When renovating or building a house, you have to face the question: how to protect the wood? Every owner strives to get maximum quality at a low cost. The best solution to this problem would be ship varnish.

Yacht varnish for exterior woodwork manufacturer? Already from the name of the material one can understand that it was originally used to cover the surface of various ships.

This waterproof varnish will protect the wood from the destructive effects of liquid. It is clear that if the product protects yachts that are constantly at sea, then it will do an excellent job of protecting walls, floors or ceilings. Due to its structure, the composition penetrates deep into the pores of wood, thereby reliably protecting it for a long time. Yacht varnishes can be purchased in aerosol form.

They are also sold in banks with different denominations. It is more convenient to use aerosols, but they are sold only in small quantities.

Dilute, dilute or dissolve

At first glance, there is no difference. Using a special tool, we bring the varnish substance into “working condition”. A solvent is a liquid that dissolves dried varnish, bringing it from a solid to a liquid state. We use a thinner if we need to change (reduce) the viscosity of paints.

Some types of organic eluents perform both roles, but some may be effective in one task and completely useless in another. For example, white spirit can be used to dilute compositions of polyurethane, alkyd and oil groups. But if the varnish has dried, it will not be possible to dissolve it with white spirit.

White spirit can be used to thin some varnishes.

But shellacs, on the contrary, are equally dissolved and diluted with denatured alcohols. But let's not go into such subtle details.

If you need advice on what to thin varnish or what to use for thinning paints, it is better to consult with specialists in this field.

We propose to consider in detail which solvents need to be used in specific cases.

Packing method

Manufacturers of yacht varnishes package their products in cans or cans. The latter option is more convenient during application, since it does not require a roller or brush. The aerosol allows you to achieve good uniformity of the dispersed layer of the required thickness.

The weak points of varnish in cans include the small packaging volume and high cost (a varnish product of the same volume in a can will cost an order of magnitude less).

As practice shows, it is more convenient to apply glossy compounds to wood by spraying, while matte ones are more convenient to apply with a traditional brush or roller.

Polyurethane mixtures

Polyurethane varnishes, paints, primers, adhesives, etc. contain polyurethane - a modern polymer. The totality of its properties surpasses such well-known materials as rubber, plastic, rubber, and metal. To obtain high-strength paint and adhesive solutions, in industrial production it (polyurethane) is mixed with special chemicals.

A lot of polyurethane varnishes are also water-based. This parquet chemistry is environmentally friendly and non-toxic.

If it is necessary to make the substance more liquid, you can use the following as a diluent for polyurethane compounds:

- toluene;

- xylene;

- acetone;

- eluents such as R-4, R-5.

It is not recommended to add alcohols, water, or type 646 eluents.

Acetone is a good thinner for polyurethane varnishes.

Main types of solvents

All compositions that are used for diluting and diluting varnishes differ in properties. When working with them, you must adhere to basic precautions - use personal protective equipment, beware of getting the solvent in your eyes, nose and mouth, and ventilate the room. Almost all compositions are fire hazardous and require proper storage and careful use.

The most common thinners:

- White spirit - has an average evaporation rate, is practically odorless, dilutes yacht and other varnishes.

- Solvent - evaporates quickly, highly flammable, flammable.

- Ethyl alcohol is a colorless solvent liquid with a specific odor that spontaneously ignites at 402 degrees.

- Petroleum benzene is insoluble in aqueous solution and interacts with gasoline, kerosene and turpentine.

- Turpentine - dries slowly, smells unpleasant, can spontaneously ignite, suitable for diluting oil varnishes.

- Solvents for nitro varnishes – improve the quality of the film-forming agent and ensure good adhesion of the coating.

- Methanol is a dangerous, toxic solvent; it dilutes shellac and alcohol-based compositions well.

- Butyl alcohol - dilutes nitrocellulose paints and varnishes, gives the varnish shine and mechanical strength.

- Ethylene glycol is a viscous, odorless substance that is used to dilute the composition.

- Methyl acetate - evaporates and dries quickly, the substance is highly toxic.

- Butyl acetate is a yellowish substance that takes a long time to evaporate from the surface, increasing the drying time of the varnish.

- Ethyl acetate is a pleasant-smelling substance with a high evaporation rate.

- Acetone - dissolves and dilutes most varnishes, has an unpleasant, pronounced odor.

Popular brands of solvents are 646 and 647. Solvent 646 is a mixture of several components that, when combined, dilute epoxy and acrylic varnishes well. The 647th solvent consists of toluene, butanol, ethyl acetate and butyl acetate. Used to dilute nitro varnishes.

Solvent P-4 contains a compound of esters, ketones and aromatic carbons. Suitable for thinning varnishes based on vinyl acetate and its copolymers.

Using a varnish thinner allows you to obtain the working composition of the required consistency and give the coating additional strength. The applied layer becomes uniform, the composition is easy to work with using rollers or paint brushes.

How to dilute paint and varnish (2 videos)

Various products (20 photos)

Alkyd mixtures

Alkyd compounds have good adhesion, moisture resistance, insensitivity to ultraviolet radiation, and strength. They can be used for external and internal work. Alkyd mixtures contain a main component, organic solvents, driers (for faster drying), and additives. The main component may be:

- pentaphthalic resin;

- glypthal resin with cotton oil;

- a mixture of melamine-formaldehyde and alkyd resins.

To enhance the properties of materials, elements of alkyd resins are often included in multicomponent varnishes, paints, and enamels. The traditional thinner here is white spirit.

Application specifics

Initially, only the outer surfaces of the wooden hulls of river and sea sailing ships were treated with this product.

In the classic version, yacht varnish is prohibited from being used indoors due to the presence of substances hazardous to health (toluene and xylene) in its composition. It is these components that give yacht compositions such qualities as durability and reliability, the achievement of which was emphasized during the development of the formula.

A more reliable way to protect wooden products from the active effects of water has not yet been invented.

As a result, in addition to the shipbuilding industry, yacht varnish began to be widely used in construction and finishing work.

With its help you can solve the following problems:

- treat facade surfaces;

- decorate wooden floors;

- cover instruments;

- put garden furniture in order;

- equip wooden baths and saunas;

- create protection from climatic influences for various buildings.

Specialists have developed separate lines of yacht varnish for wood for interior work so that this unique material can be used indoors.

Bitumen mixtures

Bituminous varnish is a mixture of a special grade of bitumen, various resins and oils. After drying, a durable black film is formed on the surface, moisture-resistant and impervious to chemical attack. It is considered a fairly new material in household use. Belongs to the inexpensive category. It is often used as an anti-corrosion protective layer.

For wooden surfaces it is used when there is no need to emphasize the natural texture of the base (instead of paints). Bituminous material has found application as a decorative coating for the effect of aging surfaces (patina). Another unique feature of bitumen mixtures is cold gluing. The bitumen solution is diluted with white spirit.

To prevent it from thickening during storage, the container must be airtight. The storage location should be dark (without direct sunlight), with moderate temperature and humidity.

Bituminous varnish protects the surface very well from moisture and chemical influences, diluted with white spirit

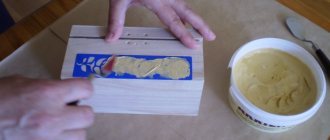

Wood varnishing:

We are talking about the situation when you have already completely processed your wooden product (sanded, treated with insect repellent, or covered with stain), and all you have to do is coat it with varnish. Varnishing wood is a very simple procedure if you know a few features. For example, you need to consider the grain of the type of wood your piece is made from. For each type of wood there is probably a suitable type of varnish. This is very important to take into account because wood coated with varnish can acquire a new shade (darker or lighter) and even new properties (fire resistance). And the most annoying thing is if, after a painstaking and long selection of colors (for example, when carving wood), you varnish and the colors fade. Try to coat the wood product with an adequate type of wood varnish.

Yacht varnishes

Yacht (or yacht) varnish is one of the most effective means of protecting natural wood surfaces. Already from the name the features of the area where it is used are clear. At the same time, the yacht composition is excellent for woodworking inside and outside of any objects (not just boats, boats, yachts). It is impervious to moisture, temperatures, and aggressive environments.

Yacht varnish. Basic properties:

- high degree of protection of wooden structures;

- physical and mechanical immunity to the influence of external environments;

- durability, extending the life of wood.

To achieve such results, toxic chemical elements (toluene, xylene) are used in the production of the material. There are several production technologies:

- alkyd yacht (based on the organic solvent white spirit);

- urethane-alkyd yacht (the eluent is the same, but in smaller quantities);

- alkyd-urethane yacht (solvent additives are highly volatile);

- acrylates (water-based compounds).

Dilutes yacht varnish with white spirit, no more than 5% of the total volume. The solvent acts on the substance only in its fresh form. After drying, the varnished parquet coating will become impervious.

Varnish for yachts, boats, boats has high wear resistance and can also be diluted with white spirit

Precautionary measures

Yacht varnishes contain harmful components necessary to perform the tasks assigned to the product. After application, toxic fumes may be released into the air. Whatever the manufacturers say, using shiplap varnish to cover the floor is not the best option.

If you still decide to use it, give preference to urethane-alkyd based products. Otherwise, after a few months you may experience problems with your physical condition.

It is not recommended to use this product on furniture that comes into contact with food. For example, it is strictly forbidden to use it on kitchen cabinets. It is better to use ship varnish outdoors. This is due to the released harmful substances.

Using it at home can cause depression and nervous disorders. It is especially dangerous for children. Therefore, think about whether it is worth using yacht varnish at home.

The price of health is still higher.

How to protect acrylic paints from drying out

In order not to find yourself in a situation where the paint has begun to thicken too much or has completely dried out, it is necessary to provide it with proper storage conditions. It is important to remember that one of the components of acrylic paint is water. It tends to evaporate. And the higher the temperature, the faster this will happen. As a result, hardening will begin. Along with polymerization, the positive properties of the product are lost. You can avoid this effect by adhering to the following recommendations:

- Do not dilute or add coloring pigments in a common container. It is difficult to find out exactly in advance whether the entire jar will be used up at once. Therefore, it is better to pour a certain amount of the composition into a separate container and dilute it in it.

- The lid on the jar must be closed as securely as possible. This will prevent the water from quickly evaporating from the acrylic. The drying process will still occur, but much slower.

- When the next part of the work is completed, it is necessary to thoroughly clean the edges of the can from traces of paint. Then it is closed with a lid. This will prevent the main container and the lid from sticking together.

- Do not store paintwork materials in a place with high air temperatures. Heat only increases the rate of evaporation of liquid from the composition. As a result, the properties will be lost and the consistency will become too thick or completely dry.

Acrylic paints are quite often used for covering various surfaces. They are actively used in renovations, embodying this or that interior. But in order for the coating to be of high quality, smooth and rich, it is important to follow the rules for using and storing acrylic paints. If you find that the consistency is too thick, use plain water or special compounds. But first, carefully study the information to do everything correctly. It’s more difficult with dried paintwork materials; they often cannot be restored.

Rules and recommendations for varnishing

Experts recommend adhering to the following rules when applying acrylic-based varnish mixtures:

- before you start varnishing, you need to stir the solution well, especially if it contains any pigment;

- Before starting work, you must wear personal protective equipment such as gloves, goggles and a respirator. These products are needed even if an odorless water-dispersed material will be applied;

- the varnished surface must be dry, clean, free of greasy stains and crumbling old material;

- the air temperature should not exceed 25 degrees, and the humidity should not be more than 50%;

- to apply the mixture, you can use a spray bottle, roller or brush;

- water-dispersion mixtures are diluted with clean water, and white spirit, xylene or toluene is added to varnish solutions with organic solvents as a diluent, in a volume of no more than 10% of the volume of the varnish;

- the paint and varnish material must have the same base as the primer, tinting, or other chemicals applied to the surface.

By following these simple recommendations, the protective layer will be strong, reliable, durable and attractive.

Modifications of acrylic paints and varnishes

Acrylic refers to polymer compounds based on secondary elements of acrylic compounds, elementary samples of carboxylic acid compounds.

This liquid substance has a strong odor and is transparent in color. Acrylic can be diluted in a solution of chloroform, pure water, or diethyl ether.

The purified composition has remarkable properties:

- does not tend to degrade quality due to exposure to temperature;

- is resistant to solar radiation;

- when combined with other substances it becomes quite durable;

- has some positive mechanical properties.

To produce paint and varnish dyes necessary for decorative finishing, acrylic is mixed with a special organic diluent or water.

The compound mixed with an organic thinning compound can be used to varnish wood, metal, glass and stone products.

Acrylic paintwork material consisting of aqueous dispersion

This type of composition is the most environmentally friendly, suitable for interior decoration.

Accentuates the natural texture of wood (on parquet, furniture, caissons, panels, etc.).

It is easy to apply, the paint dries very quickly and has a high level of adhesion. The finishing layer is strong, long-lasting, resistant to abrasion and exposure to physical or chemical environments.

It has excellent decorative properties.

When the water-dispersed acrylic resin thickens, or it initially had a high viscosity, a solvent can be poured into it.

A product with a water structure of up to five to ten percent of the total volume is suitable - without losing the qualities of the product.

This type of varnish should not be combined with other chemical compounds for parquet.

It is prohibited to use them together with drying oil, gasoline, white spirit solution, acetone and other organic diluting liquids.

Acrylic coatings based on organic solvent

In this case, the agents that help dilute are compounds of complex ketones, esters, and aromatic hydrocarbons.

Occasionally, the structure of the substance consists of plasticizers. The created protective layer is quite strong and does not turn yellow over time.

Technical properties include strong adhesion to the base coat, moisture resistance, and even coloring.

The composition can be used to finish surfaces both outside and indoors.

In contrast to water-based varnishes, this type has a specific odor, which can be classified as a disadvantage. However, once the varnish hardens, it ceases to emit an odor.

To clean painting equipment after finishing or thinning acrylic varnish that has become thick, you will need a powerful solvent.

Most often, turpentine or another universal eluent is used.

It is recommended to paint the surface two to three times.

Keep in mind that to cover the first layer of acrylic varnish based on organic thinning elements, it must be diluted by thirty percent.

This measure will help increase the wear resistance of the protective layer.

Acrylic-based paints and varnishes are grouped according to structure and decorative qualities. The product is produced in one-component form (the base is one acrylic), and two-component (the base consists of acrylic and a polyurethane element).

According to decorative functions, it is grouped into matte, semi-matte and glossy.