Description of material

Hardboard boards.

Hardboard is a sheet of pressed waste from the woodworking and pulp industries. It is widely used for assembling furniture, performing construction and repair work.

Outwardly, it looks like a fibrous building material, one side of which is rough, the other smooth. It acquires its strength properties thanks to the manufacturing method - pressing and adding special components.

The difference between hardboard and fiberboard

The difference lies in the composition and characteristics. Hardboard boards are more rigid and dense. They are often made thick, but there are also thin varieties. One or both sides can be painted, varnished or laminated.

Sometimes fine wood pulp plays the role of coating. It gives the surface evenness and smoothness. If you compare photos of hardboard and fiberboard, it is impossible to understand what kind of material it is. The latter belongs to the soft and semi-hard varieties, but it is imperceptible even tactilely.

Material on the topic: What is OSB board

Production technology

Manufacturing stages:

- Washing and chopping wood chips. The raw materials are steamed and broken into fibers. The process is repeated several times until the particle size reaches a length of 1.5-2 mm and a width of 0.04 mm.

- Filling. A mass of wood fractions mixed with water is infused. Stir occasionally.

- Mixing, sizing. Adhesives, polymers, resins and other additives are added to the raw materials, affecting the characteristics of the final product (strength, moisture resistance).

- Heat. The mass is thoroughly mixed and brought to a temperature of +60°C.

- Molding. When the humidity reaches 72%, the raw materials are distributed into casting molds.

- Pressing. The sheets are squeezed under high pressure to squeeze out excess moisture.

- Drying and hardening. After vacuum drying, the moisture content of the workpiece is reduced to 8%. Afterwards it is compressed under a pressure of 0.85 MPa and calcined again.

- Steam treatment. The workpiece is kept under hot air, the temperature of which is +190...+210°C. At the same time, impregnation components are added to improve the moisture-resistant qualities of the finished product.

The formed slabs are sent to a rolling mill, where they are cut to specified sizes. Before being sold, they are kept in the warehouse for 24 hours.

Knowing the technology, it is easier to understand what hardboard is and what it consists of. The second production method is used for the production of soft and semi-hard fiberboard varieties. It involves grinding the fibers, pressing them and processing them at high temperature and low pressure.

The technology is distinguished by the absence of the stages of washing and infusion in water. Because of this, the workpiece has a porous structure. It is less rigid, has low thermal conductivity, and is therefore used for insulating walls and roofs.

On the rolling mill, the blade is cut to a given size.

Material composition

Hardboard is based on crushed wood fibers, shavings, paper, and cellulose.

Components are added to the composition to improve its characteristics:

- Phenol-formaldehyde resins, binders. They act as glue, binding fibers and imparting rigidity.

- Pectol, polymers. Provide resistance to mechanical stress.

- Antiseptics. Prevents the development of fungus and mold.

- Fire retardants. Increases fire resistance.

- Hydrophobes (paraffin, rosin). Responsible for moisture resistance and water-repellent properties.

The use of low-toxic components is permitted during production. The share of adhesive substances should not exceed 1.5% of the total mass of the product.

The process of grinding wood chips to make hardboard.

Performance characteristics

The characteristics of the material depend on the manufacturing method, density, thickness of the sheets, and the inclusion of additives.

The average indicators are presented in the table.

| Characteristics | Soft varieties | Semi-solid | Solid | Super hard | Solid waterproof |

| Humidity, % | tends to 0 | tends to 0 | 5 | tends to 0 | 3 |

| Density, kg/m³ | 100-400 | over 600 | 800-1000 | 950-1000 | 850-1000 |

| Tensile force limit, MPa | no data | no data | 0,3 | 0,32 | 0,3 |

| Limit under bending forces, MPa | up to 1.8 | 15 | 33-38 | 47 | 40 |

| Swelling in 24 hours, % | no data | 40 | 20-23 | 13 | 10 |

Laminated hardboard and regular: what is the difference

Laminated products are produced by applying decorative PVC film to the front side of the workpiece. Bonding occurs due to the adhesive composition and heating. This type of processing is called caching.

To create a protective and decorative coating, melamine film is also used - paper impregnated with melamine-formaldehyde resin. It is applied to the surface of the slab and pressed using elevated temperature.

Due to heating, the resin reliably fixes the protective film. It can have a pattern: imitation of wood fibers, stone or brickwork, plain and abstract textures.

Differences between laminated material and untreated material:

- Higher cost.

- Mechanical resistance: protected from scratches, abrasions and accidental damage.

- Practicality. Less dirty and dusty.

- Easy care. When cleaning, you can use water and chemicals without fear of causing damage or changing properties.

- Durability. Manufacturers indicate a service life of 20 years.

- Aesthetics. The scope of application is expanding due to the variety of textures.

- Moisture resistance. Penetration of water inside and swelling is practically eliminated.

- Strength. Due to the lamination of the walls, rigidity increases, but flexibility decreases.

Laminated and plain hardboard.

Advantages of finishing fiberboard floors

A floor lined with fiberboard is suitable for laying linoleum or parquet.

Fibreboard is a fairly popular material. It is often used for repairing and finishing various surfaces.

The material gained its popularity due to its low price and good quality. Most often, fiberboard is used for:

- floor leveling;

- laying under linoleum or parquet;

- finishing of different surfaces.

The advantages of this material are:

- Quite a simple installation method.

- High strength despite fragile appearance.

- Protection against temperature changes.

- Long service life.

- Environmentally friendly, because fiberboard is made only from natural ingredients.

- Low price.

Moisture has a detrimental effect on this material.

- to level the floor you will need a beam that will act as a base;

- low protection against moisture;

- with strong mechanical impact or impact, a gap may form between the lags;

- low fire resistance, which can become critical in a fire;

- Additional protective treatment is required, otherwise the coating will wear out quickly. To see what happens to fiberboard in a damp room, watch this video:

Thus, fiberboard is a good solution for treating almost any surface provided there is low humidity.

Where is hardboard used?

Hardboard blanks are widely used in the furniture industry for the manufacture of:

- back walls;

- bottoms of drawers;

- doors, frame (super-hard and laminated types);

- decorative facade.

A sheet with high flexibility is capable of stretching. Furniture of non-standard radial shape is made from it. It became a replacement for more expensive plywood. This allowed manufacturers and assemblers of cabinet furniture to reduce production costs.

In the field of construction, hardboard is used for cladding interior doors, partitions, and attic floors.

Hard grades are suitable for arranging a rough surface before laying laminate or linoleum. Laminated types are widely used in design, as this allows you to “play” with textures.

Hardboard can be used as packaging. For example, construct dense boxes and crates from it or lay it on both sides of some building materials to protect surfaces from damage and damage.

Interior decoration of the room with hardboard sheets.

Scope of application

Fiberboard has proven itself to be a reliable component in construction, finishing works, and in the furniture industry. A solid slab is needed to level floors, walls, ceilings, build elevator cabins, install partitions in rooms, build ventilation ducts, and as packaging containers.

Fiberboard for floors, walls and ceilings is also used as soundproofing and heat-insulating materials.

In furniture making, fiberboard is needed for the back walls of cabinets and chests of drawers, as well as the bottom of drawers. Decorative fiberboard wall panels look modern and stylish in place of the kitchen apron.

Types of hardboard by markings

Product marking is carried out using letters that explain the degree of density and hardness:

- M - soft.

- NT - sheet with low hardness (semi-hard).

- T - hard.

- ST - super hard.

This classification is typical for both types of wood-fiber building materials, but fiberboard is not marked with the letters ST, and hardboard - M. This is due to the degree of their density.

Additional letters in the marking indicate the properties of the product:

- T - untreated (one side is porous);

- TS - one or both sides are smooth (application of finely dispersed mass);

- T-P - the outer part is treated with varnish and paint;

- T-SP - covered with a finely dispersed mass and painted;

- T-B - contains substances that improve water-repellent characteristics;

- T-SV - covered with a finely dispersed mass, painted, moisture resistant.

The sheets come in grades I and II. For the first, the presence of defects, chips, scratches, depressions on the surface, different shades of coating or damage to the integrity of the edge is unacceptable.

Material Density

You can find out about the density of the material by marking. The area of application of the selected slab also depends on this parameter. For example, hardboard with a strength of 800-900 kg/m³ is best used as the back wall of furniture, since its structure resembles cardboard.

It is also suitable for creating packaging, packaging, finishing and construction work.

Denser grades (900-1000 kg/m³) are used for arranging subfloors. You can use them to assemble furniture and create decor, especially if they are laminated or coated with varnish and paint.

Hard hardboard grade.

Moisture resistance of hardboard

Denser brands that have a protective layer or are laminated have the greatest moisture resistance.

Solid brands swell by 20% when left in water for more than a day.

Superhard ones are saturated with moisture 2 times slower under similar conditions. Material with increased resistance to swelling is marked with the letter B.

This means that it is impregnated with special components that prevent water from affecting the fibers. It is suitable for use in damp environments.

Tensile strength

When performing some types of work, the slabs need to be bent. In this case, you need to choose softer sheets of small thickness. They have sufficient strength, but are better susceptible to deformation.

When choosing a brand for conditions where stability under loads is important (for example, installing drawer bottoms), you should pay attention to the tensile strength. This parameter is higher in hard and superhard types. It will be larger for thick slabs.

Thick soft slab.

Fibreboard cutting procedure

When processing using sheets, it must be taken into account that cutting of the material may be necessary. Some shops provide this service, but you will need to tell them the exact dimensions of the room where the work will be carried out. For more information on how to cut material, watch this video:

Keep in mind that it is better to make the material shorter and use the empty space for installing the plinth, rather than leaving excess, which is very difficult to get rid of.

Cutting using a machine will provide higher quality work. If this is not possible, you can use the following tools:

- jigsaw;

- saw with special discs;

- Bulgarian

Jigsaw device

Trimming is quite often used to create recesses for pipes, plumbing and heating systems, and niches for walls. Holes can be made using a jigsaw or a sharp construction knife. We recommend that you first make a template on cardboard and only then mark the sheet.

Hardboard size range

For everyday use, sheets are cut into lengths of 120-366 cm and widths of 120-214 cm. The parameters may vary for each manufacturer. Standard sizes: 122x214 cm and 122x275 cm. For production needs (for example, furniture factories), blanks are made 1.2-6 m long and 1-1.8 m wide.

Soft stamps are molded thin - 2.5-4 mm. Plates of medium and hard hardness are 8-25 mm. Therefore, they also have greater heat and sound insulation. Superhard grades are molded at 2.5-6 mm.

Standard slab sizes.

Types of fiberboard

Choose the optimal type of fiberboard

The material can have different densities. According to this indicator, slabs are divided into the following types:

- Soft fiberboard. The density does not exceed 350 kg. The product has high porosity. Perfect for insulating and insulating any surface. It has good sound and thermal conductivity.

- Semi-solid. The density of such material is no less than 850 kg. Mainly used for furniture production.

- Solid. Density varies from 800 to 1000 kg. They have low porosity and are used to make furniture and doors.

- Super hard. The density indicator is not less than 950 kg. They are used for finishing various surfaces, as well as in the manufacture of furniture. The front part is smooth and covered with protective varnish or paint.

Fiberboards are produced in standard sizes. Length varies from 1220 to 3000 mm. Width from 1220 to 1700 mm. The thickness ranges from 2.5 to 40 mm. The dimensions depend on the type of product and its density.

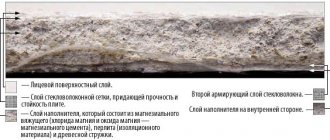

Hardboard design

The raw building material has a cork structure. The presence of a coating of finely divided wood pulp gives smoothness. The shade is close to natural: from light beige to brown. Products can be painted white, black and other colors.

Laminated sheets come in different designs. For example, hardboard panels for walls are made to imitate the structure of wood, stone, tile, and brick. They can be used for decoration.

Variety of slab designs.

How to choose material

When choosing slabs, you need to understand their purpose. This determines what density, flexibility, and water resistance are suitable, what sheet sizes will allow you to save on delivery and installation.

Hardboard

For furniture, it is better to buy soft or semi-hard brands. Important criteria are flexibility, resistance to stress and stretching. The laminated version is suitable for external doors or creating decor.

If sheets are needed for use in conditions of high humidity, it is better to purchase a hard, extra-hard variety with a protective coating and high resistance to swelling.

Slabs as building materials must be rigid and durable. You can choose layers for large floors or walls to simplify the fastening task.

Criterias of choice:

- appearance;

- edge sealing;

- presence of scratches, chips, stains;

- product thickness;

- dimensions (ease of transportation, storage, installation);

- price.

Fiberboard

When choosing fiberboard, you should be guided by the principles described above. Since the material is softer and more flexible, it has less moisture-resistant properties, so it is not suitable for all types of work.

Fiberboard does not have a protective coating, which affects its service life. It is best chosen for situations where flexibility and tensile strength are more important than rigidity. For example, to create radial-shaped furniture.

Fiberboard sheets are softer than hardboard.

Standard sheet sizes

To save on the purchase of materials, you need to take calculations seriously. If the sheets are too large, they will have to be cut, and the pieces will go into the trash. These are unnecessary expenses. Ideally, when drawing up an estimate or cutting drawing, you should choose a slab size such that as little hardboard as possible goes into waste.

The table shows the standard sizes of fiberboard sheets according to GOST 4598-86 .

| Slab type | Length, mm | Width, mm | Thickness, mm | |||||

| Nomin. | Prev. off | Nomin. | Prev. off | Nomin. | Prev. off | |||

| Maximum | Main | Maximum | Main | |||||

| Solid | 6100 | 3660; 3355; 3050; 2745; 2440; 2140 | ±3 | 2140 | 2140; 1830; 1525; 1220 | ±3 | 2,5; 3,2; 4,0; 5,0; 6,0 | ±0,3 |

| 5500 | 3660; 3050; 2745; 2440; 2350; 2050; 1830; 1700; 1220 | 1700; 1220 | 1700; 1220; 610 | |||||

| Soft | 5500 | 3000; 2700; 2500; 1800; 1600; 1220 | ±5 | 1220 | ±5 | 8,0; 12,0; 16,0 | ±1,0 | |

Manufacturers can meet the customer halfway and produce a batch according to individual sizes. In this case, the maximum side length of soft material is 5.5 meters. The indicator for solid species is 6.1 meters.

Storage Features

Hardboard sheets are intended for indoor use, so it cannot be stored outdoors. With prolonged exposure to moisture and ultraviolet radiation, it can be destroyed.

In warehouses, products are stacked according to size and grade. The height of the stacks should not exceed 3.5 m. This will avoid excessive pressure on the material and changes in its strength properties.

During handling and storage, manufacturers must ensure that there is no mechanical impact to avoid damage to the surface of the sheets.

Storing slabs in warehouses.

Technology for installing material on a frame

To install the material on the walls and floor, you need to prepare a frame. It can be made from timber or slats. For use in rooms with high humidity, it is worth using metal profiles. Fiberboards can be secured with nails and self-tapping screws.

Instructions for hardboard

Instructions for installation on the frame:

- Frame padding. Due to the high strength of the sheets, cells can be made 30x30 cm or larger. The material will not bend or sag under its own weight.

- Laying insulation and water barrier if necessary.

- Slicing. If possible, it is better to lay whole canvases. Then less time is spent on fitting and installation.

- Fit. The parts must be in close contact. If the dimensions do not match or cracks are found, cut off the protrusions.

- Laying. The blanks should be placed end to end. Place spacers under the joists on uneven areas. If the hardboard is laminated, you need to pay attention to the design. If there is a stylization for masonry or stone, you may need to customize the design.

- Installation. Nail to the sheathing.

- Treatment. The surface can be treated with varnish or paint.

You can seal the seams with a putty solution. It is suitable for applying to the heads of nails and screws. This will protect them from corrosion when moisture penetrates.

To install it on furniture, you need to make markings and cut parts. They can be secured with furniture nails, self-tapping screws or glued.

Preparing the frame for stuffing panels.

Algorithm for fiberboard

Installation of fiberboard is carried out using a similar technology.

There is another method of fastening, which implies the following algorithm of actions:

- Clean the wall or floor and treat it with an antiseptic.

- Use a level to check the evenness of the surface. Eliminate depressions and bulges, seal them with cement-sand mortar and putty.

- Prime.

- Apply clear glue to the surface. Attach the sheet and press down.

- Glue the parts, adjusting them to each other.

Conditions for laying fiberboard

There is no need to remove old boards.

Laying fiberboard on a wooden floor has its own nuances. Removing old boards can be neglected especially in older houses. They will help provide strength and provide an additional source of heat, but over time they can become unusable, so individual sections will need to be replaced.

It is recommended that leveling using wooden slabs be carried out on logs made of timber. But, unfortunately, this method will not work if heavy loads are placed on the floor, such as:

- a working machine with high vibration;

- metal furniture legs;

- heavy furniture, especially if pressure will be applied to the gaps between the joists.

It is extremely important to choose the right material and carry out the installation procedure. The quality of the floor, its strength and service life depend on these factors.

Horizontal coverage is an extremely important factor in the floor installation procedure. So you will need to prepare all the necessary tools in advance, especially a building level, which will help you take measurements correctly and accurately.

It is also extremely important to treat the old base. For this you will need:

- get rid of dust and dirt;

- remove the skirting boards that prevent the installation of fiberboard;

- seal all cracks to ensure a good level of tightness;

- make markings according to which alignment will be carried out in the future;

- if you plan to make a cellar, for example, in a private or country house, it is better to start working with its arrangement and only then move on to treating the floor.

Please note that the installation of fiberboard should not be done too tightly, otherwise the edges of the material may be damaged. Also, the distance from the wall should be about 6 mm; this gap will be used for installing skirting boards.

It is recommended to start processing from the opposite wall to the front door. If you have little experience in the construction craft, the first layer will need to be carefully checked with a building level to prevent possible inaccuracies and unevenness.