Home / Ceiling design / Design solutions / Features of using unedged boards for facade finishing

The façade of a building is usually decorated with standard materials. However, if you want to get a unique design, you will have to use not the most familiar solutions. One of them could be finishing the facade of a house or other buildings with unedged boards. The appearance is very peculiar and certainly atypical. At the same time, the cost of such design will be low due to the low cost of the material used.

Lap siding

A quick and budget-friendly way to imitate overlapping planks and install plastic and metal siding to look like wood. You can make a sheathing from a metal profile and attach acrylic or vinyl panels to it. It is possible to distinguish a “fake” only at close range.

Ventilated facades last up to 20 years. Virtually no maintenance required. But this is not wood with its warmth and uniqueness.

Finishing with unedged boards is the most common and simple technology, which, with the correct and competent approach, can decorate the facade of a residential building.

This is a simple and inexpensive building material, the characteristic feature of which is not sawn edges, which give design originality and aesthetics to the structure.

Often, when arranging and decorating your home, preference is given to environmentally friendly building materials.

Therefore, cladding with boards or similar materials based on natural wood has gained popularity.

Among the positive physical properties of wood, the following should be noted:

- Beautiful view;

- Resistance to mechanical stress;

- High thermal insulation;

- Partial replacement of damaged planks;

- High strength;

- Noise insulation;

- Easy installation and operation;

- Compatibility with other finishing building materials.

The cost of the natural product is higher than its imitation analogues, but is quite justified.

The modern construction market offers a wide range of wooden products, but the most popular are:

- Lining;

- Timber imitation;

- Siding panels;

- Unedged board.

Thanks to the raw edges, an amazing style of facade decoration is created with proper cleaning and processing of the material.

Careful adjustment of the planks creates the impression of a completely wooden structure. It is possible to leave the edges of the planks with bark elements, which adds style to the finish.

It is only important not to forget about the use of protective impregnating compounds and antiseptics. Impregnation with stain and subsequent application of varnish is possible

Previously, such material was spent on non-residential structures and for sheathing roof structures due to the lack of demand for aesthetic appearance.

But in recent years, unedged boards have also been used for... However, it will first require competent processing and aesthetic location.

Among its positive characteristics are high strength and high resistance to mechanical damage, good resistance to changes in humidity and temperature changes.

And the low density of wood makes it possible to easily process it, which reduces the time spent on finishing work.

Use timber nailed in increments of 1.5 m to the top of the unedged board and at the corners of the building.

The fit of unedged material may not be ideal; the resulting cracks are covered with mastic or a sealing compound.

Advantages and disadvantages of wood:

Pros: independence from climatic zones, designs of any complexity, environmental friendliness and naturalness, simple installation that does not require special skills.

As well as durability and repairability, installation of additional insulation, reconstruction of the facade without harming the fundamental foundation, affordable price and variety of colors and textures.

Watch a video on the topic:

Disadvantages: flammability without special treatment, natural components in the form of knots, resins and cracks, frequency of renewal of protective paint, fungal manifestations without antiseptic treatment.

Examples

Previously, such finishing methods were used only for outbuildings. Nowadays there is a tendency to use the most environmentally friendly materials and give residential buildings an unusual look. Therefore, finishing the facade of a house with unedged boards has become a very popular technique, and several photo examples of such finishing are presented below. Using them, you can form your own opinion about such repair options and see different cladding methods.

How is a house covered with other types of boards?

This option for finishing the façade of a building is not the most economical. You should know that only specialists can carry out high-quality cladding of a house with boards.

The cladding of the front part of the house can be done in the form of lining using smooth or rough boards. The elements are laid overlapping. This can be done by using special boards that have tongue-and-groove or quarter joints. This type of cladding is used for finishing work on walls made of bricks or blocks.

This type of cladding combines decorative and heat-insulating functions. The latter option is used in the case of insulation using the “dry” method.

Cladding the facade of a private house with boards: technology

Wood is an organic material, as a result of which it rots in a humid environment. Therefore, the cladding of the façade with boards will need to be done with ventilation on the reverse side. In order to create such ventilation, it is necessary to install a wooden sheathing on the wall.

When installing ventilated facades, a windproof film is used, which is laid as insulation or directly on the base of the wall.

In this way, it will be possible to prevent the weathering of fibrous insulation materials and provide additional heat resistance to the wall. Such a film will block water, but will not prevent steam from escaping from the building.

The gap for ventilation between the wall and the wooden sheathing should be 4-5 cm. A flow of rising air will form in it, which is capable of removing moisture.

In the lower part of the facade, you will need to provide gaps for free access of air, as well as its subsequent exit under the roof. The holes at the bottom can be covered with a metal mesh to protect against rodents.

The sheathing is made of wooden planks with a square or rectangular cross-section.

To reduce water absorption, they need to be impregnated with an antiseptic and special compounds - impregnates.

If the cladding is carried out without the use of insulation, then the frame strips must be filled vertically, observing a step of 50-60 cm. If the board is installed vertically, then a double frame must be made.

This can be done by installing horizontal strips on top of the vertical ones. If the wall is uneven, then it must be leveled using pads made of impregnated plywood.

How to strengthen a facade made of boards with your own hands?

The tree will be exposed to environmental influences, so it will need to be protected. The wooden facade will need to be varnished, painted or treated with decorative impregnates. Before applying a protective coating, the wood will need to be coated with a fire retardant compound.

The only exception may be the case when the facade is painted with special fire-resistant paint. This composition will prevent the boards from igniting even in the event of prolonged contact with fire. Ventilated wooden facades will definitely need to be treated in a similar way.

Covering the facade of a private house with wood has a large number of advantages. But there is also a drawback, which is that the boards require updating the protective surface every few years. If tree species are used for cladding roads (for example, cedar or teak), then you don’t have to think about the problem with subsequent painting. In addition, these types of wood will practically not be subject to deformation over a long period of time. Today on the market you can find a fairly large number of boards for sale that have already been processed and painted.

Vertical wall cladding with unedged boards looks more beautiful in interior spaces. For external coverings, horizontal cladding with unedged boards is most often used, which has an original appearance when secured with an overlap. Combined cladding can decorate a building inside and out - all you need is diligence and imagination.

The finishing of facade elements with wood using boards of various sections is carried out by carpenters and joiners. To sheathe a private house yourself, you need to have relevant work experience and a certain set of electrical tools.

Protecting log walls from the outside from damage by rain, sun, wind and frost is done in various ways. The most environmentally friendly is cladding the facade of the house with wood. The overlapping arrangement of the boards creates a barrier to air flow. Water flows down the protruding surface without getting inside the sheathing and wall. Board finishing is expensive. Its advantages are the naturalness of the material, a comfortable environment inside the house, and the unique beauty of natural material.

Board façade: technology originating from northern latitudes

The Swedish, otherwise Scandinavian style of exterior decoration involves the use of ordinary edged boards, which are stacked vertically in two overlapping layers. The board is coated with a special paint designed specifically for rough, unplaned wood. The vertical orientation of the finishing board, coupled with the ventilation gap, provides the facing screen with durability, due to the fact that moisture does not stagnate in the wood, but is removed. Naturally, the board for covering should not be damp; the maximum permissible humidity is 18-20%.

Exterior board installation

After all the internal boards have been installed, it is necessary to begin fastening the external ones. How to do this correctly?

Horizontal trim around the window.

Each board is pre-marked with an overlap so that the work is done quickly and efficiently. When drying, the material may become slightly deformed. Therefore, when purchasing, it is best to use well-dried wood.

Tools for work:

- screwdriver;

- jigsaw;

- hammer;

- ruler and building level.

During the exterior cladding of the house, it is necessary to use a building level so that the surface of the façade finish is smooth and beautiful.

Options for joining boards for external wall cladding.

There are many options for fastening external edged boards:

In rustic, with lower end parts protruding at an angle, the groove is made at the bottom. With a bevel into a tongue and groove. A complex profile is used, the external cladding is beautiful and stylish, and the thickness of the board is significant. Semi-rustic. The surface of the wall is smooth with small triangular grooves, the board is cut at an angle, the groove joint is not used, the overlap is angular. With a quarter slope. The surface of the facade is smooth, a complex straight quarter profile is used for the connection. The surface of the facade is smooth and beautiful, the board is laid firmly and tightly, moisture does not have any opportunity to flow under the cladding. The grooves for fastening are cut at right angles, making the connection one of the most reliable and simplest. To the tongue

To lay the boards, a tongue and groove connection is used; it is important to cut the grooves using a template. Otherwise, reliable docking will not work. The facade has a smooth and beautiful surface, moisture does not flow into the wall, drafts will not bother you, as will heat loss. Glue-on installation

The board is glued together, there is no overlap.

The facade has a smooth and beautiful surface, moisture does not flow into the wall, drafts will not bother you, as will heat loss. Glue-on installation. The board is glued together, there is no overlap.

When covering a house with wooden boards, experts advise adhering to certain rules that will ensure a beautiful and durable finish:

- For work, it is best to take a board that is planed on one side and not on the other. The rough side of the material is mounted outward. Then the primer, and then the paint, will last much better and longer, and the appearance of the house will be more attractive.

- The boards do not need to be nailed only at the bottom and at the top, as the material will easily split and absorb moisture. It is necessary to use the staggered fastening option, when the boards are fixed on the surface of the facade in increments of 30-45 cm, i.e. in a checkerboard pattern.

- Wood of various species can be used for cladding a house. It can be cedar, pine, spruce, mahogany. Based on their experience, it is best to use cedar planks. They are not only durable, but also easy to process and have a beautiful appearance. Mahogany is difficult to process; it is difficult to drive a nail into the surface, although it does not warp over time. Pine has numerous beneficial properties, but it is not very good for external use, as it easily warps and splits. Spruce is rarely used for exterior work on facades, although its performance is much better than that of pine. Spruce boards are full of knots, and this does not have the best effect on quality.

- Sheathing a house is best done with regular steel nails rather than galvanized ones. The problem is that the galvanized layer is easily peeled off during installation, and when exposed to moisture, the nails quickly rust. Stainless steel is much more expensive, but the quality of finish is higher.

Sheathing a building with edged boards is an attractive and simple option for any country house. This facade is not only stylish, but also environmentally friendly. After installation, the board can be varnished, painted, or impregnated with oil. It all depends on the imagination of the owner of the house and the general style of construction.

15185

Wood species from which it is made

To sheathe the outside of a house with unedged boards, you need to choose the highest quality material. An important parameter is the duration of service. For these purposes, there are only a few options to choose from:

- Pine has a denser structure, which allows it to withstand strong mechanical loads.

- Spruce is not so dense, so it retains heat well.

- Larch is reliable in all aspects.

With the edged finishing board everything is clear. If there are any defects on the surface, then you should not buy it. It’s even easier with an unedged board. But when choosing this material, you should pay attention to several points:

- quality of cut - a good product should not have chips, gouges or other defects;

- bitches – there can’t be too many of them. The presence of such a defect reduces the quality of the board and also provokes curvature of the material during drying;

- cracks - reduce strength, reduce service life and compromise the integrity of the material;

- curvature - if the board has such a defect, it is difficult to fix it on the base.

Features of installing an external board

After installing the internal boards, they begin to fasten those that will be outside. This part of the finishing work must be approached with the utmost seriousness, strictly following the recommendations.

Each plank is laid on top of the other, overlapping. Simply put, the boards should overlap each other by at least 2.5 centimeters. To prevent mistakes and avoid distortion, the overlap location must be marked in advance. To prevent the wood from deforming, you need to use only well-dried lumber.

When performing façade cladding work, the following tools are used:

- A screwdriver.

- With a jigsaw.

- With a hammer.

- With a ruler.

- Construction level.

Without the tool listed last in the list, it is simply impossible to trim a house with an American quality and accuracy.

There are many possibilities for attaching edged boards to the facade of houses. Here are some examples:

In rustic. In this case, the end part will protrude. The groove is at the bottom.

With a bevel into a tongue and groove. It should be noted that this cladding option has its own difficulties, but the end result is very attractive and beautiful. The board for finishing is taken thick.

Semi-rustic. On a flat surface, triangular grooves are obtained. The board must be cut at an angle. There are no grooves as such, and the overlap itself will be angular.

With a quarter slope. The facade of the house will be smooth. The connection of the boards is complex.

If we use a straight quarter, we get a smooth and beautiful façade. This option gives a tight and durable installation, so no moisture gets under the sheathing boards. The grooves are selected at an angle of 90 degrees. In addition, performing such cladding is not at all difficult.

A tongue and groove connection is considered reliable, but for this you need to correctly cut the grooves using templates. If an error is made, the strength of the connection will be compromised. The outer walls of the building are smooth, neither snow nor rain will get under the cladding. Moreover, this facade decoration is a thermal insulation layer.

In gluing. This option involves gluing the boards together, so there is no overlap.

What material the house itself is made of does not matter. Covering a brick house with wood is quite possible. The main thing is to follow the advice of experts. Then the house will not only be beautiful, but will also last much longer:

The board for covering must be well dried. It only needs to be planed on one side. The rough side is taken out. The fact is that subsequent wood processing will be of better quality.

Primer and paint will last longer on such a surface, and the house itself will attract attention. The choice of wood depends on the requirements of the home owners. You can use cedar, pine, spruce or redwood boards.

Let's consider these options in more detail.

Experts suggest choosing cedar planks. They are durable, easy to process, and most importantly, give the building a unique look.

As for mahogany boards, they last a long time. But it is very difficult to work with them: it is almost impossible to forget nails.

Pine boards are an excellent material, but not for external cladding. Cracks quickly appear on them, and natural disasters lead to deformation.

Spruce boards are good for everyone: they don’t warp or crack for a long time. But the presence of a large number of knots contributes to a decrease in the quality of the cladding. It is for this reason that facade cladding with spruce boards is practically not carried out.

- It is better to use ordinary steel nails as fasteners, but galvanized ones are not a suitable option. After all, the coating on them will be destroyed during installation work, which will lead to the appearance of rust. Don't skimp on nails if you want the sheathing to be of high quality and last a long time.

You can cover the facade with wooden boards in any country house. This method will make it not only attractive, but also maintain its environmental friendliness. After the facing work is completed, the board needs to be further processed:

- Cover with special varnish.

- Paint with exterior paint.

- Soak in oil.

The choice will depend on the requirements of the owner himself. In addition, you need to take into account the style of construction.

Related materials:

What you need to do to use it

In order to decorate the outside of the house with unedged boards to look as attractive as possible, you will have to put a lot of work into the design. And you should start with the most important thing - making the material resistant to water, fire and protecting it from pests. After such treatment, you will no longer have to worry that the façade cladding will not last long due to rotting or destruction by pests.

You should also decide what type of finish you like - with or without the bark left. In the first case, you just need to select dies from which the bark does not crumble or peel off. In the second, there is still a lot of work to be done - all the bark remaining on the slats will have to be removed and the resulting cut cleaned.

When all previous operations are completed, you can begin to apply stain if you need to give the surface a certain color. It is necessary to take into account that after applying all the compositions, the final color may differ from the intended one due to the mixing of all components. Therefore, it is better to try in advance to apply all the compounds one by one on a scrap of material and only then use it to decorate the facade.

Sheathing a house to protect a load-bearing wall

Sheet clapboard house

It was necessary to sheathe a wooden cottage. It was Vadik’s turn to help me. We worked with him based on his questions and my stories. My friend is not just a scientist, but a curious mathematician who wants to learn how to do everything with his own hands. We were preparing the outside of a wooden house for finishing, and I told him where the sheathing of the walls with overlapping boards came from.

When exploring new lands, first America, then Australia, ships often crashed on reefs near unfamiliar shores. The settlers used wooden cladding on the sides to decorate the outside and inside of their houses. They used selections at opposite corners of the board and laid them in a herringbone pattern. The edge protruded outward above the bottom bar. The water did not flow down the wall all the way to the base, but dripped down from each board. Inside, the sheathing and wall remained dry.

Depending on the climate of the area inhabited by the settlers, cladding the outside of the walls with overlapping ship planks protected the housing from various natural factors:

- strong wind;

- scorching sun;

- frost;

- rain;

- heat.

Over time, finishing with boards and timber became popular. People appreciated not only the practicality, but also the beauty of the wooden facade. It is easier and cheaper to replace the most expensive exterior cladding than to restore the walls.

Edged board facade from Blin135642

Blin135642 looked closely at the Scandinavian style of cladding in the Raklaru theme, and then implemented it on the walls of his frame house.

The frame was sheathed with a 50x50 mm block for additional insulation, insulated with stone wool, and covered with a membrane. They upholstered it with a vertical board, first a 50x25 “latch”, and on top - a 150x50 mm board. There is natural ventilation under the lumber to the height of the wall.

The price of the paint is about four thousand rubles for two hundred liters. So far I have welded one 10-liter bucket for testing - the color is excellent, the paint does not get dirty. The boards were painted on both sides.

Swedish paint recipe

Step-by-step technology of overlap cladding

The boards are primed or coated with a protective layer with deep penetration compounds.

Primer is a connecting link with adhesive and paint compositions, which helps to increase the wear resistance of the coating and reduce the aggressive influence of the environment. The walls are also primed.

Installation of a coating-type waterproofing layer. The walls and blind areas of the building are waterproofed three times to protect against moisture penetration and the formation of microorganisms.

The mastic is applied with a brush. If there are cracks, they are filled with the compound, and the excess is removed with a spatula.

It is important to allow the waterproofing to dry to avoid stickiness of the surface. Installation of an insulating layer in the form of mineral wool, characterized by its non-flammability, moisture resistance, and cold resistance

Installation of an insulating layer in the form of mineral wool, characterized by its non-flammability, moisture resistance, and cold resistance.

Fastening the planks vertically over the waterproofing layer with nails. Vertical unedged boards are packed onto the wall surface, then horizontal ones are attached from the bottom up.

Sealing joints with polyurethane sealants, which are highly elastic and not susceptible to stretching and deformation.

Currently, developers give preference to natural materials, not only during construction, but for the exterior decoration of finished buildings. Today, natural materials are becoming popular again not only for construction, but also for cladding a house. Wood is an environmentally friendly material that will not only preserve the house, but also make it attractive.

There are many technologies for performing finishing work. Today, many home owners prefer to clap their houses with shiplap boards. This method is most often used to decorate low houses or country houses. To increase service life and add originality, wood can be:

- Cover with varnish.

- Paint it.

- Soak in special oils.

Sheathing a house does not cause any particular difficulties, so most often they do not resort to the help of specialists to carry out the work, but do everything themselves. The main thing is to have the necessary skills and follow the recommendations. In addition, choose high-quality materials and necessary additional elements.

Final finishing

After the boards for finishing the facade are securely fastened, sealant can be applied to the joints. Experts recommend using polyurethane sealants, which are more elastic and can withstand fairly strong stretching. They are not so afraid of mechanical damage.

A combination of beauty and economy

Lastly, the finishing coat is applied. Most often, varnish is used, which must be carefully applied to each board with a small brush.

An unedged board for finishing a facade is an excellent and economical option that will look very beautiful and original. Installation does not take much time and does not require any special knowledge.

Installation work

You should always start by treating load-bearing walls with protective compounds that will prevent mold, fungi and pests from appearing under the cladding. Then the following work is carried out:

- Marking of vertical lines is created along the entire perimeter of the facade;

- Using the created markings, the wooden planks are secured using self-tapping screws;

- A casting is made on the upper part of the base;

- A beam is installed above it, the thickness of which is equal to the thickness of the lining. This element will provide the skin with the required level of inclination;

- From the bottom corner they begin to fasten the boards with nails. When attaching the boards, you need to step back 2 cm from the side end. Nails are nailed on top and bottom of the wooden block.

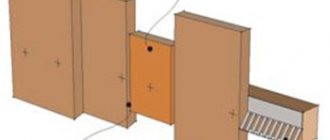

Plan for fixing overlapping boards on the façade

After completion of construction work, the joints at the corners of the facade are closed with typesetting elements. They will protect the cladding from premature destruction and give the facade a complete and neat appearance.

We began sheathing transportable bathhouses with overlapping or herringbone boards (linings) in 2014. And these were barrel baths, which we then called “Exclusive”. Despite the fact that “American” (and this is precisely the name given to this facade finishing technology) has been known since time immemorial in the States, Canada, and Scandinavia, it became widespread in our country not so long ago.

The technology is simple, proven, and the result looks impressive. Suitable for exterior decoration of houses, bathhouses, and any other buildings.

Here's what it looks like live:

Article navigation

Subtleties of wooden wall design

If you have already chosen a wooden option for finishing the facade, you should take care of the material in advance. Unedged boards require a special approach. First, they decide whether to leave the bark on the board or not.

If the bark is left, then you need to choose elements where this layer is securely held and does not peel off or crumble. In the case when the bark is not needed, then everything is cleaned and thoroughly sanded.

Further, absolutely all wooden parts are coated with antiseptic and moisture-repellent compounds. If this is not done, the material will quickly become covered with unpleasant-looking stains, and over time, rot.

Facade board. Types and features

The familiar lining, block house, imitating the style of log houses made of hewn logs, and boards imitating timber, are similar in the installation method. They are fastened using the tongue and groove method. They are mounted tightly, without gaps, often using the open method, that is, with self-tapping screws through and through.

Planken

A new word in the field of construction. Planken - what kind of material is this? At its core, it is an edged board, well sanded on all sides. There are two types of plank profiles - with straight and beveled ends of the boards. The straight ends of the plank have an edge angle of 90°; as a rule, installation occurs with an overlap.

Figure 2. Finishing the facade with planken.

An innovative material that has burst into the construction market. Previously, only floor coverings were made from composite wood boards. Today, with the advent of new technologies, the production of panels is practically waste-free. In the process of manufacturing a wood-polymer composite, wood flour is mixed with synthetic substances and polymer resins.

As a result, the resulting product is very durable, not subject to deformation, resistant to fading and does not require special care. The appearance completely matches the structure and color of the wooden covering. Siding is easy to use: it can be easily sawed off or trimmed; the plasticity of panels made of fiberboard is achieved precisely because of the presence of a polymer composite in the composition.

Thermal board

The appearance of the finish is not inferior to elite types of wood, repeating the structure and color of, for example, oak. Basically, planken made from thermal boards is in high demand. But if you wish, you can clad the house with clapboard or panels that imitate timber. For facades, thermally treated fir, alder, beech and maple are used. The “thermo” prefix does not affect installation methods in any way.

Particularly loved by admirers of natural finishing materials is larch. It is able to transform the appearance of the facade, giving it a noble, status look. And the price of larch panels is quite affordable. When choosing facade slabs from this coniferous wood, you only need to be guided by the chosen design style. A variety of color solutions will help realize any design idea.

The technical and operational characteristics are amazing. Even in the absence of any treatment with impregnations and special means, a larch facade will last at least 25 years. The antiseptic properties of wood will prevent the development of fungi and mold, and will protect against wood insects. Larch is resistant to large temperature changes and changes in weather conditions. If there are no shortcomings, the larch facade will become an original decoration of the house.

Price overview

The price range for facade panels is in a wide range. You can get by with unedged boards when cladding, for example, outbuildings. It is, in fact, not a facing material; it is sold by the cubic meter and can be quite inexpensive.

| Name | Unit. | Price |

| Planed board | 1 sq. m. | From 210 rubles |

| Lining | 1 sq. m. | From 460 rubles |

| Planken (oblique and straight cut) | 1 sq. m. | From 799 rubles |

| Planken/siding | 1 linear meter. | From 250 rubles |

| Thermal board | 1 sq. m. | From 1600 rubles |

| Dpk board | 1 sq. m. | From 1900 rubles |

Facade panels made from elite wood species are usually made to order, and there is no maximum price range.

Edged board facade from Raklaru

Raklaru chose to decorate the house with façade edged boards due to availability, as a “test of the pen” on a guest house.

I'm building a frame house, but I always had a headache about the facade, how to make it. I really wanted planken, but it’s expensive, the building is not the main one, it’s a guest house, (training) house, such a façade didn’t fit into the budget. I accidentally saw a Swedish or Scandinavian style on the Internet: facades made of boards, vertical edged boards, painted with red Punamaali paint.

Lathing

According to the original technology, to ensure a full ventilation gap, a counter-lattice is required.

But since there remains a longitudinal ventilation duct between the layers, in this case 5x2.5 cm, and the facing screen itself cannot be completely sealed, the craftsman considered it possible to do without a counter-lattice. The result was the following “pie”: frame, sheathing for additional insulation, sheathing for wind protection, wind protection, sheathing for sheathing.

Painting the board

The craftsman purchased a 25×100 mm board, grade A, raw, dried it for a month before painting and installation; when drying, it may shrink, but not as significantly as a completely damp one. And strong fixation with a large number of nails will prevent serious distortions.

For finishing work, Raklaru used a special paint, Punamaali, this is not a brand, but a rich red paint intended for edged boards.

Due to its composition, the paint replaces both the primer and antiseptic impregnations; the board is simply painted on three sides, once before installation on the facade of the house, and a second time after - to hide the fasteners.

Our craftsman used a brush for painting; when using a spray gun, paint consumption increases and the quality of the coating decreases, since this method is mainly for planed boards.

As for brushes, I tried a dozen, and large round brushes with short bristles turned out to be very convenient. And it doesn't hurt to have a lot of patience when painting edged boards. Since I made a mistake with the quantity, I painted the boards on four sides; after painting, there are practically no wood defects left.

The paint sets quite quickly (10-15 minutes in the sun), at first it gets a little dirty, but after it dries completely (two to three days) this effect disappears. In the topic, many complained about exactly the opposite, but the topic starter walks near its facade without fear of becoming a regular dry cleaner customer.

Facade made of boards: installation

According to the technology, the bottom board is nailed to the sheathing, the top one is attached not only to the sheathing, but also to the bottom board along the entire length at a distance of about 30 cm, in a checkerboard pattern. The use of galvanized rough nails is justified both from the point of view of the reliability of the connection - smooth ones can move over time, and from the point of view of aesthetics - ordinary ones can rust over time and develop drips.

It was suggested that when cladding a façade with boards, one should prefer self-tapping screws, deepen the caps and cover them with putty before painting. However, the labor intensity of this method outweighs the possible advantages, and the rough nail holds quite firmly. One of the participants in the topic carried out the fastening this way.

I made two templates with a handle - 75 mm wide (top and bottom), the gap is an amateur, it’s better to leave at least 20 mm for the overlap. I measured each top board using a laser level. Nails, for example, were first hit 65x2.5 mm every 30 cm in a checkerboard pattern, flush. Then I rented a nailer and finished it off with it, it turned out faster.

To ensure that the geometry of wooden facades of this and other types undergoes minimal changes, and the presentable appearance is preserved for as long as possible, portal participants recommend following several rules.

And the most important thing is not to expect a wooden facade to be in perfect condition for the next twenty years; naturally, after a certain time you will have to renew the coating. But this is a property of wood, and not a disadvantage of this or that cladding method.

Our craftsmen have proposed several schemes for framing window and door openings.

The only clarification is that the gap between the casing and the ebb should be made slightly larger, 0.5-1 cm, to prevent moisture leakage.

Raklaru framed all the slopes with wood and painted them in contrasting white, both the corner strips, the front board, and the overhang trims, previously covered with boards left over from the facade.

How to mount everything

Typically, finishing the facade of a house with unedged boards begins with applying waterproofing compounds to the walls. This will protect the walls from moisture and you won’t have to think about the condition of the base surface after decoration. Next comes the insulation operations - if necessary, it is at this stage that an additional layer of insulation can be installed on the outside of the buildings. Only after all this work does the actual finishing begin. It is performed in the following sequence:

There will be two cladding methods - overlapping, checkerboard or herringbone. The first option involves placing the boards in such a way that the upper one covers the edges of the lower ones on both sides. The second option is similar to a siding plane - the lower edge of the upper plank overlaps the top of the lower one. In both cases, the overlap must be at least two centimeters to ensure maximum aesthetics of the structure and to prevent the formation of large gaps between the dies.

What is an unedged board

Unedged board is a special type of lumber that has different widths and thicknesses. The main feature of the products is that their end is not cut off. Due to the different shapes and sizes, finishing the facade of a building with unedged boards can have an attractive and original appearance.

What types of wood are suitable for cladding?

For cladding, you can use different types of materials.

- If we consider the characteristics of various types of wood, then larch is considered the best option. Wood is not afraid of high humidity; it has a lower degree of warping than all other species. It is easy to work with and holds nails well.

- Finishing the facade with unedged spruce boards is considered not a very popular option. Wood has its own impregnation. Due to the presence of a large number of knots, the boards have an attractive decorative appearance. After some time, noticeable cracks appear on them, so unedged spruce boards are used extremely rarely.

- The pine will quickly warp and soon become unusable. It is never used for exterior cladding.

- Hardwood will look very nice. In addition, it has a long service life. It is worth remembering that hard rocks are difficult to process, and nails can cause them to split if the work is not done carefully. Also considered a disadvantage is the high price of the material.