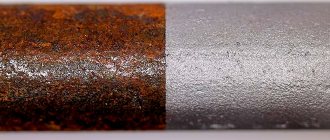

Imitation rust

In order to get the rust effect, it is not necessary to spoil the material. You can simulate rusting. Moreover, you can give a rusty look to both metal and other materials, in particular wood.

Rust paint

The rusty shade is formed by mixing red, yellow and brown pigments. You can also add a little blue - this will add brightness and depth to the coating.

There is a natural pigment that, without any mixing of different colors, makes it possible to obtain a rusty tint. This pigment is called ocher (another name is red lead), which is a mixture of clay and iron oxide hydrate.

Natural ocher is not an independent type of paint. This is just a component that is added in varying quantities to paints and varnishes (paints, enamels) and primers. In addition to this component, paints also contain other substances.

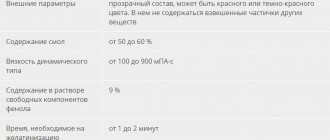

The pigment has the following characteristics:

- hiding power - from 60 to 80 grams per square meter,

- oil absorption - from 25 to 35 grams per 100 grams of substance,

- The pH of the water extract is from 7 to 8.

The rust effect will give any product a completely unique, inimitable look. Moreover, you can do all this with your own hands. The main thing in the work process is to follow the technological process and adhere to protective measures, since in many cases you will have to work with chemicals that are unsafe for health.

Rusting technique

Natural rust

Please note that first of all you should make sure that the metal that is to be rusted is susceptible to corrosion. Metals that contain iron are susceptible to rust. But many materials are resistant to rust, for example, chrome alloys or stainless steel. Cast iron and wrought iron will corrode well.

Copper acid solution

The instructions are:

Pour 60 ml of hydrochloric acid (also called hydrochloric acid) into a container. Be sure to use safety glasses and gloves during the process.- Dissolve just a little copper in acid (use coins or copper wire for this). The container should not be closed very tightly, since gases will form inside as a result of the reaction. Thus, after about a week we will obtain a solution that will provoke corrosive processes.

- Remove any remaining copper from the acid. Dilute the copper-acid solution with water in this proportion - for 1 measure of acid, add 50 measures of water.

- Strip the metal that you will rust from the paint and varnish material, and then wash the surface with a soapy solution.

- Apply a thin layer of acid to the metal surface. This can be done with a spray bottle or brush. Allow the material to dry in fresh air. At the same time, as before, one should not forget about safety measures (goggles and gloves), as well as good ventilation of the room.

- After an hour, noticeable rust will begin to appear on the metal surface. It is not so important to wash off the solution, because it will gradually evaporate naturally. If the resulting rust is not sufficient, the surface can be treated again.

Let's consider another method.

Vinegar solution and bleach

This method is best suited for metals based on tin or iron. A prerequisite is that the surface should not be primed or even coated with sealants.

The instructions are:

- Mix one measure of vinegar and two measures of bleach in a container.

- Stir the metal in the container so that it is completely damaged. Wait about ½ hour, and after this period, rust will begin to appear on the surface.

- Wipe the material with a rag.

- Until the item is completely dry, you should avoid direct contact with it to avoid damaging your skin with chlorine.

- Fix the rust with primer. The easiest way is to use a primer in an aerosol can.

What other ways are there?

Other methods

In addition to paint with a rust effect on metal, there are other very popular methods for accelerating corrosion processes. But there are other methods. Rusting with hydrogen peroxide + salt:

- Pour the peroxide into a container - it is advisable to use a spray bottle, because this method will be the easiest to apply the liquid to the surface of the material.

- Spray metals well.

- Sprinkle the wet surface with salt. The metal will begin to rust almost immediately, and the intensity of the rusting will depend on the amount of salt.

- Let the metal dry in the fresh air. The surface cannot be wiped until it dries, as rusting will be very uneven. You can wipe the surface only after it has completely dried.

Another rusting method using vinegar and hydrogen peroxide:

- Clean the surface (if necessary).

- Spray peroxide over the surface from a spray bottle.

- Spray vinegar over the surface of the metal.

- Wait a few hours for rust to begin to appear.

Rusting with salt and lemon juice:

- Mix four measures of lemon juice and one measure of table salt.

- Treat the cleaned surface with the solution, and soon traces of rust will begin to appear.

Now a little about artificial methods.

Imitation rust

In order to achieve the rust effect, the material must be damaged. You can imitate rust, and at the same time you can give a rusty look to metal and other types of material, in particular wood.

Rust paint

A rusty tint will appear when yellow, red and brown pigments are mixed. You can also add a little blue color - this will give the coating depth and brightness. There is a natural pigment that, without mixing different colors, will make it possible to obtain a rusty tint. This pigment is called ocher (another name would be red lead), which is a mixture of iron oxide hydrate and clay. Natural ocher will not be an independent type of paint, and it is only a component that is added in varying quantities to paints and varnishes (enamels and paints) and primers.

In addition to this component, paints also contain other substances. The pigment has the following characteristics:

- The coverage rate is 60-80 grams per square meter.

- The oil capacity will be 25-35 grams per 0.1 kg of substance.

- The pH of the water extract is from 7 to 8.

Ocher has excellent resistance to aggressive chemical substances (acids, organic solvents and alkalis), as well as resistance to moisture and light.

Imitation film

It is not necessary to buy paint with a rust effect if you can give the metal a rusty look using a special film. Below are instructions for use:

degrease the surface with alcohol.- Try the film elements onto the treatment surface.

- Moisten the metal with a special spray bottle, and the film should be glued to the wet surface better.

- Tear off the film from the backing.

- First glue the middle part of the canvas, and then smooth the edges over the surface.

- Dry the glued film with a hairdryer.

There is one more interesting method left.

Activation of the aging process (rusting)

In this process, exposure time, correct application and color control play a big role.

Liquid for pickling baths

is a compound that acts on the surface of corten steel. The product must be applied uniformly to the product by spraying; the sprayer must be kept at a distance of about 50 cm from the product, this will give the surface a more uniform rusty appearance.

The treatment must be performed over the entire surface of the product. Then, to give a more uniform layer, the surface can be treated with a roller made of fine-pored foam rubber. As soon as the cor-ten steel aging activator has evaporated and the first ocher (rust) tones appear, you can apply a second layer of liquid to the product, of course, provided that you are not satisfied with the result after the first layer. The procedure can be repeated until you are satisfied with the color and texture of the cor-ten steel. Although after applying 2 or 3 coats, we recommend waiting 24-48 hours for the steel to acquire its final appearance. It is worth remembering that the process will continue until you use a rust stopper.

The drying time of each applied layer depends on the temperature and humidity: it can range from 20 to 45 minutes. Temperatures below 15ºC or relative humidity above 95% can significantly prolong drying time and in some cases can lead to unexpected results. Also avoid direct exposure to sunlight during application and drying. When applied correctly, 2-3 coats of pickling bath liquid are sufficient to achieve rapid and uniform rusting, but depending on the thickness of the sheet, the quality of its workmanship, or environmental conditions, more coats may be required to achieve the final desired result.

The best paints for rust 3 in 1

The presence of the “3 in 1” prefix indicates that the product works in several directions - primes, transforms rust and decorates. Products of this type are resistant to any impact. After analyzing reviews from consumers and experts, two nominees with the best recommendations were selected from among a variety of products.

Novbytkhim primer-enamel

Novbytkhim primer-enamel paint is intended for painting any type of surface. It is applicable both on new and already partially or completely corroded products. The composition of the product consists of resins of synthetic origin, additives, solvents (organics) and anti-corrosion components. The product combines the qualities of an anti-corrosion primer, a rust converter and a finishing enamel. Its consumption is quite small - up to 120 ml per m² when applied in a single layer.

Work can begin at an air temperature of -10°C. The coating is pre-cleaned from existing detachments. If it was painted with oil or alkyd compounds, then cleaning to a matte state is necessary. A brush and roller are suitable for applying the composition. The paint also adheres well when applied by air. For best results, apply 2 layers. Intermediate drying should last at least 60 minutes. It only takes 2 hours to dry completely.

Advantages

- Quick drying;

- Resistance to different types of exposure and temperature changes;

- High adhesion rates;

- Excellent decorative properties;

- Good hiding power.

Flaws

Not suitable for heated surfaces due to odor.

Metallista

The paint in question for rusty metal from a myrrh brand called Tikkurila provides a “3 in 1” effect. Thanks to the wax included in it, it creates increased protection of the metal from the negative effects of moisture, giving it excellent water-repellent properties. Structures coated with the composition will last at least a decade without updating. Metallista is immune to the effects of fats, lubricants, technical alcohols and turpentine, so its scope of application is unusually wide.

The manufacturer offers several basic shades for tinting, but in total they can be created up to 32 thousand. The hardened layer can easily withstand heating up to 80°C while maintaining the original color. It takes up to 2 hours for the applied composition to dry before it sticks. Before using Metallista, you need to add solvent. It fits well on uncleaned surfaces without first applying primer.

Advantages

- Creation of an insoluble base;

- Delay in corrosion formation;

- Eliminates the need for preliminary preparation of the base;

- Double chemical formula;

- Ease of use with any tool.

Flaws

- Sales in small volumes;

- The need for tinting;

- Not a very large number of ready-made colors (four).

Enamel is sold in small containers – from 400 ml to 2.5 liters.

Film

If you want to try the Rat Look style on your car, but do not want to spoil the body with natural rust, then there is a film with a corrosion effect especially for you. It is important to understand that the development of a sticker must be carried out individually for your car in order to repeat all the indentations and bends of the body.

Rusty color is often used to give the surface a specifically attractive appearance. Rust-like paint will help you get this shade. There are also options for obtaining natural rust or simulating it. Methods for obtaining a “rust-like” surface will be discussed in this article.

Corrosion of metal

In this part of the article we will tell you how to make rust by accelerating the corrosion processes. This can be done through a chemical reaction, which will provoke rapid rusting of the material.

It must be taken into account that corrosion develops only in those metals that contain iron. However, even in this case, not all iron-containing metals can rust easily. For example, you should not mess with chrome alloys or stainless steel. But ordinary steel and cast iron rust very quickly.

To carry out a chemical reaction, you will need to prepare a copper-acid solution. A mixture of bleach and vinegar is also effective.

Copper acid solution

We prepare the chemical solution as follows:

- Add 50-60 milliliters of hydrochloric acid to the dishes.

- We put copper in the acid (this could be any copper part). In this case, we cover the dishes, and do not close them tightly, since the gases formed during the chemical reaction must come out. After about a week, the output will be a copper-acid solution, which accelerates the rusting of the metal.

- Remove copper from the solution and add water to the container based on a ratio of 50 to 1.

- We remove traces of paint from the metal and clean the surface with a soap solution.

- We treat the surface with the solution using a brush or spray.

- After applying the acid, the surface must dry.

- After 60-90 minutes, noticeable rust will form on the surface.

- Mix one part of vinegar with two parts of bleach.

- We place the metal in the dish in such a way as to completely hide it in the solution. We wait for 30 minutes until signs of corrosion appear.

- Wipe the metal with a rag.

- We wait until the material has completely dried, and until then we do not touch it so as not to damage the skin.

- To ensure that rust adheres firmly to the metal, we prime the surface.

- Add a little peroxide to the bowl.

- Apply the solution to the metal. It is preferable to treat the surface with a sprayer - it is more convenient.

- While the surface is wet, sprinkle it with table salt. Rusting will begin almost immediately. Moreover, the rate of development of the reaction depends on the amount of salt poured.

- After this, we place the material to dry in fresh air. We do not touch the metal until it is completely dry: this way we will avoid uneven coating.

- We clean the metal from paint.

- Apply peroxide using a spray bottle.

- Wet the metal with vinegar.

- We expect traces of corrosion to appear within a few hours.

- For 1 share of table salt, take 4 shares of lemon juice.

- Apply the solution to a clean surface. After some time, rust will appear.

Note! There is no need to rinse off the hydrochloric acid solution, as it will evaporate after some time in any case.

Bleach and vinegar mixture

This method is best used for rusting materials with the addition of tin. There is an important clarification: the metal cannot be primed or sealed before applying the solution.

Procedure:

Other rusting options

You can provoke corrosion using hydrogen peroxide and salt as follows:

Another way to create a rusty color on metal is to treat the metal with vinegar and hydrogen peroxide:

And finally, the metal can be rusted with a lemon-salt solution:

Recommendations

To get the maximum result from your purchase and enhance its qualities, as well as to fully understand the benefits of the mixture, it is recommended to listen to the simple advice of experts. They can increase the effectiveness of the paint and varnish mixture.

- Before making a purchase, carefully study the instructions. In some cases, special solvents may be required. In this case, immediately purchase additional products and strictly follow the instructions.

- Certain mixtures position themselves as 3 in 1. But, if time permits, additional funds will not be superfluous.

- Only the manufactured structure is painted after the metal has completely cooled. Then they clean the seams and then proceed to the final stage.

- Carry out external work taking into account the temperature (over 27 degrees - postponed). Likewise if it is too low. Since the dye will quickly harden and will not be able to fully affect the material.

- Despite the fact that the instructions indicate the possibility of application to an unprepared surface. Experts recommend preparing and degreasing it. In this case, the paint will react more effectively and the result will be better.

Rating of the best

Now let's look at what is the best paint for metal and rust for exterior use.

In first place you can put paint from the HAMMERIT company. This is a universal 3 in 1 composition. That is, it performs the functions of paint, primer and inhibitor. It can be used to paint metal surfaces, both clean and once coated with paint. This is the most durable rust resistant paint for exterior use. Although the manufacturer recommends using it indoors as well. And this is a big plus.

So, the advantages of this material:

- versatility;

- ease of application;

- good hiding power;

- long term protection;

- excellent external data.

The only downside is the high price.

So, the product from HAMMERIT can be called the best anti-rust paint for exterior metal work.

Rust paint HAMMERITSource m-delivery.ru

Second place goes to Dufa Retail Metall. The manufacturer produced this paint and varnish material to protect large metal structures. Hence the high demands on the paint itself. But life turned the situation around so that they began to use it in everyday life. In addition, it should be noted that this variety has an optimal price-quality ratio.

Today the manufacturer offers 9 shades in a semi-matte design. You can also add to the advantages the drying time - 2 hours, which is very good. High adhesive qualities, as well as high resistance to mechanical stress and sunlight. But the biggest advantage is the ability to apply paint to an unprepared surface, ensuring high quality of the final result.

ALPINA takes third place. Here are its advantages:

it is a three-component material: inhibitor, primer and antiseptic; absence of odor, which is very important when work is carried out indoors; economical in application; long service life; Can be applied directly over rust; relatively wide color selection.

As for the disadvantages, it is still the same high price; it is not always possible to find the required colors in the store.

ALPINA is one of the best paints for rustSource mirkrasok.ru

We give fourth place to “Belinka”. Let's start with the pros:

- high quality coating;

- applied directly to rust;

- high hiding power;

- dry within 2 hours;

- the paint is not afraid of the sun and moisture;

- The result is always a glossy surface.

And two disadvantages: unpleasant odor, high consumption of material.

And fifth place was taken by paint from the Euroclass company. By the way, it is a hammer. The biggest advantage of this material is its low price. Adding to the advantages is the possibility of use at low temperatures - down to -10C. The process of preparing a metal surface takes a minimum of time. This paint is often used for painting equipment located in factories and workshops. Therefore, she is not afraid of contact with moisture or oils. She is also not afraid of the sun's rays and sudden changes in temperature.

As for the minuses, there are also two of them:

- poor hiding power;

- smudges when paint is applied to a vertical surface.

The best metal and rust paints for cars

KUDO

Alkyd enamel contains anti-corrosion elements and pigments that make it possible to paint not only clean surfaces, but also those with severe damage. Used for interior and exterior work.

KUDO alkyd enamel

Advantages:

- good hiding power;

- adhesion above average;

- stylish decorative layer;

- resistance to negative atmospheric manifestations;

- use even in hard-to-reach places will not cause problems.

Flaws:

- minimum temperature for work +10 C;

- Complete drying in 5 hours.

DECORIX 520 ml

Product from a brand that has been known on the market for 10 years. The product has earned many positive reviews from beginners and specialists who know their business perfectly. The products are aimed at a wide range of applications.

DECORIX 520 ml

Advantages:

- neutralizes pockets of corrosion, primes the protective and decorative coating;

- glossy finish;

- does not fade;

- weatherproof.

Flaws:

- targeting small, hard-to-reach areas;

- high consumption;

- Application of 3 layers is recommended.

ABRO with polymers for calipers, discs, springs, drums

Acrylic spray paint using ABRO ceramic polymers from a well-known American brand as a base and is aimed at transport. The brand includes over 1,500 different items covering all sectors of human activity. It can withstand heavy and extra heavy braking loads. This allows them to be used even on road trains.

ABRO with polymers for calipers, discs, springs, drums

Advantages:

- wear-resistant protective layer;

- maximum temperature is 260 C;

- reduces the risk of overheating and enhances heat transfer;

- resistant to chemicals, sand, stones and moisture;

- dries quickly.

Flaws:

- narrowly targeted use;

- high consumption;

- palette of 3 colors.

The market for paints and varnishes offers products suitable for almost any type of metal work. The assortment is amazing and can cause confusion for an unprepared consumer. The presented top will help you navigate all the diversity and make the right purchase. It presents products not only from well-known brands, but also budget ones. All of them earned positive reviews and showed themselves to be good.

Criterias of choice

In order for rust paint to correctly and fully cope with its purpose, when choosing it, you must take into account:

Type of metal and its purpose. Metal structures made of steel or aluminum must be painted with different mixtures. The same rule applies to structures with different purposes. For example, for roofing it is better to use mixtures that are not afraid of high temperatures and do not fade in the sun. But for plumbing, standard hammer paint is also suitable.

Anti-corrosion paint, selected in accordance with these recommendations, will certainly help solve all problems associated with rust on metal products and their further protection against it.

The best anti-rust paints for cars

Paints from this group are used to restore the metal structure of car body parts. A high-quality coating provides a full protective cycle, preventing the negative effects of water, oils, and chemicals. Due to its high strength, the layer does not chip when hit by stones. This section presents only one winner, selected based on the results of comparative tests.

Yaroslavl Paints Spetsnaz primer enamel for rust

This primer is designed to interact with corroded cast iron and steel substrates, including rust. The product is suitable for protecting structures of large dimensions or with a complex configuration, if pre-treatment is not possible. The product is ideal when it is necessary to organize effective protection of car body parts, such as the underbody and fenders. The enamel forms a dense three-layer coating that is impervious to the negative influence of external factors - precipitation, salts, various chemical reagents, etc.

You can start working with paint when it is slightly frosty (-10°C). The remnants of the previous coating and loose rust are first removed, and then it is degreased with white spirit. Yaroslavl Spetsnaz Paints are applied in two or three layers, each requires at least half an hour to dry, and final hardening occurs after 60 minutes. When the temperature drops below 15ºC, the time increases. On average, 1 kg of paint is required to treat 7-10 m² with one layer.

Advantages

- “3 in 1” effect;

- No primer required;

- Quick drying;

- Possibility of storage at sub-zero temperatures;

- Coating with varnishes and paints such as XC, XV, NTs, PF, EP.

Flaws

Quite a high cost.

If the paint is too thick, it is diluted with solvent No. 647 to the desired consistency.

Metallization in Moscow

The procedure in which a metal layer is applied to a structure is metallization. Using this technology, surfaces made of metal, as well as wood, plastic, glass, and other materials are processed. Metallization is one of the most effective methods of anti-corrosion protection in various environments. The technology allows you to extend the effective operation of metal structures and protect them from aggressive environmental influences and mechanical damage.

MetalHunters cooperates with leading companies involved in the development of equipment (zinc plating, aluminization) and improvement of relevant technologies. Therefore, MetalHunters offers the most effective and profitable services for anti-corrosion treatment of metal structures using electric arc metallization. The company today successfully applies aluminum, zinc, steel and combined coatings to structures used in various fields and branches of heavy, light and petrochemical industries. And in each case, metallization of structures turns out to be the most reliable way to protect against corrosion and other influences.

Calculate the cost of work now.

Leave your contact, we will call you back

Possibility of bending and straightening of treated structures (depending on the thickness of the protective coating, treated products can withstand bending at a radius of up to two thicknesses without damaging the anti-corrosion surface).

Metal protective coatings applied by the electric arc method have the property of self-healing , that is, if the surface is mechanically damaged, they simply “heal” on the metal.

Metallization, unlike the application of paint and varnish coatings, is carried out in only one layer, which allows large surfaces to be processed faster .

Metallization coatings have high adhesive strength , that is, they do not peel off from the structure to which they are applied.

Applying markings to metal structures after processing Metallization is carried out at different external temperatures , which significantly expands the technological capabilities of anti-corrosion treatment - when applying coatings, surfaces are not heated above 70–100°C .

Application of metallized zinc coating on the structures of POARE trusses for a waterworks in the Ryazan region. Anti-corrosion coatings can withstand temperatures down to −60°C without peeling or collapsing, which allows their use even in the far north.

Protective metal coatings do not contain organic substances , which allows various liquids to be stored in treated tanks.

Metallization coatings can be used to protect large surfaces of various structures directly at the site of their operation.

Rust effect on wood furniture

Imitation of rust can be done not just on metal, but even on wood. You will need two types of paint, table salt, sandpaper and varnish composition. One of the paints should be in the color that is most similar to rust. The second paint will act as the main paint, and it should match the furniture and other accessories inside the room. Before applying rust-colored paint, you should clean the surface of the wood from any types of flaws.

You can also varnish the wood. Next, paint the furniture with rust paint and wait until the surface dries a little. Apply a layer of table salt to the surface that is not completely dry. When the surface on which there is salt dries, apply the base paint. Wait for the surface to dry, and then remove the salt using fine-grained sandpaper. If you don't remove all the salt, it will create a slightly roughened effect that will enhance the rusty color. The last step is to treat the wood with a protective layer of varnish. The rust effect will give any product a completely unique and unique appearance.

Moreover, you can do all this even with your own hands. The main thing in the process of work will be to comply with the technological process and adhere to protective measures, since in most cases it will be necessary to work with chemicals that are unsafe for health.

How to make brown?

The easiest way to get brown is to mix yellow, red and blue paints. That is, from primary colors. First, red and yellow are combined (to make orange), and then blue is added. All paints are taken in equal proportions.

Interesting materials:

What is the correct name for the headphone input? How to wear a bandage correctly when the kidneys are prolapsed? How to wear medals on a jacket? How to wear a weight loss belt correctly? What is the correct designation for phase and zero? How to properly treat tomatoes with copper sulfate? How to properly process walnuts? How to properly process dried apricots? How to properly process nuts? How to properly treat the soil with Fitosporin?

The best anti-rust paint for a car

Used for quick car restoration. It is recommended to pre-clean the body from pockets of corrosion. A high-quality coating performs a whole cycle of protection - from water, oils, and chemicals. The layer is dense and does not chip when hit by stones.

NewTon

NewTon

The material is available in 8 colors and can be:

- white;

- red;

- yellow;

- blue;

- green;

- gray;

- golden;

- brown.

The coating can withstand temperatures up to +600°C, while reliably protecting the base from the formation and spread of corrosion. Due to its characteristics, the product can be used for cladding not only external parts, but also elements that are located near the heat source. The maximum coverage area directly depends on the intensity of spraying - up to 2 m2, while the time interval for drying from dust varies within 7-10 minutes.

DECORIX

This is an aerosol enamel primer that performs both a decorative and protective function. It reliably protects the base from the formation and development of corrosion. This product makes it possible to significantly reduce preparation time.

DECORIX

Thanks to the packaging in 520 ml containers, the products are convenient for use in hard-to-reach places. Enamel creates a durable glossy coating that is not subject to mechanical and atmospheric influences. Acrylic mixture 520 ml costs up to 200 rubles.

VIDEO: How to paint a rusty metal surface and protect it for a long time?