Bronze powder paint is increasingly being used to give decorative items a metallic shine. It is distinguished not only by high aesthetic qualities, but also by convenient modern application technology. The coloring powder coating is distributed over the surface in a uniform thin layer, which can highlight the relief and texture of the product, ensuring durability and reliability of the color.

Due to its aesthetic appearance, bronze has been used for decorative interior decoration for many centuries. And only relatively recently, about 150 years ago, paints were invented that could recreate the imitation of the shine and shades of precious metals, giving the opportunity to enjoy luxurious decor to anyone, regardless of wealth.

Unlike traditional paints and varnishes, powder coating is much faster, cleaner and more economical. This happens because the bronze pigments contained in the powder are attracted and cover the parts of the products with a layer of just a few microns, without requiring preliminary preparation of the coloring composition. After which, through polymerization, the coating reliably sets, forming a durable film on the surface.

Modern bronze powder paint has several significant advantages that have become the reason for its enormous popularity - speed and ease of painting, excellent external characteristics and a pronounced aesthetic effect of the coating. With its help, you can not only refine your interior items, but also turn them into real antique treasures.

How to select and prepare the necessary composition for painting

Nowadays, using bronze paint is not as labor-intensive as before. Previously, in order to obtain the required composition, bronze powder had to be thoroughly mixed in an organic solvent. Now special acrylic pigments are introduced into the composition of bronze paint, which are easily soluble even with water.

The presence of an acrylic component allows you to get rid of another drawback of the previous bronze paint - its electrical conductivity, which limited the use of the composition when painting some metal surfaces. Finally, replacing the solvent with acrylic also eliminated the unpleasant odors that inevitably accompanied painting. Therefore, the choice of bronze paint can be made from two main options:

- acrylic paint, which is applied to the surface using traditional painting supplies;

- bronze paint in cans, the aerosol of which will perform the coating using conventional spraying.

Each method has its own rational areas of application. For example, to paint surfaces with complex configurations or to renovate certain areas of antique interior items, painting with a brush is more suitable. Aerosol is more profitable if you want to get a bronze coating on a flat surface.

Composition of coloring powder

The paint contains powder particles with the addition of bronze pigments of various shapes - in the form of powder impurities or scaly elements. When containing dyes in powder form, the paint forms a smooth layer on the surface. If particles of bronze paint (powder) are presented in the form of flakes, then a rough bronze coating is formed on the surface.

These bronze pigments are also called float and non-float pigments due to their ability to distribute evenly throughout the paint or float to the top. When the pigment elements float up, a leaf effect is formed. This bronze powder paint, despite its high decorative characteristics, does not have a sufficient level of durability.

To avoid chemical exposure and oxidation, it is recommended to coat the products with an additional layer of protective varnish. Specialized powder coating based on bronze pigments with the addition of silicon dioxide is highly resistant to atmospheric, temperature and chemical influences.

After applying and drying the dye in accordance with the requirements of the technology, the painted surface has a uniform, beautiful coating that meets modern standards of durability and quality.

Benefits of the shade

They can be considered from the point of view of functionality and aesthetics of the achieved result:

- The metal-containing pigments of the original powder or aerosol actually contain bronze, therefore, they protect the metal from corrosion (this applies to heating registers made by welding porch elements, etc.).

- The excellent moisture resistance of the final coating will provide it with sufficient durability in the face of noticeable fluctuations in relative humidity. It is for this purpose that painting, for example, the metal frame of the mirror in the hallway in bronze color is a reasonable solution.

- The bronze coating protects the surface from exposure to ultraviolet radiation, so this paint is functional for objects that are constantly exposed to the sun.

- The aesthetic perception of things that are decided to be painted bronze turns out to be much higher: the bronze coating increases the nobility of the objects, and sometimes allows them to be successfully stylized as antique furnishings.

Naturally, all these advantages can fully manifest themselves only if all the interior items of the house are made in a similar style, for example, antique.

If the decoration of the premises contains, for example, silvery shades, painting something with bronze will mean stylistic inconsistency and basic bad taste.

Where are bronze powder paints used?

Today, bronze powder paint is used in various painting industries. Despite the fact that bronze is considered mostly decorative, bronze powder paint is successfully used for painting:

- automobile parts and decorative elements;

- household appliances;

- commercial and entertainment equipment;

- bronze fittings;

- tools and instruments;

- equipment and engineering parts.

Also, paint based on bronze dyes is used in the interior to create an antique style and an antique atmosphere.

Preparatory work

An old surface on which cracks and chips are clearly visible, and for metal - also traces of corrosion - must be thoroughly cleaned and sanded before painting. The fact is that the presence of a metal-containing acrylic pigment will not protect the metal from corrosion, but will only aggravate it, since a layer of bronze paint is not one hundred percent protection from atmospheric moisture.

To remove the previous coating, you can use one of the following methods:

- Mechanical cleaning by brushing using a steel brush or rotary sanding attachment. The method is suitable for flat metal surfaces.

- Sandblasting, in which a metal surface is exposed to grains of sand under high pressure. In this way, you can obtain a cleaned surface of any configuration, but the apparatus itself is relatively scarce and most often has a stationary design.

- Chemical cleaning with special compounds that are applied to the old coating.

- Thermal cleaning, for which a powerful construction hair dryer is used, which increases the surface temperature to values at which the previous paint is separated from the surface. This method is not suitable for antique items, since it can irreversibly damage the configuration of the item.

The dry surface must then be primed using a clear primer.

Bronze paints for metal

Bronze-colored metal paint is the leader in sales among compositions for interior work.

This color is incredibly popular not only in classic, but also in modern interiors. Bronze is similar in color to copper, but you can tell them apart. Copper has a reddish tint, while bronze has a greenish tint due to the presence of tin in the alloy. One of the fashion trends has become decorative antique processing (patination). Bronze metal paints are used in painting forged products, including interior stairs and railings, window grilles and furniture, lamps and interior items. Together with zinc primers they can be used for exterior painting, as well as 3-in-1 combination compositions.

Types of bronze paint for metal

- Hammer

. A beautiful decorative effect that creates embossed surfaces. Irregularities and potholes resemble blows with a hammer on metal. They hide base defects and give products a pleasant texture to the touch. Hammer coatings can be seen on steel doors, safes, radiators and fences. Bronze metal paint Zinkor-Top Hammer 3 in 1 is intended for external treatment. It not only creates a finishing coating, but also acts as a primer with rust inhibitors (converters). - Semi-gloss

. Initially, bronze has a glossy shine, but it darkens quite quickly due to interaction with moisture and air. Products with a semi-matte finish look more natural, so Zinkor-Top Semi-Gloss paint is often used for painting. Gives the metal a noble appearance and expands the possibilities of its use in the interior. Another advantage is that it is a ready-made paint for metal with a combined composition of 3 in 1. It forms a primer layer, transforms rust and creates a finishing coating. - Patina

. For bronze and copper products, aging technology (patination) is often used. Over time, these metals develop a greenish coating, which is recreated by bronze paints with a patina effect. To obtain a vintage finish, Zinkor-Top Patina paint is applied to the cleaned metal. For anti-corrosion treatment, you must first apply zinc primer. And fireplace grates and barbecues that come into contact with fire must be treated with heat-resistant enamel modifications.

Bronze paints for artistic forging

Forging paints allow you to independently perform cold galvanizing and process forged products. Zinkor-Top paints are economical, quick-drying compositions. They can be applied with improvised tools (paint, roller, spray gun). Thanks to various effects, they are suitable for vintage and trendy products. They create protective and decorative coatings with anti-vandal properties. They will not need to be constantly updated. Together with the primer, one coat of paint provides anti-corrosion protection for 10 years. To save processing time, 3-in-1 combination paints and primers are offered.

Do you need advice and help in choosing the right composition?

Call us at: +7, 8 (800) 555-34-18

You can leave a request in writing by e-mail:

[email protected]

We work for

Call right now, we guarantee the quality of our products and affordable prices!

Powder paint bronze gives products a decorative look

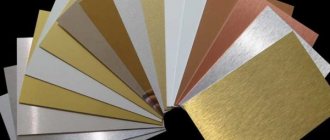

For the last few years, paint and varnish materials with various decorative effects have been supplied to the Russian market from European countries; powder paint bronze. Manufacturers also offer a huge range of decorative pigments, including excellent imitators of silver, gold and bronze.Throughout the centuries, people have been fascinated by the shine of gold, silver and bronze. In order to possess precious metals, people committed and still commit crimes. In the late nineteenth and early twentieth centuries, people learned to imitate silver, gold and bronze. Thus, the replacement of expensive metals with cheap imitations has spread everywhere; successful imitations decorate our lives - we enjoy luxurious decor, regardless of status and financial situation.

For quite a long time, powder pigments of different colors, including gold, silver and bronze, have been produced using a certain technology. Bronze pigments are flaky particles in the form of flakes or fine ground powder. Bronze powder paint has excellent coverage, creating a shiny, smooth surface on the metal. And coatings in the form of flakes have excellent gloss and form a rough paintable surface. Pigments are divided into two types: pop-up - exhibiting a “sheeting” effect, that is, particles of bronze paint float to the surface, positioned parallel to the substrate. And the second type is non-floating, in this case the pigment particles are evenly distributed throughout the coating.

Bronze pigments are obtained from an alloy of zinc and copper; depending on the proportion of the composition, the color of bronze can change from golden to red. This color is a pop-up color and is characterized by high density, so its pigments are less sensitive to various mechanical influences. However, they are not resistant to chemical attack, such as acids, strong alkaline solutions and ammonia. The consequence of chemical exposure is the formation of greenish salts, therefore a protective layer of varnish must be applied to the decorative coating, which is based on bronze pigments.

Powder paint bronze , modified with silicon dioxide, has high heat resistance, chemical resistance, in addition, products coated with this dye can be used outdoors in any climatic conditions. It is also worth considering an important detail - bronze powder paint does not emit harmful volatile substances when applied, which cannot be said about liquid paints and varnishes. In addition, bronze powder paint is much more economical than its predecessor, because it has the smallest percentage of waste. Thus, to summarize: products painted with bronze powder paint at the exit of the drying oven have a quite attractive appearance, amazing quality and are used almost in full.

Antique paint is currently very popular; it can give the surface of a product the appearance of antique bronze and copper products. Thanks to its original structure, it can age the surface of any detail and create the effect of antiquity, which is very important for designers and artists when creating an interior in the baroque style and in the classic one we are accustomed to. Powder coating of various design elements can give the interior a sophisticated and rich look, and in combination with textures, you can achieve an imitation of genuine antiques, which carries the spirit of the past - the mysterious history of generations.

Universal powder paints today have a huge range of applications, because their service life can last for decades and at the same time have an excellent appearance. Due to the fact that more and more metal products and various parts are produced every day, the demand for powder paint for coating them is also growing. For example, bronze powder paint is widely used in the automotive industry; it covers machine tools, agricultural vehicles, heating boilers, household appliances, electrical instruments and medical devices.

See also:

- Automatic powder coating line - an opportunity to start your own business

- Decorative powder paint allows you to obtain original coatings

- Powder paint spray gun allows you to obtain high-quality coatings

Back

Types of dye and their advantages

Previously, bronze paint contained organic solvents.

This resulted in a strong odor coming from the paint. Nowadays, instead of outdated compositions, mixtures are used for coloring metals. They are water soluble and contain only natural ingredients. Modern dyes now contain metallic pigments of natural origin. They use acrylic dyes as binding elements.

Painting metals bronze has the following advantages:

- Environmentally friendly and odorless.

- Low price, which is explained by the water-based paint composition for metal.

- Possibility of obtaining various natural stylizations (for example, antique).

- Ease of processing products.

- Reliable protection of metal surfaces from moisture and corrosion.

- The service life of surfaces painted with this composition is tens of years.

If the surface is pre-painted with a layer of electrically conductive paint, its corrosion protection is simplified due to the formation of a galvanized film.

Also, the advantages of bronze dye include high resistance of the coating to UV radiation and external mechanical influences.