Foam concrete is becoming an increasingly popular material for building houses. It retains heat well and can serve for many years, but getting the maximum from these characteristics is only possible if the installation is done with glue for foam blocks; the use of cement mortar is not so effective. In this case, you need to choose a suitable solution. The existing types and rules of work will be discussed in more detail below.

Cement base or glue

For masonry, you can use both glue and classic cement composition. A realistic assessment of the construction process will help you make a choice. If foam concrete modules are non-standard in size or have an unusual shape, preference should be given to a cement-based solution.

It is better to use professional glue in the following situations:

- Sufficient experience and skill level of the construction team.

- Foam concrete blocks having strictly regulated sizes and shapes.

The special glue is free of impurities and various additives that can cause sediment to appear. The only permissible component (mandatory for use) is fine sand, and to improve the degree of adhesion, polymers and plasticizers are introduced into the solution.

How much is needed, how to calculate correctly

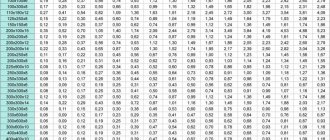

Any adhesive for laying foam blocks is calculated for a thickness of 2 mm, and 1 cubic meter of masonry is taken as the norm. It should be clearly understood that if the master takes on the job for the first time and does not have the proper experience, the generally accepted costs will increase.

The popular stone size is considered to be 600 by 300 by 200 mm; for this type of product, 15-23 kg of solution per 1 cubic meter will be required, but as the layer thickness increases due to defects in the material, the glue consumption for the foam block will increase. The calculation cannot be ruled out taking into account measurements of the partition; the experience of builders has shown that per 1 sq. m. you need about 1.4 to 1.7 kg of mixture, if the layer does not exceed 1 mm.

Advantages of adhesive for foam blocks

Carrying out repair and construction work with your own hands requires a detailed approach to the choice of consumables. This rule applies to both main blocks, modules, slats, and fixing compounds.

The quality of the fixative used will determine the duration of operation of the building, tightness, and heat retention in the room.

The positive characteristics of adhesive for foam blocks include:

- The presence of sand (mostly of a minimal size) makes it possible to reduce the thickness of the applied layer. Thus, the master manages to save consumables.

- Thanks to its special elasticity and viscosity, the adhesive is evenly distributed over the surface of the foam concrete modules, covering all irregularities, recesses, and the smallest chips.

- Optimal water consumption for diluting the adhesive composition.

- Not only foam concrete blocks, but also the adhesive solution itself retains heat perfectly. Thanks to two components, home owners can significantly reduce residential heating costs.

- Many craftsmen especially highlight the high degree of adhesion of the glue to the surfaces being treated.

- After complete hardening, the fixing coating is resistant to moisture, salts, abrasives, and sudden temperature changes.

- There is absolutely no shrinkage of the material, even during everyday use.

The advantages of practical choice of material also include simple rules of use.

Even the most inexperienced craftsman will understand how to lay foam blocks on glue with his own hands, how to make beautiful seams, and how to fix the modules in one position.

You can dilute the adhesive according to the attached instructions, observing the recommended proportions of the main components.

Composition consumption per cubic (1m3) and square meter of masonry

When considering how much glue needs to be diluted per 1 m3 in order to fasten wall elements together, you can pay attention to the average consumption rates, they range from 15 to 23 kg.

When it comes to the correct approach to measuring the area of the future partition, it will be difficult to do without a tape measure and the help of a partner. Having derived the total amount, it is important to understand that the average figures assume the application of a layer 1 mm thick, then the solution is consumed at 1.5 kg per square meter. m.

Types of glue for foam blocks

No composition used in construction can have universal properties and characteristics. This rule also applies to construction adhesive for foam concrete blocks.

Depending on the recommended temperature for using the material, the following types of glue are distinguished:

- Summer option. Such solutions should only be used at ambient temperatures of 5 degrees or higher. The classic composition necessarily includes white cement. After dilution and stirring, the solution must be used within 2 hours.

- Frost-resistant adhesive for foam blocks. To carry out construction work in the autumn (or warm winter), you can choose an adhesive to which antifreeze and gray cement are added under production conditions.

Due to its unique composition, the second type of glue is popular among craftsmen. However, after dilution and stirring, the adhesive composition retains its properties for 30-35 minutes.

Varieties of compositions with technical characteristics

Having calculated the glue for the foam block, calculating the consumption per 1 cubic meter using a calculator or yourself, you should move on to studying the indicators of the finished solution.

In addition to temperature conditions, it is necessary to take into account the rate of hardening of the prepared mixture; summer product samples do not lose elasticity for up to 2 hours, but winter ones will remain in working condition for no more than 40 minutes, during which time the location of the stone is adjusted and the level is displayed.

The presence of modifiers will indicate that the layer will be protected from cracks and the liquid will be retained in the solution for as long as possible. Polymers are needed to create a composition with better consistency, capable of filling even small pores.

What to glue foam blocks to, popular brands

Not all brands of fixing agents are in demand; after lengthy searches, professional builders settled on the best examples of products; the list is worth taking note of.

In addition to the brand names, it would not be superfluous to give an approximate price, the situation is like this:

- Ceresit 300 rubles.

- Volma 230 rubles.

- Fund 250 rubles.

- Ytong 350 rubles.

- KREISEL 275 rubles.

Products are most often packaged in paper bags of 20-25 kg, packages with an indicator of 50 kg have long ceased to be popular due to their large weight, and reduced samples can easily be carried by one person.

Adhesive consumption for foam block

The only disadvantage of using foam concrete blocks is the high cost of the material. It is for this reason that the home owner or craftsman needs to calculate in advance the expected consumption of glue for foam blocks.

This parameter is quite variable and depends on the following factors:

- The thickness of the glue that the master applies to the underlying surface. A classic example and recommended standard is a thickness of 0.3 cm. However, these indicators are excellent only for perfectly smooth foam concrete modules. In the presence of grooves, chips, gross defects, for non-standard block shapes, the thickness of the applied layer increases (sometimes up to 0.6 cm).

- The presence and type of tool with which the adhesive is applied. In practice, craftsmen can cope with the task with the means at hand, however, a professional tool significantly reduces glue consumption.

- The total number of blocks used in construction.

- Qualitative composition of building modules, condition of their surface.

- An important role is played by the ambient temperature and the correct adhesive for the job (winter or summer version of the product).

The degree of qualification of the master is of great importance. Having experience and dexterity allows you to distribute the adhesive composition as evenly as possible over the surface of the blocks, without unnecessary losses.

Material cost

You can buy dry mixture for 160-500 rubles. The price depends on the volume of the package and the number of components the material contains. The properties of the mixture also play a role: strength characteristics, elasticity, temperature conditions at which it is permissible to carry out work.

The higher quality the material, the higher its price. Often the consumption of such compounds is low and their service life is long. In addition, frost-resistant adhesives belong to a higher price category.

Rating of glue manufacturers (TOP-best)

A mistake in choosing a manufacturing company can cost home owners significant financial losses. Low-quality types of glue may use coarse sand, poor modifiers, or may contain impurities.

The most popular and recognized leaders in manufacturers of adhesives for foam concrete blocks are:

- Knauf. This company produces glue that contains gypsum chips and various polymers. The crumb increases the degree of adhesion and reduces the thickness of the applied layer. Polymers give the composition viscosity and sufficient thickness.

- Titanium is another very well-known type of adhesive used in construction. On the market you can find containers with a volume of 0.75 liters, which is very convenient for use in everyday life. This type of glue is characterized by a high drying speed, as well as noticeable strength of the material.

Among the winter options for fixing compositions, Ceresite should be highlighted, which has special plasticity and resistance to external factors.

Which adhesive for foam blocks is better is up to the owner or craftsman to decide personally.

Masonry process

First of all, it is worth noting that when working with foam blocks, the first row is always placed on cement mortar, in order to avoid various (certainly possible) unevenness of the foundation, and glue is used from the second row.

During the laying process, if you are working with ordinary, standard blocks, then glue must be applied not only to the horizontal edges, but also to the vertical ones. In the case of using blocks with a tongue-and-groove connection, applying an adhesive solution to the vertical ends is optional, if not necessary.

Naturally, it is also best to prepare the blocks themselves immediately before laying, cleaning them from dust and possible fine dirt so that the glue is applied to an absolutely clean surface.