There are several ways to connect various objects and materials, but the simplest and most effective method is adhesive fixation. To use a glue gun, you need to know the general operating rules. The principle of operation is simple - the device heats up a polymer rod, which becomes plastic under the influence of temperature. Using a gun, the adhesive mass is applied to the desired area. Then the gluing itself is done.

How to use

Thermal guns are used at large furniture manufacturing enterprises, where they are used to install finishing elements on cabinets, upholstery of sofas, and armchairs. They are used in construction and the production of decorative items. When purchasing for home use, the list of operations increases. Hobbies, children's crafts, interior decoration, minor repairs are the area of application for a glue gun. You need to know the rules for using the device at home. Additional information will make the gun more effective where it can be used, and put it aside where it is inappropriate.

How to charge

Manufacturers have tried to make the operation of the device simple. The design of the pistol allows it to be loaded without additional devices, disassembly, or other operations. The simplest charge is the first one. The rod inlet and nozzle are clean. There are no traces of past work, signs of physical impact, or damage. For work, take the glue of the required brand. When purchasing, you need to know the characteristics of the rod. Products include the following types:

- Transparent. Universal rods with low melting point.

- Black. Designed for sealing joints, like sealant. They have a high melting point.

- Colored. The polymer is painted over the entire mass and the glue on the parts is not visible. Widely used in handicrafts.

- Decorative. They are used when the glue itself becomes a finishing element. May contain glitter, mother-of-pearl, and fibers.

- High temperature. Special types of glue for fixing elements that are subject to increased loads.

When purchasing, pay attention to the diameter of the rod. The most popular brands have values of 7 and 11 mm. However, products of other standards are also available for sale, for example, 8, 12 mm. The rod size specified in the instructions cannot be replaced.

As a rule, charging the glue gun itself is not difficult. The rod is inserted into the hole in the back of the device until it stops. In some models, it is necessary to advance it by repeatedly pressing the trigger until it rests on the heating chamber. Guns with a temperature indicator are convenient. A glowing diode indicates that the device continues to heat up. When the indicator goes out, you can start working.

Warm-up rules

The melting point is indicated on the packaging with the rods. If you purchased a low-power gun, then not every type of glue will work. There are models designed to work with low-temperature rods that melt at 105 °C. It is not recommended to insert consumables with a higher melting point into them. Even if the glue begins to soften, the work will be very difficult and long. Excessive pressure on the mechanical parts of the gun may cause them to break.

What you need to know about glue sticks

Polymer rods/stickers (the so-called glue for hot-melt guns) are not the same. They differ in length, diameter and color. Consumables for household adhesive devices are produced with a thickness of 7-11 mm, and for professional devices - with a diameter of up to 45 mm. The length of the rod is not strictly established, it varies in the range of 4-20 cm, but the longer the spare tire, the longer it can be used. Features of stickers by color:

- Transparent - universal, any material (plastic, fabric, metal, furniture).

- Multi-colored (blue, pink, green) - decorative sets, mask seams, are widely used in needlework and creativity.

- Black stickers are used for sealing, rods are suitable for carpets and floor coverings.

- Yellow refills are designed for paper products, cardboard and finishing materials.

- Options with glitter are used in needlework, and white stickers are useful for ceramics and tiles.

If the specifics of the job require the use of black and transparent stickers, it is worth purchasing two guns for each set of rods. We must not forget that reserves differ in temperature and melting speed - 105-150°C. You need to choose glue rods depending on the specific task and the characteristics of the materials being glued with thermoplastic hot glue.

How to use glue sticks without a gun

There are situations when you urgently need to fix/glue some fragments together, but the gun is broken. In this case, craftsmen and needlewomen use the following life hacks:

- A fragment of the rod is inserted into the body of a ballpoint pen and held over a candle to melt. The glue needs to be constantly heated.

- A drop of hot glue is applied to the match near the sulfur head. If the gun overheats, you can light a match and use glue.

- A small fragment of a sticker is used instead of an eraser by gluing a small piece of the rod onto a pencil.

But it’s still more convenient to use adhesive stickers using a hot-melt gun. To make the device last longer, try to avoid overheating, which can lead to wear of the rubber in the coupling, damage to the wire insulation, and unhindered leakage of glue.

How to change the color of the rod correctly

Sometimes in the process of creativity, a needlewoman needs to use different stickers of different shades. In order not to break the gun, it is forbidden to pull out the remaining glue from the coupling with pliers or other tools. The excess part of the sticker must be squeezed out through the nozzle by pressing the trigger. But before that, a new refill of glue of the desired color is loaded into the gun. The spare rod will push the remaining sticker through.

Experts recommend: If you use the gun frequently, a large number of short fragments of rods accumulate. Remains of the same color are glued together and a new long sticker is obtained, which can be used in work.

Safety instructions for use

The device operates on mains power, and electric current always poses a health hazard. A gun is, first and foremost, a heating device. Temperatures can reach up to 200 °C. Glue is also an energy-intensive substance. It cannot cool down instantly. In case of contact with skin, burns are inevitable. When performing certain operations where contact with heated polymer is possible, it is necessary to wear gloves, ensuring the safety of your hands.

Lifehack. During a break, between individual operations, the glue gun is left on the stand with the nozzle down, under which you can put a piece of paper, a piece of fabric, which after work can be thrown away with the remaining glue. The working surface of the stand will remain clean. The glue will not get on the floor or table.

During operation, do not reach into the body with metal objects to remove glue or correct the position of the rod. Do not touch the nozzle during operation. The very same safety precautions when working with glue are not regulated, with the exception of the heating period. When cooled, it is completely harmless, therefore it is allowed for the manufacture of interior elements and children's toys.

Power when choosing an electric heat gun

When choosing a glue gun, it is advisable to be guided by its power characteristics. You must understand that the higher the power of the heating element, the faster the glue will reach working condition.

Equipment used by professionals consumes from 300 W, devices intended for home use consume from 30 to 150 W.

There are often cases when the power developed by the device is not enough to solve the assigned tasks. In this case, there is a need for pauses necessary to create the required amount of melt. Based on the above, we can draw a simple conclusion: power consumption is an important parameter, but it is advisable to choose a device based on performance.

Some manufacturers are promoting variable power equipment on the market. That is, to obtain a melt, the heater mounted in the gun consumes 200 W, and as it reaches operating mode, it reduces it and consumes, for example, 35-40 W. The device consumes only 10-16 W in standby mode.

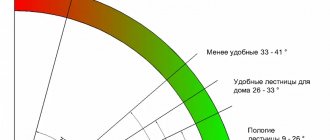

Professional heat gun MS200

Another subtlety regarding the technical parameters of glue guns is the operating temperature of the adhesive composition. We must always remember that it is not materials that withstand high temperatures. For example, to work with fabrics, paper and a number of polymers, it is necessary to use low-temperature compounds. Or the equipment must be equipped with the ability to select the temperature. On the market you can find equipment that can operate in two ranges of 105-165 °C. This engineering solution allows us to expand the scope of application of the hot glue gun.

Problems and their solutions

Over time, some parts wear out. Most often this is the plastic from which the trigger, the advance mechanism and the o-rings in the feed coupling are made. Being in close proximity to the heating chamber, over time they lose elasticity, crack, and crumble. You can replace them yourself by cutting new seals from silicone or heat-resistant rubber. Then the glue under the pressure of the rod will again come out through the nozzles, and not through the resulting gaps or cracks into the gun body.

The nozzles need to be cleaned regularly. If the glue cannot be removed in a cold state, then the device is heated and excess polymer is removed using rags, thick paper, or cardboard. The device is inexpensive, so repairing it with replacement parts is unprofitable. The most vulnerable parts of the device are the trigger and the rod feed mechanism. During operation, the hot glue in the gun is quite mobile, so you should not press too hard on the trigger. You can damage it, or create excessive pressure in the heating chamber, which will lead to accelerated wear of the seals.

Features of the structure and functioning of nozzles

Damage to the coupling can be caused by trying to remove the rod after work by twisting it. Then the glue will spoil the rubber; in this case, it is better to cut off the tip of the rod to avoid such effects.

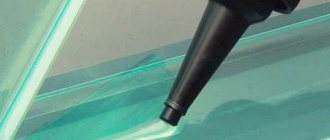

What is the name of the part of the hot glue gun through which the substance comes out? The answer is the name - the nozzle. It is necessary to regulate the size of the glue seam, determine the dosage of supply and closing the outlet of the substance. There is also a shut-off valve here, which is responsible for holding the solution so that it does not flow out excessively.

To avoid increased pressure due to overheating of the glue, the channel is not completely blocked, for this reason it is better to place some material under the tip.

There are direct-flow nozzles, but with them the glue consumption increases. It happens that different types of nozzles are attached to the device; their replacement can only be done in a heated state, when the glue is in an uncured state.

Many devices have a special window through which you can monitor the glue consumption, the condition of the rod and coupling; this addition may increase the cost. You should not place the gun on its side while heating, otherwise the temperature may damage the product on which the device rests.

The nozzle is necessary to regulate the size of the glue seam, determine the dosage of supply and close the outlet of the substance.

How to change the color of the rod correctly

Often during operation it becomes necessary to replace the rod. For example, to change the color of glue for decorative finishing. To do this, turn on the device. After heating, carefully remove the rod. Insert the desired one. After the time recommended to achieve the required temperature has been maintained, the remnants of the old rod are squeezed out of the nozzle until new glue appears. It is advisable to refill with a rod of a similar brand. Then the operating mode will remain the same, and there will be no noticeable difference in texture on the finished product. You can change not only the color of the glue. You can install a rod with filler to create an original design.

On what principle does the tool work?

The principle of operation of a glue gun is to melt glue cartridges (this name is also acceptable) in the shortest possible time due to high temperature. The level of degrees is maintained in the solution until the material exits through the nozzle.

Since there is no such heat outside the case as inside, the molten plastic begins to harden - the period of complete hardening lasts no more than two minutes. During this time, the substance penetrates into the pores and crevices, forming the integrity of the result. Therefore, it is important that the gun heats up to the limit, but without an excess of degrees.

The device is best demonstrated when working with the following materials:

- Wood;

- Glass, mosaic and beads;

- Metal and rubber;

- Plastic and PVC panels;

- Ceramics and foam;

- Paper and cardboard.

The adhesive that hardens after extrusion is waterproof and airtight, therefore it can be used as a sealant.

You can also interact with concrete, but under the condition of high porosity - it is important that the glue gun only glues if it is not perfectly smooth.

Direct operation of the glue gun

In fact, the rod does not contain adhesives. Adhesive qualities appear only when heated. It is a waterproof polymer that, in its liquid state, can adhere to almost any surface. This is achieved with the help of a pistol. The inserted rod is brought to the melting temperature in the heating chamber and extruded through the nozzle onto the part. The mode depends on the power of the device and the brand of glue.

Preparation time for low temperature rods is about 2 minutes. Then the glue is applied to the surface. The second part is pressed and held in this position until it sets. The time may increase if a significant amount of glue is used. If it is a small drop, then a few seconds are enough. If several grams are applied, then the structure needs to be kept for up to 2 minutes. Complete cooling and set of operational characteristics occurs in approximately 5 minutes.

What is glued with a hot-melt gun?

The main task that this tool must solve is connecting parts using heated glue. Hardening of this material occurs within a few minutes. Its advantage with instant adhesive joints is that the worker has a small margin of time to correct mistakes. The use of a glue gun and compounds specially produced for these devices allows you to connect different materials together, for example:

- wood;

- metal materials;

- concrete;

- polymers;

- glass;

- natural and artificial stone and many others.

Using a glue gun

Which model of a good heat gun should I choose?

Perhaps the best model for home needs, having balanced all the key qualities and parameters, is the Stayer Master - a budget option for working with both small details and covering large-scale surfaces.

The tool is designed for leisurely use, so you will have to wait about five minutes to reach the maximum permissible temperature. The main advantage of the device is its weight of 150 grams, so the user will not experience any inconvenience during operation and his hand will not become overtired.

Application area

Various materials are glued together with a glue gun:

- cardboard;

- ceramics;

- glass;

- plastic;

- metal, leather;

- tree;

- cork.

The pistol is indispensable in the household. Options for its use are presented in the table.

| Application | Picture |

| If a tile plate has fallen off or a piece has broken off from it, then using polyurethane glue you can quickly repair the area. | |

| When laying linoleum there is good adhesion to the base. | |

| The wood adheres well to the surface when installing skirting boards. | |

| As a hobby, needlewomen create all kinds of patterns. | |

| The fabrics are well connected with melted glue. | |

| Using this glue, rhinestones or artificial pearls are attached. Dye is first added to it. |

Design and principle of operation

During operation, the gun is held by the handle. On top is the barrel, which includes all the elements of the device.

When the device is turned on, the heating element located in the heating chamber is heated. A heating stick touches it, which melts at a temperature of 105-210 degrees. With its further supply, excess pressure is created, and the molten glue is pushed out through the nozzle.

Body and handle of the product

The handle is hollow. Only wires pass through it, and a trigger is installed on the side. The housing houses the entire device. It is made of plastic with a low degree of thermal conductivity. This is due to heating of internal parts.

The weight of the device is 300 g. After turning it on, the device should only be positioned vertically. You can’t lift it with its nose up and put it on its side. This is due to the presence of molten glue inside it.

There is a platform at the bottom of the handle, and a folding pad is fixed in front of the body. The gun is mounted on these support points.

Feeder

When you press the trigger, which can be carousel or slide, the force is transferred to the ring pusher. This structural element is in direct contact with the rod. The rotating ring grabs the rod and pulls it towards the heating element.

The ring pusher is the weak element of the system. If there is even a slight defect, the rod may slip through the ring.

Guide coupling

The part is made of heat-resistant rubber. One side of it is put on the heating chamber, and the other side is inserted with a glue stick.

The coupling performs 2 functions:

- It keeps the molten mass of glue from flowing into the body of the device.

- Creates temperature uniformity. In its absence, during downtime, the rod would begin to melt in front of the heating chamber.

This is another weak point of the pistol. If heated, the rubber may tear when trying to rotate the rod.

Heating chamber

Externally, it is a tube in which the heating element is located. Some types of devices have two heating elements built in. In this case, heating of the rod occurs not only in the end part, but also on the sides.

The performance of the equipment depends on the size of the chamber and the power of the heating elements. This design unit is the most reliable. If used correctly, the likelihood of it breaking is very small.

Nozzle

An exiting stream of glue is formed in this element. Nozzles come in direct flow and with a valve. With the first option, the heated glue moves by gravity. The dosage is ensured by the feeding mechanism. With high fluidity of the glue, it begins to come out constantly. This is a disadvantage because of its large losses.

A spring-loaded ball is built into the nozzle with a valve, blocking the hole. Opening occurs under the influence of excess pressure when the glue is heated. The channel is never completely blocked by the ball. This is so that when overheated, excess glue can leak out on its own.

A protective cap is installed on the outside to avoid burns. Depending on the type of gun, nozzles can be stationary or removable. Each nozzle has its own channel thickness. Attached with a threaded connection. Replacement is carried out only when the device is warm, otherwise the hardened glue will not allow this to be done.