Moisture-resistant wood glue Titebond II Premium is a unique product from the Titebond company. It creates a super strong connection. According to professionals, this is one of the best modern compounds for working with wood.

You can buy Titebond II Premium moisture-resistant wood glue for wood at an excellent price in our online store “Building Materials-Cheap”. You can choose the most convenient product packaging option: 237 ml, 473 ml, 946 ml and 3.78 l. We deliver goods in Moscow and by transport company throughout Russia. In addition, we sell mounting adhesive from the same manufacturer

Application

The adhesive is ideal for outdoor applications including patio and outdoor furniture, exterior doors, windows, birdhouses, mailboxes, picnic tables, etc.

- Gluing hard and soft wood in carpentry and furniture production: furniture panels, tenon joints, ideal for working with wood both indoors and outdoors.

Forms a transparent adhesive joint and can be used for the installation of floating wood and laminate tongue-and-groove floors, including heated floors based on a radiant heating system.

- Used for gluing hard and soft wood in carpentry (butt and surface joints such as tongue/groove, tongue and groove, etc.).

- Also used for applying laminate, postforming, laminated plastics, paper films, natural veneer to any wooden surfaces, MDF, fiberboard, chipboard, plywood using the cold and hot method.

- Thanks to the formation of additional chemicals. ties provide moisture resistance and can be used for patio furniture and exterior windows and doors.

Glue characteristics

Despite the possibility of professional use, the products in the series do not require special skills or knowledge during application. They are easy to use; you just need to read the instructions carefully. A regular tool, including a metal one, is suitable for the job; the glue does not stick to the metal, and all devices can be easily cleaned.

The main property that distinguishes Titebond adhesives from PVA and liquid nails is their high moisture resistance, which meets American standards.

Other properties and technical parameters of Titebond adhesives:

- All adhesives become transparent after hardening, despite the initial dullness of the consistency. They can be applied even to delicate items.

- The products are frost-resistant; after drying, the seam will withstand temperatures down to -35 degrees. Also, glued bases can be heated to +40 degrees, but at +100 the seam area can catch fire.

- The strength of the glue joint will be very high, much higher than the wood itself. This determines the durability of the glued products. The seam is resistant not only to water, but also to the influence of solvents and acoustic vibrations.

- Adhesives are universal, they are suitable for all types of wood, as well as other wood-based compounds, combined materials, and many types of plastic. You can also effectively fasten paper and cardboard with these products. Elastic compounds are suitable for use as sealants.

- All errors in work - stains, drips - can be washed off with water before complete hardening. This is very convenient for adjusting the adhesive seam.

- Polymerization of the composition is quick (10-20 minutes), but still not instantaneous, and it is quite possible to correct the position of the parts. As humidity increases and temperature decreases, polymerization may slow down. You cannot work with the composition at temperatures below +10-12 degrees.

- There is no need to subject the parts to strong compression or installation under a press. They will stick together even with a moderate degree of fixation, adhesion will not decrease.

The most popular adhesives of the Titebond brand have a dry residue of 48%, their viscosity is 4000 mPa/s, and their acidity is 3 pH. Material consumption is 180 g/sq.m. see. After opening, each product remains suitable for use for a long time (up to 2 years) if stored at a temperature of about +20 degrees. It is not advisable to apply the composition to painted substrates; use it in rooms with too high humidity or poor ventilation.

Description

A one-component adhesive that meets ANSI Type II water resistance standards. The adhesive is characterized by a strong initial set, high curing speed, it forms a strong connection, is easy to process, and can be used in cold, hot and HF presses. High water resistance; Low application temperature; Excellent connection strength; Easy to clean when wet. For outdoor use; Perfectly processed, does not affect finishing coatings; Load group according to EN 204/205 1K/D3. Dries quickly; Easy to apply; It has a white color, when applied, its excess is clearly visible; Dried glue is resistant to water and solvents.

Advantages

- high gluing speed and excellent durability of joints;

- Ideal for exterior and interior carpentry projects;

- water resistance class D3;

- working time: 7-10 minutes and short clamping time 10-20 minutes (20°C);

- ease of application;

- non-toxic;

- easy cleaning with water;

- made in the USA.

You can buy Titebond Premium glue in Ukraine in the online store, the price of a container of 3.78 liters is 900 hryvnia.

Characteristics

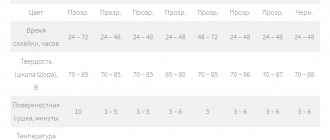

Base: Cross-linked PVA Condition: Liquid Color: White Dry film: Transparent Density: 1.09 g/cm3 Freeze-thaw cycles: Stable White point (12.7°C) - the lowest recommended temperature of the adhesive, air and bonded materials at which high-quality connection is possible. Estimated VOC: 13.7 g/l White point temperature: 12.7 °C Solids: 48% pH: 3.0 Viscosity: 4000 mPa*s Shelf life 24 months in original packaging at 23 °C. Application temperature: above 12.7°C Working time: 5 minutes (at 21°C and 50% humidity) Pressure: 7-10 kg/cm2 for soft wood, 9-13 kg/cm2 for medium wood, 13-18 kg/cm2 for hard rocks. Minimum consumption: approximately 162 g/m2, when installing parquet floors, approximately 38 linear meters per 473 ml bottle. Adhesive bond strength according to ASTM D-905 (on hard maple) Temperature Bond strength, kg/cm2 Solid wood failure, % Room 264 72 65°C overnight 123 6

LKMFLOT

Code: 100005348

Category:

Adhesives

Brand:

Titebond

Packing:

0.119, 0.237, 0.473, 0.946, 3.785, 18.9

Packaging:

1

Titebond II Transparent Premium Wood Glue (Tybond 2 Transparent Premium Wood Glue)

DESCRIPTION: TITEBOND II Transparent Premium Wood Glue is a one-part adhesive that meets ANSI Type II water resistance requirements. It is ideal for outdoor applications including garden and outdoor furniture, birdhouses, mailboxes, picnic tables, etc. Forms a transparent adhesive joint and can be used for the installation of floating wood and laminate tongue-and-groove floors, including heated floors based on a radiant heating system.

The adhesive is characterized by a strong initial setting, high curing speed, it forms a strong connection, is well processed, and can be used in cold, hot and HF presses.

PRODUCT FEATURES: - High water resistance - Low application temperature - Excellent bond strength - Easy to clean when wet. — For outdoor use — Excellent processing, does not affect finishes — Ideal for use in cold, hot and HF presses — Load group according to EN 204/205 1K/D3. — Meets ANSI Type II Water Resistance Standard — Dries quickly — Easy to apply — White in color, with excess visible when applied — Dried adhesive is resistant to water and solvents.

PHYSICAL PROPERTIES Base: Cross-linked PVA Condition: Liquid Color: White Dry film: Transparent Density: 1.09 g/cm3 Freeze-thaw cycles: Stable White point (12.7°C) - the lowest recommended temperature of the adhesive, air and bonded materials, at which a high-quality connection is possible. Estimated VOC: 13.7 g/l White point temperature: 12.7 °C Solids: 48% pH: 3.0 Viscosity: 4000 mPa*s

Bond strength per ASTM D-905 (hard maple)

| Temperature | Connection strength, kg/cm2 | Destruction of solid wood, % |

| Room | 264 | 72 |

| 65°C overnight | 123 | 6 |

INSTRUCTIONS FOR USE Application temperature: above 12.7°C Working time: 5 minutes (at 21°C and 50% humidity) Pressure: 7-10 kg/cm2 for soft wood, 9-13 kg/cm2 for medium wood, 13-18 kg/cm2 for hard rocks. Minimum consumption: approximately 162 g/m2, when installing parquet floors, approximately 38 linear meters per 473 ml bottle. Application method: roller or brush, using a plastic bottle with a flat spout. Cleaning: Remove uncured adhesive with a soft cloth. Dried glue is removed mechanically.

LIMITATIONS Titebond II Transparent Premium Wood Glue is not suitable for permanent submersion or below water levels. Not used for load-bearing products. Do not use when the temperature of the adhesive, parts and ambient air is below 12.7°C. It is recommended to test the adhesive on samples of the materials being bonded.

PACKING: art. 1123 – 237 ml art. 1124 – 473 ml art. 1125 – 946 ml art. 1126 – 3.8 l art. 1127 – 20 kg art. 1128 – 225 kg

SHELF LIFE: 24 months in original packaging at 23°C. The adhesive is best used within 24 months from the production date. It is recommended to mix the glue before use. Avoid freezing. Freezing may not affect the properties of the product, but it will make it thicker. Stirring should restore the adhesive to its original form.

Usage

Application method: roller or brush or using a plastic bottle with a flat spout. Surfaces must be clean and dry. The parts to be glued must be tightly fitted to each other. Apply glue to one of the surfaces and compress firmly (clamps, presses, ties). Compression time in room conditions is at least 1 hour. If the surfaces are porous, glue is applied to both surfaces. Remove excess glue with a clean soft cloth. Minimum application temperature 10 degrees. Open exposure after applying glue at 21°C and 50% humidity for 5 minutes. The compression time depends on the environmental conditions. Before painting, thoroughly sand the adhesive seam. Undried glue is removed with a soft cloth. Can be cleaned with water immediately after application. Dried glue is removed mechanically.

Restrictions:

Titebond II Transparent Premium Wood Glue is not suitable for permanent submersion or below water level.

Not used for load-bearing products. Do not use when the temperature of the adhesive, parts and ambient air is below 12.7°C. It is recommended to test the adhesive on samples of the materials being bonded. The adhesive is best used within 24 months from the production date. It is recommended to mix the glue before use. Avoid freezing. Freezing may not affect the properties of the product, but it will make it thicker. Stirring should restore the adhesive to its original form. Precautions:

Use only in well-ventilated areas. May cause skin irritation. If dizziness or other unpleasant effects occur, you should go out into fresh air and consult a doctor. If glue gets into your eyes, rinse them with running water for 15 minutes. If glue gets on your skin, wipe it off and wash your skin with soapy water. Keep the glue out of the reach of children! Use only for its intended purpose.

Supplied in plastic bottles with a convenient dispenser spout. Manufactured by Franklin International (USA).

What other advantages does Titebond 2 moisture-resistant wood glue have?

- Provides almost instantaneous strong adhesion to the surface, the connection quickly gains strength;

- Wood glue Titebond II allows you to complete the work very quickly, since when using it, the surfaces to be glued do not require long-term pressing;

- The resulting seam has a very high density;

- Non-abrasive;

- Wood glue Titebond (Titebond, Titebond) 2 can be purchased in packages of various packaging, choosing the optimal one for your needs and without paying a higher price for a larger volume.

- Before drying, the composition can be easily removed with water; after drying, excess wood glue Titebond (Titebond) for wood is removed mechanically.