Many people have a question: is it possible to paint polypropylene pipes? The answer to this is unequivocal - you can paint pipes, but it is not advisable to do so. It is much wiser to simply wash these pipes more often and they will look quite beautiful. It is also important to know that not every paint is suitable for painting polypropylene pipes, and the pipes themselves will have to be treated before painting. In this article we will talk about how you can paint these pipes.

First of all, before painting, the pipes must be thoroughly washed and dried. The surface of polypropylene pipes is almost glossy and the paint on it will not last long if the pipes are not treated with fine sandpaper. After this, you need to thoroughly wash off the dust from the pipes and degrease them with alcohol or another chemical reagent. Only after this can the pipes be coated with a primer. Polypropylene pipes can also be coated with an adhesion promoter. You can prime the pipes in any way - brush, roller or spray. Apply a coat of paint only after the primer has completely dried.

An important technological feature of polypropylene pipes is that they can be painted at an ambient temperature of at least eighteen degrees and a humidity of no more than eighty percent. Apply paint to the primer in only one layer with a thickness of 60 to 120 microns. If you do not exactly fulfill at least one condition from the above recommendations, then the paint from your pipes will soon begin to crumble.

Under production conditions, paint on polypropylene pipes is dried at a temperature of one hundred degrees Celsius for twenty minutes. Complete strengthening of the paint layer is completed only after a week. Of course, it will not be possible to create such a high temperature at home, so you will have to dry the pipes in natural conditions.

In conclusion, we will tell you what kind of paints can be used to paint polypropylene pipes.

Krylon®Fusion For Plastic spray paint is the best material for painting polypropylene. The fact is that it not only sprays evenly and easily, but also does not require the application of a primer. The drying time of this paint is the shortest of all other paints suitable for polypropylene pipes.

Lankwitzer is considered the best primer for this material. This paint lasts firmly and for a long time even on smooth surfaces. However, we still recommend that you treat the pipes with sandpaper under this primer.

Of the water-based acrylic paints for polypropylene pipes, PaliPlast PL is suitable. It can also be used to paint external pipelines.

For enamel paints, we recommend using NEW TON aerosol paint. Its distinctive feature is the increased strength of the dried layer.

vseotrubakh.rf

What are polypropylene pipes intended for?

Due to scientific and technological progress, polypropylene pipes are now often used instead of metal ones. So-called PPRCs are a new alternative approach that is increasingly being chosen by installers and residents themselves.

But what kind of material is this? And why is it better than metal?

Polypropylene belongs to the group of polymers. The manufacturing process is as follows. Since plastic itself is very fragile, it is modified for use in providing water to the population.

The plastic is exposed to metal catalysts, which turns it into polypropylene.

LLC DESIGN PRESTIGE

Carrying out work

Before you start painting the tubes, you need to prepare your tools and work surfaces.

Preparation

- Wipe the pipes with a dry cloth to remove dust and dirt.

- Degrease the surface and wait until dry.

Additionally, it is recommended to clean the plastic using fine sandpaper. Large grains can leave scratches that will lead to damage to the integrity of the material.

Sandpaper (Photo: Instagram / novostroy26)

Tools and materials

To perform painting, you will need a number of tools and consumables:

- masking tape;

- film for covering surrounding objects, walls, floors;

- paint in a can or can;

- if the coloring composition is without a can, you will need several brushes and a roller;

- sandpaper;

- a few dry rags.

After preparing the tools, you can start painting.

Painting of sewer systems

To paint sewer pipes, you need to choose a coloring composition that will meet certain requirements:

- enamel must contain organic components;

- the layer should be hard and dense;

- Drying time: more than 12 hours.

- Remove the old paint layer, if any.

- Prepare surfaces, degrease them, and clean them with sandpaper.

- Sweep away polypropylene dust.

- Apply coloring composition.

Sewer PP pipes (Photo: Instagram / set_mir_sveta)

Gas pipe painting

There are no difficulties in painting gas lines made of polypropylene, but such systems are rarely made of plastic. To carry out the work, it is enough to select a waterproof paint composition and coat the tubes with it.

Heating system painting

Before painting heating pipes, you need to turn off the circuit and wait until the pipeline has cooled completely. When painting is completed, hot water should not be run into the tubes for 3 days.

Painting water supply pipes

When painting water pipes, you need to take into account some nuances that depend on the type of enamel.

Advantages of the coloring composition for metal:

- low price, availability;

- no surface preparation required.

- Acrid, persistent odor. It takes a long time to ventilate the room.

- Intended for a different material, but this does not stop buyers.

Advantages of wall paints:

- versatility of compositions;

- large selection of shades;

- compatibility with the walls if the same shade was chosen.

- the top layer of the pipe will be destroyed if a water-based dye is used.

- not suitable for hot water pipes because it is destroyed by heating, expansion, and contraction of the plastic.

READ ALSO: Hydrochloric acid for sewer cleaning: sulfuric acid

Advantages of acrylic compositions:

- no negative impact on plastic;

- ease of application;

- large assortment of shades;

- no pungent odor.

- Plastic expands when heated. This may lead to cracking of the layer.

- Before applying the paint composition, you need to apply a layer of primer. It is recommended to use mixtures in aerosol cans as primer. They are easy to apply and durable.

Plastic pipelines running through rooms often spoil the interior. Paint can be used to improve aesthetics. You need to select paint, prepare polypropylene surfaces, and apply enamel. Until the layer hardens, do not touch the pipes or turn on the hot water supply.

PVC pipe painting technology. Painting ventilation pipes. CrimeaKamService. Igor Usenko...

Watch this video on YouTube

Advantages of polypropylene pipe

Polypropylene has a number of advantages, including:

- heat resistance (which is why they are used to supply both cold and hot water);

- wear resistance;

- density and strength;

- resistance to corrosion.

Plastic elements can be made in different colors. To do this, dye is immediately added to the plastic. But what to do if you bought white plastic materials and couldn’t hide them?

In this case, there is a way out - paint the plastic pipes with paint that would fit into the interior of the room. For example, many people decide to paint such elements to match the color of the walls to make them less noticeable. Others, on the contrary, focus on painted pipes. For example, you can paint them green and then wrap them with artificial grape leaves. Painted in this way, they will look like a grape tree trunk. But this option is suitable, of course, only for the kitchen.

LLC DESIGN PRESTIGE

Reasons for painting pipes

We all know that paint, applied even in a small layer, serves as protection for water and heating pipes.

It prevents their corrosion. In addition, using paint of a certain color, you can complement the interior or simply successfully fit pipes and a radiator into it. And even if the radiator you bought already has a suitable color and a protective layer against corrosion, the same cannot be said about the pipes.

It doesn't matter what material they are made of. It is better to treat plastic and metal pipes with paint. There are a number of reasons why this measure must be carried out without fail:

- The layer of old paint has begun to peel, cracked, or has been damaged in some other way. You have just installed pipes that do not yet have protection against corrosion. The need to create completeness in the interior, decorating the heating elements. A planned measure to prevent damage to the heating system.

Is it possible to paint polypropylene pipes?

Many owners have a question about whether it is permissible to paint plastic pipes.

Experts say that they can be painted. The main thing is to choose a good suitable paint and follow the correct painting technology. In this case, it will be painted with high quality and for a long period.

The only problem with painting plastic pipes is how to do it correctly, so that the painted materials remain beautiful for many years, and do not peel off and crack every month.

So, having decided to paint the pipes in your home, you should adhere to the following stages of work:

- If they are already installed, then you need to come up with a design for the room in which they are located. If this is a bedroom, then it is best to paint the pipes to match the color of the wallpaper or curtains - this way it will be less noticeable. And if it’s a children’s room, then you can add originality and paint it in a bright color. For example, with pink wallpaper, you can make an element of raspberry color or, conversely, a more pastel shade. You can also come up with an ornament. For example, make it with polka dots or stripes. You should not proceed to the next stage without resolving the issue with the interior of the room. Nobody wants to paint an element a hundred times: there is no need for unnecessary hassle and waste of money. Therefore, it is better to think through everything down to the details from the very beginning. You can use the Internet and look at alternative options, and then add something of your own.

- Having decided on what you want, you can go to the store. Here you have to choose the paint that will stick well to the pipes without losing its appearance. Painting pipes with regular paint is just a waste of money. This type of paint will not last long and will begin to peel off even before the heating season. Therefore, you need to familiarize yourself with the range of paints specifically for plastic. It is worth considering that not only cold but also hot water is supplied through the pipes in the house. That is, the paint must be designed to withstand heat.

Polypropylene pipes, threaded transitions and fittings for connections.When choosing paint, it is better to contact a specialist in the appropriate store. He is more aware of their characteristics and features. You need to explain to him what exactly needs to be painted, how and where. But since there are different consultants, it’s still worth having at least some idea about paints. So, for polypropylene pipes it is suitable:

- ordinary paint for metal;

- acrylic paint;

- special paint for plastic.

Wall paint;

The choice of paint should be influenced by the type of polypropylene pipes.

LLC DESIGN PRESTIGE

By manufacturer

We can give several examples of the most common and high-quality paints for painting heating elements, which are offered to us today by manufacturers from different countries.

For heating pipes you need to use special paint

Radiator Paint is an enamel with a durable white color. It is resistant to temperatures of 90 degrees Celsius, does not emit odor or harmful substances. Millertemp is a metal paint that perfectly prevents corrosion. Available in two color options: charcoal gray or matte aluminum.

It can be applied without a primer, and after drying it can withstand temperatures up to 600 degrees Celsius. Heitzkorperlak is an alkyd enamel that forms a neat surface and can only be applied to cold metal. Elementfarg is another alkyd product that is used without a primer and dries quickly. The maximum permissible temperature is 100 degrees. It can serve as a basis for further painting or act as a finishing layer.

The paint must withstand high temperatures (preferably at least 90–100 degrees). It may contain coloring pigments or special metal powder. The last option is a higher priority.

Methods for painting polypropylene pipes

LLC DESIGN PRESTIGE

Painting with regular metal paint

People write a lot about this method on forums, and the reviews are mostly good.

The advantages of using the method are:

- availability. Finding paint for metal is the easiest way. It is very widely used for economic purposes. And if you’re lucky, you can find it in your pantry at home, because when painting batteries, exactly the same paint is used;

- low price;

- ease of application. There is no need for any base, no need to sand the pipe - just apply paint and let it dry.

But there are also disadvantages when painting using this method:

This is what the water supply system wiring diagram looks like.

LLC DESIGN PRESTIGE

Painting with regular wall paint

But in this case there are several more disadvantages:

- instability. Such paint is not designed for heating, and if pipes are used for heating, this will lead to negative consequences;

- destruction. You cannot use water-based paint, as it will destroy the top layer of the pipe itself (cause corrosion). If you still use water-based paint, then you must apply a base to the pipe - alkyd enamel. This will prevent a negative effect.

But there are also advantages:

- invisibility. The pipe is painted with the same paint as the walls and practically blends in with it. This makes it as invisible as possible;

- versatility;

- diversity. Wall paint comes in all sorts of colors and shades;

- usual work.

LLC DESIGN PRESTIGE

Painting with pre-primer

This method consists, rather, not in the paint itself, but in the base under it. Often a special aerosol is used for priming. It will protect the pipe. This primer is often used in car dealerships and tire shops. Therefore, you can find it there. Having processed the required object, you need to give it time to dry. And then you can paint the element with any paint. The main rule to follow when choosing it is heat resistance. It is indicated on the label of any paint.

LLC DESIGN PRESTIGE

Painting with acrylic paint

Acrylic paint is considered the softest for coating polypropylene pipes. The solvent it contains is not dangerous for plastic, unlike many other paints.

The positive features of this choice are:

- safety - does not damage the material;

- wide choice of colors;

- ease of application;

- no pungent odor.

The negative side can be considered two aspects:

- acrylic paint may crack. Since polypropylene pipes tend to contract and expand under the influence of heat, acrylic can simply crack;

- Do not apply acrylic directly to the pipe. First you need to prime it.

LLC DESIGN PRESTIGE

Painting with special paint for plastic

The only disadvantage of special paint for plastic is its cost. It costs more than all the others, but it is impossible to say that it is definitely better. Many users complain that it lasts even less than even regular metal paint. But you don’t have to worry about the safety and condition of the materials themselves.

Its solvent does not destroy the material, and its heat resistance is sufficient for temperature changes.

After painting the pipe, you should let it dry completely. Of course, it is better to paint in the warm season, when the heating system is cold - this way the paint will dry much faster.

Share a useful article:

Related Articles: Featured Articles

In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our heating page > resant.ru/otoplenie-doma.html < you can view and get acquainted with examples of our work. But to be more precise, it is better to check with an engineer about the cost of work and equipment.

To contact us, use the contact number of DESIGN PRESTIGE LLC 8(495) 744-67-74 , which you can call around the clock.

note

Our company DESIGN PRESTIGE LLC is part of the non-profit organization ANO INTERREGIONAL BOARD OF FORENSIC EXPERTS. We also provide independent construction technical expertise services.

resant.ru

Accuracy

Do not forget that you must be careful not to stain the objects around you.

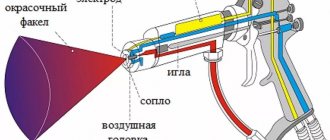

Often the pipes are located in niches and can be difficult to get to. Therefore, apply the primer first, and apply the paint with a spray gun so that the layer is thin and even. In addition, it will significantly reduce the overall operating time.

Paint elements from top to bottom. In this case, you will avoid unnecessary drips and waste of paint, and the surface will be neater.

Each element must be painted on all sides, including those hidden from view, and not just on the front side.

Now you know how to paint heating pipes, so next time you can do it yourself.

https://youtube.com/watch?v=DHq_Ot0RoNMrel%3D0%26controls%3D0%26showinfo%3D0

This article was produced by our experienced team of editors and researchers, who reviewed it for accuracy and comprehensiveness.

Number of sources used in this article: 18. You will find a list of them at the bottom of the page.

wikiHow's content management team carefully monitors the work of its editors to ensure that every article meets our high quality standards.

Most people believe that PVC pipe is difficult or even impossible to paint due to its smooth surface. But with proper preparation and having the right tools, completing this task becomes incomparably easier. And while PVC does contain certain compounds that make it water-resistant and prevent foreign substances from sticking to it, a little sanding and a coat of primer will allow you to change the color of PVC pipes to any shade you like.

I want to paint the ventilation grilles, electrical box covers and radiators in the kitchen to match the color of the wall. Well, simply because in the kitchen, apart from the above-mentioned elements, there is nothing white at all.

I bought water-dispersed “heat-resistant enamel for radiators” “AQUA”. Painted the vent. grilles and metal-plastic pipes leading to radiators. I had to paint it in several stages, because enamel naturally doesn’t adhere well to plastic. But everything seems to be covered. However, when the paint dried, it began to peel off easily from the surface.

I understand that answers like “What did you want? Naturally, enamel will not stick to plastic.” However, I would like to receive more objective advice.

It is better to buy radiators of a certain color - I already understood this from the forum. But how to paint the rest? 1) Plastic ventilation grille 2) Metal ventilation grille (i.e. already covered with factory white paint) 3) Metal-plastic heating pipes (i.e. they have white plastic on the outside).

How to choose coating paints

The coating is selected depending on how the product will be used. If the pipes are intended for hot water supply (for example, heating or bathroom), then be sure to choose a material that can protect against rust when exposed to hot water. When you see the “hot water supply” marking on the package, you can safely take it from the store shelf. Anti-corrosion paints are: pentaphthalic, organosilicon and alkyd. You can also use water-dispersed ones, but only before thoroughly priming the surface to be painted. Oil paints should not be used because they quickly change color.

- Alkyd paints. Pros: they provide good coverage, withstand high temperatures, resist mechanical stress and are wear-resistant. The color palette of this paint is varied. Cons: smells unpleasant even after drying.

- Water-dispersed. Pros: dry quickly and do not have a pronounced odor. Cons: they lose color over time and require updating.

- Acrylic. Pros: they give a glossy shine and are made from organic components; they retain their original appearance for a long time. Cons: they take a long time to dry and have a persistent and pungent odor of acetone and other solvents.

For cold water, pipes are painted with materials that can resist condensation. They should adhere well to the metal and be applied without gaps. Be sure to clean the pipes from the old coating, otherwise the new layer will peel off. Even if everything looks normal on the outside, it is quite possible that the old layers are susceptible to corrosion and have already begun to peel off.

There are many types of paints in stores. The most popular of them are PF-115, because they are inexpensive and durable. But you can also use polyurethane and epoxy materials, which are more resistant to various influences.

You can also try special enamel for rust, but it is much more expensive than regular paints, since it contains a rust inhibitor, a primer with adhesion and the enamel itself.

ogodom.ru

What paint and how to paint heating pipes with your own hands

Nowadays, paint for heating pipes can give a unique look to the pipeline and batteries, which will last for a long time. The purpose of the paint is to protect against corrosion and give the visible part of the system the required color, as well as a decent appearance overall. To obtain high-quality painting of batteries and pipes, it is necessary to properly prepare their surfaces for the painting process.

We will tell you in detail about the choice of paint for heating pipes, as well as the technology for painting them in our article.

Heating pipes before and after painting

Paint selection

Now let's find out how to paint heating pipes. The final result will directly depend on choosing the right paint. When choosing paint, you must proceed from the requirements that apply to them. So, paint for heating pipes and radiators should have:

- high heat resistance (not lower than 100 degrees);

- abrasion resistance;

- not be toxic;

- resistance to aggressive environments.

Types of paints for heating pipes

There are paints on sale that are specifically designed for painting heating pipes:

- Acrylic enamels. They are produced on the basis of organic solvents, so painting heating pipes with their help and the drying process will be accompanied by a characteristic smell of the solvent. However, this justifies the end result - glossy shine and long service life.

- Alkyd enamels. When used, they also emit an unpleasant odor, which can later be felt when the heating system is operating. But the surface painted with such paint will be resistant to abrasion and high temperatures. It should be noted that manufacturers produce a fairly wide range of colors of this paint, which can satisfy any demand. Due to this, it is quite popular among consumers.

Heizkorperlack water-dispersion paint from the Dufa and Alpina brands is perfect for the restoration of radiators and heating pipes

- Water-dispersion paints. Painting heating pipes with water-dispersion paints that are specifically designed for this purpose is the most common choice. There is no specific smell when working with them, and they dry very quickly.

There is also oil paint, but now it is rarely used for such purposes.

What paint should I use? The final choice always remains with the consumer.

The best manufacturers of paints for painting heating pipes

Manufacturers, both domestic and foreign, produce a wide variety of paints that differ in color and quality. The price most often depends on the brand of paint and manufacturer. Among the countries producing paints that can satisfy virtually any taste, we should note Holland, Germany, Sweden, etc.

Thus, Radiator Paint enamel produced in Holland is white in color and after painting allows you to obtain a flawless glossy surface.

Heizkorperlack enamel and Mipatherm 600 paint produced in Germany are famous for their quality and do not require preliminary surface preparation. Within 3-4 hours after applying such paints, you can turn on the heating system, which is an advantage if repairs are carried out in winter.

Alkyd paint Elementfarg Alkyd produced in Sweden is used both as a primer and as a paint, which is very important, because There is no need for a separate primer. It is enough to just paint the surface in 2 layers.

Painting heating system pipes

Preparation for painting: cleaning and priming the surface of pipes and heating radiators

Before painting, heating pipes must be thoroughly cleaned of rust or old paint.

Pipes are prepared for painting according to the following instructions:

- Before painting the surface, it must be thoroughly cleaned - remove the old layer of paint and primer, and clean the places where rust has formed to a metallic shine. Remove dust and dirt with a wet cloth and brush. Old paint is removed using a spatula and special removing solutions.

- The rinsing solution is applied to the surface of the radiator and covered with a film to soften it. After some time, the paint can be easily removed with a spatula or drill with a metal brush attached to it.

- After this, the surface is treated with sandpaper and degreased with white spirit.

- Next, the surface is treated with an anti-corrosion primer. Its purpose is not only to protect against corrosion, but also to increase adhesion - the adhesion of paint to metal. A primer with an alkyd base is suitable for this.

Now the surface is ready, in fact, for applying paint - it will fit perfectly on such a surface.

Nowadays, the industry offers special “two-in-one” and “three-in-one” primer paints. They usually contain a primer, color pigments and a rust converter. Such primer paints are applied to the surface of a pipe or battery without preparation for painting.

Instructions for painting heating pipes yourself

Step-by-step instructions for preparing and painting pipes and heating radiators in pictures

Next, we’ll look at how to paint heating pipes. You can, of course, invite a professional painter for these purposes, but it will be much cheaper, and it won’t be difficult to do the painting yourself.

So, how to properly paint heating system pipes:

- When starting work, first of all, you need to protect the floor from contamination. To do this, they usually use unnecessary newspapers, paper, and fabric, which are laid directly under the pipes and radiators.

- You will also need to select brushes before the painting process. Brushes must be small in size with soft, straight and curved bristles.

- The paint begins to be applied from the top and moves towards the bottom. Cover the battery and pipes with paint on all sides, then apply a second layer of coloring solution. In this case, you will get a perfectly evenly painted surface. When painting two layers, you need to wait until the first layer dries, and only then apply the second.

Painting can also be done using a spray gun or a spray can. When painting with a spray gun, it is advisable to remove the battery in order to thoroughly paint all hard-to-reach places. When using a can of heat-resistant paint, the surface of the pipes and radiator is painted with high quality and very quickly. Additional instructions on how to paint surfaces with a spray can can be found on its packaging. Typically, the balloon is made in a zigzag motion from top to bottom at a distance of approximately 30 cm from the surface.

Types of compositions

As mentioned earlier, each type of pipeline must have its own paint:

- The most capricious in this regard are heating wiring and radiators;

- External pipelines can be placed behind them;

- The least capricious, but also requiring attention, is the plastic wiring.

Painting heating wiring

- Currently, alkyd compounds are rightfully considered the first in popularity here . They form a strong, stable covering film, which has fairly good elasticity indicators, which is very important for surfaces subject to thermal expansion. Alkyd enamels have an enviable glossy sheen, but since they are based on an organic solvent, they smell strongly during application and require good ventilation.

- Water-emulsion or water-dispersed mixtures can theoretically be used . These paints apply well, have no odor, but they are not durable, plus they cannot be used everywhere for heating systems due to the fact that they have a heat-insulating effect.

- Acrylic and acrylate enamels are a relatively new product on the market and during this time they have gained a lot of fans . They can be either matte or glossy. They have high abrasion rates and good heat capacity. The coating itself is a thin, elastic layer of plastic polymer. The only serious drawback of these enamels can be considered the high price.

Important: regardless of what composition you decide to buy, first of all you need to pay attention to the heat resistance of the finishing paint. The instructions on such paints should contain information about the lower and upper temperature thresholds for use, plus an indication for which base the composition is intended.

The video in this article shows special heat-resistant paint.

- If we talk about oil compositions that were popular in the old days, then they are absolutely not suitable for heat-conducting surfaces . Firstly, they are extremely unstable to temperature changes and quickly change color. Secondly, these compounds do not have good elasticity and can become covered with a network of small cracks even before the end of the heating season.

The video in this article shows the principle of painting radiators.

Work on external pipelines

- Traditionally, red lead has been used to protect external pipelines from corrosion. This compound converts iron oxide into a strong film, providing reliable protection against rust.

- If you choose the right primer for pipes, coating with various types of enamels will protect the surface for at least 5 – 7 years. Modern enamels are distinguished by their spectacular appearance and good resistance to atmospheric surprises. Moreover, if you apply several layers of paint, you will forget about this problem for many years.

- For internal surfaces and cold pipes, you can safely use inexpensive oil paints. The only thing you should pay attention to is that this paintwork material is approved for use on metal.

Tip: if the amount of work is small and you want to do everything quickly with your own hands, you can purchase a special automotive primer for metal. This composition is sold in aerosol packaging, has excellent characteristics, is sold at auto markets, but the price is decent.

Plastic pipes

- Painting polypropylene and plastic surfaces is a purely amateur matter. Modern plastics are already quite strong and well protected. But some owners want to paint the pipes in order to improve the appearance and harmonize the interior.

- But paint for polypropylene pipes must be selected separately. The fact is that the surface of the pipe is very smooth, has low adhesion, and not every composition will adhere to it. The second problem may arise later; many paints can simply corrode the surface of the plastic, resulting in the pipe being destroyed.

- The easiest way out would be to use special enamel, packaged in aerosol cans for plastic. Moreover, pay attention to the markings; some compositions do not require preliminary preparation or priming of the surface at all, but there are also those that are applied only to the ground. By the way, special soil is also sold for plastic.

- A good solution would be to purchase acrylic paints for working on plastic or metal. Acrylic compounds have perhaps the widest palette of colors, plus the paints are quite durable and effective. They are available for both external and internal finishing work.

What should the paint be like?

Do you know which open communications have the greatest length in our apartments? Of course, heating systems, and since heating pipes are a special type of surface, the painting composition must therefore meet certain requirements.

Captain Obvious informs: it is not recommended to use ordinary paint on batteries and supply pipes, since, most likely, it will not live up to expectations and will quickly become unusable.

So, what paint should you use to paint heating pipes? Among the requirements, the most important are the following:

No water permeability

It is important that the paint functions as an anti-corrosion coating. Even if the heating pipes are located in a dry room, there is a risk of rust on black steel

Properly selected paint will avoid this; The aesthetic point is no less important, since the color of the paint should not only not disturb the external aesthetics of the room, but also complement it. In principle, if the pipes are located in niches that will be closed in the future, then only protective properties will be required from the paint.

However, you should not hide any communication pipes with any insulating materials, as this will make it difficult to access them in the event of a breakdown;

Pipeline paint can be any color.

- Since the surface of the battery is often subject to heat, one of the most important points among the paint requirements is its resistance to high temperatures. Otherwise, the coating may become yellow in the future, and cracks and delaminations may appear on the painted surface.

- It is preferable to choose paints with good adhesion to metal, otherwise you will have to treat the surface to be painted with a primer.

A few words about technology

- Naturally, every painting begins with surface preparation. Initially, the pipe should be dry and clean. The optimal temperature regime is +18 - +20º C. Metal surfaces must be cleaned of old paint and rust. Typically this is done with a wire brush or sandpaper.

- After cleaning, it is advisable to degrease the pipe. For this purpose, an alcohol solution, gasoline, kerosene, turpentine or any organic solvent are traditionally used. Please note that it is not recommended to degrease plastic with a solvent; an alcohol solution is better here.

- When preparing to paint polypropylene, in some cases, it is advisable to sand the surface to a matte state using P2000 - P3000 sandpaper; too coarse grain can greatly spoil the appearance of the pipe.

- The heating system is turned off during operation and starts only after 3 - 4 days, when the coating crystallizes properly. If you need urgent hot painting, you need to buy a special paint whose instructions allow such actions.

- It is most convenient to paint with your own hands using a spray gun or an aerosol can. But if you have a small amount of work, then you can get by with traditional paint brushes. Begin application from the inside, gradually moving to the entire surface.

Tip: Don't forget to cover the wall and floor. Newspapers and paper can be used, but they can become saturated with paint, so we recommend using polyethylene with tape.

Important: cold water pipes must first be dried to remove condensation. If you do not use cold water for a day, the pipe will dry out on its own. Or you can force dry it using a fan.

Color options

- over the old layer, only if it is smooth and undamaged (no cracks, chips, bulges, etc.); preliminary sanding of the surface or complete removal of the old paint: if the previous layer is damaged (cracks or swelling are visible) or you notice rust (remove it with a metal brush); if the old paint comes off, it must be completely removed and then painted.

Don't forget the primer if needed. The primer mixture is applied to a clean and dry surface, so thoroughly wipe the pipes with a damp cloth and wipe them dry with a rag.

Wait until the primer layer dries and only then start painting.

As a rule, the paint is applied very simply and does not dry for long.

Try to keep the layer minimal. If the paint is translucent, it is better to open it twice with a thin layer than once with a thick one. Although usually even manufacturers recommend applying at least two layers of coating.

After the primer has dried, apply the paint with a roller or spray gun, and you can reach hard-to-reach places with a brush (if you can’t get by with a straight brush, use a special radiator brush - it will easily fit into a thin opening and paint the part of the pipe hidden from view).

Compositions for painting cast iron pipes

The choice of product for painting cast iron sewer pipes must be carefully considered. Any paint will not work here. If you choose the wrong composition for painting sewer pipes, over time the layer may peel off, fall off, or collapse. Most often, the following types of paints are used for painting pipes:

- Alkyd paint provides high quality painting of pipe surfaces. Its main difference is that the paint layer does not fall off when exposed to high temperatures. Some products can withstand temperatures up to 1000 degrees.

- Water-dispersion paint refers to compositions that retain their technical properties for a long time. The main advantages of the paint are its environmental friendliness, quick drying, and durability.

- After painting a sewer pipe with acrylic paint, an attractive gloss remains on it. The paint contains only natural solvents. The enamel is resistant to fading and does not crack over a long period. The disadvantage of paint is that it does not adhere well to the surface of the pipe, so before applying a layer of paint, the pipe should be thoroughly primed.

- Sometimes oil paints are also used, however, it is worth considering that they can lose their attractive appearance over time, turn yellow on the pipes and gradually crumble.

Note!

Before painting a sewer pipe , its surface should be carefully prepared.

Technology for painting polymer pipes

You can paint hot pipes made of polymer materials only after preliminary preparation. This is due to the fact that the glossy surface of the pipe prevents high-quality adhesion of the paint, and the coating will leave much to be desired, which will entail the need to apply several layers of paint. To prevent this, the surface of the pipe is cleaned with sandpaper.

At the next stage, the pipes are wiped with a damp cloth after sanding to remove dust. Make sure the pipes are dry and clean before painting. After this, it is necessary to cover the floor and walls with protective material (film) to prevent paint from entering.

If you use high-quality paint, which was mentioned earlier, then you can paint the pipes without prior priming. Otherwise, it makes sense to cover the surface with a primer and only after it dries, apply paint. The heat level of the pipes does not matter when using high-quality paint, because its range of use allows painting at any radiator temperature.

Pipes are painted with a brush 5 cm wide. You can also use a roller in places where this is possible. Apply the paint in a thin layer so that there are no smudges. If the surface is not completely covered, painting must be done a second time.

How to paint plastic pipes

Plastic pipes have certain features compared to cast iron products. They have a very smooth surface. On the one hand, this is an advantage, since the smooth surface does not allow sediment to accumulate inside the pipe. Some types of pipes cannot be painted at all. Polyethylene and polypropylene pipes can be painted, however, the paints crack and darken.

So, how to paint a plastic sewer pipe? The coloring agent must be selected taking into account the following requirements:

- organic composition;

- the paint must dry in less than 12 hours (drying time is indicated on the label);

- layer hardness and color density.

Note! Plastic sewer pipes should be painted in rooms where the temperature fluctuates within +18 degrees.

Is it possible to paint hot heating pipes in an apartment?

If you use a special dye correctly, you can give pipes and radiators a pleasant, updated look even during the heating season. But when choosing such paint, you need to have certain knowledge. After all, the work will be carried out in a residential area, therefore, special requirements are imposed on the dye:

- absence of harmful fumes;

- short drying period;

- long service life;

- protection of metal from rust;

- ease of use.

But even when choosing a paint with optimal characteristics for painting batteries, the average person can make a lot of mistakes when painting, since they still need to properly prepare the surface, select a tool and perform the work properly. More on this later.

Preparing the surface for painting

Before you begin the painting process, you should carefully prepare the surface of the pipe. If it is an old cast iron pipe that has already begun to be damaged by corrosion, then you need to clean it with sandpaper. Then the surface is degreased and a layer of primer is applied to it. Preference should be given to primers with an anti-corrosion effect, this will ensure more reliable contact between the pipe and paint, and also prevent the progression of corrosion.

You also need to prepare the tools and materials that may be needed during the work:

- paint for sewer pipes, selected taking into account the operational needs and technical characteristics of the pipeline;

- a bucket from which you could conveniently remove paint;

- several brushes of different sizes, preferably made of natural bristles;

- masking tape;

- primer;

- protective equipment (glasses, rubber gloves).

Note! It is much easier to work with pipes that are freely accessible. Certain difficulties may arise when painting sewer pipes in a bathroom or toilet, where communications are hidden from prying eyes.

prokommunikacii.ru

Question : Help me solve the problem. I repaired the heating system in the apartment, changed the batteries and replaced metal pipes with polypropylene ones. There is a red line on the pipes - as they say, this is the marking of the center of the pipe, and during installation the master did not turn it towards the wall. Now the red line looks into the room and gets on the nerves, and the master says that it “was necessary for centering.” An acquaintance said that this is a pipe seam and if the pipe breaks along the seam, then I will not be able to approach the riser and shut off the system, so let them turn the pipe so that the seam is facing the wall. Maybe the red line can be painted over with something or washed off. I tried it with acetone and other solvents - it doesn’t wash off. What to do?

Answer: Yes, as many people as there are opinions, live forever... don’t listen to your neighbors. I’ll say right away that your pipe replacement was carried out by not entirely conscientious “installers-plumbers”, and you still have the opportunity to present a claim to them regarding the quality of the work performed, if it was carried out by a “company” - write a complaint to the management and demand monetary compensation for such hackwork, and if private owner, then... alas. They completely deceived you... Polypropylene pipes are made using seamless technology, and the red line is the technological marking of the pipe - it means that the pipe can be used to transport hot water, the green stripe is a pipe for cold water, the red and green stripe is a pipe for both cold and hot water supply During the installation process, the strips should be turned towards the wall and not into the room, and this is not “centering”. Another interesting question is whether they performed pressure testing of the system or told you that there is no heating and cannot do it. If so, then you are sitting on a powder keg, unfortunately, and they deceived you again - these tests can be carried out using water from the tap; a pressure of 2.5 atmospheres is enough to check the soldering points and threaded connections at the inlet and outlet of the coolant in heating radiators.

You can paint the pipes. First, you need to apply an adhesive acrylic primer to the pipe, preferably an automotive primer, for example Mobihel; on the packaging it says “primer primer for plastic.” And your polypropylene-PP is also included in the list of plastics.

After the primer has dried, the pipe can be painted with acrylic paint for radiators Element escaro, a special high-temperature semi-matte enamel.

You can go the other way, install a decorative box from plasterboard and thus cover the pipes from prying eyes. An even simpler way is to take a self-adhesive film, cut it into strips and stick it on the pipe, you will forget about your problem for at least three years.

It’s up to you to decide what to choose – the most expensive option is painting the pipes, the cheapest is covering with film. In any case, first try to return some of your funds from the installers and then be on your way. Good luck.

blogstroiki.ru

Content

The general rule for ferrous metal pipes is to clean the steel from rust, first coat it with a primer, then paint.

To paint metal pipes you will need:

- Tools for cleaning the pipe surface from rust and old paint: grinder, grinder, turbine, sandpaper, spatula.

- Household chemicals to prevent rust and remove its residues.

- Flute brush or roller.

- Primer for metal pipes

- Rags

- Covering material to prevent paint from getting on surrounding objects.

- Gloves.

You should not paint rusty pipes; they need to be prepared. Traces of corrosion are completely removed with a stiff wire brush or sandpaper. Phosphoric acid-based rust converters can only serve as an aid by modifying small, hard-to-reach areas of corrosion left after machining.

To paint a metal pipe, you should choose primers and paints based on organic solvents. Water-soluble ones cannot be used. Among primers, the domestic GF-021 has an excellent price/quality ratio.

We can recommend domestic oil paints, pentaphthalic paints, ours and imported alkyd paints. If a primer is available, a water-based finishing enamel can also be used. Today, manufacturers also offer universal paint compositions that simultaneously function as a primer and paint. It is more convenient to work with them, because you can paint a steel water supply or cast iron pipe in one step. However, the traditional option still gives better results: the primer provides the best adhesion of the coating to the surface, and the paint provides a smooth and easy-to-clean finish layer. In addition, the variety of shades of paints is much wider than that of primers.

As for heated towel rails, modern models are made of stainless steel or have a galvanic coating; only very old ones, made of ordinary metal, need to be painted.

Galvanized water pipes do not need painting, except in places where threads are cut by hand, where the coating is damaged. You cannot weld galvanized steel, but if you have already done this, the seam should also be protected.

Preparatory activities

Experts in plastic materials say that polypropylene pipes can be painted. The main thing to pay attention to is the choice of a dye suitable for this material, as well as strict adherence to the rules for its application. Only when these conditions are met is it possible to keep the coating unchanged for a long time.

After deciding to protect plastic pipes with paint, you must:

- Carefully consider the issue of choosing the color of the dye.

- Please note that to paint hot water pipes you will need a special (heat-resistant) dye.

You should also worry in advance about protecting walls and floors from accidental contact with small drops or smears of paint. After taking into account all these factors, choosing the right product will not be difficult.

Dye

We have a choice for painting heating system elements.

What do we have?

We have several types of paint at our disposal:

- Oily . These may have become outdated due to the onslaught of competitors, but they are still in great use. These paints have years of proven reliability and confidence that they will not let you down.

- Alkyd enamels are resistant to high temperatures and durable. But at the same time, this coating has a distinct odor, which can only intensify under the influence of temperature.

- Acrylic organic enamels . These are also good in everything, especially for their color, which lasts for a long time. But, if you need odorless paint for heating pipes, acrylic organics are far from the best choice.

- Acrylic water-dispersion enamels . But these ones have no odor and are the most suitable for heating. There is only one condition - to choose only paint specifically designed for hot pipes.

Paint for copper heating pipes also exists, although before using it you need to weigh the pros and cons of the very idea of painting

Work progress

It takes longer to describe the progress of work when priming is done than to actually paint:

- when the primer is completely dry,

- and the system is in a switched off state, and it is best that there is no water there,

- cover the wall with newspapers or whatever is at hand so as not to stain anything; this, of course, if there is such a danger;

- then, apply the first layer of paint, which needs to be made thicker;

- We constantly control the coloring of invisible parts facing the wall;

- When the first layer has dried, apply the second; we advise you not to use hard brushes.

Dye selection

Various types of coloring compounds can be used as a coating for polypropylene pipes, among which the following items stand out:

- standard paints used to protect metal surfaces;

- classic dyes intended for wall decoration;

- acrylic compositions, as well as mixtures designed specifically for plastic;

- polyurethane based dyes.

All of these types of coloring mixtures are commercially available and can be purchased at a hardware store.

Additional Information. When choosing a material suitable for painting polypropylene pipes, we advise you to contact the manager of a trade organization who will advise you on this issue.

When determining the coating application method for polypropylene, we proceed from the characteristics of the selected composition. Let's consider each of the options proposed above in more detail.

Preparing to paint iron pipes

Before you begin painting your water pipes, you need to determine what they are made of. Temperature also matters when choosing paints. In addition to paint and a brush, it will be impossible to do without sandpaper, gloves, a rag, a cuvette and primer. If the pipes are covered with old paint, it must be removed. After their surface is cleared of it, it will need to be sanded. This removes rust. After this, the surface of the pipes is degreased. Then all the garbage is removed, and fresh air is allowed into the room. Only after all this do the coloring begin. To prevent paint from dripping onto the floor, the brush must be held over some kind of vessel.

READ ALSO: Do-it-yourself shoe rack from cardboard pipes or how to make a shelf for shoes

Features of application

Dyes for metal

Advantages of using regular metal paint:

- the availability of this dye, widely used in everyday life;

- reasonable cost;

- ease of preparation for application, which does not require pre-treatment of the surface of polypropylene pipes with special protective agents.

When working with this product, no material preparation is required; You just need to apply paint on it and wait for it to dry.

Note! For this purpose, a spraying method is used, implemented using a special spray gun.

But this method also has disadvantages, which are manifested in the sharp and unpleasant smell of the dyes, as well as the fact that they have a very thick consistency. Therefore, you should work with them as quickly as possible or use a solvent specially designed for diluting these paints.

Regular dyes to match the color of the walls

This approach has even more disadvantages and they are expressed in the instability of the coloring compositions used in heating systems. Wall paint is not designed to withstand high heat, so the coating will lose its original appearance over time.

Its deterioration usually manifests itself in peeling of the top layer of dye and its gradual falling off in the form of characteristic scales.

But this option also has its advantages, expressed in the invisibility of pipelines against the background of walls, the versatility of the compositions used, as well as an expanded range of colors.

Painting with compositions based on acrylic and polyurethane

Dyes of this class are among the “softest” of all household mixtures used for painting pipes. The solvent they contain does not pose a danger to plastic, which has a wide range of colors. In addition, such compositions are easily applied to pipe surfaces and do not have a pungent odor.

The disadvantage of such materials is the threat of cracking under strong heating, which is possible when they are used for painting workpieces of limited thickness used in heating systems.

Let's add to this that before applying acrylic to the surface, the latter must first be thoroughly primed.

Polyurethane paints are used extremely rarely for these purposes, which is explained by the need for preliminary priming, as well as the limited temperature range.

Use of special dyes

The only drawback of special compositions for painting polypropylene is their high cost. Despite this, many users note that they do not last any longer than the materials already discussed.

In this case, you don’t have to worry about the safety of polypropylene.

The solvent contained in these dyes is completely safe for pipe products, and their resistance to high temperatures allows them to be used in heating lines.

After painting with these mixtures, the pipes must be left to dry for some time. The drying speed of paint depends on the current time of year and increases significantly on hot and dry summer days.

Painting pipes with priming

This option for painting polypropylene is fundamentally different in its approach to surface preparation. It involves the use of a special primer, which is available in the form of an aerosol.

The primer composition reliably protects the surfaces being treated and ensures good adhesion to the paint used.

Additional Information. This protective agent is used when painting car bodies, so you can find it in car repair shops.

In conclusion, we note that in order to give the elements of water supply and heating systems the desired color shade, it is necessary to be able to choose the right type of dye and method of its application. This can be achieved after studying the recommendations discussed in our review.

infotruby.ru

How and how to paint polypropylene pipes: features of the use of dyes, preparation, painting

Polypropylene pipe products are colored in production by adding a dye of a certain color to the source material. However, most people purchase white or gray pipes even before making a final decision regarding the design of the premises.

Therefore, you have to decide how to paint a polypropylene pipe with an open installation so that it matches the interior.

- Preparatory work

- Dye selection

- Features of application

- Dyes for metal

- Regular dyes

- Acrylic and polyurethane

- Special dyes

- Painting with primer

- Conclusion and video on the topic

Preparatory work

Experts know very well how to properly paint plastic pipes. One of the main points of the process is the choice of dye. And strict adherence to the rules for applying the composition.

Paint in cans

This is the only way to achieve good and durable painting of the entire or just a separate part of the utility line.

When the decision is made to coat the pipes with paint, you need to choose a material. For a hot water system, you will need a special composition that is heat resistant. In addition, it is necessary to protect the floor and walls from paint drops.

Dye selection

Different compositions can be used for painting polypropylene pipes. The most commonly used dyes are:

- ordinary paint for coating metal products;

- polyurethane dyes and acrylic substances;

- special mixtures for plastic;

- a classic version of a paint composition for walls.

The listed substances are available in regular hardware stores.

Experts will provide information about dyes and help you choose paint for polypropylene pipes. The characteristics of the selected paint composition influence the coating application method.

Features of application

The choice of color for painting depends on preference. Some cover products to match the walls, while others make the mounted pipes more noticeable in the interior.

So, you can paint the pipes green, and then decorate them with artificial grape leaves. The result will be a grape vine that will look good in the kitchen if the entire room is designed accordingly.

Dyes for metal

Conventional metal paint has the following advantages:

- Low cost

- Availability, sold in all hardware stores.

- Easy to use because there is no need to prepare a base. The composition is simply applied and dries on the surface.

Often painting with conventional paints for metal substrates is carried out using a spray gun. The device allows you to evenly distribute the composition over the surface.

Using metal paint is accompanied by an unpleasant and pungent odor.

Such substances have a thick consistency. Therefore, the process must be performed as quickly as possible and additionally use a solvent to dilute the coloring composition.

Regular dyes

This method of painting polypropylene pipes has many negative aspects. The main disadvantage is the instability of coloring compositions when applied to heating pipelines.

Wall paint cannot withstand high heat. Therefore, the appearance of the created coating will deteriorate over time. The applied top layer will begin to peel off. Therefore, after some time you will have to repeat the painting process.

Using regular wall paint can reduce the visibility of pipes in the interior. After all, the system will have the same color as the wall structures.

Acrylic and polyurethane

Acrylic and polyurethane dyes belong to the group of “soft” compounds used at home for painting polypropylene pipelines. One of the components of such substances is a solvent. However, it does not cause any harm to the plastic.

Dyes based on acrylic and polyurethane allow you to paint polypropylene utility lines in any desired shade, as they are available in a wide color range. The ease of application of such compositions and the absence of odors have made the substances one of the popular means for painting pipe surfaces.

Acrylic and polyurethane dyes do not tolerate strong heat. Increasing the temperature of the painted surface may cause the paint layer to crack.

Therefore, acrylic and polyurethane substances should be used on pipes with the thickest walls possible. You need to pay special attention to this point if a heating system is created from pipe products.

Acrylic substances are applied exclusively to previously prepared surfaces. Typically a primer is used for processing. The required pre-treatment and limited temperature range of use have reduced the demand for these paints.

Special dyes

The main disadvantage of special paints for polypropylene pipelines is the high price. However, such compositions are no more durable than other commonly used materials for painting plastic engineering systems.

Solvents in special paints are not dangerous for the polymer from which pipe products are made. Such compositions are resistant to high temperatures. This allows them to be used for painting heating networks.

The drying time of special mixtures depends on the period of the year. If work is carried out on hot days in the summer, the painted pipeline will take longer to dry than in moderately cool weather.

Painting with primer

This method of painting polypropylene surfaces differs from other methods, since it involves preliminary priming of the pipes with the same composition. Preparation of pipelines is carried out with substances released in the form of aerosols. Primers are designed to protect treated surfaces.

The substances also help to increase the adhesion of coloring compounds. Primers for polypropylene pipes can be purchased at markets and auto parts stores. After all, such substances are used when painting vehicle bodies.

Conclusion and video on the topic

To paint plumbing and heating PP systems in the required color, you need to choose the right dye and method of applying the substance to the surface of the pipelines.

The video will help you better understand the intricacies of choosing paints and the technology for applying them. It will become clear from it whether it is possible to paint polypropylene pipes at home.

Scooter plastic painting (polypropylene)

I have already talked about painting ABS plastic, and now I want to share my experience in repairing and painting parts made of polypropylene. If we consider scooters of the Honda Tact AF-30/31, Honda Dio AF-27/28 models (probably this applies to others), the list of polypropylene parts is impressive: beak cap, lower side fairings (“skis”), front internal pocket, apron, floor guard, air filter housing, air intake casing, trunk (for Honda Tact AF-31), front shock absorber covers (for Honda Tact), rear mudguard, lower gas tank protection - and others, already inside the scooter.

Polypropylene differs from ABS plastic in three important properties for us: it is more wear-resistant, more flexible, but the adhesion of paint materials and adhesives to it is much worse.

If you only need to restore the color of polypropylene parts, read the advice “How to restore the appearance of plastic on a scooter.” It is likely that nothing more needs to be done if there is no damage to the plastic. And this time I wanted to paint the mantle and side fairings, because these body parts were scratched, worn, and even had one crack (which I, of course, soldered).

An approximate view of the beak can be seen in the photo below, plus the photo does not include scratches on the front and especially the bottom:

Necessary materials

To repair and paint the underbeak and skis, I needed the following items and materials:

- sandpaper with grit 120, 500 and 1000

- car putty Novol Bumper Fix

- primer for plastic Bosny Plastic Primer

- spray acrylic paint Motip

- aerosol acrylic matte varnish, I used KUDO varnish. Varnish is needed if the paint is metallic

- White Spirit

- Sander

Preparation

The preparation technology is almost no different from the preparation of ABS plastic, but there is more work.

After removing the plastic parts, you need to wash them thoroughly and inspect the surface. If there are cracks, they need to be soldered (I will devote a separate material to this). And scratches need to be repaired with putty. Since polypropylene is a flexible material, the putty must also be flexible; it is best to use putty for repairing bumpers. Based on my experience, I recommend Novol Bumper Fix putty; it holds very well even on polypropylene.

Do steel pipes need to be painted?

The main reason to paint pipes is, of course, to protect against corrosion. … Paint could only delay the inevitable; but this is better than nothing. Unfortunately, steel water pipes in apartments are still the most common today. Tip: a galvanized pipe itself does not need painting to protect it from rust.

Interesting materials:

How to turn a summer house into a residential building? How to convert a dynamic disk to a primary one? How to convert MBR to GPT? How to make one from a regular sheet with just an elastic band? How to make a zip archive from a folder? How to turn pink into red? How to make an isotonic drink for training? How to take a high-quality Google map screenshot? How to take a high-quality screenshot of your desktop? How to make tiles shiny?

Choosing the best

In order for the result of restoration procedures for plastic parts to be positive, you should carefully select a primer. Today the most popular brands are:

- KUDO is the best aerosol as recognized by many auto repairmen.

- Uni-Bet Liquid Plastic is a universal product for creating optimal conditions that allow you to apply enamel to any surface, including non-traditional materials.

- Reoflex is an ideal product for ABS plastic used in the production of bumpers. Allows you to create a flat surface with a solid base for applying paint and varnish.

- Motip is a classic option, familiar to many auto repairmen and car owners who independently repair and restore car parts. It is produced in the form of an aerosol in cans and in classic tin cans.

Plastic primer is used, among other things, for wood, glass, ceramics, metal, vinyl, polystyrene and various types of plastic. The high waterproof properties of the soil allow the treated parts to be used in any conditions.

The aerosol is applied to the parts according to the following algorithm:

- The can is shaken to evenly distribute the particles of the product.

- Spray the aerosol product at a distance of at least 30 cm in several layers. After each coat the primer must be allowed to dry.

- The cylinder must be positioned upside down and if gas begins to flow, it must be returned to its normal position.

It’s worth stopping at soil like liquid plastic. This product can be used on both plastic and metal materials. A high degree of water protection allows it to be used in any conditions. The important advantages of this tool are the following:

- High resistance to temperature changes.

- Weather resistant.

- Strength and durability.

- Long service life.