Varnish for artificial stone made of gypsum

Gypsum is a material of natural, even plant origin. It is often used nowadays for finishing gypsum tiles, and is a wonderful interior decoration. Gypsum mixtures are often used in the fields of art, medicine and construction. But such a mineral must be reliably protected, because it is quite fragile and quickly begins to collapse. Using a varnish composition for gypsum. Which helps strengthen and protect the material, and also create a beautiful finish that looks like natural stone. We suggest considering plaster varnish.

Gypsum decorative stone is made by many manufacturing plants, and it can even be created at home using dry powders. Usually they make an aqueous gypsum mixture, which is poured into molds in which it hardens.

The result is beautiful figurines, slabs or other products that can be used to decorate rooms. They can be given any color by adding the required pigment or paint. To enhance the strength of gypsum products, special modifiers and sand are added.

What varnish to coat artificial gypsum stone in an apartment

Read in this publication: Decorative gypsum stone: advantages and disadvantages Laying gypsum decorative stone What to glue gypsum decorative stone on How to cover gypsum decorative stone

What is decorative gypsum stone? Simply put, this is a tile that imitates the surface of chipped natural stone - it can be given almost any shape and structure. Such tiles can imitate almost anything, despite the fact that they were originally developed as an alternative to natural stone - they are made to resemble natural stone, brick, or even cut wood. It has become widespread due to its low cost, very attractive appearance, elementary manufacturing and gluing technology - all this will be discussed in this article, in which, together with the site stroisovety.org, we will examine in detail this material and the features of its independent use.

What to glue gypsum decorative stone to photo

Painting plaster – what colors does plaster like?

Gypsum is present both in plaster mixtures and as an independent material for the same modeling that we use to decorate our homes. And not always its natural whiteness may suit you in terms of combination with other interior elements or simply not suit you - it’s too easy to stain such parts during cleaning. It’s much easier and more interesting to paint plaster surfaces or elements! Of course, you won’t be able to take watercolor paints and give the desired color to plaster products; this process has its own secrets.

It's time to lift the veil of mystery!

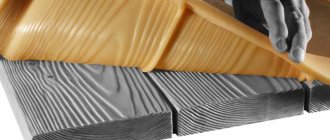

How to apply varnish to decorative stone

In principle, plaster, like almost any natural material, can easily be applied to all kinds of paints and varnishes, gilding and other simulators of silver, bronze, and even ivory! Acrylic paints adhere well to a plaster surface, however, adhesion to this material is high for almost all compositions. For better preservation of the paint layer, it does not hurt to apply an additional layer of colorless varnish; by this time the paint should be completely dry.

General information

Application of gypsum

Gypsum stone has a beautiful shape, and it also closely resembles brick or faux tiles, and also looks great when facing doorways and walls. Moreover, it can be used in combination with tiles, plaster, wood, photo wallpaper, as well as simple wallpaper. Gypsum stones are used either as fragmentary or complete finishing of premises. The stone is used for cladding fireplaces and emphasizing the base of columns. Gypsum stucco molding is sold in hardware stores, and they also sell moldings made from this material, used to decorate walls and ceilings. From gypsum powder you can make beautiful figurines for the garden, figurines, and various sculptures.

Advantages

Various building mixtures are made on the basis of gypsum, both for internal and external types of work. Dry gypsum is added to many putties, adhesives and plasters as an excellent binding component. This material is added to the majority of many construction and finishing materials, because it will have the following advantages:

- External beauty.

- A small mass that will be combined with a high degree of strength.

- Creates excellent noise and heat insulation.

- They can be used to make beautiful, unique products for decorating the exterior and interior.

- Environmentally friendly and safe material for human health.

- Mold and fungal colonies will not settle on it.

- It is a vapor-permeable material that breathes.

- Very easy to process and can be applied to all types of surfaces.

- Using affordable and uncommon tools, you can easily change the shape of plaster products.

How to apply varnish?

How to make plaster stronger - the secrets of reliable modeling!

Gypsum itself is a fairly strong material, but it wouldn’t hurt to make it even stronger, maybe 10 times stronger! This can be done both at the stage of mixing the solution, and after the product is ready. In the first case, for all the manipulations you will only need knowledge and a little lime and PVA construction glue, but in the second case you will have to go to the hardware store for iron sulfate or zinc sulfate. The easiest way to increase strength is to reduce the proportion of water in the solution.

If an ordinary solution is mixed at the rate of seven parts of water to ten gypsum, then a stronger one is made from six portions of water for the same ten gypsum.

If you overdo it with reducing the amount of liquid, you risk getting plaster crumbs. Varnish natural stone outdoors? The risk can be reduced by adding PVA glue to the solution.

Zinc salt will not change the color of the product, but vitriol will turn it yellow-brown.

How to paint

Before painting a gypsum stone, care must be taken to reduce its hygroscopicity. To do this, it must be endowed with a water-repellent effect. This can be done using special compounds. At the same time, the vapor permeability of the material is not affected. You can find a ready-made solution in hardware stores or dilute it yourself from concentrates. By the time of application, the gypsum stone should already be thoroughly dry. It is necessary to remove dust from it. The composition is applied using a brush or spray gun.

The following types of varnishes can be used to coat gypsum stone:

- acrylic;

- oil;

- yacht

Acrylic varnish is water-based. It contains various resins. The consistency is similar to thick milk. It can be used for interior and exterior decoration. Most often, such varnish provides a finishing coat that will protect the base layer. It creates a special film on the stone that has a water-repellent effect. It also protects against exposure to ultraviolet rays. The dried surface is easy to clean using various products. Available in glossy, semi-matte and matte varnish. Each of them has its own unique effect. Glossy varnish gives gloss to the gypsum stone. When using it, it is important to maintain moderation, because the surface will strongly reflect light, which can spoil the idea. Matte varnish on gypsum stone looks solid. It creates an atmosphere of comfort and peace.

Oil-based varnish can be used with the same success for gypsum stone. It provides excellent protection to the cladding due to the fact that before complete drying a film is formed, which remains after drying. It increases resistance to mechanical stress. To achieve the required consistency, special solvents are used. In terms of surface matte level, oil varnish has the same properties as the previous type. It is worth considering that this varnish may darken a little after drying.

Yacht varnish will provide the most protection for gypsum cladding. It must be applied in a thin layer to avoid drips, which will be difficult to get rid of later. It dries in about a day. This period may be extended due to low temperature or high humidity. After drying, another layer is applied. In some places, you may need to sand the surface with fine sandpaper to remove drips.

Paints

Painting plaster cladding is easier than it might seem. One option would be to add pigment to a water-based varnish. You can use water-based paint with the addition of any pigment. There are special pigments that are diluted with water. Gypsum will perfectly absorb the coloring base. In this case, you don’t have to try hard to draw lines. The manufacturer often colors the gypsum cladding himself by adding dye to the base. A video about painting gypsum stone can be seen below.

Improving the performance of gypsum finishes

Manufacturers of alabaster cladding most often offer consumers products that have already undergone a process of improving characteristics and are varnished. The price of such material is higher due to the cost of additional processing. Knowing the optimization technology, you can purchase gypsum cladding without protective treatment, for example, the popular hand-made Monte Alba decorative tiles, and independently improve the properties of the material, and then varnish it. Let's consider what the pre-treatment of gypsum products is before applying varnish, types of varnish compositions and methods of their use.

Impregnation of gypsum tiles with hydrophobic agents

To neutralize the hygroscopicity of gypsum products, they are hydrophobized, which consists of impregnation with water-repellent compounds (hydrophobizers) based on organosilicon polymers. Due to the deep (up to 20 mm) penetration of water repellents into gypsum without the formation of a film, porosity is reduced, but the vapor permeability of the products is maintained, the degree of hygroscopicity and the susceptibility of tiles to mold are reduced.

Impregnation allows you to preserve the attractive appearance of stone and decorative stone tiles for a long time

Water repellents are offered by manufacturers in the form of ready-to-use solutions, as well as concentrated formulations that require dilution. The method of use is indicated on the packaging of the mixture.

The general requirement for the use of hydrophobic compounds is that they be applied to completely dry gypsum tiles that are free of dust. Gypsum products are processed on all sides in two layers until saturated, without waiting for drying. This processing method reliably isolates the cladding not only from the humidity of the outside air, but also from the moisture of the base material. For application, depending on the area of the surface to be treated, a brush or roller is used.

The treatment should be carried out wearing protective glasses and gloves, avoiding contact of the composition with exposed skin. Contamination of adjacent glass and metal parts with a water-repellent agent must be promptly eliminated, as the composition hardens quickly.

Examples of well-proven hydrophobic compounds include:

- water-repellent silicone composition White Hill;

- silicone impregnation “Optimist C405 – Natural stone”;

- a range of Tiprom water repellents.

Silicone waterproofing impregnation – Natural Stone

Varnishing the plaster finish

After hydrophobization of the alabaster tiles, the base is faced by laying gypsum products on an adhesive mixture selected in accordance with the type of wall surface. A day after installation is completed, they begin to decorate the finish with paints.

To protect the artistic layer of the cladding, it is necessary to cover the tiles with a protective varnish layer. This operation begins after finishing the decoration, but not earlier than 5-10 days after finishing laying the tiles, so that the tile adhesive under the finishing not only hardens, but also dries.

To apply a protective coating to gypsum tiles, acrylic or oil varnish is used. These materials differ in properties, so we will consider each separately.

Protecting alabaster tiles with acrylic varnish

Acrylic varnish is a ready-to-use aqueous dispersion of resins, a milky liquid, the application of which to interior and exterior decoration is used for protective and decorative purposes. This solution is resistant to cracking and forms a durable, transparent film on the surface, which after drying can be removed using a special solvent.

The acrylic-based coating is resistant to detergents, moisture and ultraviolet radiation, and temperature fluctuations. The composition is odorless, harmless to humans and the environment, dries quickly and becomes transparent. Acrylic varnish is diluted with water to the desired consistency and applied to the surface with a brush, roller or spray.

Varnish for natural and piece mineral surfaces

Acrylic varnish is available in three types: glossy, matte or semi-matte.

When applying a glossy solution to gypsum tiles, it should be taken into account that the cladding will receive shine and glare from the lighting, which will distort the colors of the tile decoration.

Matte acrylic varnish will preserve the velvet surface of the tile, imitating rough-cut natural stone, without changes. This composition is an ideal protective coating for Monte Alba tiles.

The semi-matte type of varnish occupies an intermediate position between the two described types in terms of its effect on the cladding.

When dry, a thin film is formed that prevents moisture from being absorbed into the plaster.

When decorating gypsum cladding, which was painted with water-based paints, 10% acrylic varnish can be added to the emulsion to enhance adhesion to the gypsum. After covering with two layers of such paint, only one layer of varnish can be applied to the alabaster tile.

Important! If you do the opposite, add paint to the acrylic solution, the coating will end up with paint-colored stripes, which is not always desirable.

An example of a successful choice of protective and decorative coating for gypsum finishing is Finnish paint and varnish products.

Coating gypsum tiles with oil varnish

Oil varnish is a solution of natural or artificial resins in oils of plant origin. After application to the base, such varnish first forms a film on the surface of the layer, and then dries throughout its entire thickness and serves as a strong protection for the surface from mechanical and physical damage.

Oil varnishes, like acrylic varnishes, are available in glossy and matte finishes. To bring the solution to the desired consistency, special thinners are used that do not change the characteristics of the varnish. Oil-based varnishes are available colorless or transparent, but have some tint, so when choosing a material for coating gypsum tiles, you need to take into account the compatibility of the varnish shade with the color of the alabaster finish. All oil solutions, including colorless ones, darken a little after drying, which also needs to be taken into account when decorating gypsum tiles.

Using yacht varnish

The most durable coating is provided by yacht oil varnish, so its use to protect plaster cladding is most advisable. After thoroughly mixing with the thinner, the varnish is applied to the finish in a thin layer with a brush or roller. The solution should be well distributed over the surface, avoiding the formation of drips. Yacht varnish dries, depending on the room temperature, in about a day.

Varnish for gypsum tiles is an indispensable thing for giving the surface the desired shade or glossy shine.

After the first layer has dried, the cladding is inspected for the presence of drips, which must be carefully sanded with fine sandpaper before applying the second layer. The second layer of varnish also dries for about a day, after which the varnished finish is wiped with a clean, damp, soft rag to eliminate any residual adhesion.

Decorative tiles "Monte Alba", covered with a protective layer of yacht varnish, despite the corrugated surface, are easier to keep clean and last longer.

DIY painting method

There are several ways to add color to gypsum stone. The most commonly used method is hand painting with a brush. Each tile is painted with a base color, and then several pieces are highlighted with a darker shade. When applying paint, care must be taken to ensure that no smudges form and that no unpainted fragments remain. This method is labor-intensive and time-consuming, so it is used for painting a small amount of tiles and eliminating defects.

The use of electric and pneumatic tools makes the job easier. Painting gypsum products with a spray gun is popular among professional craftsmen. To do this, the tiles are laid on a horizontal surface measuring 1x1 m and the base layer is applied with a spray. The technology for applying shades is simple: after the tiles have dried, a layer of paint of a darker color is applied to individual areas using an airbrush or spray gun with a fine nozzle.

Some experts believe that it is best to paint tiles laid on the wall. This makes it possible to place darker pebbles over the entire treated surface. Paint applied to plaster dries quickly, which helps to immediately identify and eliminate defects. After this, the tiles are varnished. With this surface treatment, the care of the product is simplified, since you can wipe the gypsum stone with a damp cloth without fear of smearing the paint.

Mixing pigments to create color

Painting of plaster can be carried out both during the manufacture of the product and after. In the first case, the pigment is added to the mixture or directly into the mold, and in the second - into the paint. It is difficult to select the same color of gypsum mixture in large volumes. Therefore, this method is used for the individual production of small quantities of tiles.

It is easier to prepare paint using dry pigment or liquid color. It is not recommended to mix several colors to obtain the desired shade, because when mixed with paint, colored stains may appear. With a large volume of work, it is simply impossible to obtain the same color.

If a dry dye is used, it must first be dissolved in water and then added to the paint. To prepare the background and shading mixtures, different containers are used. If the tiles are painted to look like brick, the shading color is most often made lighter than the base color. Before applying the next layer, each time it is checked whether the previous one has dried. It must be remembered that after the product dries, its color becomes lighter.

Types of varnishes and their application

To improve the performance characteristics of gypsum tiles, they should be varnished. The following products are considered the most popular on the market and in construction stores:

- oil-based varnishes;

- yacht varnish for gypsum surface;

- protective acrylic coating.

Oil based varnish

The composition of oily varnishes includes a solution of artificial resins and a collection of plant herbs. The substance is brought to an oily consistency and combined with additional materials, which as a whole form a varnish. Due to its texture, the coating forms a thin film on the surface, which, after complete drying, protects the gypsum tile from physical and mechanical damage.

Oil varnishes can be transparent (colorless) and are also available in a variety of shades. Therefore, when purchasing, compare the color of the original material and its future coating. To give the surface different effects, you can purchase glossy or matte varnish. It should be noted that if you varnish (even colorless) a plaster surface, it may become slightly darker than it was originally.

When covering a wall decorated to look like stone, try to protect your body and face from getting paint and varnish. Wear protective clothing, gloves, goggles and a respirator, as the composition has a specific pungent odor.

On video: varnish for stone.

Acrylic composition

When purchasing varnish for gypsum tiles, most builders want to get a material that will combine “two in one” characteristics. That is, initially it is a protective coating, and only then performs a decorative function.

All desired requirements will be met if you cover the tiles with acrylic varnish. In construction stores or on the market you can purchase ready-to-use material, which, when applied to the surface, forms a durable thin film.

Acrylic varnish is a “protective shield” for artificial stone. It is moisture resistant, reflects UV rays, and is resistant to various detergent compositions and temperature changes. The material has no toxic odor, dries quickly, and if excess needs to be removed, this can be done using a special solvent. If the acrylic varnish is too thick in consistency, it can be diluted with plain water.

Acrylic coating is divided into three types:

- matte;

- semi-matte;

- glossy.

If you use matte acrylic varnish to cover the plaster, the imitation of rough stone will be preserved down to the smallest touch. After application, the composition penetrates into all existing cracks and recesses, and as it dries it takes on a transparent matte texture.

Semi-matte plaster varnish has similar characteristics to the previous material. The coating has only one drawback - after drying, you can notice a light light coating on the finish. Of course, if you choose a varnish that matches the tone of the tile, this effect can be avoided, but colorless compositions can present an unwanted surprise.

When choosing a glossy finish, keep in mind that in a brightly lit room the surface will be very shiny. Consequently, the interior decoration will be distorted due to glare.

If, according to the designer’s plan, the gypsum tile will be painted with water-based paint, then for better adhesion of the material to the surface, add acrylic varnish to the solution. The paint should be applied with two salts, and after complete drying, open with one layer of varnish.

Yacht varnish

The most durable material for treating gypsum surfaces is yacht varnish. Based on the name, you can guess that this material is used to cover wooden surfaces on yachts. Its composition will give gypsum tiles 100% waterproofness.

Before applying to the surface, the product must be thoroughly mixed with solvent. The solution is distributed on the tiles with a thin brush or roller, and the surface should be evenly exposed, avoiding smudges. The material dries in about 24 hours, depending on the room temperature.

To achieve maximum protection, decorative gypsum stone is coated with 2 layers of varnish. But before application, minor cosmetic errors should be carefully sanded with sandpaper. The second coat will take about the same amount of time to dry. After this treatment, the relief surface of gypsum tiles is easier to keep clean. To do this, you just have to wipe it with a damp cloth.

Features of yacht varnish

This category of building composition is considered the most reliable and in demand. Yacht varnish is intended for processing gypsum decorations. The advantage of this type is the formation of a dense film with water-repellent properties.

- Before use, the mixture is thoroughly mixed in certain proportions with the solvent.

- Next, using a thin brush, distribute each layer evenly.

- For the coating to be dense and reliable, you need to wait 20 to 24 hours.

- The drying speed directly depends on the humidity conditions and temperature inside the space.

To create an elastic shell on the surface of the decorative stone, it is recommended to use 2-3 layers. To increase adhesion between parts, you will need to use a primer or sandpaper.

In this way, it will be possible to correct minor defects on the plane. Treatment with yacht varnish makes it easier to care for the decorative surface.

Impregnation of gypsum tiles

After laying the gypsum tiles and finishing the work with the seams, the tiles should be treated with a special product before applying varnish. Hydrophobization is the treatment of decorative tiles with a water-repellent agent that contains an organosilicon polymer.

When the product penetrates inside the tile (2cm), the porosity of the tile decreases, while maintaining vapor permeability. A water repellent also reduces the appearance of mold.

This solution is supplied to the construction market in finished form. It can also be a concentrate that must be diluted before use.

Water-repellent impregnation for gypsum tiles

You should work with this solution wearing glasses and gloves. The product hardens quickly, so drops of it from the surface can be immediately removed with a damp or flexible cloth. High-quality solutions for decorative tiles imitating brick and imitating stone for interior decoration:

- Organosilicon solutions that are water-repellent White Hill.

- Solution with silicone "Optimist S405".

Solution with silicone “Optimist S405” - Tiprom has several solutions with different functionality.

Return to contents

Tips and tricks

Since gypsum is a vapor-permeable material, over time it becomes similar to natural stone. This makes it desirable in many types of interiors. Professionals advise using an acrylic primer diluted with water before starting work. After applying the layer and drying it, all other work is performed. Painting gypsum tiles and figurines with your own hands is not difficult, but such a material has many advantages, and the effect will be exactly as intended by the user.

Benefits of varnish for brick and stone

It is necessary to varnish not only the bricks themselves, but also the seams between them. If brick varnish is used for interior and exterior decoration of a room, you can safely apply it to both vertical and horizontal surfaces. The specialized composition has many advantages:

- The brick is destroyed by moisture, and the varnish creates a moisture-repellent layer, which is also protective. The external facade of a building is often exposed to moisture, so the use of the substance allows you to preserve the structure for many years. Moisture is not absorbed into the treated material and, accordingly, does not destroy it.

- Protection from high temperatures is an important property for fireplaces made of brick. If you coat it with varnish for brick and stone, you can not only emphasize the texture of the material, but also protect it from destruction.

- Over time, whitish salt stains appear on the facade of a building or a brick fence. To prevent them from appearing, it is better to coat the surface with a suitable paint and varnish.

- If decorative brick is used, it can be coated with a paint and varnish composition to emphasize the texture of the material and make the color more saturated. You can use both glossy and matte composition. The choice depends on personal preference. The varnish can be semi-matte, semi-gloss or matte.

- Regardless of whether an expensive brick was used or a cheap one, over time it will begin to deteriorate under the influence of moisture, ultraviolet radiation and other factors. A brick protectant will help significantly extend the life of the material. Brick coated with paint and varnish will not fade in the sun.

- Thanks to the product, the surface becomes smooth and dust accumulation on it is prevented.

- A specially developed composition protects against the appearance of fungus, mold and rot.

- If desired, you can use a substance with a higher percentage of shine. It will create a wet effect, emphasize the texture of the stone and give an expressive appearance to the facade.

Tips and tricks

Since gypsum is a vapor-permeable material, over time it becomes similar to natural stone. This makes it desirable in many types of interiors. Professionals advise using an acrylic primer diluted with water before starting work. After applying the layer and drying it, all other work is performed. Painting gypsum tiles and figurines with your own hands is not difficult, but such a material has many advantages, and the effect will be exactly as intended by the user.

Source

Laying gypsum decorative stone: features of self-installation

As with laying any tile, the most important point in the process of installing decorative gypsum stone is careful preparation of the surface - this type of decor cannot be laid on a thick layer of glue. You need a flat surface on which only minor potholes and irregularities are allowed, not exceeding the dimensions of the tile itself. It goes without saying that the surface to be coated must be thoroughly cleaned of dust and dirt, and also treated with a deep penetration primer. Like all other tiles, gypsum artificial stone is installed using the following technology.

- Installation begins from the second row from the bottom - a guide rail is installed here, which sets the horizontal level of laying the tiles. This can be a wooden block or a drywall profile, nailed or screwed to the wall with self-tapping screws or dowels.

- Next, glue is applied to the surface of the wall - this is done using a comb (notched trowel with a tooth height of no more than 8 mm). Gypsum stone adhesive is applied specifically to the wall, since if you apply it to the tile itself, there is a high probability of getting unsightly stains on the material.

- Then everything is simple - the tile is simply pressed into the glue. Here you don’t even have to control the vertical laying, since the tiles are lumpy and the level here turns out to be completely useless. The evenness of the wall surface is achieved through a comb, which is designed to withstand the same layer of glue.

Laying gypsum decorative stone photo

Grouting is not used in the process of laying decorative gypsum stone, as well as crosses for creating equal gaps between the tiles. Small gaps between fragments of gypsum stone are simply not able to spoil the appearance of the surface - in addition, they are partially eliminated after finishing coating the surface with a protective material, which is varnish or various types of azure.