and apron. The joints are treated with a metal primer.

Finally, the cap is coated with an anti-corrosion compound and paint in 1-2 layers. The structure dries for 1.5-2 hours and is attached to the base of the pipe.

Master class from the Country Master on how to make a cap for a chimney pipe

Watch this video on YouTube

The principle of operation of the cap on the chimney pipe

- The air flow, hitting the walls of the upper cylinder, bends around it from all sides.

- The air stream, sliding along the surface of the cylinder, turns upward, thereby sucking in the smoke coming out of the pipe.

- The movement of air inside the pipe becomes more intense, therefore, the draft increases.

- When wind flows are not horizontal, but vertical or at an angle, the wind vane also helps to increase traction. Wind currents penetrate the upper cylinder through the gap and suck smoke into the chimney.

- When there is a low wind, vortices are formed under the weather vane hood, which slow down the release of smoke.

High-quality and competent organization of draft in the chimney system is, first of all, not only the safety of the people living in the house, but also a prerequisite for the proper operation of the heating system. Therefore, it is worth taking the time to make and install a chimney umbrella yourself. This simple device will help not only to organize the correct operation of the heating system, but also to eliminate weak draft in the pipe.

Principle of operation

Before making a plastic or metal chimney cap, you need to become familiar with its operating principle.

Most often, the fungus is used to protect the pipe from precipitation, debris or birds. It is also installed to catch sparks that may fly through the chimney while the stove is in use.

The operating principle of this design is quite simple. It is equipped with a protective cap that covers the smoke outlet and thus protects it.

There are also deflectors that speed up the removal of combustion products. Their operating principle is based on the law of aerodynamics. When gusts of wind collide with the deflector, an air rarefaction effect occurs. This helps to increase draft and remove smoke.

To better remove combustion products from the deflector, it is equipped with an additional cap. It is installed under the cover of the structure.

How to choose

When choosing a hood, you need to base it on the functions for which it will be intended.

When choosing a ventilation hood, you should pay attention to the following characteristics:

- Dimensions. To select the size, assume that the width is 10 centimeters larger than the surface for which it will be installed.

- Room temperature. When choosing, you should take into account the temperature of the vapors and gases entering the chimney. On this point, it is better to consult a specialist.

- Air flow. This indicator is calculated from the volume of the room, power and number of installed plates. Prepare this information before purchasing and present it to a specialist.

- Air speed and resistance. The air exchange of the umbrella should be from 0.8 to 1.5 meters per second. If the speed indicator is lower, this will significantly reduce the quality of work.

When choosing, pay attention first of all to the type of umbrella you need (see above), and when purchasing and manufacturing, proceed from this parameter

Installation technology

The main requirement of building codes is that the cap should not impede the exit of flue gases from the pipe .

To comply with it, you need to follow a number of principles:

- When the pipe is removed from the roof ridge by 1.5 meters or less, the top of the cap should rise above the ridge by at least 50 centimeters .

- When the pipe is removed from the ridge by 1.5-3 meters, the head should be on the same horizontal line .

- When the pipe is 3 meters or more away from the ridge, the head should not be below a straight line drawn from the top of the roof at an angle of 10 degrees .

- If the height of the external chimney masonry is 1.2 meters or more, then before installing the cap you need to secure the pipe with roof braces .

Most head models are prefabricated, which simplifies their installation. The general installation algorithm is standard for all additional elements: first, the main product and its additional parts are fastened, then all joints are sealed.

The head should not impede the exit of flue gases from the pipe

The lower part of the cap is installed first; it must be attached to the top of the chimney. Screws or rivets are used as fastening elements.

Next, intermediate elements and the top of the structure are installed, which are connected to each other using brackets. Rubber or silicone-based compounds are used to seal joints. Particular attention should be paid to insulating the joints of the head and chimney.

Form and function

The main tasks of the chimney cap:

- Increased air draft;

- Protection against birds accidentally flying into the pipe;

- Preservation of the chimney masonry;

- Protection from snow and rain.

Please note: the use of a hood increases the efficiency of the chimney by almost 20 percent.

The pommels differ in geometry, shapes and sizes. Their varieties are determined by the style of the facade of the house and the peculiarities of the weather vagaries of the area.

- Umbrella (cover) – protects the pipe from rain and snow. Can be made in the form of a weather vane, flat cover or gable cover.

- Drip cap - removes moisture from the pipe walls and stops the formation of ice.

Caps are made from materials that are resistant to the destructive effects of weather conditions. This product is fixed in a very hard-to-reach place, so it is better not to save money and purchase stainless steel or sheet copper.

Some features of the use of caps:

- The semi-circle shaped deflector is more suitable for European design;

- An umbrella with a flat top will look natural on a cottage in the Art Nouveau style;

- A wind vane with a weather vane installed can be equipped with a damper, which will make the pipe work effectively even in the absence of wind;

- A weather vane with a gabled top promotes intensive ventilation;

- Hoods with a movable roof make it easy to clean the chimney.

Design

A chimney cap is a device that resembles an umbrella or canopy in appearance and is installed on the head of the chimney to protect against moisture. There are a huge number of variations in the appearance of weather vanes, depending on the shape and size of the smoke exhaust duct. The design of all types of hoods consists of the following elements:

- Protective umbrella. The top of the cap is in the form of a cone, pyramid, semicircle or other more complex shapes. The umbrella protects the chimney from precipitation, debris, and birds from entering the chimney.

- Drip apron. This element of the cap protects the pipe head from drops bouncing off the umbrella. It helps to increase the service life of the chimney, prevents corrosion and fungus. The apron is used when a cap is installed on a rectangular or square pipe.

Important! For a chimney, you can make a cap with your own hands from sheet metal, however, more complex models are easier to buy or order. The most convenient type to maintain and operate is a protective umbrella with an opening lid. Due to the mobility of this element, the protective visor is not removed during cleaning or inspection of the chimney.

To make a durable cap for the chimney pipe, sheet metal that is not subject to corrosion is used. DIY production from galvanized steel, copper or aluminum is common. An umbrella with a copper head has a noble shade, it looks respectable, but often becomes a “victim” of non-ferrous metal collectors.

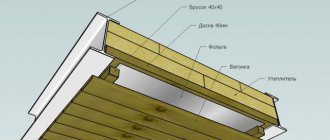

Installing a protective apron around the pipe

To ensure that the connection of the roof deck to the chimney system is airtight, an apron is installed on the roof slope.

Or rather, two are installed: internal and external. The inner one is under the finishing roof deck, and the outer one is above it. A waterproofing flashing is necessary to prevent melt water from getting into the attic and into the house. You need rolled metal sheets with a height of 40-45 cm. A flexible lead or aluminum tape, which can be easily cut with metal scissors, is suitable. On the pipe at a height of 20 - 25 cm from the rafters, a line is marked on all four sides, which will be parallel to the rafter flooring. A 1.5 cm deep groove is laid along this line along the entire perimeter. You can cut it with a grinder, then wash the cut or blow off the sawdust.

The installation of a metal apron begins with the bottom wall of the pipe. Take a piece of sheet 15 cm longer than the width of the pipe wall. To enter the groove, bend the tin along the edge by 1 cm at an angle of 90º in one direction and after 20 - 25 cm bend the remaining part at an angle of 90º in the other direction, use the remaining 20 cm to overlap under the roof covering. This will prevent leakage. Do this on all four sides. Fill the edges of the additional elements inserted into the groove with heat-resistant sealant.

After the finishing roof covering has been installed, you can install an external apron. It is more necessary as an aesthetic element. Therefore, a material is selected for it that will be harmonious with the roof. It is easy to select rolled products with a polymer coating both in color and quality. An apron for a round chimney can be purchased in a store; it comes in metal with adjustable sizes and silicone (rubber), which is easily adjusted due to the elasticity of the material. Making a roof passage by hand is even easier than making a chimney cap.

Such a structure can only be attached to the roof system. since shrinkage of the house can play a cruel joke and prematurely damage either the pipe or the apron. A clamp with an elastic heat-resistant gasket must be put on the pipe.

Wind vanes on the chimney pipe

How and from what to make umbrellas for chimney pipes. Headband for a chimney pipe. Installation of a chimney on the roof.

Advantages and disadvantages

The advantage of installing a cap on the chimney is:

- more aesthetic appearance of the chimney duct;

- protection of the internal space of pipes from foreign objects and various debris;

- protection of the chimney material from the effects of precipitation;

- the chimney covers part of the mouth, preventing the wind from overturning the draft.

There are not many disadvantages to installing an umbrella on a chimney, but they are quite significant:

- the product is installed in the path of combustion products exiting and serves as some obstacle to their free outflow. An incorrectly selected and installed model can reduce draft and lead to smoke in the room;

- The water vapor generated during fuel combustion exits along with the smoke through the pipe to the street and condenses, coming into contact with the cold metal of the cap, and then freezes when the temperature drops below 0º. As a result, icicles freeze on the chimney, blocking the passage opening of the pipe and preventing the smoke removal process.

How to choose a cap

Most often, heads with a hipped roof are used for brick pipes, and chimneys with cone-shaped umbrellas are used for round pipes.

However, it is worth paying attention to other options. For example, a cap with a gable top provides better protection from snow

IMPORTANT!

The shape of the chimney cap is not so important. In order for it to fully perform its functions, the main thing is to choose the right size. The overhangs of the umbrella should protrude several centimeters beyond the outer perimeter of the pipe on all sides.

If you want to ensure that leaves and other debris, as well as birds, do not get into the pipe, you need to opt for a cap with a mesh located under the umbrella. The role of the mesh can be played by artistic openwork forging; such heads not only cope with the tasks assigned to them, but also have an excellent appearance.

- Painted chimneys are not suitable for wood stove pipes, as the paint fades quickly.

- Heads with a sealed double lid better withstand exposure to hot air, and two-story models allow for better ventilation.

- A cap with a deflector will provide the best possible draft and thus increase heating efficiency.

- If you install a cap with a hinged lid on the pipe, it will be easy to clean.

When choosing a cap, you need to find a model that not only looks good, but also harmoniously combines with the rest of the elements of the roof and the house in general and will fit well into the exterior of the building.

Types of different caps

For buildings that have a distinctly modern look, caps with a flat roof are suitable, and for most standard “classic” brick houses, the best choice would be a cap with a hipped, gabled or semicircular cap.

To correctly select the size of a cap umbrella for a brick pipe, you need to measure its length and width. If there is an extension at the top of the chimney, the umbrella must cover it too, which means that it is necessary to focus specifically on the dimensions of the outer perimeter of such an extension. The base of the cap should fit easily onto the chimney, but it should sit tightly; to find the required dimensions of its long and short sides, add 4-5 mm to the length and width of the pipe.

Tips and tricks for choosing

When choosing a hood design, you should take into account what material the chimney pipe is made of and the type of fuel used to operate the heating device.

This is due to different flue gas temperatures and heater efficiency:

- For a brick stove with a chimney of square or rectangular cross-section, also made of brick, a special cap is suitable - a deflector. A feature of chimneys of this shape is the danger of the formation of vortices, which impair draft. In addition, more soot, soot and dust are deposited on the rough surfaces of the brickwork, narrowing the lumen of the pipe, which can greatly impair traction, even to a complete stop. The deflector will protect the chimney walls from excess moisture, thereby reducing the adhesion of combustion products and acting as a draft amplifier. It will create a vacuum in the upper part of the channel and promote the outflow of air from the firebox;

- Solid fuel boilers are usually equipped with ceramic pipes or chimneys made of “sandwich” pipes with a double wall. They have a smoother surface than brick structures and are equipped with a condensate collector into which condensate and precipitation drain, so they have much less soot deposits on the inner walls. The draft stability of such boilers depends on the height of the chimney. If you do not organize forced draft, then you need to install a very high pipe (up to 8 m). When installing a deflector, the height of the chimney can be reduced by 15-25%, while the stability and draft force will remain at the same level, and installation of the reduced pipe structure will be less complicated. If you have a boiler whose operation is based on the principle of pyrolysis, it is better to install a cap with an open nozzle on the chimney pipe. It will be able to protect the channel from debris and precipitation, but will not become a barrier to the exit of low-temperature smoke;

- For gas and diesel boilers, it is also recommended to use a hood with an open nozzle. In them, the draft is forced, so there is no need to increase the draft using a chimney - deflector.

Installing the deflector

Its effectiveness has been proven by many owners of houses and cottages who have used this model.

Despite the fact that the price of such products can reach up to $140 for standard designs, the demand for them remains constant. In order not to overpay, you can make the described device yourself. The whole process will take no more than 3 hours. It all depends on the skills of the collector. At the first stage, a drawing is created, after which the blanks are made. Next comes the assembly of the device and its installation on the chimney, followed by fastening.

Before drawing drawings, you should calculate the diameter of the outlet pipe and the diameter of the cap

It is also important to measure the height of the deflector itself. To prevent mistakes at this point, special formulas will help:

- height=1.6−1.7 x diameter;

- diffuser width=1.2−1.3 x diameter;

- cap width=1.7−1.9 x diameter.

After drawing the outline of the blanks on paper, you can proceed to creating metal blanks.

It is better to take stainless or galvanized steel, the thickness of which varies from 0.5 to 1 mm. After preparing the metal pattern, you can begin the assembly stage of the product. This will require a drill, riveter or welding. If the latter option is preferred, maximum care must be taken so as not to burn through the deflector section.

The cap is secured to the base with legs, which are drawn in the same way on paper and then cut out from a sheet of stainless steel. When all these stages have been completed, only the most crucial moment remains - installation on the chimney.

Drill holes on the pipe to secure the deflector. Rivets are fixed. After this, you need to check whether the installed device has a slope in different directions. Installation of a clamp will be required if the deflector is loose. If the pipe is not made of brick, this option will come in handy. If we are talking about a ceramic pipe, then you will have to use special adapters.

Gable model

To make a gable weather vane, you need to use a machine called a sheet bender.

Just as in the previous case, first measure the outer surface of the brick chimney. Calculate the pattern and make the corresponding diagram. Next, the cap is assembled using a simple algorithm.

You need to cut the metal and bend it following the dashed lines. The resulting parts must be connected with rivets. The function of rigid racks is performed by ready-made corners made of painted metal , the thickness of which varies from 0.5 to 0.7 mm.

European cap

This model is more designed to prevent the formation of condensation and has a rounded appearance. A chimney of this type can be made independently using a steel sheet and hand-made holders.

How to make a European cap:

Take a standard metal sheet and carefully bend it around the pipe, or directly along the contour of the chimney. They remake the spoons that will hold the cap directly on the pipe. It is best to do this with a special machine or ask a welder you know

You can also make transverse cuts that do not go all the way and carefully bend the strips using pliers. These cuts do not have to be transverse. It is permissible to use longitudinal strips if the piece of metal is quite long

A rectangle is cut out along the edges and the tails are left in the center. After this, roll the sheet in the shape of a semicircle and press the tails with a clamp. Gently bend the legs.

It is permissible to use a regular chimney pipe clamp to mount such a cap on the pipe.

To make a European cap, all you need is a piece of sheet metal and a grinder disc.

Varieties

The abundance of shapes and types of chimneys force manufacturers to produce caps of various shapes, styles, and sizes. In construction stores you can find the following types of products:

- Standard weather vane. Her umbrella is a pyramid made of sheet metal, attached to a drip apron using brackets.

- Four-slope weather vane. The top of such models resembles a hipped hip roof. As a rule, they are used for rectangular brick pipes.

- Wind vane with a semicircular umbrella. It is used for installation on the roofs of European-style houses. From the point of view of increasing traction, it has low efficiency, however, it looks beautiful on the slope.

- Flat weather vane. It is equipped with a flat rectangular umbrella and is used for buildings in the minimalist and modernist styles. The flat cover of the hood does not allow snow to roll off, which is why the brackets of such models experience increased load and sometimes become deformed.

- Round weather vane with a cone-shaped umbrella. They are used to protect round stainless steel pipes; such models are not equipped with a drip line.

Note! Wind vanes are equipped with additional functional elements: dampers, double roofs, folding doors. Don’t get carried away with elaborate details, because the main thing in choosing a deflector is durability and efficiency. An ill-conceived shape can cause noise or vibration in the pipe.